How to choose a stove for a bath?

Bath - is a traditional place of rest of the Russian people. In the steam room you can relax, spend time in good company. At the same time the healing effect of the bath is indisputable. The main and main criterion for arranging a comfortable sauna is the stove. Today there is a huge variety of various furnaces for a bath. They may differ in material, method of installation, thermal conductivity and vary in price range.

Special features

In order to correctly select the stove in the steam room, it is very important to take into account some of their characteristic features and a number of specific criteria that will make the rest in the bath pleasant and comfortable. When choosing a sauna stove, it is worth considering a sufficient level of thermal power of the furnace. It must be correlated with the size and area of the room.The stove must warm up the steam room itself and its adjacent rooms for a rather short period of time. In the summer season, the whole area of the steam room should heat up in about 30-40 minutes, and in winter it usually takes about 2 hours.

The next important criterion when choosing a traditional furnace are the stones. Their mass and quantity should also be sufficient to quickly warm up the steam room. Usually in the baths there is enough 100 grams of water to warm up one cubic meter of steam room. An indicator of the quality of stones is also the color of steam, which comes from them when water is splashed out. Steam should not be very thick, but should have some degree of transparency.

It is not recommended to lower the temperature of the stones below one hundred degrees. For one cubic meter of steam room you need about 5-8 kg of stones. With a standard warm-up mode, the stones need a temperature of about 200-250 degrees.

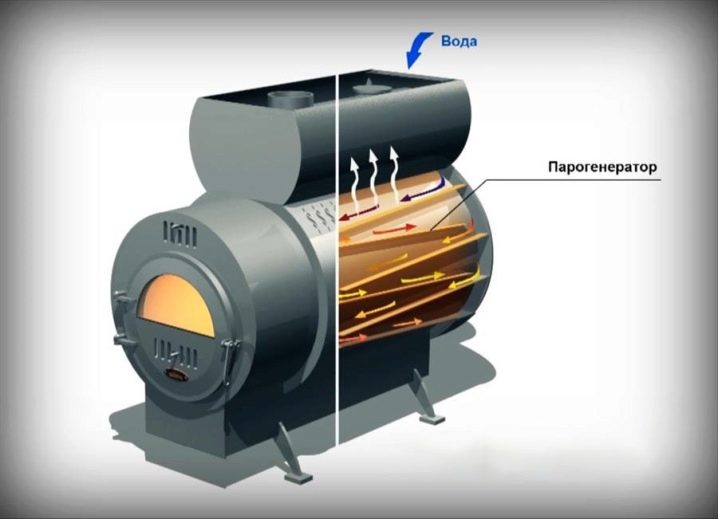

Also, to set the desired mode requires a steam generator in the furnace. Some heaters provide a steam generator that provides automatic water flow into the stove, where it evaporates and the steam is evenly distributed in the steam room.This is a very convenient feature, but it is not available in all sauna stoves.

Pay special attention to the material from which the stove is made. This is one of the most important and fundamental criteria when buying a heater. Many low cost furnaces are manufactured using structural steel. High temperatures affect this material is not the best way, since its strength is quite strongly reduced when heated. In this regard, even stainless steel furnaces are more durable, have low cost and are easy to operate.

Main characteristics

The so-called "hot" stoves for baths and "cold" are distinguished. These two options have their own specific characteristics. In particular, the “hot” stove in the steam room is heated to a temperature in excess of 100 degrees. It is expedient to use such furnaces when it is required to warm up the room having a large area. But it is necessary to use such furnaces with increased caution. trying to avoid accidental contact with the surface, otherwise it will lead to very serious burns.

Also, due to the rapid warming up of such a furnace, it is necessary to constantly control the temperature of the air in order to prevent its overheating, at which it will be harmful for a person to be in the steam room.

For "cold" furnaces do not require such strict rules of operation. Their walls usually do not warm up above 50-60 degrees. This reduces the risk of burns if you accidentally touch the stove. Heating the air in the room when using a “cold” furnace is much easier to maintain at the required level for a long time.

