How to make a furnace for the bath?

Many owners of the bath think about how to make their own oven for it. This solution has many advantages, among which are savings, the ability to make a product with the necessary dimensions, and high quality of the furnace. However, you should consider a few nuances before taking up the independent production.

Special features

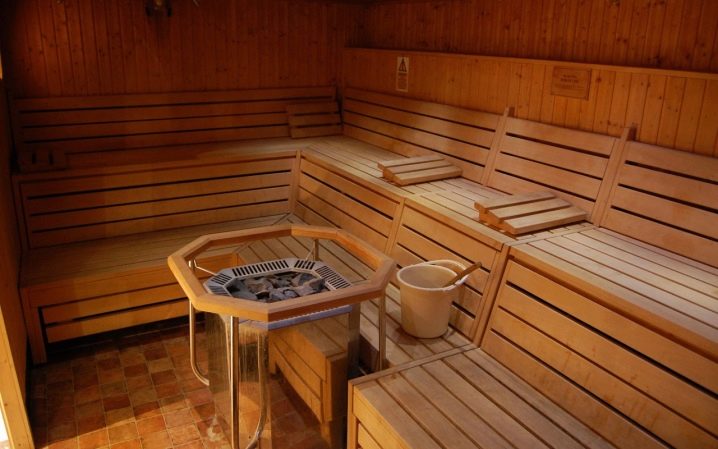

Bath and sauna are not the same thing, so the stoves for them will be completely different. If you need to create a high temperature in the sauna, while the heat must be hard and dry, then in the bath it is the opposite. The temperature also remains high, but due to the high humidity the heat is mild and the temperature is almost not felt. Such procedures are useful for both physical and mental state.

Most of the baths are made of wood, and the type of furnace that will be built there also depends on this. For example, oak baths are designed to create high temperatures, and brick furnaces are most often built there.

Linden facilities are extremely rare due to the fact that lime wood is a scarce product, and few people can afford such construction. Stoves here should not have strong power.. The heat should not be strong, as the lime baths belong to the category of light. Of course, the simplest solution is to buy a ready-made stove designed for a specific bath area. However, many reject this decision.

First, do not want to overpay. Indeed, a high-quality stove, built by hand, is two to three times cheaper than the same version from a well-known manufacturer. Secondly, the own-built stove allows the master to express himself. Thirdly, such a design can be made of any size and configuration, so that it perfectly fits exactly in your bath. Furnaces made according to personal measurements to order are very expensive, so it is much easier to manufacture the stove yourself.

Pros and cons of homemade designs

Independent manufacture of furnace design has both its advantages and disadvantages. It is necessary to take into account both of them, and others, in order to soberly assess their own strength and understand whether it is worth taking up an independent production or it is better not to save money and order a ready-made solution.

Thus, the advantages include the following provisions:

- Attractive appearancewhich can be varied at will. Those who have experience in welding, as well as in all that concerns the independent production of things, can make a truly unique design, which is not inferior in beauty to the factory analogues.

- Efficiency. Self-made baths, arranged properly, are not inferior to the factory in terms of fuel or electricity, if this option is chosen.

- High performance. A properly designed and built bath stove has a high efficiency, so that no heat is lost in vain - everything is transferred to the steam room.

- Easy maintenance. Self-made ovens are easier to maintain, because the person making them knows where everything is, which places need to be cleaned more carefully, and which can only be slightly swept away.

- Durability. Like factory, furnaces, made with their own hands, serve more than one year, and if we are talking about brick, then it can serve for several decades.

- Space saving. Due to the variability of the parameters, it is possible to rationally enter the stove construct into the bath without leaving too much gap or occupying an unreasonably large amount of space.

As for the shortcomings, there are not so many of them, but still they are:

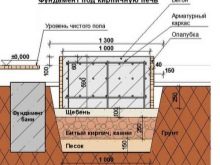

- If a homemade stove is made of stone, then it may have too much weight. This will require additional strengthening of the foundation, which will entail additional costs.

- There is a need to protect the environment, because not always the amateur stove-maker has the necessary knowledge on how to reduce the temperature outside the stove.

- It is necessary to carry out all the work with a high degree of professionalism, because an incorrectly made stove will not properly heat up the steam room and in general will cause more problems than joy.

The difference between the furnace and the boiler

Many people mistakenly believe that the furnace and the boiler are one and the same. Indeed, it is somewhat easier to make a boiler than a furnace, but this does not eliminate the disadvantage that the boiler will never create the required temperature in the bath. The main purpose of the furnace - heat release. It dissipates heat around or transports it to a specific place, but does not concentrate within itself.

