What is better to build a bath: the pros and cons of materials

Own bath in the summer cottage or in the country house is the dream of many owners. The benefits of bath procedures are obvious - they strengthen the spirit, improve blood circulation, improve the condition of the skin, and are effective in preventing colds.

Today, the construction market offers a lot of building materials for the construction of baths.

Special features

All steam rooms for private use must comply with the norms of SNiP. Requirements for the rules of building plots are set out in SNiP 30-02-97, requirements for creating projects in the plots of land are set out in SNiP 11-106-97. It is necessary to start building a bathhouse after reading this documentation.

It is also important that the requirements for the construction of baths are tougher than the standard standards for residential premises - this is due to the high fire risk of bath buildings due to the presence of a furnace in it.

When buying materials, one should focus not only on personal preferences and cost, but also on the compliance of the proposed product with the conditions inside the steam room and in adjacent rooms.

The materials used for the construction of the object must meet the following requirements:

- provide high levels of thermal insulation;

- have the necessary fire safety threshold;

- be environmentally friendly - do not isolate toxic compounds during operation and heating;

- resistant to moisture.

It is almost impossible to find a material that simultaneously meets all the specified requirements. However, special handling or use of auxiliary materials allows for balance. For example, wood is an environmentally safe and warm material, characterized by durability. To increase the moisture and fire resistance of wood allows the impregnation of fire retardants.

When planning the construction of a bath, it should be understood that even a small-sized building needs to be pre-designed. Drawing up drawings and the availability of calculations ensures quality and reliable construction,therefore, it’s better to start by creating a project.

Do not forget that the bath should be built at a distance of 10-15 m from residential buildings.

What material to choose?

At installation of a bath features of a climate, its sizes and number of storeys are considered. For example, if a bath with accommodation is supposed, for example, having a second floor or a used attic, then a solid foundation is needed, the selection of certain materials for the construction of walls.

The walls of the construction are traditionally laid out of wood or brick. However, today the construction market offers new materials. Each of them has specific advantages and disadvantages, therefore, the choice of one or another option should be approached responsibly.

A necessary element of most baths is insulation. The exceptions are only steam rooms in the country, which are used only in the warm season, and it is desirable that they be built of wood.

Exterior finishing of baths allows to increase the protection of the material of the walls, to give the structure an external attractiveness. It is recommended to choose a single finish for the house, bath and other buildings, which will create a single exterior.

Wood

Wooden buildings are a kind of classic. Depending on the type of wood used, the structure will have certain characteristics. Among the popular varieties distinguish the rocks described below.

Pine

This wood, thanks to the excreted resin, is protected from mold and pests. The material is moisture resistant, pleasant in appearance, has a low cost. However, in the process of heating the pine produces resin, which can burn.

In this regard, it is not recommended to use pine wood in the steam room.

Linden

This type of wood has good heat resistance. For use under the bath, linden should be subjected to special treatment, since it is characterized by low moisture resistance. Over time, the material darkens.

Aspen

At first glance, it seems that aspen is the best variety for organizing a steam room. It has such qualities as high density, which over the years only increases, moisture resistance, the ability to retain heat and a pleasant reddish tint. However, due to the increased density, the material is difficult to process, and also has a considerable cost. The main feature is the release when heated substances that affect the person (the head starts to hurt).

Fir

This type of wood is practically not used, because it quickly absorbs moisture, which causes rotting of the material. In addition, the wood is friable, does not have sufficient strength.

Alder

Wood of a beautiful reddish tint does not shrink, does not emit toxic substances when heated. The use of special impregnations allows to prevent the material from rotting. Among the shortcomings, it is worth noting the ability of the material to darken after several years of operation, as well as high cost.

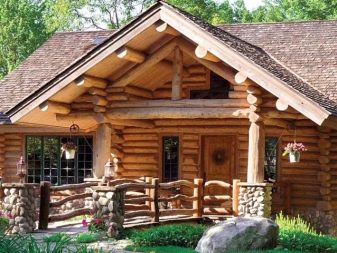

The construction of a bath can also be carried out from a bar - rounded or profiled. The first type is considered to be environmentally friendly and attractive, and therefore the construction does not need external and internal lining. Thanks to the ability to connect the bars at different angles, it is possible to implement diverse design solutions. Another advantage is high thermal insulation. Should know that the material shrinks, so it is important to follow the installation technology and give the building time to shrink the log house.

