Warming the floor on the balcony

Thanks to modern finishing materials, a usual cold loggia can be turned from a banal smoking room, a clothing store and a place for drying clothes into a warm and cozy continuation of living space - a study, workshop, extension to the kitchen or a comfortable recreation area. An important stage of such a transformation - floor insulation on the balcony.

Features and benefits

To consider a warm balcony an unnecessary luxury is to lose not only the extra square meters of your home, but also its thermal insulation, and the possibility of a more rational improvement. After all, usually the base of the loggia consists of concrete slabs, which freeze through much in winter and quickly collect condensate in the summer. Therefore, to achieve the maximum effect when changing the functionality of the balcony space, it is necessary to combine the construction of a heated floor there with wall insulation and high-quality glazing.

The advantages of this arrangement are quite obvious:

- a significant increase in useful square meters, which is valuable for small-sized housing; - a change in the microclimate in the adjacent room for the better;

- device excellent sound insulation;

- a significant reduction in heat loss throughout the apartment.

The main feature of the balcony warming is that it is unlikely to connect the apartment’s central heating, but it is possible to arrange it with electric radiators and a convenient floor heating system. The heat-insulating material optimal for such works should be selected especially carefully.

Types of insulation

Balcony - external design, usually located on a single concrete slab, which connects it to the house. It means that it cannot be overloaded with heavy finishing materials. Therefore, for thermal insulation, it is necessary to select those options for insulation that have a small weight, are easy to cut out and simply mounted.

Styrofoam - the cheapest version of the material for warming the floor on the balcony. However, all of its indisputable advantages in the form of low prices, excellent insulating properties, lightness, hygroscopicity, bactericidal, frost resistance,long-term operation and simple installation outweigh the disadvantages: complete vapor impermeability, high flammability and toxicity. Therefore, the foam is better to lay only under the screed - so its vapor permeability will not be so important, but it will not be able to catch fire. Typically, the foam is available in sheets of white color from 2 to 10 centimeters thick. For the insulation of the floor on the balcony most often used the thickest sheets.

Extruded Polystyrene - inexpensive material for warming the floor on a balcony with chemical composition and positive properties similar to foam plastic, but with fewer negative characteristics. Extruded polystyrene is capable of transmitting light, is completely resistant to the negative effects of the environment and temperature extremes, is not prone to decay, retains compressive strength and does not require the use of additional insulation for high-quality thermal insulation. Available in slabs of 60x120 and 60x240 centimeters. The main disadvantage of polystyrene is its flammability.

Penoplex (polystyrene foam) - treats heat insulators of new generation.It, like foam, has a low weight, low vapor permeability, is convenient in installation, is very effective as a heater and is also available in the form of plates with a thickness of 2 to 10 centimeters. At the same time, to insulate the balcony floor with foam plastics, the thinnest tile is sufficient - in fact, it favorably differs from the foam plastic by a more dense, moisture-and heat-resistant structure, excellent sound insulation, durable and durable in operation. The only significant drawback of penoplex is its significant cost. Although some manufacturers note that styrene in the penoplex is poisonous and volatile, and therefore it is advised to close it with plaster or drywall very tightly, leaving no gaps.

Minvat is considered the most optimal material for insulating the balcony floor. It is made of porphyrite, slag, gabbro, diabase and other minerals and comes in the form of rolls or mats with a thickness of 5 to 10 centimeters.

Mineral wool is used most often not only because of its low cost, but also due to the abundance of its positive properties:

- high refractoriness (does not burn even at + 1000 ° С);

- minimum thermal conductivity;

- excellent sound insulation;

- air permeability;

- resistance to negative bio-effects;

- environmental friendliness.

Minor deficiencies of mineral wool include moisture fear (eliminated when mounting the film), intolerance to tamping, and hence to laying under a screed (exception is high-density basalt minplate) and an increased content of formaldehyde in low-quality samples. Wood flooring on the balcony floor is better to warm laid "stone" (basalto) mineral wool.

System "warm floor"- the most comfortable solution for warming a balcony. Its main advantages are to establish and evenly distribute the required temperature throughout the room (it saves the balcony from settling dust and regulates the air humidity there), corrosion resistance (thin aluminum tubes of the construction are covered with plastic outside and inside ), safety, compactness and aesthetics (all heating devices are hidden in the screed), as well as ease of installation, ease of operation and further maintenance.

At the same time, the balcony equipment with warm floors can bring some inconveniences:

- it slowly heats up and cools due to the need to warm up the concrete screed;

- during major repairs it is easy to damage and difficult to repair;

- not all finishing materials are combined with a warm floor;

- furniture installed on it should not restrict free air circulation.

Expanded clay - although inexpensive, but not the best material for floor insulation on the balcony. Firstly, it is not able to retain heat as well as mineral wool or foam. And secondly, the creation of a reliable insulation layer will require a lot of expanded clay, which will significantly increase the weight of the balcony, which is undesirable. But the clay is completely environmentally friendly. And it is sometimes mixed with a concrete mortar leveling screed or used in the "dry" technology of its device.

What material is better

Usually, we need thermal insulation of the balcony to rescue from the winter cold and summer heat, as well as to protect its facade and supporting structures from temperature changes and precipitation. Conventionally, all heaters can be divided into traditional (expanded clay, polystyrene foam, mineral wool) and innovative (polystyrene, polystyrene, penoplex, underfloor heating, etc.) or according to the composition of the raw materials used for their manufacture (organic, inorganic and mixed).

By the way, all thermal insulation materials that are similar in their characteristics cost about the same, so you should not consider the price as a determining factor for their choice. But before buying a heater for the floor on the balcony, decide what will be its finish and who will be engaged in the installation - you yourself or the master. And also remember that the insulation should not greatly increase the weight of the balcony, otherwise it may collapse.

If your balcony is reliably protected from moisture from the street, and the base floor is sufficiently even and dry, then it is cheaper to lighten and at the same time insulate it with wood. You can lay the boards directly on a concrete base or fasten on specially installed logs. In this variant of insulation, it is preferable to use a coniferous tree (its natural resinousness will increase its moisture resistance) and it is necessary to arrange a slope in the flooring to drain off any moisture that has accidentally entered. If it is required to insulate the wooden flooring itself, then with good waterproofing, ordinary mineral wool will be suitable, and with high-quality sealing of the joints - foam plastic.

It is better to choose the one that is not afraid of laying under a screed (polystyrene foam, polystyrene, polystyrene foam, basalt mineral wool or "warm floor") as a heater for tile or tile.. However, the construction of a concrete screed together with laying tiles on the balcony floor will eventually significantly increase its weight, and this, as is known, is unsafe. To insulate the floor under linoleum, you need a sufficiently durable, springy and good water repellent insulation - such as penlex. It is possible to warm the floor under the laminate with claydite, foam plastic, mineral wool, plywood, and even foil on the balcony, depending on whether it is laid on a concrete or wooden base. Well, the most environmentally friendly, the most durable and at the same time the most expensive option for insulation - cork panels.

As for the installation of insulation, the most simple to install - insulating plates of foam, foam, polystyrene and mineral wool. It will be more difficult to equip active heating "warm floor", which is recommended to warm polypropylene, polystyrene foam, cork panels and metallized lavsan film.

How to insulate a balcony: step by step instructions

To warm the floor on the balcony, but not to glaze it and not to warm the walls with the ceiling - it's like throwing money away.. Especially if it is with a hatch or with panoramic windows.Only competent thermal insulation of any and all surfaces of the balcony and connection with their high-quality further finishing will allow it to consistently maintain the room temperature level there even in winter and even without heating. And by inserting a second glass into the window frame, you can make the balcony suitable for living, and this will increase its chances of joining the room according to the law, which is especially valuable in a small-sized "Khrushchev". By the way, the balcony will look especially advantageous if you combine the space of the adjacent room with a stained-glass window or partition - so the play of light, color and shadows can beautify and diversify both these rooms.

Install insulation on the balcony floor only after installing high-quality glazing, sealing up all the cracks, removing the old flooring and thoroughly cleaning the room from debris and dust. If it is necessary to wash the floor, then the work on its thermal insulation is possible only after the concrete of the balcony base is completely dry.

In addition to insulation, you may need a hammer, a construction knife, a jigsaw (preferably electric), a construction pistol, dowels, a drill, self-tapping screws, a perforator and, of course, a tape measure with a pencil for marking.

Having prepared all the necessary materials and tools, you can start laying insulation for the floor on the balcony without heating:

- all irregularities in the base are filled with epoxy resin or sand-cement mortar;

- the joints of the floor and walls are filled with foam or cement mortar with sand;

- priming the area prepared for insulation and letting the primer dry out;

- waterproofing the balcony base (prevents the ingress of moisture from condensate);

- we install wooden logs (to the height of the door threshold - for convenient accession to the room adjacent to the balcony);

- we lay out between the lag the required number of layers of the selected heater;

- we fix a vapor-permeable diffuse waterproofing membrane;

- we lay plywood or board flooring to install the finishing coating;

- we install boards, linoleum, tile, laminate or other selected material as a topcoat and fasten the baseboard.

For the device of active insulation (such as a warm floor) the procedure after laying insulation will be different.

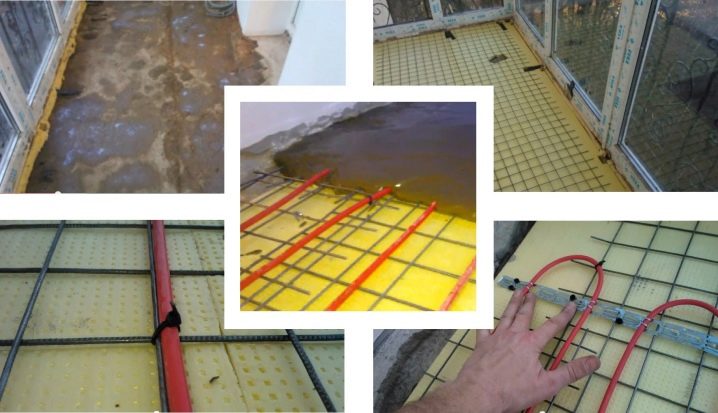

All insulation plates must be tightly joined together with each other (to cover the entire floor), and with waterproofing covering them.We lay reinforcing elements on top (reinforce the outer part of the balcony), pour the screed over the exposed beacons, carefully align it and dry for at least 6 hours (you can safely walk on it in a day). Then we fix the dowel-nails with the mounting tape (we use pre-marked and drilled holes) and with a snake we lay the heating floor cable on it.

By the way, it is more convenient to start laying a cable from the end section, putting a plug there, and to complete it by connecting it to the power supply network using a thermostat. After a reliable fixation of the heating cable to the mounting tape, we install the beacons again, fill in another level of the screed floor screed and let it dry completely.

To make "warm floor"Balcony with a finishing coating of laminate, tile or other material is possible only after the screed has completely dried - this will avoid deformation and can do without mold. Usually the cement screed drying process takes about 7 days - provided that the beacons were set correctly. If at this time it is warm outside, you can open the windows - the floor will dry faster and pick up the necessary strength.But in the winter the coupler should be dried only with the shutters closed.

We warm inside

Without a scrupulous hermetic seal of all the cracks at the joints of literally all surfaces of the balcony, its further internal insulation is meaningless. But its competent device allows to avoid occurrence "cold bridges"and helps to shift the freezing points of the balcony from the inside to the outside.

Equally important is the quality waterproofing of the concrete elements of the walls, ceiling and floor of the balcony, with the installation of reflux and the processing of the window frame hydrophobic antiseptics - especially if you don’t want to find a fungus or mold in one of its corners one day while safely maintaining a comfortable temperature and ventilation on the balcony. And therefore, one should not ignore the vapor barrier of the insulation - the vapor barrier placed in front of it will not allow undesirable accumulation of moisture and provide the necessary degree of air circulation. In addition, good internal thermal insulation helps to get rid of extraneous street noise.

Choosing insulation for the internal space of the balcony, it is necessary to pay attention to the coefficient of its thermal conductivity.Modern materials for thermal insulation have an average of 0.03-0.04 W / mS, and the higher this value, the lower will be the insulating quality. So, to insulate a balcony, it is worth choosing materials with a minimum value of thermal conductivity, but high cost, or simply to increase the thickness of the insulation, which will inevitably lead to the loss of the useful area of the balcony.

We warm outside

It is believed that the external insulation of the balcony not only saves its usable area due to the use of thin insulation from the inside, but also helps to save almost 30% of the cost of heating the apartment. However, high-rise residents will be able to take advantage of such outdoor insulation only with the help of industrial climbers. But using different materials in the decoration of the balcony, the owners will be able to significantly change its appearance and even the configuration.

Interesting solutions in interior design

After weatherization of balcony designs, there are ample opportunities to change its functionality and interesting solutions in the design of its interior. Having attached a warmed balcony to the living space of an apartment, there you can arrange a cozy office, a hookah room, a corner for children’s activities, a dining area or even a small spa.When the balcony is warm, dry and comfortable, the mastering of its space depends only on the imagination and the capabilities of its owners.

Our video will tell you about how to cut, stack and fix foam polystyrene insulation. We wish you a pleasant repair!