With the boiler, everything is exactly the opposite. It pumps heat inside, and then passes it through the pipes.However, the lion's share of heat is lost in the process of passing through the pipes, which is why the temperature drops sharply, so the boiler is not able to properly heat the bath.

Thus, the choice in favor of the furnace, rather than the boiler, is obvious, although it turns out to be many times more difficult to make. It is important that you are not deceived, having met in numerous instructions assurances that the boiler and the stove are one and the same.

Kinds

Today, homemade ovens are divided in many ways. Among them are not only materials, but also the location of the furnace, the presence or absence of fuel, the method of heating the heater. In order to properly evaluate the advantages and disadvantages of each of the options available, it is necessary to examine all of them.

It is important that not all of these types are available for the master novice. Most require a certain amount of experience and knowledge as to exactly how such structures should be made, what to focus on. Knowing what kind of stove you want to see in your bath will help avoid when people spend time and energy on adding options that will not be used in the future.For example, it does not always need a steam generator or tank. The same goes for dimmer.With which you can set the temperature.

The latter option is available only to either professional stove experts or people who are well versed in the nuances of similar technological devices and have decided to build an electric stove.

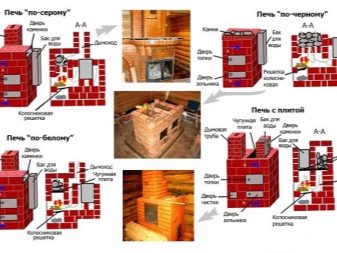

Closed and open

The division of bath furnaces into closed and open is a fundamental factor on which the type of heat that they serve depends fundamentally. So, in the closed furnaces stones are covered with a cover. This is done to ensure that the stones do not cool down longer, giving off heat only as needed. Whatever the temperature, in the baths with the stove closed, the steam will be wet, soft, light.

In the Russian baths you can find similar heaters more often.

As for open stoves, they are more typical for the sauna than for the bath. They give a hard heat, humidity is almost at zero. With all this, the stones are heated almost instantly to high temperatures.

Such a furnace is easier to build., because you do not have to work on the manufacture of the cover, however, for the bath this option is not the best because of the dry hot steam. In the bath is welcome wet steam.

According to the material

Material separation is the most obvious of all. There are not many options. To date, only metals and bricks are available for self-production.

Brick

The dream of many owners of baths is a brick oven. This is due not only to its traditional and solid look, but also to its durability, its ability to keep warm for a long time and other positive features. However, in order to lay out such a stove, you have to work hard. Masonry takes a lot of time, besides it requires some experience. Also it will be necessary to purchase special materials: an ordinary brick will not work.

An important disadvantage of brick kiln structures is their weight. Small a stove designed for heating an average bath can weigh up to 300 kilograms, therefore the foundation under such a stove will need to be strengthened. However, this disadvantage is covered by the fact that such a furnace is suitable for heating and a two-story bath, and not just to create a sufficient temperature in the steam room. Moreover, aesthetically, such a stove looks most attractive precisely because of its traditional appearance.

Many bath owners do not represent their steam room without such an impressive structure.

Metallic

Metal furnaces - a more common option due to the fact that to build such a structure itself is much easier. All that is needed is sheet metal, tools for cutting and fastening it, and welding skills. Due to such a simple set of metal options and gained such wild popularity among stove-lovers.

However, the furnace can not be made of any metal. For example, Aluminum, which is so easy to work with, is absolutely not suitable for these purposes. It bends easily when it is cooled, and if it is warmed up, it will warp and bend strongly. As a result, the stove will lose its shape after the first heating.

Copper is not suitable for this purpose.. Copper ovens are excellent in operation, but by itself this non-ferrous metal is quite expensive, as a result of which it turns out to be cheaper to buy a ready-made unit than to mount it manually.

Steel

It is easiest to make steel stoves because steel is a material that is malleable, but not too much. Steel sheets are easy to handle, but it is hard to bend with your hands, therefore they are preferable for building furnaces.. But practice shows that steel furnaces have many drawbacks.

Thus, the steel is heated to the point where the heat becomes uncomfortable and hard, which makes it unpleasant to take such a bath. It is impossible to eliminate this drawback, since it is the cost of using a steel case.

Among other things, the steel furnace emits harmful infrared radiation, which generally negates the entire beneficial effect of the bath.

Steel stoves cool quickly, although they heat up quickly. A constant feed will be required to keep the temperature at least approximately at the same level.

You also have to keep track of exactly which wood or other sources of combustion are used to maintain heat. If you use a heat source that has too high a temperature of burning, then the furnace can be deformed and stop looking attractive.

Cast iron

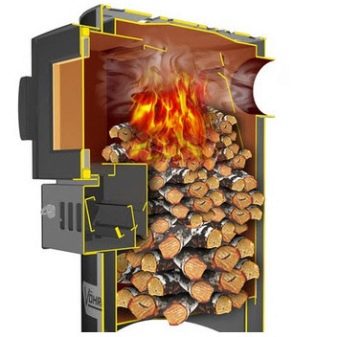

Cast iron furnaces are wildly popular, because cast iron among all metals is most well adapted to the manufacture of furnaces.This is due to some specific features inherent in cast iron.

So, the cast iron stove heats up quickly enough. Not as fast as steel, of course, but faster than brick. At the same time, it also warms up the steam room quickly. Compared with the brick furnace design, cast-iron “works” twice as fast.

Cast iron stoves keep the temperature for a long time, emitting warmth that is comfortable for a person. The heat is soft, the steam is wet. At the same time there is no adverse infrared radiation, which can adversely affect health. By the service life of a cast iron stove can be compared with a brick.

Cast iron is not afraid of high temperatures, so in theory it is possible to create any temperature in a bath. Pig-iron constructs are not deformed even as a result of shocks, not to mention the effects of heat. In addition, cast iron units do not rust, which is an additional advantage.

For energy

As for what you can stoke a bath, then there are many options. Among them are both traditional and modern. In advance, you should make a reservation that the manufacture of electric or combined ovens requires special skill.In the first case, you may need knowledge of engineering, in the second - the ability to combine several techniques in one product.

As a rule, for home sauna stoves such fuel options are selected that do not require a large amount of money in the future. Energy-saving technologies or recycling of raw materials are used.. This is especially true of wood stoves.

Some people heat the bath with wood-shaving plates, which have remained after the repair, but it is strongly not recommended to do this, since it is still more beneficial for the health to choose real wood (oak, birch).

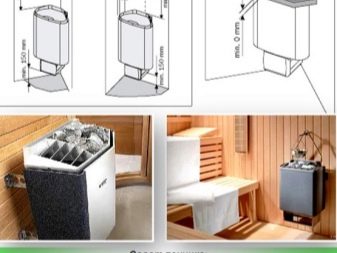

Electric

Electric sauna stoves appeared not so long ago. To date, widespread factory analogues. Few people dare to make such a construction on their own, afraid to make a mistake and spoil the expensive raw materials. but electric fireplaces can be found much more often than electric furnaces. It does not make sense to make just an electric stove, since with moderate electricity consumption it will warm up the steam for too long, and for rapid heating, you will have to use too much electricity, which will adversely affect utility bills.

It is better to use the power of electric make-up only to maintain the existing temperature in the room. Then there will not be a lot of electricity spent, and you will not have to fight over a full-fledged electric oven, and keeping the temperature at the required level will become much easier.

Wood burning

A favorite option, which prefers the majority, are wood burning stoves. They are recognized as the best option for a bath, as a pair of real wooden firewood is good for health. It is easiest to build a wood stove: there are many schemes and ways with which you can do this.

Best served stone wood stoveshowever, cast iron analogs are also quite acceptable. So, a brick stove on firewood does not cool down for a long time, and if you use long-burning firewood, then you can maintain the desired temperature at least all night.

However, problems may arise in order to fold this option correctly. For this you need the help of a professional stove-maker, and there are quite a few of them on the market. The wood stove can be made of steel or cast iron. If you have some experience, choose cast iron.. It is more difficult to work with it, but the furnace will be more reliable.

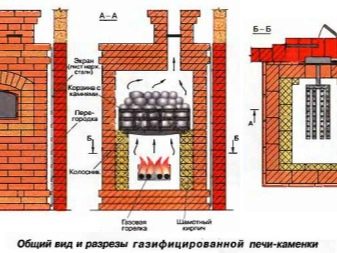

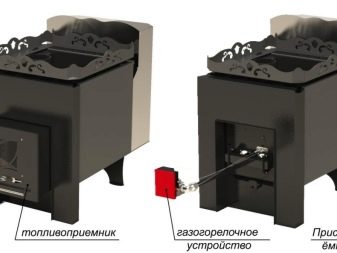

Gas

Today, gas stoves are almost as demanded as wood-burning ones. Often do the combined options in which the furnace can be fed and firewood, and gas. However, such popularity of gas baths is explained not only by their ability to quickly and efficiently heat the air in the steam room.

Gas is one of the cheapest types of fuel, so not much will be needed to buy it. Among other things the gas stove will not have to be cleaned and cleaned as often as wood-burningBecause gas cannot clog the chimney or clog the fuel chamber.

Independent production of a gas stove is a rather complicated procedure, since many requirements will have to be taken into account, but this guarantees high safety of the use of the stove in the future.

If you are not confident in your abilities, it is better to refuse to manufacture a bath stove for gas, otherwise the bath may simply turn into a gas chamber.

By location of the furnace

When the sauna stoves were only invented, the firebox was located inside the stove and there was no thought that it could be located in any other way.However, over time, people realized that minor modifications can completely change the furnace structure itself, as well as the air quality and heat in the steam room. So there were portable firebox. To date, there are only two options for the location of the furnace - built-in and external.

Each of the options has its own advantages and disadvantages, therefore, it is impossible to clearly determine which of the options is better. Each of them is suitable in a particular case, often the only possible one.

Built

Built-in firebox is used only in cases where you need to save space. It happens that you have to abandon the presence of a waiting room when it comes to a very tiny bath. However, all the advantages of this option end there.

The drawbacks of the built-in firebox are many times more than the advantages. Thus, the location of the furnace inside the steam room contributes to the fact that the room burns oxygen, which is already there a little. The only way to fix the situation is to adjust the ventilation system.. There will indeed be more oxygen, but this will cause the temperature to drop dramatically and have to heat the stove more.As a result, the oxygen will burn out again. It turns out a vicious circle.

Also, the prospect of throwing firewood, if the firebox is inside the steam room, does not seem tempting, since the accidentally leaped coal can cause the whole bath to flare up like a match.

Portable

The portable firebox is much more functional, but it requires a lot of space. In this case, the camera itself, in which firewood is thrown, is located in a room adjacent to the steam room. The advantages are obvious: there is no risk of getting poisoned by the lack of oxygen, firewood is thrown from another room, so the risk of a fire also is minimized. Whatever the temperature in the bath, the microclimate will still be comfortable., because precious oxygen will not fade and the heat does not seem hard.

A significant disadvantage is only that the bath must necessarily consist of at least two rooms, that is, it must have a larger area. However, this minus can be called a minus only with a stretch, since very few people make a bath consisting only of a steam room.

Another important note: in the vicinity of the firebox it is better to arrange a fire extinguisher just in case.

By way of heating the heater

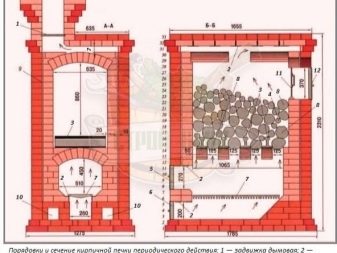

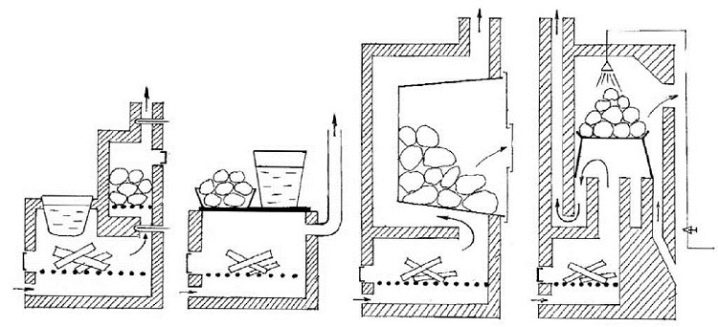

This item involves the placement of stones relative to the heat source. Distinguish between furnaces of periodic and continuous heating. In furnaces of continuous heating, which are more common today, the stones do not come into direct contact with the exiting combustion products. They are placed in a special container, which is located in the steam room itself. The stones of the middle fraction remain clean, you can pour a little water on themto make steam more wet. Thus, the maximum temperature of heating stones reaches 400 degrees, the steam is dry and tough, more characteristic of the Finnish sauna.

