How to build a bath from a rounded log?

Wooden baths are popular for a long time. Wood contributes to the creation of a unique atmosphere, this material is very pleasant in appearance. Constructions from the rounded log differ in special charm. Let us consider how to build a bath from such material, what recommendations should be paid special attention to.

Special features

A round log is a tree trunk, which is processed in a special way during manufacturing so that its diameter becomes standard. Thanks to this treatment, the strength characteristics of wood are significantly improved. The most durable, solid part of the trunk is the core.Immediately under the bark is sapwood, which is much wetter than the core. It is prone to cracking, rotting.

When logging is carried out, the core is ground and the sapwood is removed. Due to this, the service life of materials becomes longer.

It is also worth noting that the resulting blanks are very smooth, so the rounded log does not need finishing at all.

Rounded log has several advantages.

- Ease of use. Installation of baths made of logs can be done quite quickly.

- Long service life. If properly carry out installation work, the construction will last more than one decade.

- Optimum thermal conductivity. Such building materials are able to retain heat remarkably. Such baths are quite easy to heat even in extreme cold.

- Relatively low prices. Buildings from such materials are cheaper than stone or brick.

- Natural ventilation. Thanks to this you can avoid drafts.

- Environmental friendliness. Inside the bath it will be safe, because the round logs do not emit substances harmful to humans.

However, there are some drawbacks:

- in the first year the humidity in the bath will be increased;

- It is quite possible that materials will start to deform due to shrinkage.

Project

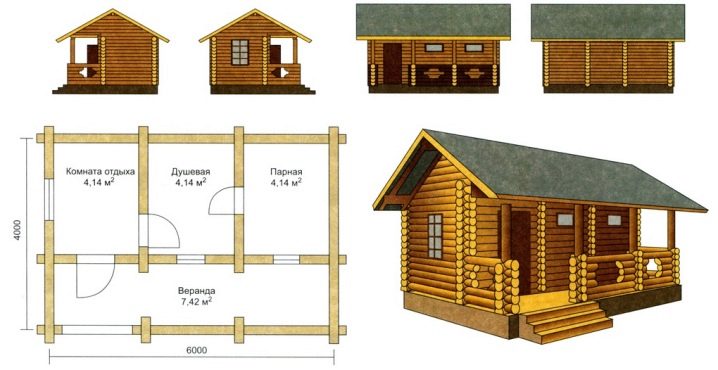

Choosing the size of the bath, you need to focus on the number of visitors. A small construction of 3x4 m is quite enough if there are not many people. However, more often they order projects of baths 4x6, 5x5 m.

Many opt for complex projects. Baths with a veranda and an attic are very popular. Some choose home-baths with a complex layout, create a whole bath complex, decorate the area next to the building with decorative elements - for example, an original gazebo. Pretty popular option - a two-story building. On the second floor you can arrange, for example, a kitchen.

The largest baths are usually designed for high permeability. They can accommodate additional facilities: for example, designed for spa treatments.

Varieties of material

Most often for baths choose logs with a diameter of 200 to 360 mm. Determining the diameter, you need to consider the following factors:

- wood natural moisture or drying chamber;

- the building will be operated all year or only in summer;

- bath size;

- temperature in the winter season.

When choosing the best logs, you should also consider the type of wood.

- Pine - a fairly inexpensive building material, it is convenient to handle. Pine logs are relatively light. However, this material has disadvantages. Pine allocates resin, which can cause severe burns (this is important for the steam room), besides it is short-lived.

- Spruce also easy to handle, convenient to use. Such wood differs from pine in color. Spruce is golden and pine is white. Resin can also be released from this tree, so it is not suitable for use in the steam room.

- Expensive conifers - cedar and larch. They are characterized by increased strength, resistance to various external influences.

- Oak quite expensive, but it is also very durable. Buildings of such wood are almost eternal (of course, if you consider all the recommendations for the care). Oak is very resistant to high humidity.

- Linden used for the construction of baths quite often. Due to the presence of special essential oils in such wood, it is very pleasant to be in the bath, besides, they have a positive effect on human health. Lipa is not highly resistant to rotting, and it is also quite expensive.

