Loggia insulation

Loggia is a modified balcony, in most cases in houses of panel type, built-in and having walls on both sides. For many people, a loggia is a collection place for all unnecessary things in the house. But this space can be used with advantage, for example, to be converted into an additional room. To get rid of blowing and cold on the balcony, you need to warm it from the inside and outside.

Features and benefits

It is important to decide for what purposes the loggia is being heated. For those who do not plan to be constantly on the balcony, it is possible to simply isolate the room from drafts and frosts. But to obtain a full-fledged living room should be a more comprehensive insulation.

Warming of the balcony is often done when there is a shortage of living space in the apartment. If the windows overlook a noisy courtyard or the road, insulation from sounds will be the advantage of loggia insulation. Plus, a warm loggia will reduce the penetration of cold into the apartment. This is a rather complicated process that requires certain skills and knowledge.It is necessary to choose the right material, prepare all surfaces for repairs and correctly perform all the steps of insulation. It is not enough to glaze windows, it is necessary to warm the floor, walls and ceiling well.

Types of insulation materials

In our time, construction stores have a large selection of materials for thermal insulation. When weathe loggia you can use both the simplest and the most expensive materials. The choice depends not only on the buyer and his financial capabilities. It is necessary to take into account the climatic features of the living area so that it is not cold in winter and the size of the loggia in order to save as much usable space as possible. For small balconies, it is better to buy insulation materials no more than 30 mm thick, and for large areas it is already possible to choose more than 50 mm.

The most popular insulating materials are:

- Mineral wool. It is made of glass wool by melting, stamping, cooling and crushing, it looks similar to ordinary wool. It is sold in roll and sheet form. The advantages of this material are high thermal insulation, moisture resistance, fire resistance and biological safety. Also mineral wool is better than any material that fills any gap.But it is not practical to use, caustic and entails the necessary waterproofing. The most famous brands can be called Rockwool, Isoroc, Izovol, Termostek, Paroc.

- Styrofoam. This material has long been very popular in the construction business. It is made in the form of plates and is easily attached to the dowels. It has excellent quality characteristics in the field of thermal insulation, waterproofing and sound insulation. The foam has antifungal functions, does not provoke the appearance of mold. The most common options are: Penoplex, Primaplex, Ursa, Styrof, Teplex.

- Extruded polystyrene foam. On sale, you can choose the roll and tile version. It is well insulated and has a good degree of moisture insulation. But there is a minus: poor vapor permeability, which can lead to the appearance of mold. To avoid this, before starting work, the wall should be treated with a special anti-fungal drug, and a vapor barrier material should be attached to the foam itself. It is important to know that in the case of burning the foam releases toxins.

- Penoplex. Sold by plates, which is convenient in the calculations. The material itself is very light, due to the special cuts for dowels convenient to use.It is used for insulation not only of walls and ceilings, but also suitable for flooring.

- PE foam. This material has a porous internal structure, which contributes to excellent thermal insulation. The top coating on both sides of aluminum foil does not allow moisture to enter and protects against ambient sounds. It can be both a panel and roll type under the names “Penofol” or “Izolon”.

- Penofol. This material is known by such names as foam rubber or PU foam. Due to the film surface there is no moisture permeability, it has excellent performance in noise and heat insulation.

Now on the market you can find a new invention - this is polyurethane foam-spraying. This material is sprayed onto the wall and freezes immediately.

Walkthrough

A good project of actually increasing the area for housing is redevelopment of the loggia with subsequent warming. The most important step of combining a balcony with a room is competent insulation.

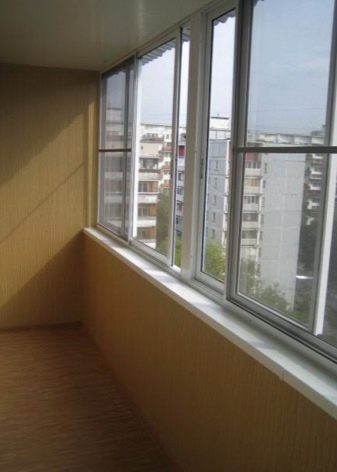

Glazing

For a full-time pastime in the loggia of a prefabricated house in the winter, its glazing is required. There are two types of this process, this is a warm and cold glazing.It is better to think carefully and make the right choice in order to do in the future without replacing cold-glazed structures with warm ones. After all, a warm finish expands the space much more: from such a balcony you can create a full-fledged room.