Profiled timber is solid and glued. Unlike the rounded analog, it does not shrink. Thanks to special impregnations (fire retardants and antiseptics) it is possible to improve the performance characteristics of the material.

The one-piece version is environmentally friendly, because there are no adhesive components in its composition, and glued laminated timber has greater strength and is not subject to cracking.

A wood bath keeps heat well, removes gases and toxins. Having a low weight, it does not require additional reinforcement of the foundation. It is worth noting the ecological safety of wood - in the process of heating it highlights useful elements. The tree is able to absorb moisture, so the walls are “breathing”, the room does not accumulate moist air, the steam in the bath is dry and light.

However, this ability has a negative effect on the state of the wood itself - it darkens, dampens and rots. Find the "middle ground" allows the use of a special impregnation. Another disadvantage of the material is its increased fire resistance. To improve the fire safety of the tree allows the processing of antipyrine.Finally, the shrinkage of the tree is about 13%, which is quite a lot, so after a year and a half after construction, the bath will have to be caulked again.

For the construction of the bath is unacceptable to use birch, beech and maple.

The frame bath is considered to be a budget option - this is due to the lower cost of the frame compared to brick and lumber baths. However, it should be borne in mind that the installation of frame baths will increase spending on insulation and interior lining of the structure, while you will have to abandon the use of mineral wool and foam insulation materials and look for another material that would be moisture resistant and fire safe.

The advantage of frame baths is high installation speed (on average 2-3 weeks), which is partly due to the low weight of the material. It, by the way, allows to refuse additional strengthening of the basis. Finally, such a bath can be collected at any time of the year, including at temperatures as low as -15 ° C.

The building material is environmentally safe, “breathable”, and in terms of its thermal insulation characteristics, the frame construction is not inferior to its counterparts made of lumber or brick.

Brick

The most important advantages of this material are the following positions:

- a long period of service (the average period of operation is 15-20 years, but in practice this period is 2.5-3 times longer);

- external attractiveness and no need for external cladding;

- fire resistance - the material is not flammable;

- low coefficient of moisture absorption, which ensures the durability of the bath and the absence of mold and fungus on its walls.

However, the brick is characterized by considerable weight, therefore, under the steam bath you must perform a tape base.

This causes the duration of the construction process - it is necessary to build a concrete foundation and wait for it to pick up strength. Laying brick walls also takes a lot of time. In addition, the material is more expensive in comparison with a frame or block bath.

Brick walls do not “breathe”, therefore, ventilation gaps should be left during construction. It is better to warm the bath from the inside. When building a brick structure, it should be taken into account that it will warm up for quite a long time - about 1-1.5 hours.

The most convenient for work is red one-and-a-half or gas silicatebrick. Used ceramic brick has slotted holes, which significantly increases the thermal efficiency of the material. In addition, it is durable, attractive in appearance.

Solid brick has a large margin of safety, so it is recommended to use it for the construction of load-bearing walls and parts of the building that are exposed to increased loads. The silicate brick has high heat-insulating indicators, but at the same time differs in democratic cost. Cement mortar requires cement, the brand strength of which is not less than M200.

For the construction of walls, red brick is usually used, for the steam room - fireproof or ceramic. At the base of the refractory brick is a mixture of clay subjected to dry pressing. The result of this technology is a solid brick that has impeccably smooth forms, a smooth surface and a high ability to absorb moisture. Only such a material is able to remove gaseous waste arising in the combustion process, and not to collapse under the influence of high temperatures. The mark of such a brick must be at least M200.

Ceramic brick is produced by high-temperature calcination of clay solutions. Thanks to this technology, hollow brick with high thermal insulation performance is obtained. A ceramic brick bath warms up faster than a full-bodied counterpart, which is achieved due to the presence of cavities in this material.

However, ceramic bricks quickly collapse under the influence of hot moisture, which means high-quality steam and waterproofing baths.

For laying bath stoves use fireclay bricks, which is the only material capable of withstanding exposure to open fire. Its basis is clay, to which quartz grains, graphite powder and other additives are added. Raw materials are fired at high temperatures, which reach 1500С.