- Aspen - Wood, which has a more reasonable price than oak and linden. It is easy to handle, it has a small weight.

How to choose a place?

When deciding where to build a bath from a rounded log, you can only focus on your own preferences. Exception - built with a pool.

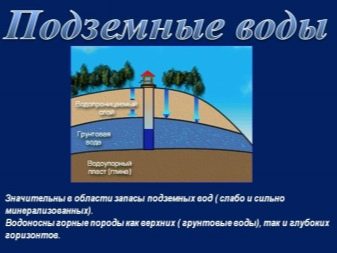

For such a bath is better to choose a place where the groundwater is not very high.

How to build with your own hands?

You can start building even before you bring the logs. It is recommended to prepare the foundation in advance. When you create it you should focus on the drawing of the building that you will build.

Foundation

Since the buildings of otsilindrovannyh logs have a significant weight, the foundation for such a bath should be very strong. Usually it is made tape. This is a rather complicated process, but it is quite possible to cope with such work.

First you need to properly mark the territory in a vertical, horizontal planes and prepare the trench.

- Mark the plan using a laser level.

- Then you will need to install rags and pull the thread.

- Dig trenches. Determining its depth, it is necessary to focus on the weight of the building, the depth of soil freezing and the type of soil. Most often, the required depth is determined by professionals.

After preparing the trenches, install the formwork and fill the foundation.

- Pour and tamp the gravel (about 15 cm layer).

- Then you will need to pour sand and re-ram everything.

- Assemble the formwork from unedged board and install it.

Take care of the presence of external supports, otherwise the structure may eventually collapse due to the weight of the concrete.

- Create reinforcement elements. Assemble two lattices (cells - 200x200 mm), using reinforcement, the thickness of which is 1 cm. This can be done by using binding wire or welding. Place one of the gratings at a distance of 50 mm from the foundation (its upper edge). The second will need to be placed at a distance of 50 mm from the bottom of the trench. Using the twigs, connect the grids with each other.Then you will need to install the reinforcement cage.

- Then the formwork will need to pour concrete. After that, make the surface as flat as possible and let it dry. Concrete material, which is based on Portland cement, becomes hard for 24 days.

Waterproofing

Before construction, you need to prepare the foundation: to carry out its waterproofing. Can be used for this ruberoid.

- Spread the molten bitumen on the foundation and place the roofing felt on it.

- The surface should cool down. After that, put the ruberoid back on and wait for it to cool.

First crown

If the construction project was ordered at an enterprise that specializes in such construction work, all materials will be enumerated. You will also receive a diagram showing how to assemble the structure correctly. The assembly will need to carry out, following the step by step instructions.

- First we build the first crown. To find materials that are designed specifically for this, focus on the scheme. The diameter of the logs for the first crown is usually slightly larger.

- To ensure that the materials are positioned correctly, use a level.The first crown is in a horizontal position.

- The gaps between the logs and the foundation will need to be filled using mounting foam.

Wall construction

It will be necessary to lay the insulation on the first crown. You can use jute or tow. Then assemble the second crown, install it and fasten it using wood pins or metal pins. It is recommended to drill holes for them during the manufacturing process. Next, the construction will need to be built in the same way.

Do not fasten the two upper crown. When shrinkage is completed, they will have to be removed to install the ceiling beams. So that the bath is protected from the impact of the liquid, while it sits, protect the frame with roofing felt and unedged board.

If the material itself is rather dry and therefore shrinkage is minimal, the installation of the doors and windows can be done immediately. However, experts still recommend doing it after a while.

Caulking iron

Reception, which is usually used to give the bath an additional tightness, is called a caulker. It is necessary to use tow as a compactor: hammer it into the existing slots.

Usually use jute, flax tow. Jute tow is more resistant to rotting, and flax is softer, so it is easier to work with it.

Begin to drive in the seal from the bottom. Only one wall of the caulk should not be, otherwise there may be a bias. The gaps need to be hammered both outside and inside.