Quite different looks like a heater of periodic heating. Here, the smoke from the burning fuel passes directly through the stones, later exiting through the chimney. This imposes certain restrictions: for example, you can not wash in the bath until all the fuel is burned and all carbon dioxide is releasedotherwise you can get mad. Stones in this case are heated to extremely high temperatures - 1000 degrees. Steam is formed as soon as you water the stones. By the way stones for such heaters should be large and rounded.

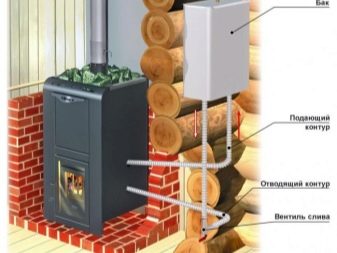

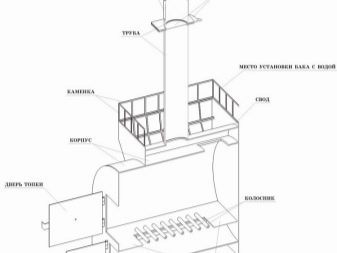

By the presence of a tank

Often baths are equipped with a water heating tank on the side. So the heat from the side walls of the stove is not wasted in vain, but it warms up the water in the tank, which you can later use at will. The side tank also acts as a heat exchanger, due to the presence of which an optimum microclimate is reached in the dressing room and steam room.

Another purpose of the tank is to heat the rest of the building. It happens that the bath is on the ground floor of the house. After the furnace has been heated, it warms up the water well, which is subsequently carried around the house through a pipe system.

Such improvised heating radiators can be made by hand, if you additionally examine how such a system works, what it is based on. Boil the same ordinary tank on the side of the furnace or the chimney is not difficult.

With steam generator

As for the device of the steam generator, this solution allows you to fill the room with heavy wet steam, as in the Hammam, and without resorting to a complete rework of the stove.The most interesting solution is to install a mini-steam generator in addition to a home-made sauna stove, which will save space, while coping with its task just as good.

In addition to the above, there are several varieties of bath furnaces that do not fall under any classification. One of them can serve mobile oven. It has a much smaller size and weight, so that it can be relatively free to move from room to room.. Mobile stoves are usually equipped with a built-in firebox, since there would be more problems with the remote.

Bath upper burning, or feeding - design, in which the combustion begins with the upper tier of stacked firewood, gradually spreading to the underlying rows. Such constructions from ancient times were used for Russian baths, because they allow to avoid serious heat loss at the very beginning of combustion.

Testing of fuel occurs gradually and corruption already falls on the period when the steam room is hot enough, and all that is required is to maintain the temperature.

What to look for when choosing?

Before you make your final choice on any of the options, you must evaluate it by several parameters. Such thorough preparation is required because the construction of the furnace (especially brick) is troublesome and requires financial investments, therefore it is important not to be mistaken.

The assessment is made on the basis of the most obvious and common factors, and they affect both the choice of material and design.

Heating rate

How quickly the stove heats up is crucial when it comes to a bath for year-round use. If in the summer there is practically no risk that the bath room will not warm up well enough, then in winter this probability is extremely high.

So, in the summer you can heat the bath for 3-4 hours, while in the winter you will need to spend 8-12 hours on it.

It is also important how well the stove keeps warm. For example, the steel structure is heated well, but it cools down just as quickly, which negatively affects the time during which you can wash in the bath. The controversial question is whether it is worth heating the bath for 3 hours in order to be able to steam in it for only an hour. It will take too much fuel to maintain the temperature, which is not rational from a financial point of view.

Layout

This implies the presence of a steam generator, tank, as well as the location of the furnace relative to the furnace. All these nuances were discussed in detail in the section with the classification.

Heating method of the heater

The contact of stones with smoke from heat sources plays an important role, since it determines how soon it will be possible to wash in the bath. This affects the temperature and humidity of the air in the bath, as well as the microclimate. Some types are more suitable for saunas, others - for Russian baths, but lately The most popular are the combined options when you can vary the humidity of the air at will.. For this most suitable stove periodic heating with a miniature steam generator.

However, if you only need to receive steam of a certain type (for example, if you are a fan of the Finnish sauna and only her), then it would be more logical to save and build a sauna stove without supplements, but only one that would be provided with the necessary parameters.

Fuel used

Decide in advance what you want to feed your stove.From this depends largely on the complexity and high cost of manufacture of the stove. So, the simplest version to perform is a wood construction, since it does not have to resort to technical improvements.

The best solution would be to combine in one furnace the ability to feed from several power sources. For example, when one ends, you can use the other. The most popular is the combination of gas and firewood.

In addition to these, there are several other factors that are not so extensive, but also significant. These include the temperature of the furnace.

It does not make sense to make too powerful a stove for a small bath, but too small a design cannot cope with the heating of a large room. Be sure to relate the square of the bath with the thermal efficiency of your product.

The temperature of the walls of the furnace unit is also not in last place in importance. Not so long ago, the so-called "cold" stoves appeared. They have to warm up much longer, but their temperature outside never exceeds 60 degrees, while inside it can be several hundred degrees higher.

Blueprints

Drawing up a drawing is an important and crucial step. Without proper education, it is almost impossible to create a competent drawing, and without a correct drawing, it is impossible to build a good furnace. Fortunately, there is a simple solution - to use a ready-made scheme. They are in abundance freely available, so that you can choose the most appropriate.

Another option is to order the production of a drawing according to your own measurements. This solution has several advantages:

- such a unit is ideally located in the niche of the bath, which you took under it;

- there will be all the necessary additions (for example, a tank);

- The connection scheme of parts, as a rule, is immediately indicated on the drawing, so you will avoid difficulties.

The cost of such a custom option is not so high, so you can quite afford it. The money spent on the purchase of the scheme will allow you to save a lot of time, energy and nerves in the future.

Materials

As mentioned above, today there are only a small amount of materials from which make bath heating structures.

This is due to the specific requirements that are put forward to them:

- ability to withstand high temperatures;

- not susceptible to corrosion, rotting;

- incombustibility;

- acceptable price;

- durability and other.

Because of this, the list was reduced to only two positions: brick and metal. Stone stoves were and remain the preferred option for Russian baths, but the metal is much cheaper and easier to operate. This led to the fact that metal structures are gradually replacing brick. For self-production, it is also better to prefer a metal unit, since it is easier to make it yourself., than to lay out a brick classical construction.

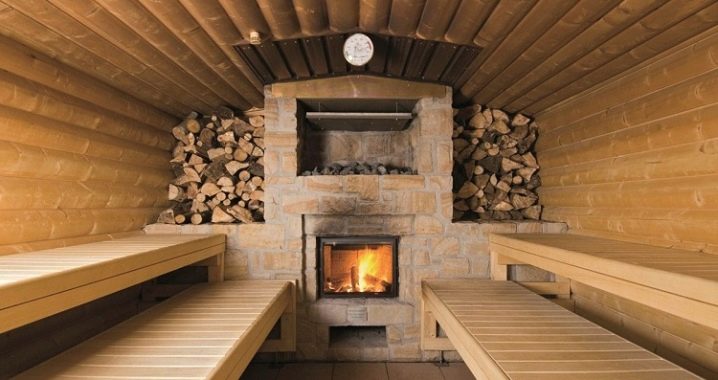

Brick kilns are beautiful, with high heat dissipation. Due to the fact that they are difficult to make themselves, many abandon their construction, but with enough experience, a similar design can be done by yourself.

Simple stoves look like this:

- A simple stove without frills looks decent and interesting despite the fact that much time and effort was not spent on its construction. Such a laying under the force, even a beginner.

- More difficult option, laid out by the professional master. Such beauty requires professionalism, but the result is worth it.The result was a full-fledged Russian stove.

As you can see, the brick is aesthetically attractive, but working with it requires a certain skill. Simple metal units are made by home-grown craftsmen throughout Russia, and the furnaces are no worse than the factory ones. There are products as simple as possible, and with forged elements.

Approximately this type of have metal constructions made by hand. The simplest unit with a heater and all the necessary does not take up much space. This furnace has a built-in furnace, so that it is designed to be installed in the smallest bath. Homemade stove design with wrought iron elements and a tank for heating water will fit perfectly into any bath.

Making forged parts will require blacksmithing skills or they can be custom made. It is up to you to choose which material suits you best.

Instruments

For the manufacture of a metal furnace will need the following tools:

- welding machine for tight connection of parts;

- Bulgarian with a diamond disc for cutting metal sheets;

- drill for making small holes;

- construction level, mounting tape, protractor and marker for marking;

- disk for grinding metal.

For a brick kiln, more varied tools are used:

- various trowels and spatulas for applying a solution that holds the bricks together;

- pickaxe to give bricks the necessary form and chipping off extra pieces;

- laser building level for estimating contour lines;

- plumb line for evaluating verticals;

- construction "triangle" with dimensions of 40x40x57 cm;

- the rule for removing excess mortar and leveling bricks;

- buckets and pallets in which bricks mortars will be diluted.

Design

Home-made ovens can have a different finish that determines their appearance. However, everything depends not only on this. First of all, the beauty and aesthetic appeal determines the accuracy with which all work has been done.

The most interesting may be the following self-made options presented:

As you can see, there are no metal products among them, since brick units look much more advantageous in design.

Where to install?

The answer to this question is obvious: in the steam room.However, in reality, everything is not so simple. If the unit with a built-in firebox is simply to be installed in the steam room, then with the remote one, only at the wall adjacent to the room into which the firebox will exit. Also, the firebox may have access to the street.. Then it is important to assess where you want to see the exit, and install the oven there.

The decision on where the installation will be performed must be taken at the stage of laying the foundation. Such a measure is due to the fact that the foundation in this place will need to be well strengthenedotherwise the floor will simply not bear the weight of the kiln structure and will fall apart. It will also be necessary to lay a mounting hole in the plan for the furnace if it has a portable firebox.. Otherwise, the installation will have serious problems.

Preparatory work

At the preparation stage, it is necessary to prepare not only the materials from which the stove will be built directly, but also the sauna room itself. If you do not do all this with sufficient quality, then there is a high probability of incorrect operation of the stove. For example, heat may not be supplied where it should be, or problems may arise with the release of smoke, which can be dangerous to health.

The first step is to search or order a drawing (possibly self-made).The drawing must contain all the necessary information about the furnace.

It is also recommended to immediately indicate to what maximum temperature the metal of your choice can be heated. Usually these data can be specified in the same place where you make a purchase.

Metal preparation

This procedure is carried out after all the details are cut in the right sizes. It is necessary to let go of those elements of the future unit that heat up the most. These include sidewall, top and fire door. They are in contact with burning fuel.

Release is as follows. At first, the sheets are heated red-hot, after which they should not be rapidly cooled. It is best to leave sheets of metal to cool slowly.. It is not necessary to lower them into cold water. After these manipulations, you may notice that the details have warped, have lost their original shape. To return them to a view close to the original, use a hammer, knocking the details to the desired shape. If the hammer does not help or the parts become larger, then simply cut off the protruding parts.

This preventive measure allows you to avoid the fact that the stove will warp during the first use.

Calculations

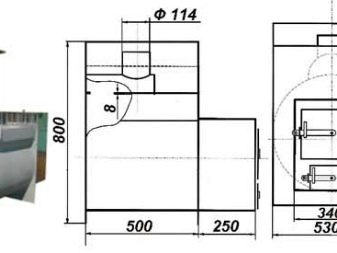

All values of the stove should be given in the drawings. It is about what the area of the foundation should be strengthened and how much of the area of the walls must be protected. Based on the size of the furnace, we can say that the foundation strengthening site should extend beyond the edges of the furnace by 30 cm. For example, when making a square metal unit with dimensions of 60x60 cm, it will be necessary to strengthen the space of 120x120 cm (30 + 60 + 30 cm on each side).

The wall must be insulated 50 cm above and beyond the stove.. For example, with a stove height of 80 cm, you will need to make insulation 1.3 m high from the floor. It will also be necessary to lay a metal sheet on the place where the stove will be installed. This is done so that if something happens, the ember does not cause a fire. The metal layer should protrude beyond the plane of the door at 1 m.

Markup

Before starting work on cutting metal all components will need to be marked. For this, again, use the data shown in the drawing.

Sometimes the markup is done on the go, when the unit is made up of rectangular and square elements, but even in this case it’s better to draw borders with a marker. In the future, it will be easier for you to cut out the necessary details, following the planned lines.

Room preparation

This refers to the laying of metal sheets on the floor and walls, the calculation of which was given in one of the preceding paragraphs. It is best to choose stainless steel for these purposes.. Despite the fact that under the weight of the furnace it will be sold, there is a virtue that completely redeems this fact - you will not encounter damage to the metal with rust, which can greatly impair its appearance and condition.

Foundation strengthening

This stage would be more logical to place at the beginning of the list, since reinforcement should be made at the stage of laying the foundation. However, if this was not done, you will have a difficult stage in disassembling the floor.

There is an alternative way: choose an electric stove, which, because of the lack of fuel, will not weigh as much as gas or wood-burning options. However, this also incurs some costs.

Manufacturing

The device of a metal furnace does not cause such difficulties as a brick one, therefore it is logical to begin the description with a simpler version.

To make a simple stove out of a pipe, use the following step-by-step guide:

- The easiest way is to manufacture the unit from a log.To do this, you will need a piece of pipe at least 50 cm in diameter. The size of the segment depends on how high you want your oven to be.

- Cut in the pipe blew with dimensions of 0.05 x 0.2 m.

- Cut through the opening for the firebox with dimensions of 25x20 cm.

- Next, weld the attachments for the rods that make up the heater. For this fit fittings with a diameter of 1 cm.

- Secure the grid-heater of twigs.

- Opposite the stove cut another hole for steam.

- Fill the stove with stones. It is forbidden to use for this purpose granite or any stones containing mica. Talkohlorite is perfect.

- Weld the cap on top of the pipe in diameter.

- Cut a hole in the lid for the chimney. The diameter of the chimney should be about 15 cm.

- Weld the chimney.

Installation of a brick oven will require much more materials, time and effort. Depending on the option chosen, you will need a certain amount of brick. Pay attention to the fact that the brick was fire-resistant.

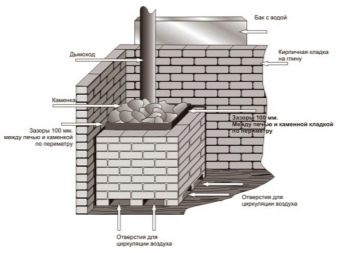

Pay attention to the following scheme. It contains the order of the bricks. Follow it to build the stove correctly. Also a brick can be made facing metal construction.This has the effect that a brick stove is installed in your bath, not a metal one.

Thermal insulation

Thermal insulation of the stove itself is necessary if only because in the process of burning a lot of thermal energy is dissipated in the surrounding space. The owners of the baths are trying by all means to level this deficiency in order to efficiently use all the available heat.

Heat insulation can be done in several ways:

- Through the installation of protective wall metal screens. They will reflect the heat. Such a screen makes sense to place around the heater, located in the steam room. Then all the heat will not be dissipated into nowhere, but injected in a double room.

- Brick shielding. In this case, the thickness of the brick should be equal to half of the standard, that is, it is optimal to use the laying of half brick.

Protection for walls and floors, which is made of sheet metal and has been described above, also serves as a measure of thermal insulation.

Safety

When you are in the bath there are two real dangers: get burned or burned. In order to prevent the occurrence of burns, they invented a special material - basalt cardboard.. It is placed around the heater so that an awkward movement does not lead to a severe burn, because in an atmosphere of hot air, touching the surface is the same as air, temperatures can cause a serious second degree burn.

To avoid the danger of intoxication, it is advised not to make such a furnace, the blower of which goes directly into the steam room. It is best to take him to an adjacent room or on the street.

Also you need to check whether the ash is removed before “naddavat”Since the combustion products are able to emit carbon monoxide, which is odorless. It’s not easy to understand that you are suffocating him.

Tips and tricks

Experts share some tricks that will make the process of making a furnace much easier:

- Do not neglect the drawing. Without it, there is a high probability to make a mistake and build an ugly and inefficient furnace structure.

- Be sure to do all the work of preparing the premises, as this will reduce the risk of fire.

- Repair of the furnace must be made in time to avoid the need to replace the existing stove soon because of the impossibility of troubleshooting.

- If you plan to use the stove not only for a bath, but also for heating, consider a piping system.

- If you are not sure that you will be able to build a furnace of decent quality, discard this idea. A sober assessment of your abilities can save you time, energy and money and save your self-esteem.

Beautiful examples

- A self-made assembly of ferrous metal with a twisted heater looks interesting and unusual. This design can decorate any steam room, regardless of its size.

- If the oven does not look very attractive, it does not mean that it serves poorly. In this image is clearly visible option available in most baths. The owners did not spend a lot of time finishing, concentrating on the functioning of the furnace.

- A metal stove in brick lining looks traditional, while making it not so difficult. The brick salary in this case plays the role of a heat insulating shield, allowing the temperature to remain at the initial level longer.

- If a person has sufficient time and patience, as well as skills in the difficult task of laying bricks, he can get such a beautiful design.With the help of grinding the bricks were given the desired rounded shape.

To learn how to make a stove for a bath of the pipe, see the following video.