Metal furnace for a bath: drawings and tips for making

The origins of the Russian bathing tradition are in deep antiquity. This fact determines a number of characteristic features. For a Russian person, the real heat of a heated heater and a steamed birch besom are important.

In this concept, modern showers, Jacuzzis, steam generators, baths and electric heaters do not hold water. Russian people appreciate the bath for the opportunity to socialize, perform a ritual of purification, discuss the news with friends. Today, no construction of a country house can not do without building a bath.

Special features

High business intensity tires a person. To replenish strength, it is necessary to return to nature, its origins. Tightness of bathrooms, synthetic shower cubicles do not contribute to peace and relaxation. There is only one place where not only dirt is washed off, but also fatigue - this is a country bathhouse.

The main attribute of a domestic bath is the furnace of an individual design made by hand. Usually this is an economical device that liberates heat.

Metal heaters meet these requirements and significantly surpass electric and gas heat generators.

The advantages of homemade metal furnaces are as follows:

- they are done by hand, but it is enough to have basic electric welding skills;

- are much cheaper than brick counterparts;

- do not require special knowledge when performing laying;

- when lined with brick is not inferior to brick counterparts in heat transfer;

- small size, which is critical for small spaces;

- ease of use, operation does not require skills;

- you can drown any kind of solid fuel;

- quick preparation - usually within an hour.

The disadvantages of metal furnaces include the following:

- limited number of modifications;

- inevitable deformations due to temperature;

- low heat capacity, which is compensated by brick lining;

- dry air;

- in the absence of a heater, there is the possibility of thermal shock;

- efficiency only in small spaces.

Iron furnaces appeared at the end of the XIX century. The prototype of such devices is the so-called stove, equipped with a steel tank, door and means of flue. This unusual term appeared rather long ago and there are two assumptions about its occurrence.

The first option is that this name was formed due to the natural "gluttony" of the structure and low efficiency. Folk fantasy has combined these qualities with the concept of “bourgeois”, which “eats” a lot of firewood and gives little heat. Only a true nationality can explain the perfect polarity of the second interpretation. It is known that this stove became popular during the bourgeois revolution, because it was undemanding to fuel and worked quite effectively.

It is worth more to consider its design features. Today the mass of similar furnaces is presented, but they are connected by practicality. This is the first thing that comes to mind when getting acquainted with the process of their work, regardless of the fact that this is a retro version or a modern high-tech copy created using nanotechnologies and composites.

Despite the fact that the stove is the simplest heating device, its design is clearly consistent with the principles of heat transfer.

Today the metal furnace for a bath is in great demand due to its exceptional properties and advantages. Modern technologies allow to achieve optimal heat exchange and long burning.

You should consider in detail the device of this heating device. The design provides the implementation of two functions - it is heating the heater and space.

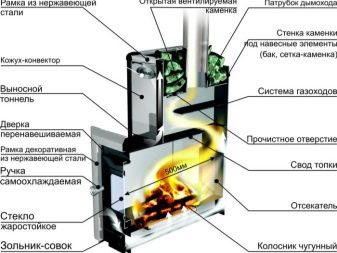

A conventional iron stove includes several functional units, such as:

- firebox - This is the area for burning energy;

- heat exchange device provides heat exchange with the heater and heats the space;

- heater - these are specially selected stones, which are the source of heat in the steam room;

- chimney removes volatile products of combustion from the room;

- water heating tank Usually made of stainless steel.

Types of designs

The general scheme of the metal furnace is divided into different types. Self-made designs have significant differences depending on local conditions.

They are due to the following factors:

- type of fuel used. Commonly used wood fire;

- type of construction. Differ in the location of the furnace, for example, the furnace from the waiting room;

- way to heat the heater.

There are many varieties of heating equipment for the bath of sheet metal, which may differ in operating parameters. The determining factor is the type of construction, the set of functional properties of the device, and the method of installation of the metal furnace in the bath depends on it.

Share the three basic varieties as:

- closed;

- open;

- combined.