Also, furnaces are characterized by their placement. Most often they are located in the steam room itself, but there are models that can be placed in the dressing room. Furnaces, placed in the steam room, do not require such a subtle approach during installation, and they cost much less than models available in the waiting room. In this case, there are some disadvantages. In particular, the firewood near the stove itself cannot be stored due to high humidity and it will be necessary to constantly go beyond it to another room. Also in the steam room because of the stove will decrease free space.

Therefore, if the total area of the bath room is sufficient, then it is better to place the portable oven in the dressing room, and leave only the heater in the steam room itself.

You can also classify the stove by the method of heating the heater. Today, furnaces in which stones do not directly touch fire have become particularly popular. In such stoves, they are in special containers. At the same time they heat up to 400 degrees. In other furnaces, stones can directly contact with fire. The temperature of their heating in this case is very high and can rise to 1000 degrees.

You can also select the furnace with a tank for water and without it. Having a tank is quite convenient because the water will heat up from the heat of the stove and can be used for water treatment.

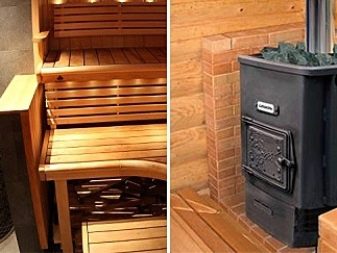

Design

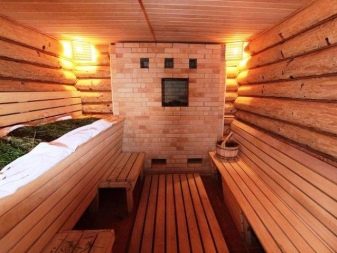

For any experienced bath attendant and even for an amateur, an important factor is not only the technical arrangement of the bath, but also its appearance. In the bath you can create a truly atmospheric room, the rest in which will be pleasant and unforgettable. But it is important to know some basic features for the proper finishing of the sauna room. Traditionally, the decoration in the Russian baths was performed exclusively from wood. And this is not only a tribute to the age-old Russian traditions, but also scientifically based facts:

- Wood is one of the most environmentally friendly materials, which at high temperatures will not emit various harmful substances, which, of course, will bring man only benefit.

- The thermal conductivity of wood is extremely low, so that its surface is not very hot, which allows you to avoid burns when accidental touches.

- Heat is distributed evenly over the wood flooring, and this directly affects the heating rate of the steam room.

- Also a huge advantage of wood is a high level of air exchange. If the bath is built exclusively with the use of wood materials, then the bath may not even require additional ventilation.

- When heated, wood can produce a very pleasant smell and substances useful to humans - phytoncides, which have a beneficial effect on the workings of the human nervous and cardiovascular systems and can have a positive effect on the psycho-emotional background.

- And one of the main advantages of wood is just an attractive appearance that is unlikely to ever go out of style. For many types of wood, no additional processing or painting is needed.

The main thing at the initial stage of the design of a bath is to choose the right material for its finishing. It is worth choosing a finishing covering, being guided by certain factors:

- the coating must be resistant to high temperatures, high air humidity and direct contact with water;

- do not emit any harmful substances with increasing temperatures;

- should not cause any allergic reactions in humans;

- have high strength and long life;

- have an attractive appearance.

One of the main rules when decorating a bath is not to use a coniferous wood covering in the steam room. This wood has a large number of resins that will begin to stand out at high temperatures. And this coating is heated by much stronger other rocks. But coniferous species should be used in areas adjacent to the steam room. They are perfect for a dressing room and washing, which do not heat up as much as a steam room. In the adjacent rooms, coniferous woods will emit a very pleasant aroma and will act on the organism in a healthy way.Also for neighboring rooms, steam rooms are well suited and materials such as drywall, PVC or moisture-resistant fiberboard.