On the modern market appeared design with stained glass. The advantage was its lightness, versatility and beauty, especially if there is a wonderful view outside the window, because the room can be made panoramic. The design of such a glass loggia will appreciate everyone.

The best PFH windows are two-chamber double-glazed windows with a polymer, composite, wooden or aluminum frame.

Glazing is a very important job that is best trusted and coordinated with professionals. They will select the frame of the correct size and fix it well. Without glazing, the process of warming the loggia makes no sense. It is not recommended to save on double-glazed windows, because poor-quality structures will not be able to fully protect against severe frosts on the street. After glazing, you can begin to warm the loggia. But this step is impossible without the preparatory stage.

Training

The first step in weatherization of the loggia combined with the room is a thorough preparation for the main process. All parameters must be accurately measured to purchase the right amount of materials of the correct thickness. After all, the smaller the joints and cutting, the less the risk of passing the cold.

For the preparatory finishing will require a number of special tools:

- Bulgarian;

- electric drill;

- perforator;

- sanding machine;

- screwdriver;

- knife;

- hammer;

- hacksaw;

- paint brush;

- scissors;

- paint roller;

- sanding pelt;

- putty knife;

- ruler;

- building level;

- roulette.

First you need to clean all the coatings from having dirt, old plaster and thermal insulation coatings. Using a vacuum cleaner to get rid of litter and dust. If there are visible violations, it is necessary to repair all the chips and remove the bulges in order to achieve the greatest flatness of the wall.

Antifungal agents need to treat all traces of mold.

It is important to know that the insulation is made on ceilings that are not in contact with heated rooms. Therefore, it is required to correctly recognize what is required of the insulating process and what is not.

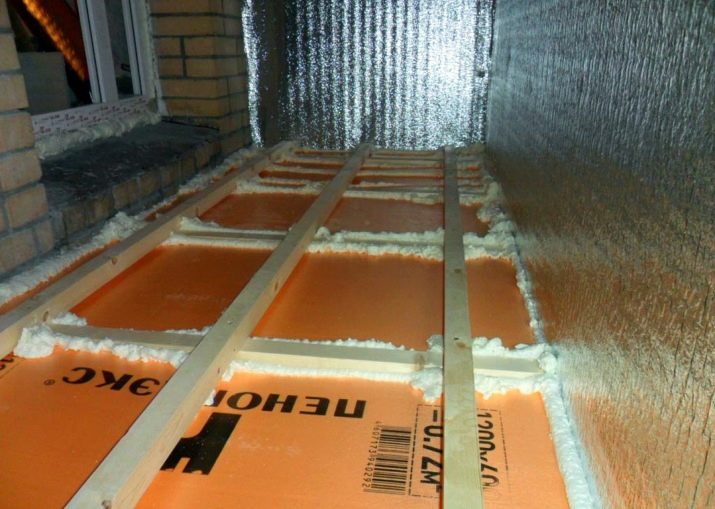

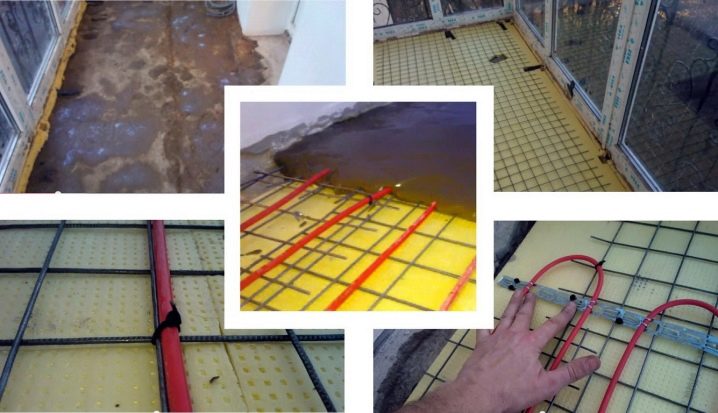

Floor

The heat-insulated floor is an important element of a design of nodes of warming of a loggia. This process consists of the following points:

- It is necessary to thoroughly clean the floor of debris to the screed. This will help to achieve the highest possible loggia height.

- To assess the evenness of the floor. If there are no strong irregularities, then a new coupler is not required. But if any, it is necessary to fill the floor with a self-leveling mixture and wait for it to dry.

