How to make the foundation for a bath?

Bath can be a pleasant and comfortable place of leisure. But in many ways, its quality and stability depend on how exactly the foundation is made, and whether the necessary requirements are met.

Detailed step-by-step instructions have long been developed, it is only required to strictly follow them.

Special features

The foundation is the basis for the construction and operation of all facilities. But in the baths, along with the mechanical load, it must also transfer the increased humidity, ensure a quiet and proper drainage of sewage to the outside. because the basis for a bath is surely thought over even before drawing up the project begins. And in the design materials should display all the subtleties and nuances, even if among all the options selected the cheapest and easiest.

In advance, you should find out which methods are generally suitable for a particular case, which schemes meet the technical and thermal requirements.

Kinds

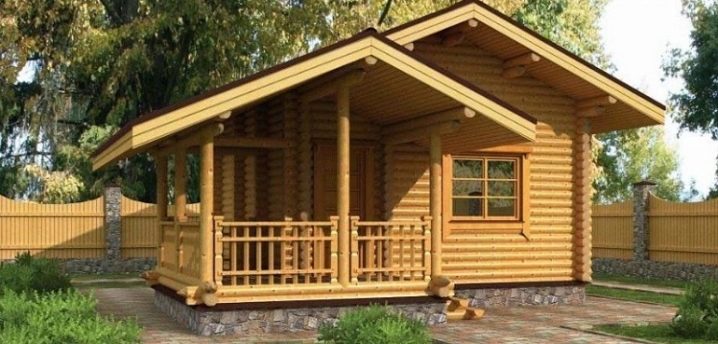

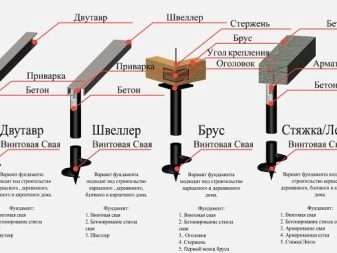

Pile (made from screw piles) foundation manifests itself perfectly in the construction of baths of various types:

- timbered;

- from a bar;

- on the basis of frame-panel construction.

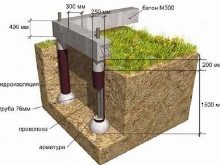

The spiral design of the support prevents it from changing its position even under the action of heaving forces. And due to the compaction of the adjacent soil bearing capacity of the base increases, it can vary from 600 to 12000 kg. As for the sizes, the smallest basement is 55, and the largest - 350 cm.

Attention: it is recommended to choose piles with a protective zinc layer, which is applied by hot method. This support allows you to immediately begin construction of the main part of the building and more economical than concrete.

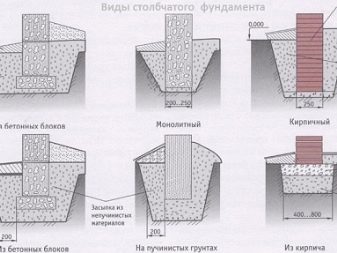

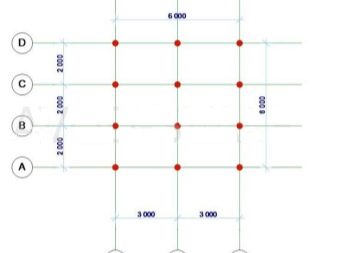

When constructing a columnar foundation, it is possible to provide increased strength and reliability of the structure. It is laid mainly under lightweight buildings, but there are cases when such a foundation is chosen for a heavy-weight brick structure.The main reason for this choice is the need to deeply introduce support. Filling the tape to the required depth can turn into fabulous expenses, and the pillars become a real salvation.

Important: the columnar and pile foundations do not allow to organize a basement room, in contrast to the construction of the blocks. But the real standard of the Russian bath does not require this! If both options are not satisfied, as well as the construction of the blocks, the exit often becomes a ribbon shallow foundation.

Such a construction is able to support even two-story buildings, unless they are too bulky. Due to the specifics of the configuration, it is possible to reduce the heat leaving down - that is, this type of foundation is also energy efficient.