Experienced professional bath attendants recommend using hardwood wood when finishing the steam room. These include wood of birch, aspen, poplar, ash or linden. In particular, the ash tree, according to many, looks the most attractive and has high strength and long service life. Quite often, linden wood is used for finishing the steam room. It creates a very pleasant aroma in the room. Aspen is one of the most durable, heat-resistant materials and is not subject to rotting.

In general, hardwoods are very well suited for use in high temperature environments.

Great attention should be paid to the design of the stove in the bath. After all, this is the main component of any steam room. Different materials can be used for the design of bath furnaces, among which brick, tile, natural or artificial stones, plaster, tiles and steel cases are often used. In the process of facing the stove with tiles, it is possible to distinguish some of its varieties:

- Clinker tiles. In the production of this type of tile used clay mixed with a variety of melters and dyes.

- Majolica. In the process of producing this ceramic tile, the clay is burned and coated with a special glaze. Also, if necessary, a variety of ornaments and paintings can be applied to such a surface. This tile has a very rich and bright colors.

- Terracotta. This tile is similar to the previous type of tile, but this instance has a very high strength.

- Marble tiles. This kind of setting makes the bath room a rather cozy atmosphere. The marble-faced stove looks quite presentable. Also marble differs in the high durability and durability.

When finishing the furnace brick, you can highlight some advantages of this type of lining. Thus, a brick coating heats well and quickly to the required temperature and is able to retain heat for quite a long time. Also to the advantages of this type of lining is its durability, because the brick is not destroyed by high humidity and temperature. Facing the stove with stone sets the room a very aesthetic look. When finishing stone can be used:

- ceramic granite;

- marble;

- coil;

- granite.

You can also arrange the oven using a steel case. Such an unusual type of decoration is as follows - the furnace surface is surrounded by a special metal frame on which steel shields are installed.

This type of lining allows the furnace to warm up the room, but it is worth considering the important point that the coating of the frame itself is very hot and can cause a serious burn if accidentally touched by a person.

Plaster is a type of design that is also quite popular and used often. If you choose the most inexpensive and simple option of finishing the furnace in the bath, then the use of plaster will be the best solution. The work of plastering the stove needs to be done in several stages:

- at first it is necessary to remove dirt and dust from the surface of the oven and apply the first layer to completely clean the oven;

- then a new coat of plaster is applied in order to level the surface;

- in the final stage, it is best to whitewash the surface using lime.

One of the oldest options for coating the furnace is laying tiles. Despite the long-standing use of such cladding, the tiles will give the stove a very original appearance, setting the bath room with a certain atmosphere.