- Apply antifungal compound to the coating.

After preparing the floor, you can move on to waterproofing works. Reiki and cross-type logs are laid on the floor, they are connected using self-tapping screws, they need to be fixed exactly, since they are the future floor.

Materials for floor insulation can be the following:

- Mineral wool. This material is spread only after the first waterproofing layer. For him, the usual ruberoid is well suited. Its skin is made around the perimeter, the joints should overlap on the wall. After that, the crate is laid down and secured with screws.The gap between the crate and roofing felt is filled with mineral wool. If its thickness is not enough, styling takes place in several layers. The last layer is a vapor barrier film from condensation.

- Styrofoam. It is the most common material in construction, has a low cost and excellent performance. The foam is laid in the same way as the mineral wool. First, the ruberoid is laid, then the foam layer, then everything is covered with a vapor barrier film. A distinctive feature is that the finishing layer is supposed to be a thin screed, over which lies tile, decorative stone, laminate or linoleum.

- Expanded clay. This is the easiest process of warming a loggia floor. It is easy to use, very durable and has good thermal insulation characteristics. Anyone can handle it: the material is simply poured evenly on the floor. The alignment of the sexual surface by this method is carried out with the help of a batten, between which the clay is poured.

- Penoplex - This is the latest material from those that are on sale. He lays down on a clean floor and secured with screws.They pass through special holes through the base of the floor.

Ceiling

Before you start repair work, you need to check the ceiling for the presence of leaks and holes. If any, it is necessary to seal them with foam for installation in order to avoid the appearance of fungus and mold in the future. The next step will be the processing of the ceiling zone material for waterproofing, which is adjusted to the batten.

The most popular materials for insulation are:

- minwat;

- Styrofoam;

- penofol;

- penoplex.

After the selected insulation there is a vapor barrier layer, as in the technology of floor mounting.

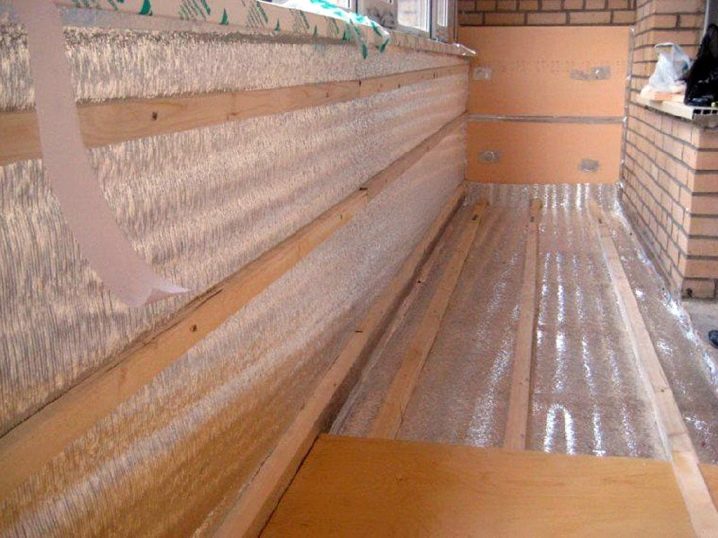

Walls

Penoplex plates are considered to be the best option for wall insulation. They are easy to use, fasten on special dowels, and if this is not enough, you can additionally use an adhesive solution. Mounting foam or a hermetic compound must carefully treat all joints in order to avoid cracks.

Loggia insulation is a difficult, voluminous and expensive process that takes a lot of time and effort. However, as a result, the loggia will become an additional residential area.

Outdoor work

For best results, insulation is required from the outside.This is a very complex process, which is life threatening and impossible without special equipment and professional skills. Therefore, it is recommended to entrust this business to specialists. It is possible to carry out a parapet warming on your own. It has direct contact with the street, so the insulation should be of high quality.

The first step is to waterproof the parapet. A plate of polyethylene or roofing material is mounted on its inner surface. According to the panels, the timber bar is sheathed and secured with dowels. It is necessary to take into account the width of the balcony, the thickness of the insulation layer will depend on it.

The next layer is a vapor barrier: plastic with foil glued on top, which will protect against condensation.

Decoration and decor

Having finished all the main stages of loggia weatherization, you can proceed to decorating and finishing all surfaces. The main stages of finishing the balconies are the following:

- Installation of slopes after installation of windows is carried out with various materials. This can be finished with plaster, drywall or plastic panels.