For the sauna stove, fireclay bricks of the ShB-5 and ShB-8 grades are suitable, which are able to withstand temperatures up to 1400С. Chamotte brick laying is carried out on refractory clay or special mixtures. Ordinary cement mortar will not work - under the influence of heat, it will crack.

Blocks

Blocks during the construction of baths are gaining increasing popularity, due to the ease of installation of such a structure, high speed of construction and availability of material.

During the construction of the bath is usually used gas or foam blocks, are considered a kind of cellular concrete. They are based on cement and quartz sand, as well as frothers. The product has the correct rectangular shape and is characterized by high strength. To reach the strength allows processing in special autoclaves.

Among the advantages of the material are the following indicators:

- fire resistance;

- high strength;

- low weight - thanks to this, it is possible to refuse additional strengthening of the foundation;

- ease of use - if necessary, the material is easily cut into pieces with a hacksaw, holes can be made in it with a drill.

The obvious minus of the material is the hygroscopicity of the blocks. The material can be absorbed by special processing of the blocks, as well as the use of a hydraulic and vapor barrier system.

The thermal conductivity of a material varies depending on its density: the lower the density, the lower the thermal conductivity, which means that the bath is warmer. This is because low density blocks contain a small amount of air bubbles.

When heated, they expand and prevent the heat from escaping to the outside - a “thermos” effect is obtained. The average coefficient of thermal conductivity of the blocks is 0,072-0,141. When moisture gets inside the material, this indicator decreases.

For the installation of blocks used cement glue. The use of cement is unacceptable because it contains water.

A more durable kind of aerated concrete blocks are gas silicate counterparts. Their increased reliability is due to the presence of quartz sand in the composition.

The most accessible kind of blocks are slag stones. In their composition - cement mortars and waste coal and other industries (slags). This material has a low moisture resistance, so it is not recommended for use for the construction of baths. When damp, the material becomes brittle.

In addition, cinder blocks have low levels of thermal insulation, therefore, when building a steam room from cinder blocks, it is necessary to take care of a reliable thermal and waterproofing system.

Before use, the material should be kept outdoors for a year - it is necessary that harmful fumes and toxins disappear from the blocks.

A more qualitative analogue of cinder blocks are almost hollow claydite-concrete blocks. Due to the voids inside the material has the lowest weight compared with the other blocks, which speeds up the installation process and does not require strengthening the foundation.

The basis of the material is cement mixture and expanded clay (burnt small fraction clay). It is characterized by environmental friendliness, low thermal conductivity (depending on the fraction of claydite - on average is 0.15-0.45) and low moisture absorption. This allows you to create an inexpensive and warm steam room from the expanded clay blocks, which will last for several decades. It is important to use for construction materials of the brand M100-M150. Less durable blocks are suitable only for facing buildings.

Expanded clay blocks are optimal for the construction of baths in the northern regions, since the cold-resistance indicators (and, therefore, the duration of operation) are 2 times higher than those of foam blocks, and 5 times higher than gas blocks. Basalt fiber with foil paper layer is recommended as insulation. When laying insulation it is important not to forget to leave a 2-3 cm air gap.

Another budget type of block are keramoblok.It consists of cement mixture and ceramic powder, which allows to speak about the environmental friendliness of the material. Like the expanded clay counterparts, such a material is characterized by low weight and durability. However, ceramoblocks have a high thermal conductivity, which makes it necessary to mount a thicker layer of thermal insulation.

For the construction should be used blocks, the strength of which is not less than M100.

A rock

Stone bath looks monumental and unusual. The material has many advantages: fire safety, low shrinkage, long service life. The stone is generally available and has a low cost. Shrinkage of the stone bath is only 5%.

However, along with the positive qualities, the stone has a lot of drawbacks, because of which it has received a small distribution in the construction of baths.

The complexity of the construction is one of them. Due to irregular shapes of stones, it is not easy to create a building of the correct shape. The stone retains heat poorly and therefore requires careful thermal insulation, as well as an increased consumption of raw materials for igniting the furnace. In addition, the material has a low gas permeability, so a powerful ventilation system should be provided in the stone bath to prevent air stagnation.

Since the stone has large dimensions, the thickness of the walls of the bath will be very large - on average it is 75 cm. For comparison, the masonry is 51 cm thick and the wooden walls are 15-20 cm. Large sizes and, accordingly, the weight of the material requires strengthening the foundation.

In addition, stone buildings do not "breathe", condensation forms on their walls. It is possible to level such deficiency only by organizing ventilation and a powerful vapor barrier system.

Despite the low cost of the material, the construction of a bath made of stone will cost more than the construction of a bath, even from an expensive sort of wood. This is due to the peculiarity of the installation of a stone steam room, a large amount of thermal insulation material, the complexity of processing and the large weight of the stone itself.

Other materials

For the construction of the bath, you can use other materials, for example, blocks of arbolita. Their basis (up to 90% of the composition) is made up of wood waste, previously crushed to the desired size. They are filled with a mixture of cement with the addition of liquid glass or calcium chloride. The latter prevent the destruction of wood under the influence of resin acids, as well as accelerate the process of hardening of concrete.

The material has the following features:

- low thermal conductivity;

- environmental Safety;

- high hygroscopicity, which necessitates the use of high-quality waterproofing;

- low cost

In addition, you can mark other items:

- Higher heat capacity of the material compared with the heat capacity of air, which means the ability to create a favorable microclimate in the bath. First, the air in the room warms up, and then the walls. In the brick bath everything will be the opposite.

- Low material strength, which means inability to withstand heavy loads. This makes wood concrete blocks suitable only for low-rise construction.

- The need for external lining of the building of arbolita. For these purposes, it is better to use the wall paneling (the most affordable option in terms of price), brick or wood, impregnated with moisture-repellent mixtures.

In addition to the selection and purchase of materials for the walls of the bath, difficulties may arise when choosing materials for the foundation and insulation.

Below are the types of foundation that can be used in the construction of baths.

Tape

It is a "tape" of concrete, which is located along the perimeter of the building.Due to this strip foundation is considered not only the most durable and reliable, but also the most expensive.

Such a base is required for brick and stone baths, as well as buildings with a large number of floors (more than one floor, baths with attic).

Columnar

It has concrete bases, columns, located at equal intervals from each other. The pillars are connected by wooden profiles, on which the walls are then laid. The advantage of the base is ease of installation, as well as the ability to put them on uneven areas. Suitable for small wooden baths on one floor. This type of foundation is recommended for wooden baths, because it allows for additional ventilation of the room, which is important in conditions of high humidity.

Pile

This type is somewhat similar to the columnar variant, but instead of concrete columns, piles are screwed into the ground. The advantage of the method is the ability to conduct construction even in frozen ground, that is, in winter. For baths of large areas or heights after installation of piles, concrete casting is performed, and in some cases, welding of piles along the perimeter.

Slab

This type of foundation is suitable for mobile soils, including when the groundwater is nearby. A simpler option is to use ready-made slabs. If you need to save money, they resort to reinforcing the base, after which they pour it with concrete.

Tips

Having considered the features of materials used usually for the construction of baths, you can decide on the choice of a particular option.

The highest quality is a wooden bath of spruce and pine. Ideally, if it is made in the northern regions - such a material is characterized by increased strength and moisture resistance. This option will allow you to maintain the necessary microclimate in the steam room, will give a pleasant feeling. Warming up, wood fills the air with forest aroma, which has a beneficial effect on the human condition. In addition, wooden baths are attractive and durable.

If you choose thermo-modified wood, it will not absorb moisture and swell, which means it will last longer. This material is recommended to sheathe at least "wet" places of the bath. In addition, thermally modified wood has a lower thermal conductivity compared with conventional varieties of wood.If funds allow, it is possible to sheathe the bath with thermally modified clapboard - this will allow to make the construction warmer and save on insulation.

Wood for wooden baths should be harvested in winter, because at this time of the year it has a greater density, and therefore moisture resistance.

If logs are used, their diameter should be 18-25 cm. If the diameter of the logs is larger, this will contribute to greater heat loss. The logs of the same batch should be the same - the maximum allowable difference between individual logs should be no more than 3 cm, otherwise they will not fit snugly together in a log house.

For the lower rims of the building, larch will be suitable as a more moisture-resistant material that is not afraid of mechanical impact and frost, the remaining crowns are made of pine or spruce. Coniferous rocks can be avoided by special treatment or the use of thermowood. Another option is not to use conifers for interior decoration of the steam room. For these purposes, cedar (an expensive option), alder, poplar and linden are not bad - these varieties of trees are characterized by high moisture resistance and ability to retain heat.

Quality logs do not have dark spots on the cut, the cut itself is solid, and the core takes a third of the cut of the log and is distinguished by a uniform dark color. The surface of the logs has a dark or light yellow color, without knots, cracks and resin pockets. Similar requirements are imposed on the timber.

During construction, you should choose a profiled bar that has a higher quality processing - this is the material that has passed through chamber drying. If funds allow, you can choose glued laminated timber. In addition to a more aesthetic appearance, it gives less shrinkage, does not "turn out" during operation. However, the glued version is not suitable for those who are looking for an environmentally friendly material, as well as for people suffering from allergies, chronic diseases of the upper respiratory tract.

The cheapest version of the timber is considered unplanned version. The cost reduction is due to the fact that it dries not in special chambers, but in the open air. However, the low cost of the material does not always mean the efficiency of the construction process. When using non-planed timber, high-quality thermal insulation, exterior and interior decoration is required. Besides, The material shrinks, so after building the base of the bath it is recommended to wait a year before proceeding with further construction.

Before using the tree, it is necessary to treat it with impregnation, which increases its waterproofing ability, fire and biostability. A similar treatment is recommended to repeat every two years during operation.

If you need a cheaper structure, then you should pay attention to the claydite. It will be possible to build a structure quickly due to convenient block sizes. At the same time, it can be of any size: in 2 or even 3 floors. The material has a low thermal conductivity and durability.

In an effort to build a budget steam room, you do not need to choose the cheapest materials - foam and cinder blocks or aspen. Such a bath will last only about 10-12 years, and when operating with it there will be a lot of trouble.

If you analyze the cost of the material, then the most expensive for the construction of a steam room is wood. If you carry out calculations in cubes, then it is 2 times more expensive than bricks and blocks. However, when analyzing the total construction cost, the use of wood is cheaper.This is due to the lack of large expenditures on the foundation (some types of baths, for example, assembled bath-barrel, do not require the usual foundation), thermal insulation, exterior and interior decoration.

Expensive wooden material for the construction of a bath is a log, a timber has a slightly lower cost (the cost varies depending on the type). Behind him for the price is a carriage, which is a log hewn from opposite sides (especially popular in Scandinavian countries), and a double timber (consists of two boards with grooves - between them is insulated, usually mineral wool).

It is important to choose the right insulation. Some baths require better thermal insulation, while other options imply only interwoven insulation. However, regardless of the material used, any bath requires insulation of the ceiling - this is due to the fact that warm air always tends to the top.

For insulation of the ceiling in the bath, where the attic is not supposed to be used, bulk insulation (claydite, sawdust) or clay ceiling can be used.When organizing an attic, it is recommended to use tile materials or to arrange a floor screed for the attic room with an addition to the concrete composition for screeding the components that provide thermal insulation. Ready mixes can be found in stores. For baths with an attic requires warming slopes of the roof with mineral wool or foam materials.

Warming of walls is required by all baths, except for timbered. Especially it concerns block and brick steam rooms. Frame structures suggest the presence of "regular" insulation material inside the frame. However, if you plan to heat the bath in the winter and at the same time live in a rather harsh climate, then it makes sense to take care of additional wall insulation.

The most fire-resistant insulators are mineral and basalt wool. Such a material is able to withstand heating up to 800 ° C, which is due to the peculiarities of the production of materials - rock is heated to 1500 ° C.

If year-round use of the bath is planned, then floor insulation will also be required. The choice of material depends on the type of foundation and features of laying the floor.For screw baths, a rough and finishing floor is required, between which a layer of mineral wool, extruded polystyrene foam or foam polystyrene is laid.

For pile foundation suitable expanded clay. It is important that it be of different sizes: the larger one will hold the heat, while the smaller one will fill the space between the clay balls. Since claydite is hygroscopic, and when wet it loses its insulating properties, it is important to have high-quality hydro and vapor insulation.

To create a comfortable atmosphere in the steam room and to protect the walls from the effects of high temperatures allows internal insulation. Protecting the walls with a layer of insulation and waterproofing, the owner protects them from moisture and thereby prolongs the life of the bath. For greater thermal efficiency of the steam zone when it is finished, it makes sense to use a double layer of insulation. The area around the furnace - the walls and the floor - is additionally insulated with protective screens. If we are talking about wooden construction, then a refractory layer is required, made of asbestos sheet coated with iron.

The minimum thickness of insulation for brick baths that are used in winter should be at least 10 cm.

When choosing insulation and flooring, it is important to acquire an option that, when heated, does not emit harmful components. From this point of view, the use of linoleum is unacceptable.

In the area of the steam room is not recommended to use mineral wool, due to the release from it of phenol-formaldehyde resins, which are a binder component of insulation, when heated. Ecowool is also unsuitable for use in the steam room, as it has a high hygroscopicity. In the area of the steam room, it is not recommended to use foiled polyurethane foam, as well as expanded polystyrene and polystyrene, which, when heated above 60 ° C, release toxic substances. However, they can be mounted in the area of the washing and the dressing room - that is, where the temperature does not reach the specified indicators.

From the point of view of environmental friendliness, the use of basalt wool is preferable. The disadvantage of the material is the tendency to shrinkage, which means the thinning of the layer of insulation during operation.

Foam glass is used on walls that can withstand heavy loads, for example, brick. It is the best insulation for the bath - retains heat, does not burn, does not shrink, is bio-resistant and environmentally friendly.The disadvantage is the high cost and the need to strictly observe the installation technology.

Exterior insulation is usually combined with decorative veneer, choosing for this suitable materials. Brick and block baths do not need external warming, if they are intended for seasonal use.

Log baths are always insulated outside. For this, natural or synthetic insulating materials can be used. The most common natural insulation is jute, as well as flax, their combined options and moss. Their main advantage is absolute environmental friendliness, and the disadvantage is the complexity of the insulation process.

Synthetic heaters are represented by insulating tapes and combined materials.

Separately, it should be allocated insulation based on sheep wool, which is considered the best option for a bath of profiled timber. The material is practical because it performs the functions of not only insulation, but also moisture, windproof material. It is important that in the process of using the bath material is not thinned.Among the drawbacks, it is worth noting the high price, as well as the risk of moths appearing in the insulation.

Experts recommend the use of vegetable insulation for logs and synthetic for timber.

The most common for creating doors in the bath received wooden models. It is necessary to immediately abandon the use of the fillet version - it is jarred under the influence of moisture. The best option - the door of the array.

It is a board or glued panels with a thickness of up to 5 cm. A cheaper option is a frame construction - a frame made of bars, sheathed with clapboard on both sides. If necessary, between the frame and the clapboard can be laid insulation. The best type of wood in this case is linden.

Plastic doors can also be used in the bath - an exception is the doorway of the steam room. Metal, by virtue of its ability to heat up, is permissible to use only as the outer skin of the entrance door.

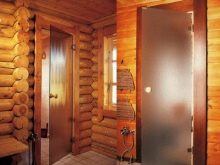

For saunas, a glass door that has undergone high-temperature hardening can be used. Usually it is a glass sheet, framed in an aluminum bath and having a small gap at the bottom for ventilation.

There is a myth that glass may burst from the heat, but for baths use tempered glass with a door thickness of 8 mm.

The material has large heat losses compared to wood, so it is necessary to heat the furnace more intensively. Another disadvantage is the high cost, as well as the output of products of standard sizes. However, you can always make a glass door to order the desired parameters. Unlike wood, such a door does not crack and looks very attractive.

Beautiful examples of buildings

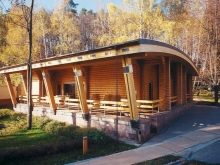

Today, baths have ceased to be a place solely for the implementation of hygiene procedures. Modern baths are real spa complexes, places for relaxation of body and soul, friendly and family meetings. This imposes requirements not only on the size of the steam room, its internal and technical filling, but also on the design.

If financial opportunities and the area of the plot allow, you can build a large bath, which includes not only a steam room, a washing room and a waiting room, but also spacious lounges, a billiard room, a small bedroom and a mobile kitchen.

Such a building is more correct to call a bath complex. It is usually built in the characteristic Russian style: from a thick log, with wings on the roof, carved platbands

The trend is to make flat roofs on luxurious baths, where you can sunbathe or simply enjoy the view or arrange a mini-garden

A convenient option is to place an outdoor pool within walking distance of the bath. Protect the font from litter and scorching sun will allow a polycarbonate visor on exquisite forged supports. The pool can have various dimensions and forms. Original look fonts with light. Lounge chairs, low tables are usually placed near the pool.

The most organic such complexes look in the event that they are made in the Russian style. As already mentioned, this involves the use of logs, simple shapes, light shades. Mandatory element are the trim on the windows, porch, welcome workshop wood carving.

Opposite options are sauna complexes, steam rooms in the style of minimalism. They differ in functionality and compact size. The interior of the room is usually divided into 3 zones: a steam room, a washing room and a rest room.

The last component of the room, as a rule, is multifunctional, combining in itself a small dining room, sofas and a billiard room.

Such bathhouses look particularly stylish when using fireplaces.The furnace of these devices is taken out to the recreation area and is issued by the fireplace portal.

The small bath with the attached terrace or a veranda glazed with sliding windows and doors looks spectacular. The terrace can go to the pond or other water structure.

Another option - a bath with a veranda. It may be small or quite spacious. In any case, its organization does not require a lot of manpower and resources. In the resulting space, you can arrange wicker furniture and a round table by organizing a cozy corner for friendly and family tea parties.

Lovers of privacy can put a volume armchair and a shelf with books on the veranda, and lovers of active pastime can organize a dance floor. In the latter case, you will need equipment and a disco ball. A small bar will be appropriate.

If you make the veranda more closed (on the foundation) and warmed, then it will turn into a terrace. It is nice to organize a barbecue area here by setting up a barbeque or mini-oven, tables and benches, chairs. Functionally and stylishly, on the terrace there is a swimming pool or jacuzzi, as well as a home spa. If you make the terrace light enough, then nothing prevents you from organizing a greenhouse here.

Economical is a two-storey bath.The main item of expenditure in the construction of such objects is the arrangement of strip foundations. The construction of the second floor, oddly enough, does not require large financial investments. On the ground floor there is a steam room and a washroom, on the first floor - a bedroom or a mini living room.

Instead of the second floor, you can equip the attic. There are a lot of options for its functioning - in addition to the recreation area with soft furniture and a billiard room, you can equip a home spa, library or a cozy cinema

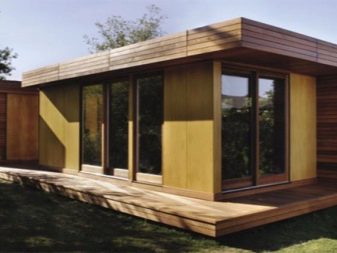

Connoisseurs of high-tech urban styles fit baths in high-tech style. As a rule, these are rectangular buildings or other simple concise forms of brick or blocks. Preferred finish - siding panels

The internal filling of such a bath usually impresses with its adaptability - multifunctional electric furnaces, steam generators, shower panels. All this allows you to get spa treatments in confined spaces.

For high-tech baths choose gray, beige, steel shades, tinted glass surfaces. The rest room looks good walls with imitation of brickwork, high bar counters, original island fireplaces.

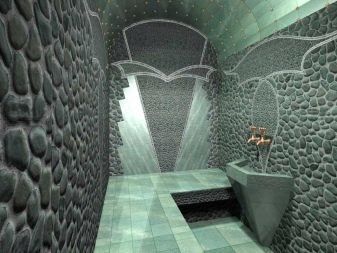

Interior decoration is traditionally made of wood. Choosing light wood, you can visually increase the space of the bath. Darker, with a reddish tint options look elegant, give a special atmosphere of comfort, homely warmth. For the washing area, as well as premises for the pool, you can use tile or mosaic.

It is important that the materials used were in the same style. For example, for a steam room, you can use wood and a stone stove, and then repeat this finish in the recreation area. In the washing room, you can use tiles that also imitate stone surfaces.

Tips for building a bath, see the following video.