Under the tape cellars and cellars are easily equipped, but at the same time build it in a short time will not work. Yes, and material costs will be quite large. Regardless of the type of base chosen, the site must be prepared for work - garbage is removed from it, the relief is leveled, and all marks are carefully marked. Since we are talking about the construction of a bath, all bases must be with a drain of proper quality.

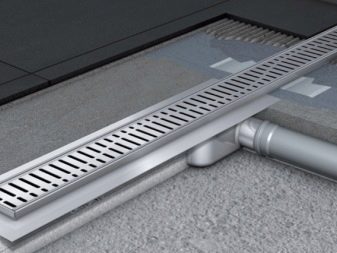

Drain water grooves are formed with a slope of 20 mm to 1 p. m .; the depth of the trench reaches 0.5–0.6 m.

When choosing the type of external sewage (directly affecting its interaction with the foundation), the following are taken into account:

- frequency of washing in the bath;

- built area;

- soil characteristics;

- frost point;

- possibility of connection to the central outflow system.

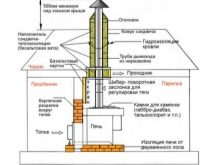

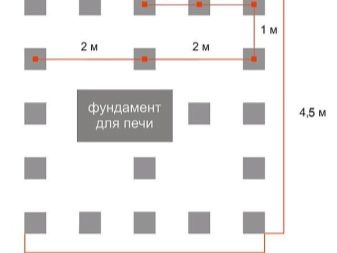

For the furnace it is necessary to make a special foundation; installing it on the same basis as the building as a whole is a gross engineering error.

A brick stove can reach a mass of 500 and even 700 kg, which requires a very strong and stable support. Steel structures "pull" 150-200 kg on average, which is also a lot. The pit is made 100–150 mm wider on all sides than the furnace itself.. Excess space is then saturated with coarse sand or gravel.

Under the heavy furnace, especially supplemented by a brick pipe, the foundation is laid below the winter freezing point.

If a center is made of steel, rectangular holes are used for its installation, the bottom of which is filled with rubble at least 0.25 m. On setting of concrete to the desired condition is given 5-6 daysotherwise, its parameters will not allow solving the set task. For kilns of brick at the bottom of the "cake" is formed by a pillow of sand.

The slab foundation (made of reinforced concrete slab) is the most durable and reliable. After all, it is a monolithic structure, which greatly simplifies the subsequent work. Even actively moving ground in an area where significant precipitations constantly fall or sudden changes in temperature do not become an obstacle.

In addition, the stove can safely be even above the freezing point, which significantly reduces construction costs. And such a solution is ideal on swampy or creep-prone soil.

Materials

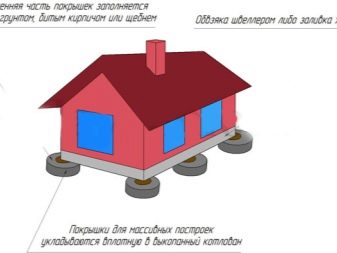

Having chosen the exact type of foundation to be mounted, it is also necessary to sort out the materials that will be used for the foundation of the bath. Tire foundations perform well in swamps - even where designs of slabs are unreliable. Sometimes they are pushed up by the force of frost heaving. But this terrible, almost all-powerful element, retreats when using car tires. Tires should be buriedbecause it will prevent them from going down and pushing the surrounding soil up.

The pressure from the column should be evenly distributed, to solve this problem and use tires filled with sand or gravel. The increased (as compared with flawless ribbons) bearing capacity and footprint allows them to carry significant loads without overturning and without causing soil subsidence.

If the product is only partially filled with earth, the rubber case assumes the main load. It turns out a kind of imitation of springs, ideally manifesting itself on soils with weak heaving. But it would be much more correct to warm the blind area and fill the tire by 100%to guarantee the same qualities of all the supports.

Of course, most developers do not use such original solutions and prefer traditional ways. They build a foundation for a foam block bath, since such a technique does not require complicated equipment. There is also no need to fix the reinforcement, to knead a huge mass of concrete. This does not affect the bearing qualities, and even more so - the speed of construction increases.

If a wooden building will be built on top, it is better to choose a pillar concrete foundation, on top of which lags are placed and the floor is formed.

But the blocks manifest themselves ideally under the buildings of:

- bricks;

- foam concrete;

- just under significant area baths.