Closed

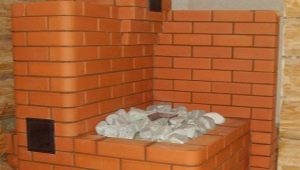

To increase the heat capacity and optimize heat transfer, the metal base is enclosed with a brick. In their mass, such furnaces are “homemade”. The basis of the design is sheet metal with a thickness of 1.5–2 mm. According to the standard arrangement, the firebox is located in the waiting room, and the heater is placed in the steam room. Face surfaces are covered with a brick layer.

To ensure the fastening of dissimilar materials, clamps of steel are welded to the base. Their length is made a few millimeters smaller than the dimensions of a brick.

The closed heater is located above the firebox, protection from above is provided by a steel sheet.The side door on the side of the steam room serves to supply water and create steam.

The closed oven has the following advantages:

- insignificant cost;

- unlimited possibilities of adaptation to local features of the room.

The disadvantages include the following:

- specificity of installation, due to the heterogeneity of materials;

- home-made solutions do not provide the necessary technological level, which reduces the lifetime.

Open

Quick steam lovers prefer an open metal sauna stove. An open construction suggests a special relationship. In order to create an optimal heating of the stone surfaces, it is necessary to ensure that the maximum area of the external surface of the fire chamber is in contact with the heater.. To increase the effectiveness of the wizard resorted to various tricks. For example, changing the configuration of the heater, which increases its area in the combustion zone. This solution accelerates the warming of the stones.

Construction efficiency can be increased by using a valve that dispenses heat to the heater zone. This principle is widely used by some manufacturers of furnaces,that create sophisticated steam transmission systems. “Light” steam is formed when a layer of stones of the outer heater passes. Feels like its quality is not inferior to a pair formed in ancient stone stoves.

The advantages of an open metal stove are the following:

- ease of use;

- low fuel consumption;

- high efficiency.

Such a modification of the metal furnace for the bath is the best alternative to traditional stone counterparts. The indisputable advantage of the design is its adaptability for small rooms. Of the disadvantages, you can select only the high cost.

Effective mode of operation is provided exclusively by factory models. "Homemade" does not have the necessary characteristics of thermal conductivity, which reduces their effectiveness.

Combined

Such designs are characterized by the presence of an additional room heating system. This allows even in the absence of autonomous heating to achieve a comfortable temperature.

The main source of heat is the firebox. An additional thermal circuit is placed above the firebox. With this design, the furnace surface is heated by transferring heat through the air gap.Usually such furnaces have an open design of the heater.

A well-designed internal heating pipe system, located around the perimeter of the room, heats the steam room and the whole bath in a short time. The pipeline is connected to the furnace pipe. Heat energy burning fuel heats the air of the internal circuit and causes it to circulate. The air supply to the internal circuit is regulated by the louvre grille.

Combined ovens have such advantages as:

- one-time heating of a steam room and a room;

- simplified temperature control.

The disadvantages of metal bath furnaces include the following:

- complex construction;

- high price;

- limited number of modifications.

How to make your own hands?

Before implementing a simple project, it is necessary to take into account local conditions in order for the installation to be successful and the wood-burning stove to be efficient. The comfort of the conditions of the Russian bath depends on the successful ratio of the sizes of the steam room, the location of the stove and how the heater is designed.

What metal is better to do?

The iron furnace has a number of features, which take into account its effectiveness and service life.The temperature in the combustion chamber of fuel exceeds + 450ºС. Such heating leads to deformation of the material. The metal plate is subject to burning under the action of fire. If stainless steel sheets are used for construction more than 10 mm thick, this can be avoided, but the warm-up time of the room and fuel consumption are significantly increased. Such a furnace would be economically disadvantageous.

To make a solid furnace without the danger of deformation and burning, as well as with good thermal conductivity, you must have real skill. In the factory, the designs are performed according to proven technologies from heat-resistant materials.

Installation of a self-made oven should be carried out according to carefully verified drawings, taking into account all the nuances.

Experts recommend using materials of certain product brands:

- 08x17T - it is high-alloyed stainless steel which is not subject to corrosion even at high temperatures. AISI 430 is a steel grade 08x17T. It does not change the structure to + 850 ºС, has a low carbon content, simplifies possible repair work.