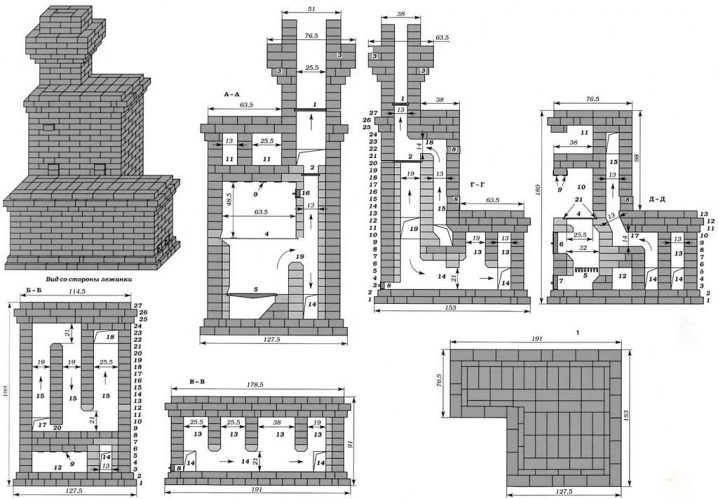

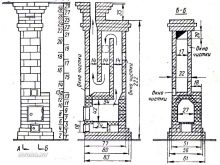

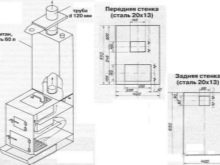

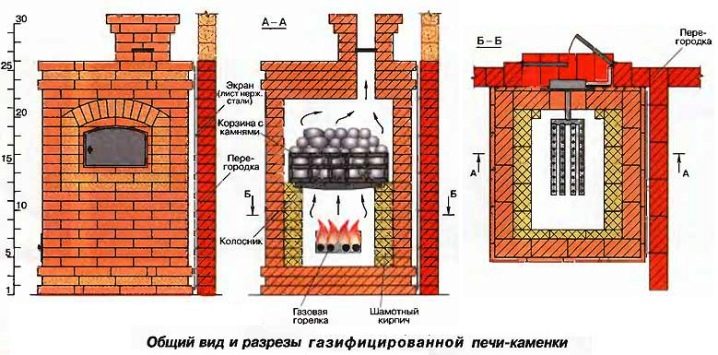

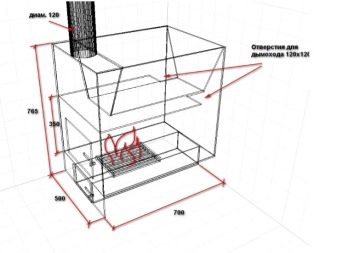

Drawings and sizes

Some experienced craftsmen prefer to build a bath stove without pre-made drawings and diagrams, arguing that the building is simple and undemanding. But, of course, such professionals already have experience in laying furnaces, and for self-design furnaces it is better to prepare the drawings in advance and calculate everything correctly. The amount of heat and steam that the furnace will produce will depend on the correct construction of the furnace.

Calculate all the parameters of the stove must be based on the area of the steam room. To calculate the volume of the steam room you need to multiply its performance, that is, height, width and length. After that, it is necessary to make calculations based on the fact that for one square meter of a steam room 1 kW of energy is required.

Below are some examples of popular drawings of sauna stoves, among which you can choose the necessary or come up with your own project.

Views: Which is better?

It is possible to classify furnaces for a bath by criterion of the fuel used by them. Furnaces can be gas, wood or work on electricity.

Gas

Gas-fired sauna stoves are not very popular and are quite rare,because their installation will require the development of an individual project, and the process of placing the furnace will take a lot of time and effort. But on the other hand, the adjustment of temperature conditions in such furnaces is completely automatic, they do not require a constant load of firewood and they do not have to be cleaned often. The same can be said about electric ovens, although their installation does not require so much power. These furnaces work from the power supply network.

Wood burning

The classic and most popular option is wood stoves. They, in turn, can also be systematized by type, depending on the material of manufacture. They can be made of brick, metal, steel or cast iron. Below will be considered a furnace of various materials and different designs.

Portable firebox

The design of such a heater has a long fire chamber, in which there is a door for laying firewood with one, and the other part is connected to a tank in which there are stones. Accordingly, such an elongated design allows you to place the firebox in the waiting room or adjacent room, and the hot stones themselves will be in the steam room.

That part of the wall through which the firebox is brought out is best laid out of stones or refractory materials.

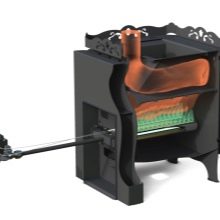

Firebox without removal

These are standard heaters that are installed directly in the steam room. This model is a one-piece construction in which the fire directly heats the stones. Such furnaces are usually equipped with an additional air intake.

Open heaters

Also one of the standard and classic options, in which the stones are on the upper surface of the stove. They heat up and give off steam when water is poured over them.

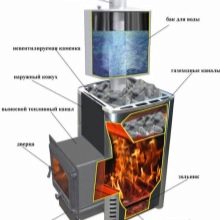

Closed firebox

Provide placement of stones inside the stove. On the top of the stove there is a tank with liquid, which gradually gets on the surface of the stones.