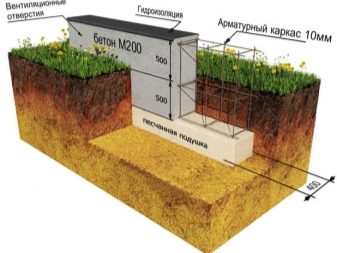

A solid concrete structure has dimensions of 39 x 19 x 18 cm, and the weight of one element is approximately 30 kg. For shallow deepening of the pillars formed by the blocks, 3 or 4 strips of masonry are enough - and 6–12 foam blocks accounted for one pole. Monolithic slab should be poured into the permanent formwork. Most specialists recommend using slate for this formwork..

It is important: it is unacceptable to fall asleep back into the trench excavated during preparatory work.

Area layout

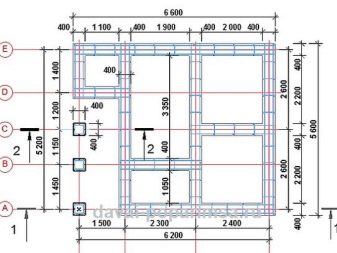

At different sites, necessarily, it is necessary to construct baths of different area. And because of particular importance is the exact calculation of the size of the foundation for them. If you make a mistake even insignificantly, you can either get an unreliable design, or run into significant cost overruns. Initially they draw a sketch on which each segment of the building should be shown, not a single room can be ignored.. When calculating the width and length of the base, we must not forget that it is always somewhat larger than the structure itself being supported.

The rectangular design of 3 x 4 m in the form of a shallow tape successfully copes with almost all the tasks. But in addition to the geometric dimensions in the plane, it is necessary to take into account the height of the foundation itself. In hard rocks, the trenching depth is approximately 0.5 m. But if the substrate is formed by soft and relatively loose soils, this figure can even be doubled. No matter what the dimensions of the walls are 4 x 6, 5 x 5, 6 x 6 m, the foundation block is made 0.1 m wider than the ground structure.

Under the small bath, the piles are set every 150 cm, and if the building is larger, the gap can be increased to 3 m.

To calculate the area of the foundation under the bath, for example, with dimensions of 6 x 4 m, you need to take into account:

- weight of structures;

- wind load;

- pressure exerted by the snow.

Dividing the sum of these parameters by the bearing capacity of the soil, get the final figure. By law, from the bath to the buildings on the adjacent site must be at least 8 m.If this distance cannot be met, then it is necessary to negotiate with the neighbors so that they are allowed to break the generally accepted rule.

It is also desirable to take into account the characteristics of the construction blocks. With the slightest uncertainty in the result obtained, you should seek help from specialists.

Independent construction

Foundation construction, on average, brings 15–20% of all costs in the construction of a bath house. Naturally, many people want to minimize these losses by doing most of the work with their own hands.

To do this, use:

- solid fractions of limestone and shell rock;

- rubble stone;

- sandstone;

- reinforced concrete;

- concrete, starting with the 500th mark;

- asbestos cement.

Any step-by-step instruction prescribes before starting work to free the site from everything that may interfere with construction. Ruthlessly get rid of the fertile soil layers.

Under the blind area and the body of the bath, the soil is cleaned especially carefully.. Those who ignore this rule and try to leave the upper segment of the soil, always face trouble. The plant mass will soon begin to rot, and when new sprouts come into contact with the foundation, even stone, it will quickly become unusable.

When the removal of the soil is completed, you need to start digging the excavation.Under the strip foundations, a new ground is laid in the voids and gaping places. Important: the soil for this operation should be selected "clean", not even containing traces of debris and organic matter.

A similar method allows you to make a billet for the subfloor or cellar, to avoid flooding the building when raising the soil water. Any ditches and trenches are dug to a strictly defined depth, it is not allowed to exceed it.. It is necessary to make a notch to the point where the earth cools down in winter to zero degrees (and in the case of clay soil, to –1 degrees).

When the depth does not exceed 1 m and the width is 0.6 m, the outer walls are made strictly vertical.. With greater deepening, the edges sometimes expand from above. In unreliable soil, it is recommended to use temporary formwork and then remove it. It is possible to build strip foundations not only from one reinforced concrete with reinforcing details. Good results are obtained by using reinforced concrete blocks of industrial manufacturing and bricks..

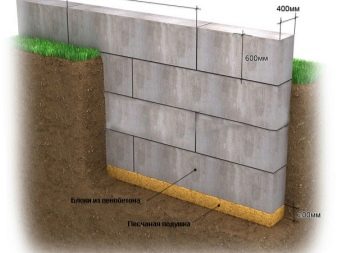

Private developers, in most cases, prefer to use butobeton, that is, to put natural stone and fill it with solid mortar.Tapes of the bases under baths, irrespective of number of floors, differ in the identical sizes. Even a three-story building crushes relatively weakly, and the total area with multiple reserves can withstand such an impact. Pour the rubble substrate to a width of at least 0.6 m, for reinforced concrete and other concrete foundations, this figure varies from 400 to 600 mm. The value for the brick site is set very strictly - exactly 0.51 m.

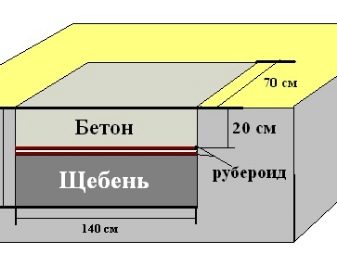

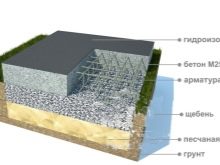

The tape will be reliable only under the condition that its filling is made on a pillow from sand. The thickness of the loose layer is not less than 0.2 m. And for heaving soils, it can be safely tripled, because only in this case can the construction be completed successfully.

You can not tamp the sand, pouring water on top; it should be already wet, and the density is increased by purely mechanical means. The device of sand cushion implies that it is invariably leveled at the construction level.

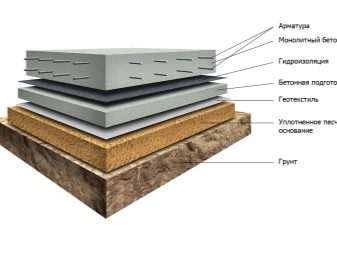

Instead of sand can be applied and mix it with gravel.when four fractions of loose rock account for six fractions of stone. When working on weak ground, the foundation is laid on geotextiles.to prevent the substrate from mixing with the sludge or its destruction by soil water. Starting to mount the formwork, the edges of the trench are punched with stakes, securing fasteners from descent. An alternative is the installation of non-removable formwork, which later becomes the “face” of the foundation. The correct method of operation implies the reinforcement of the base, even when it is supported by a lightweight construction.

The higher the mechanical strength, the longer the service life of the building, and the more protected it is from a variety of harmful factors. But also over-stuffing the concrete mixture with reinforcement is not worth it, almost always a few edges are enough.

Important: it is not necessary to lay reinforcement structures on the sand itself, there must be “chairs” or well-standing stones under them.

Thrust reinforcing rods should be tight, in two rows; at right angles to them are placed elongated subtle details, connected at all joints. Electric welding is used for the connection.

Starting work, you should mark everything thoroughly. The first step in this work is holding the baseline, which will correspond to one side of the base.Most builders first mark the line that runs parallel to the fence, wall of the house or shed, path, road. A triangle is formed, and immediately with the help of a roulette it is checked whether its diagonals coincide. The maximum justified deviation does not exceed 1.5 cm. Having stretched the cord at a height of 20–25 cm above the ground, they successively check that it never sags or goes down excessively.

Briefly fix the axis outside the trench, check the zero level will help obnoski. They will drastically simplify the preliminary work. The installation of the rags is made from the highest angle in the designated area, and the subsequent ones are verified by the first point. If you plan to install a log house, the approach to working with the foundation is somewhat different from the usual scheme. A large bath in which there is a steam room and a washing compartment, a rest room and a dressing room plus an attic should be placed on a strip footing 120–160 cm deep.

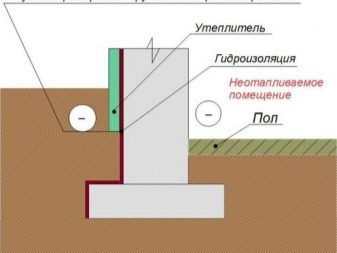

Under the log cabins with small dimensions is the basis of the shallow depth, from 0.55 to 0.75 m. And in the most compact version, you can deepen the foundation by only 420-480 mm.Thermal insulation of the base of the bath helps it to better perform its function. There is nothing super-complicated about this; moreover, the warmed foundation accelerates the heating of the steam room and the washing room.

It is possible to warm a design:

- on the outer base;

- inside;

- in a combined way.

The simultaneous execution of work from inside and outside is considered the most effective, but it is also the most complex and expensive. Laying insulation only inside is not recommended, it is ineffective. The easiest finish option - mineral wool, decorated in mats. Polymeric materials are somewhat worse, and bulk materials are the least practical. Basalt wool must be insulated from external soil with a wall.

The only advantage of sawdust is the low price and the ability to make the harvest yourself. Polyfoam and polystyrene are effective in creating a warm floor, but their strength is not high enough. It is possible to warm the tape base only when it is free of soil around the perimeter. The surface is smeared with a pair of layers of waterproofing, then wait for the bitumen mastic to dry.

In the corners, layers of insulation must be made 50% thicker,it is in these places that the heat goes off particularly quickly.

Monolithic bases are most often placed on the prepared layer of waterproofing and heat insulation. The most difficult measure will be the thermal protection of columnar foundations. A wall of red brick halves is erected around their perimeter (on a sand cushion, in trenches 0.5 m wide). This wall is smeared with mastic and then it works the same way as with strip foundations; but the total work time sometimes reaches a week or more. The laying of communications in the foundations is thought out even at the design stage, when it is determined where the sewers will be installed and the water supply system will be installed.

In both cases, the throughput diameter can not be less than 5 cm. Provision is made for the installation of compensators, damping linear expansion and contraction when the season changes. Laying pipes without polystyrene shells or heating cables should be 50 cm deeper than the freezing point.. Water supply inside the floating plates and through them is possible only vertically. But in the subfloors and basements under the recessed tapes of the pipe horizontally; Compliance with these requirements is no less important than the exposure of the voltage from the roof and walls.

Useful tips from the pros

MZLF and floating plates it is advisable to warm the contours of extruded polystyrene foam - this will help block the swelling of clay soils. There is no need to warm the piles, but the pillars are overlapped with thermal protection around the perimeter. Under the washing room in the basement, slopes are made in the direction of the ladder that drains water into the septic tank. If a suspended grillage is used, rammed or bored piles, the ground floor cannot be made. The problem is solved either by pouring a slab grillage under the right places, or by placing a galvanized sheet with a ladder.

All communications in the underground part of the grillage foundations are necessarily insulated since the ground freezes through totally. It is recommended to install monolithic caisson plates under the pools.. When the bath is built on the bank of a reservoir or river, it is permissible to locate it only on screw or bored piles. Lightweight framework-type structures are recommended to be erected on posts of ready-made concrete or bricks.. But only with a smooth relief over coarse sand, gravel or rocky soil.

You can save on the construction of slab foundations, if you direct down stiffeners down the entire perimeter. Filling slabs on peat or dusty sand turns out to be excessively expensive.If the height difference exceeds 1 m, it is necessary to fear a lateral shift.

Floating plates are placed with the obligatory removal of the arable layer, their formwork is made of 4 shields or the same number of polystyrene blocks.

If a ribbon substrate is formed on heaving soil, you need:

- warm the perimeter all along;

- overlap trench sinuses with non-metallic material;

- provide thermal protection of the blind area;

- lay crushed sliding thermal insulation along the outer surface.

When the grillage is higher than 150 cm, especially on the slope of a hill, parts of the piles protruding to the outside will have to be reinforced with connections diagonally and vertically. For obtaining these elements apply a corner or a pipe from a profile. For pouring stone parts, it is recommended to take high-grade cement, it consumes less and at the same time guarantees a solid fortress. When installing asbestos-cement pipes, they are filled with concrete from the inside. The gaps in the column base under the furnace are laid with a brick, tightly shrinkable in the usual mortar.

In this video you will find the construction of the foundation for a small bath.