- Steel is used for independent production of the combustion chamber. 10 GOST 1050-88. Convection parts are made from 08PS and 08YU GOST 19904-90. For the hull, sheet structural steel is optimal. The door of the combustion chamber must comply with the maximum thermal loads. An excellent choice is a cast-iron door.

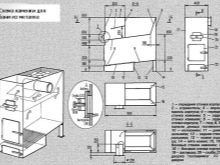

Schemes and drawings

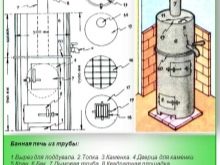

The main functional blocks are as follows:

- combustion chamber (fuel chamber);

- platform with stones (Kamenka);

- water tank (water tank).

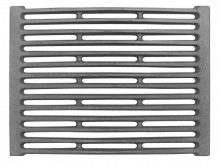

In order for the stove to be effective, it is necessary to have a clear idea of the functional purpose of these parts. Next, a calculation is made that takes into account the dimensions of the room and other local features. Firebox - a place of burning wood. It requires a door to load fuel and air for intensive combustion. Such a device is called the blower. The removal of combustion products (ash) should occur without the removal of firewood, this is achieved by means of an ash pan - a special grate.

From the fuel chamber, thermal energy rises to the site with stones. To enhance the heat exchange they are placed on the grid.. It plays the role of connecting the firebox and the bunker with stones. The bunker can be closed and open.Change of stones and water supply on their surface is provided with a special door. Above have a tank for heating water. Often a chimney is used to increase efficiency.. Usually, water is poured from above, and discharge is through a tap at the bottom.

Assembly and installation

To perform the work you will need the following basic tool:

- standard welding machine;

- scissors for cutting metal;

- measuring tools.

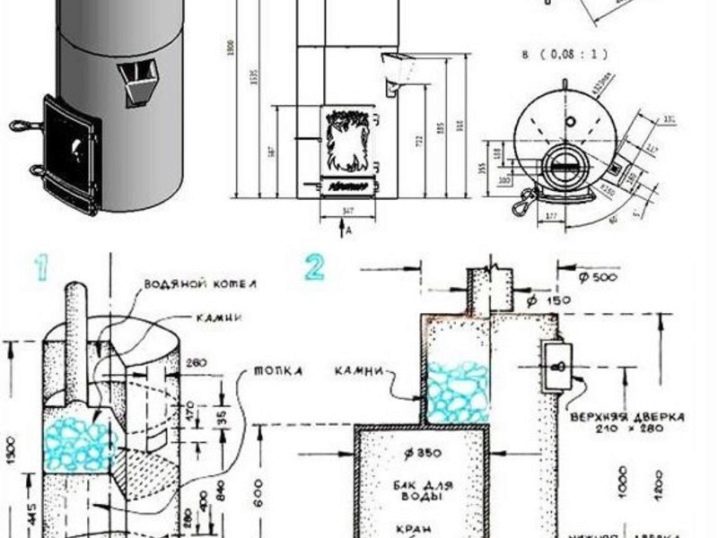

Each person who has the initial skills of working with metal and who is able to read simple drawings can make a stove for a bath with his own hands. Despite the material costs and time spent, the savings will exceed expectations. The manufacture of a metal furnace with a tank for a bath with dimensions of 700 mm (diameter) and 1600 mm (height) should be considered in detail.

In order to weld the frame will need such materials:

- steel sheet (thickness depends on steel grade) with dimensions 2.2x1 m;

- metal pipe - 1600 mm high, walls - from 7–10 mm;

- chimney (chimney) of arbitrary diameter, wall - 5 mm;

- metal rod - 10 mm;

- steel grate, cast iron;

- 8 loops and 3 heck;

- crane.

The algorithm of work includes several main stages:

- It is necessary to cut the pipe into two parts 0.7 and 0.9 meters.

- At the bottom of the pipe for the blower should make a hole rectangular 20x5 centimeters. Blower is located under the furnace, usually at a height of 7-10 centimeters from the basement and above the tank under the ash hole. Above the need to make an hole for loading fuel. Cut metal can be used for the manufacture of doors.

- It is necessary to weld the ears and hinges to the pipe for the doors, on the doors - latches, put the doors of the fan and the combustion chamber.

- It is necessary to cut a metal circle of 0.7 m. In the middle place the grid. If it was not possible to pick up a grid grate in the store, it is necessary to build a grid from a metal rod. The resulting design is welded to the pipe above the blower.

- It is necessary to make access for watering the stones and put the door on it.

- From the steel rod should be made lattice sites for stones.

- It is necessary to cut a circle with a diameter of 0.7 m from a sheet of metal. Make a hole under the chimney. It is usually located in the part that will be located at the far wall of the furnace. It is necessary to weld the chimney pipe.Above the platform for stones (or a closed bunker), the construction should be welded.

- Further, it is necessary to weld a length of 0.7 m to the long part of the large pipe. Mount a tap in the lower part of the water tank.

- A circle cut from a steel sheet (0.7 m) should be cut into two different parts. In the larger cut hole for the chimney, put this part on the pipe to remove the smoke and weld. The smaller part is hinged and forms a hatch for the water inlet.

To learn how to make a stove for a bath out of a pipe, see the following video.

As you can see, making and installing a metal furnace with your own hands is not so difficult. Depending on your own priorities and the design of the bath room, some nuances, such as a heat exchanger, screen, air supply, may differ significantly. Everyone can build their own bath with a metal stove.

Finish

In most cases, furnace finishes are performed to create an attractive look. However, do not neglect the special properties of decorating materials. They can play the role of the screen and increase the heat capacity of the furnaces. Often lining is made of brick.

In order to impose the construction itself with refractory brick or natural stone, it is enough to have a basic knowledge of construction.

When finishing self-made designs of stone and metal using materials such as:

- tile (clinker, tile);

- bricks (red, fireclay or ceramic refractory);

- stone (natural or artificial);

- steel cases (high strength);

- plaster (clay);

- tiles

The best methods are the use of bricks and stones. The main feature of finishing these materials is the location of the cladding at a distance of 10–15 centimeters from the frame of the structure, if there are holes that allow air circulation. The most common and cheap way to decorate is paint.

It must be remembered that the usual dyes based on oils and enamels will not work for this. You should use special heat-resistant, for example, OS-82-03 "Certa". Painting the bath room also requires special moisture-resistant coloring mixtures, for example, KO-8101 or KO-8222.

Before painting the oven, you should carefully prepare the surface, clean it and degrease it.

Tips and tricks

Experts advise in the manufacture of metal furnace for a bath to follow a few simple recommendations, such as:

- It must be remembered that the metal is subject to deformation under the action of high temperatures. It should correctly select the optimum thickness of the material;

- too thick metal will cause uneconomical fuel consumption and increase the heating time of the room;

- in order to optimize, it is recommended to construct the chimney so that it passes through the water tank;

- the finish of the metal structure should provide air flow;

- A low carbon sheet furnace will easily “outlast” possible repairs;

- to avoid situations when the furnace smokes, it is recommended to purchase ready-made chimney blocks;

- the basis for the furnace can be a cement floor, a sheet of metal, or a section covered with refractory tiles;

- it is worth remembering that to heat a wood stove, time and a significant amount of fuel are needed;

- effectively heat a metal stove only in a small room;

- the choice of the location of the heat source is crucial for the effectiveness of the bath;

- close to the body of the stove, be sure to cover the walls with non-combustible materials;

- after installation, it is recommended to make a finish of brick or stone. This will avoid accidental burns and make the oven more attractive.

In Russia, soaring in the bath is a whole ritual, a custom. The positive effect of the sauna on physical health has been known since ancient times. Many medical therapies today can not do without the Russian bath. It is difficult to overestimate its value in the treatment of various ailments. Modern nutrition with a broom and steam room eliminates excess weight. Bath rejuvenates and relieves fatigue and stress.

The furnace is the central component of each bath. The optimum heating of the room and the quality of the steam depend on the correct choice of design, good location and proper installation.