Wood burning stoves

Often furnaces from such material are made independently, using the welding machine and iron sheets. Also, metal furnaces have been produced for a long time by famous world brands. The positive qualities of such structures include:

- low cost of the product or component parts;

- the ability to make the oven yourself without much effort and large financial andtime costs;

- long service life;

- small size and lightness;

- fast warming up of the steam room;

- wide range of design options.

Among the minuses can be noted the rapid cooling of the furnace body. This property has the majority of metal products, as the metal is unable to maintain the temperature for a long time. Also a disadvantage is the high temperature of the housing in the running state, which can lead to burns if accidentally touched.

Cast iron stoves

These models will be higher in cost and heavier in weight than ordinary metal ones. Cast iron is one of the traditional materials in the manufacture of sauna stoves. With regard to it, a number of positive aspects can be distinguished:

- high corrosion resistance of cast iron;

- long operational life and reliability;

- these stoves can be used even when heating large rooms;

- wide range of designs;

- long storage of heat.

The main disadvantage of such furnaces is that low-quality cast iron with a sudden change in temperature in the amplitude of more than 90 degrees can burst.Such a situation is possible when tipping a bucket of cold water over the hot case. Also, cast iron stoves, as a rule, have a very large weight, which reduces their mobility. In general, cast iron stoves and metal models are similar in many parameters. Such furnaces can be made remote and without the removal of the furnace. Kamenka of such furnaces are both open and closed. Is that for large cast iron furnaces may need to strengthen the foundation because of their large mass. Based on this, it can be concluded that cast iron and metal stoves are among the most convenient and widely available options.

Stone and brick stoves

They have a number of positive qualities, for example, a brick and a stone are very well heated and can heat large rooms or adjacent rooms with a steam room. Stone stove is an excellent option in terms of design, giving the room a special aesthetic appearance.

The disadvantage of stone furnaces is their high cost, because such furnaces are considered exclusive design projects.

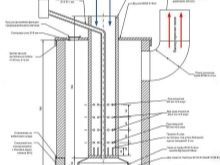

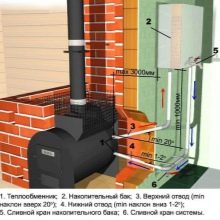

With heat exchanger

Separately and in more detail it is necessary to tell about furnaces with the heat exchanger.The heat exchanger itself is a serpentine type pipe, often referred to simply as a “serpentine.” They are designed to heat water in the presence of a tank near the stove. Such pipes can be of two types: coils of internal type and, accordingly, external. More often constructions of internal type are used. By their performance, they are more efficient and reliable.

The principle of operation of such a heat exchanger is as follows: cold water from the tank enters the coil, in which it is heated by the heat of the stove. Then the heated water enters the tank again and can be used for hygienic procedures and washing. Water will be circulated in the heat exchanger while the furnace is in operating condition. In addition to the coil, another water circuit can be used.

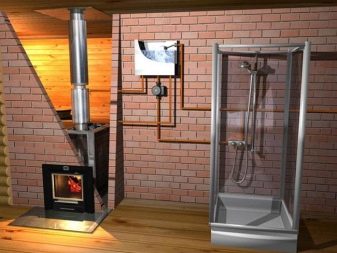

With integrated boiler

Furnaces in the bath with built-in boiler are as popular as all the others. Such models are very easy to install, and their operation does not require the expenditure of time and effort.

Electric boilers for water heating are usually not placed in the steam room itself, since they are not recommended exposure to high temperatures.

Shield Furnaces

The protective screen performs the function of protection against accidental ignition of flammable materials near the stove. In such furnaces, three main components are usually distinguished: the floor screen, the side and the front. The floor screen is designed to protect wooden floors in the immediate vicinity of the stove. Side screens reliably protect the walls of the steam room near the stove from high temperatures. And the frontal screen provides security when installed between the steam room and the waiting room. Safety shields can be made of metal. Also there are brick thermo screens.

The metal screen is mounted on the furnace body with the observance of small gaps. Thanks to such screens, the level of infrared radiation is reduced, the room warms up faster, and the air circulation between the furnace and the screen prevents the structure from heating up to high temperatures. Brick screens are an ordinary masonry bricks around the perimeter of the furnace.

Independent production

So, before you start making a bath stove on your own, you need to take care of the preparation of the necessary tools and materials. For this you will need:

- red and refractory bricks;

- clay;

- sand;

- blower door;

- fire door;

- grate bars;

- clean doors;

- asbestos cement slab;

- stones

As refractory materials, brick of standard sizes or stones is usually used (when laying a furnace with stone, it is important not to use flint, which can crack due to high temperatures).

The main criterion before starting work is to calculate at least an approximate weight of the future stove, because, depending on this, a solid foundation is prepared on which the construction can be put. Therefore, before the construction of the stove is poured foundation. Cement, crushed stone and metal mesh will also be needed to fill it. When laying the furnace is usually used standard fixtures that use stove:

- trowel;

- hammer pick;

- bubble or laser level;

- cord whip;

- plummet;

- the square is construction;

- tamper;

- plastering rule;

- capacity for the solution and bulk materials.

In order to cut the irregularities on the bricks, it is recommended to use a grinder. She must have a special circle designed to work with stone surfaces.

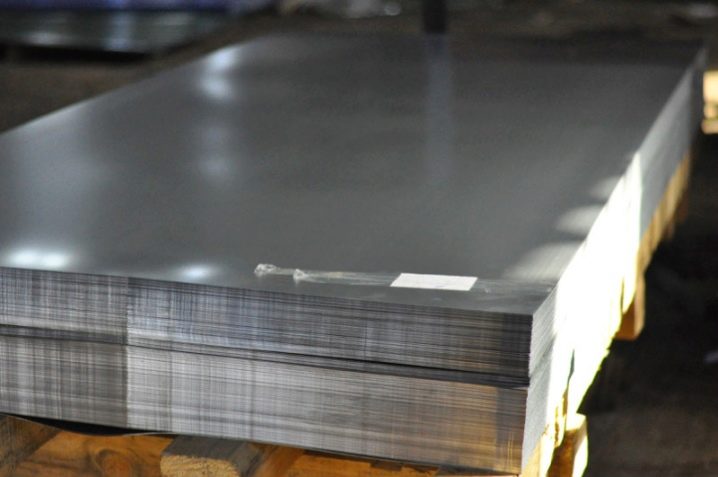

Through their efforts, it is possible to make not only a brick construction. Often used for this and metal. In this case, you need:

- sheet steel with a thickness of 1 and 5 mm (it is recommended to use heat-resistant compositions);

- grate;

- metal corner with a shelf about 40 or 50 mm.

With respect to metal structures, slightly different adaptations will be needed, in particular:

- welding transformer or inverter;

- angle grinder;

- sweep and cutting disc for metal;

- electric drill with a set of drills;

- roulette;

- scriber.

In those cases when a future tank will also be provided for heating the water, then a large volume of pipe will be needed. Also for the installation of water heating systems will need a variety of faucets with the necessary thread.

Preparatory work

To begin work on the construction of the furnace should be with the preparation of its future location. If this is a remote heating system, then a part of the wall is cut between the steam room and the waiting room. If the stove is planned to be located in the corner of the room, then in this case mineral insulation is placed on this place, which is then lined with bricks. Also consider the location of the chimney.

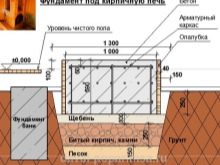

Foundation Installation

Installation of the foundation is a very important stage of work, which is worth spending time and effort. After all, even a furnace of standard dimensions is an impressive weight structure, especially if it is made of stone or cast iron. Therefore, you need to make a good basis for the furnace, observing a certain sequence of work:

- To get started is to dig a pit at the installation site of the stove. It should exceed the size of the stove by about 20-25 cm.

- Then the bottom of the excavated pit should be covered with sand with a layer of approximately 10 cm, then pour it with water and tamp it well.

- Then, a layer of rubble is covered with a layer of about 15-20 cm.

- When arranging a reinforced concrete slab around the perimeter of the pit, you need to build a wooden formwork.

- Concrete for the foundation is prepared in the following proportions - to do this, mix one part of cement with 4 parts of rubble and add three parts of sand. Water must be added with the condition that the concrete does not spread and was able to maintain its plasticity. After mixing the solution, it must be immediately poured into the pit and compacted. The surface of the foundation is leveled with a rule, and then covered with a film of polyethylene. After such procedures, you need to wait until the solution hardens and hardens.

For a metal furnace, you need to pre-select the necessary blanks. Usually they use metal sheets with a thickness of about 4-5 mm. However, it is quite difficult to cut such sheets with an ordinary grinder.

Often, a gas cutter is used for such purposes, which will significantly save time and effort spent.

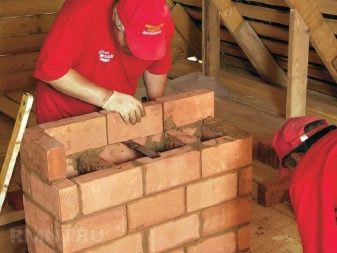

So, the most crucial stage of the work is the laying of brick walls of the stove itself. As mentioned above, there are “cold” and “hot” stoves for baths. In their construction work will not differ significantly. And in fact, and in another case, the firebox is first laid out using refractory materials, and then an ashpit is arranged under it. Also between the working compartment and the blower is installed grate. It is used to supply air to the furnace.

The “hot” and “cold” furnaces will differ only in the location of the stones. That is, in one case, the stones are in direct contact with fire and are open and heat up much faster, while in the other the stones are closed. Also in modern baths steam generator is often used.

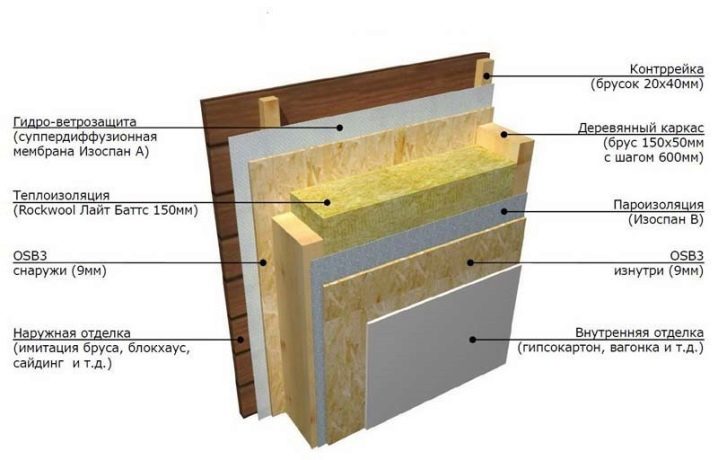

But before you install the oven itself, you must prepare a place to install it.Even in the case when there is no need for additional strengthening of the foundation, you still need to take care of the installation site. Thermal insulation and heat insulation are used for this. You can use metal sheets or clay-brick layer as a barrier for wooden walls from a working furnace. Then you can go to the installation of the stove itself.

Also for thermal insulation, you can use materials such as stone wool or apply cement-fiber plates. The average thickness of such insulating plates should be about 20-25 mm, which, in principle, depends on the power of the furnace.

Instructions for proper stove wall installation:

- The roofing material is laid on the completely hardened foundation. Then laid out the so-called "basement" row of bricks. He should pay special attention and lay out it very smoothly, constantly checking the level. Actually, this series sets the furnace required shape. Some professionals even recommend laying out two “basement” rows of bricks.

- Then on the lined rows you need to install a pre-prepared asbestos-cement sheet, which forms the bottom for the ash pan.

- The same sheet is installed on the third row, but under the firebox compartment.

- The next row of bricks will form a niche under the heater.

- Then begins the calculation of the furnace itself. At the same stage it is necessary to carry out the overlapping of the bottom.

- