Bath of claydite-concrete blocks: instructions for making

Among the many options of baths one of the most attractive at the current moment is the construction of expanded clay concrete. But in order to enjoy its benefits and not face operational problems, it is recommended to strictly adhere to the technology of work. And it, though not too complicated, but contains quite a lot of nuances.

Pros and cons of the material

Comparison with a tree shows that claydite concrete is at least not inferior to it (if you focus on the whole complex of properties). It is distinguished by a good level of thermal insulation (with other things being equal it lets out 2-3 times less heat than brickwork). At the same time, lightweight aggregate blocks are distinguished by their low mass, and even details of size 40 x 30 x 24 cm are not a problem for adults. Other benefits are:

- Reduction of terms of work (since one unit quietly replaces an average of 12 brick rows).

- Ability to work on a continuous cycle.The design should not be defended before installing the roof and start finishing.

- The ability to use in the construction of a standard solution of cement and sand. Sometimes it is replaced with mounting adhesive foam.

- Formation of extremely flat walls.

- Savings (when building a bath, for example, the size of 5 to 5 m costs are 25-50% less than with classical wooden construction).

- An opportunity to be limited to the tape base with small deepening.

The weak points of the claydite bath are the impossibility to make more than three floors, as well as the insufficient resistance of the blocks to mechanical damage. If the item falls, or is hit, it will be broken. Profitability is not so big: you definitely need to put the cladding inside and outside the building. These disadvantages can be safely neglected. Anyway, the quality of the lightweight aggregate bath is significantly superior to the wooden versions.

We build with our own hands

Layout

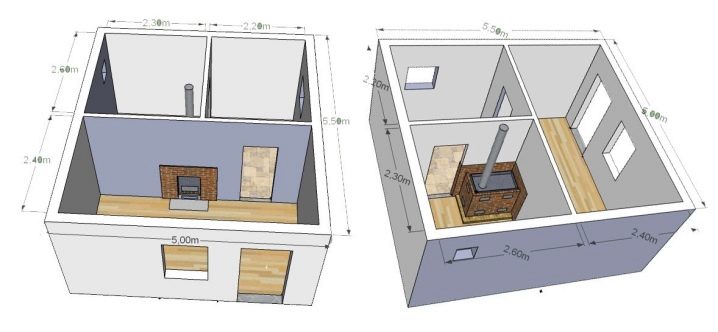

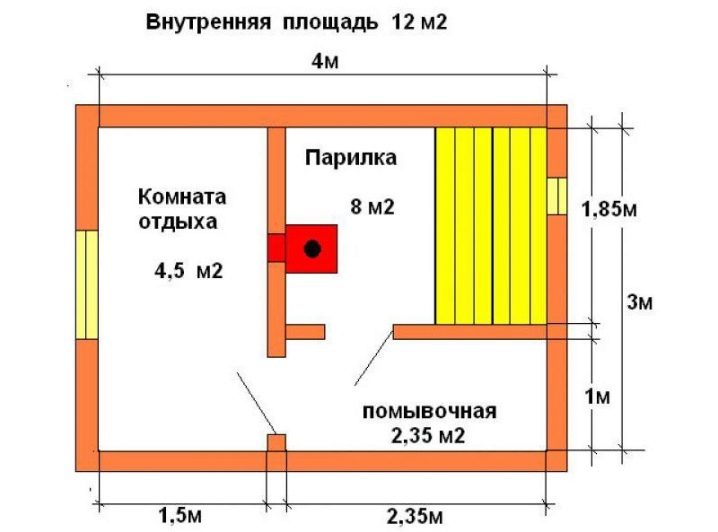

The first step in the construction is the preparation of the project. At this stage it is provided:

- building a model of construction;

- selection of locations for steam baths, showers and other parts;

- calculation of justified dimensions;

- determination of places of exposure of openings under windows and doors;

- calculation of the amount of building materials needed.

It should be borne in mind that even the best baths of claydite-concrete blocks are inferior to wooden structures in terms of thermal protection. The dried pine timber transmits twice less heat than insulating expanded clay concrete, and if the construction is carried out using frameless technology, the difference becomes fivefold. The specific gravity of the material is approximately 1000 kg per 1 cu. m. More accurate parameters for the final design can be found in the documentation of the manufacturer. Relatively compact bath area of 9 square meters. m built in one floor and is usually divided into three sections:

- 50% is given to the leisure room;

- 25% washing;

- another 25% takes a steam room.

The problem with this design is that it does not allow for proper comfort. In the presence of sufficient funds, it is necessary to build a bath of expanded clay parts in 2 floors, which is located below the full-size steam room. There it will be possible to lie on the shelf, and it will be easier for the assistant to move around.In addition, it is possible to supplement the leisure room with a warmed vestibule, which reduces heat loss.

A bath with a lean-to roof is easier to build than with a gable, but then you will not be able to organize a full-fledged attic or an attic.

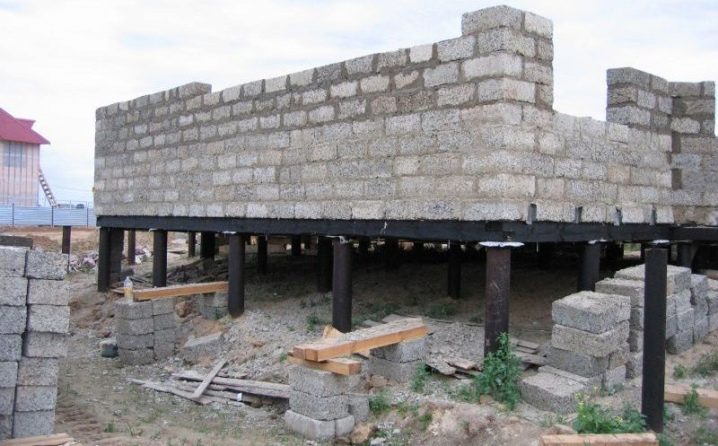

Foundation

Occasionally the opinion that household and utility buildings can be put directly on the ground is incorrect. After all, the properties of the soil can change, they change under the influence of precipitation and other unpredictable factors in advance. When building baths, claydite-based concrete most often uses tape bases, which are built very simply and unpretentious to use. Many even build similar foundations on their own, without attracting expensive special equipment.

Small baths are sometimes built on columnar bases, supplemented by razgalkami, but if the soil is prone to swell strongly, this idea is unsuitable.

The construction on difficult grounds is mainly done in a screw way. Such foundations are mounted in a matter of days, they are equally effective in the swamp and on the hills. The only serious limitation is incompatibility with rocky soil.At the same time, it is important to choose structures with the strongest welds, since corrosion in them causes many problems. Pile-screw version, reinforced grillage, is much stronger.

A monolithic foundation under the baths of expanded clay blocks is extremely rare, even with problems with the geological substrate, it is advisable to confine yourself to piles. If you choose well-treated pile elements, you can increase the service life of the structure to 100 years at least. Preparation for the formation of the base involves clearing the site and marking it in accordance with the project.

The foundations under the stoves are made separate from the main ones, since they have to carry a much greater load.

Be sure to take into account the depth of freezing, the height of the rise of groundwater.

Stacking blocks

Correctly put clay blocks, means to ensure their isolation from the foundation. Roofing material is laid in two layers, and the walls themselves are arranged in the form of half a block, using the ligation method. Preparation of the solution involves the use of cement and sand in a ratio of 1: 3. When water is added, you need to carefully ensure that the mixture is dense, but it retains plasticity.Approximately 20 mm of mortar is applied on top; in the construction of partitions, either standard blocks or thinner ones are used.

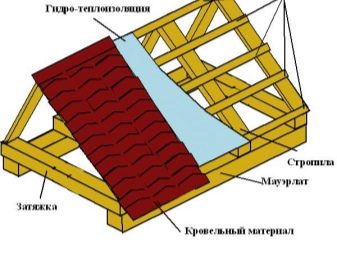

Installation of the roof

Step by step instructions can not ignore the work on the construction of the roof in the bath. It is recommended to make a choice in favor of lightweight coatings - even if you don’t like traditional slate, a good alternative would be a professional flooring or roofing material. Roofing cake necessarily contains a layer of insulation. Above the heat protection mats, a vapor barrier is placed; The best option is foiled film. There are no special differences in the formation of the truss system in comparison with other gable and single-slope roofs.

Oven device

It is impossible to avoid such a moment as the choice of the furnace of the bath. The main criterion for this choice is the achieved thermal power and the ability to adjust it. To understand whether sufficient heat is produced, the size of the vapor compartment helps. On summer days, it will warm up on average in 30 minutes, and in winter, about an hour.

When calculating the heated area, the dimensions are taken into account not only of the walls, but also of the floor and the ceiling.

Taking into account the heating of the furnace, the stones in it and the water tank, the resulting figure can be easily increased 2.5–3 times. When calculating, they also take into account what the walls and floor are sheathed with, how powerful thermal insulation is provided for, and how strong heating of the bath is required. Power adjustment is easiest for gas and electric heaters, a little more difficult to do in relation to wood heaters. Adjustment methods are as follows:

- containment of air;

- heat removal to the outside;

- adjusting the flow of fuel inside.

You can not put a low-power device that would reduce costs. After all, even if such a furnace and will be able to work properly, then she will have to give all the possible power, continuously work for wear. Because the service life is noticeably reduced. A traditional stone stove will only be acceptable if you have a professional stove-house in mind. Adherence to tradition will compel to put up with a long warm-up and with difficulties during ignition.

The firebox can be either elongated for installation in the wall, or normal. The first type is characterized by less fire risk and allows you to create a comfortable microclimate, but can cost more.To reproduce the real Russian stove, it is recommended to buy an autonomous electric steam generator, it is able to cope with all possible problems.

A high-quality stove should be able to heat the air under the ceiling to 80 degrees, so that you can steam comfortably there. Kamenka are made open or closed by execution.

In the open format, the air is heated by the hot stones themselves. This solution is ideal for an actively visited bath: the air in the steam room warms thoroughly very quickly, and cools in the same way. The closed furnace is equipped with a special valve that helps isolate the top row of stones. But long-term retention of heat slows down the warming up in general. Among other parameters, it is worthwhile to always find out how long the furnace is able to heat the room without receiving additional fuel.

Facing outside

No matter how warm and strong a bath made of expanded clay blocks, she herself does not look very attractive. An excellent solution to this problem will be the use of decorative plaster, raising the aesthetic qualities of concrete blocks.They begin to look no worse than a simple brick, and at the same time do not lose their positive qualities. In addition, the exterior finish is quite effective protection from rain and frost.

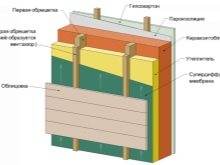

Thermal insulation of the outer surface of the walls is permissible using both extruded polystyrene foam and mineral wool.

If wadded materials are placed under the siding, you need to carefully monitor so that the wind does not blow them. The necessary protection is provided by special insulating membranes. Note: when buying, you should make sure that they are able to skip steam. It is advisable to paint the plaster layer with facade paints that increase the resistance to moisture. And before plastering themselves, experts recommend using concrete contact to ensure maximum adhesion.

Reduce the complexity of the work helps the choice of finishing siding or joining plastic panels. Such decoration methods are available even for non-professionals. And the rarest variant is the application of a paintwork material without prior plastering.

Resorted to it, if the walls are thick and allow you to abandon the use of insulation.But it is better to consult with specialists before making a final decision.

Finish inside

Even when the construction and exterior finish is completed, there remains one more important problem - what exactly is sheathing, decorating the walls. The advantages of claydite-concrete do not give a reason to forget that the masters are limited in the choice of finishing materials. And even the fact that, in principle, can be applied, is not always justified. When plastering, it is recommended to use a gypsum or cement-sand grade of mortar, it will mechanically strengthen the rough surface.

Gypsum compounds are considered easier and more comfortable, they keep heat better. If you buy a mixture that can be used without prior treatment with a concrete contact, it is advisable to reinforce the plaster with nets of polymers or steel. Moreover, polymers are considered more practical and convenient in terms of operation. Finishing facing will become more beautiful if to use a ceramic tile or a natural stone. These materials do not usually require surface preparation at all, although special tile adhesive can be used.

Owner reviews

Constructed for themselves a bath of claydite-concrete blocks say that it is more economical than the construction of the bar. With regard to possible deficiencies, experts recommend paying attention to the protection against moisture penetration into the walls. This is quite enough to guarantee long service and active operation of the bath without any consequences.

You can do all the work in a few months, and then immediately use the building for its intended purpose. Importantly, professional teams building custom-built clay-filled concrete baths rarely encounter customer complaints.

To learn how to build a bathhouse of expanded clay concrete blocks, see the following video.