Roof

The roof can be made both dvukhskatny, and odnoskatny. Construction is carried out on the same principle as in the case of other roofs. Picking up the material for the roof of a bath from a rounded log, people are guided primarily by the cost.

Natural tile works very well with wood, but not everyone can afford such a rather expensive material. It is possible to use ondulin, usual galvanized steel.

In order to achieve maximum harmony, you can use the same roofing materials for all the buildings that are located in the area next to the bath.

Tips

Choosing the right logs, pay attention to the quality of the material. There should be no knots, resin pockets. The smell emanating from the logs should not be suspicious: if the wood is of high quality, it smells very nice.

At construction of baths from the rounded logs it is not necessary to use nails. Because of these elements, the tree can be damaged, because they will start to rot in the wood. It is also necessary to correctly install floor beams. Otherwise, it may happen that the load will not be evenly distributed.

Special attention should be paid not only to the subtleties of the construction work, but also to the interior decoration. When you caulk the walls and take care of the necessary communications, you will be able to start arranging the rooms. First of all it is necessary to be engaged in floors. Lags are commonly used, but for rooms where the shower is located, a concrete screed should be chosen. Ceramic flooring can be laid on such a floor.

Specially trim the walls in a bath of logs is not required. To provide additional protection, you can simply put on the walls of impregnation or varnish. However, for washing many use special moisture-proof tools. It is also recommended to take care of vapor barrier and moisture removal. For the steam room is better to use clapboard.

Ready bath can last for quite some time.It will only be necessary to take into account the recommendations relating to the implementation of construction works, and properly care for the construction.

Owner reviews

Usually, the owners of the baths from the rounded logs leave positive reviews about this material. Professional builders also note that it is quite easy to build buildings from such logs. Many people write that the use of such material allows saving on heating (if the installation is carried out correctly, the walls will not be blown).

Some are dissatisfied with the fact that log buildings sit down for a long time. However, this is not quite true. The term shrinkage largely depends on how the construction work was carried out.

If you are unsure that you can implement them correctly, it is better to turn to professionals.

Beautiful examples of buildings

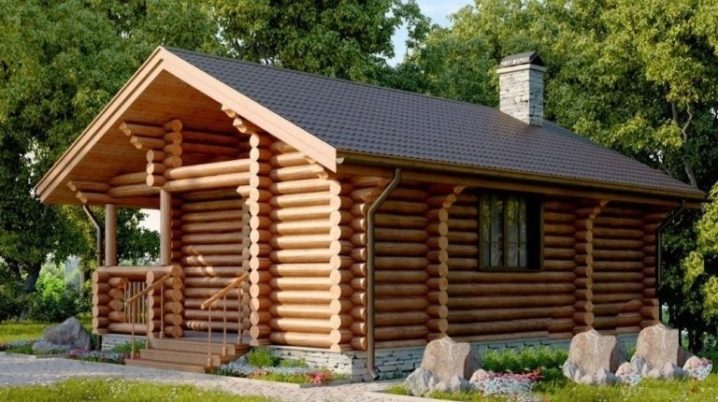

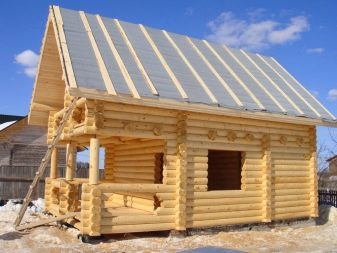

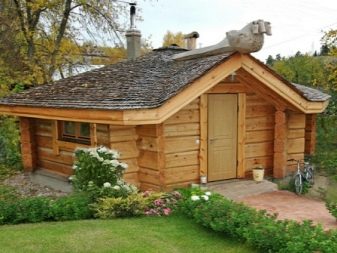

A bath from a log at first sight is associated with warmth and comfort. A bath with one floor is a very good option for a small plot.

Near the building you can arrange a swimming pool: ideal for summer holidays. The design of the bath may be more complex than in standard designs. Very well, for example, combined with the construction of a porch.

On how to make a stove for a bath with your own hands, you can learn from the following video.