- The necessary floor is covered on the subfloor - linoleum or laminate.

- Reiki, which were fixed, serve as the basis for finishing the ceiling. Options can be plasterboard sheets or slats, which are fastened with self-tapping screws.

- If the choice fell on the drywall panel, then the necessary action will be the filling of the joints and hiding all the caps of the self-tapping screws.

- A more modern way to decorate the ceiling - this tension structure.

- Walls are made depending on the wishes of the owner. This can be wallpaper glueing, wall painting, cork or stone trim.

Arrangement of furniture and lighting. If the loggia assumes a living room, then you need to make it cozy with the help of furniture placement and the placement of light fixtures.

Common errors during warming

Independent weatherization of a loggia is quite hard work. You need to carefully consider each step of the work to avoid mistakes.The most common errors are:

- The lack of agreement with the BTI. This is a very stupid mistake that many make. Before any repair work in the loggia, you must obtain permission from the BTI. After all, the inconsistencies of this layout with the data sheet entail problems in selling an apartment.

- Placement of the battery on the loggia.This is a very unreasonable step, because the location of the battery on the balcony entails great heat loss. Also pipes in the cold season can freeze. Therefore, it is better to choose another option: to insulate the floor or connect a heater.

- Glazing without frames. This glazing looks very modern, as one continuous surface. But this can not be called a good way to warm the balcony. After the installation of single glazed windows remain noticeable gap. The best option would be PVC windows, because their open doors take up little space.

- Lack of vapor barrier. This error may be worth the repair, because the absence of a vapor barrier film leads to the appearance of condensate. No matter what material was used, additional insulation from moisture does not hurt.

- Abuse of sealant. When applying a large amount of foam for installation, you should carefully cut off the remnants of bubbles. Because the sun rays falling on them have a destructive effect and provoke the appearance of cracks.

After cutting off unnecessary foam, it is required to clean these places and putty.

Unnecessary insulation of the interroom wall.There is an erroneous version that if you warm the wall between the loggia and the room, the insulation will be at the maximum level. This is not true. It is better to spend this money on a good decor of this surface. Then not to see the converted part of the apartment.

Interesting solutions in interior design

Depending on the desires, financial possibilities and space of the room, you can choose different versions of the design of the balcony 6 meters. First you need to decide for what purpose it is needed.

- For an economical option, old furniture can be updated: paint, glue with decorative film. You can add a fresh touch with the help of new curtains or additional original items, artificial flower pots, for example.

- For a small size loggia, you can purchase furniture that folds. This is a very interesting decision: it is easy to lay out a chair or push a table, but there will be significant space savings.

- Often the balcony is used as a cozy place to have a good time. Here you can listen to music, read a book, drink coffee or combine all these actions.For such an interior is well suited rocking chair, miniature table, comfortable poufs or a sofa. You can dilute the interior with curtains, colors or paintings.

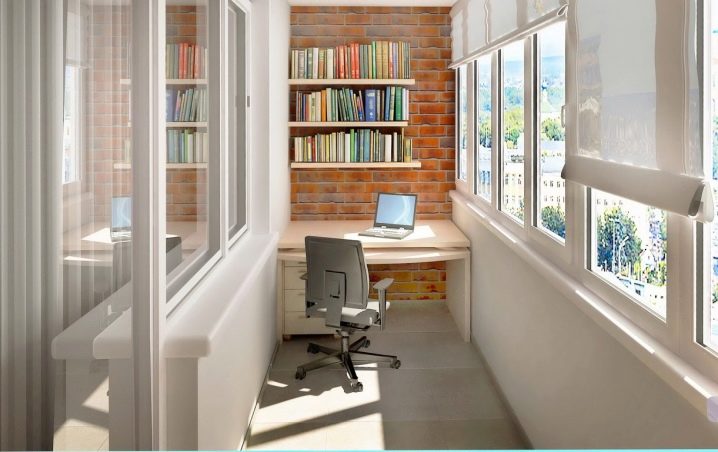

- An interesting option for arranging a loggia is a personal mini-office. A great idea for those who want to work in peace and solitude. It is necessary to put a table with a chair, place a shelf for books or documents and everything, personal space is ready.

- Loggia 6 m can be turned into a place that will appeal to everyone. It remains only to make a choice in favor of insulation.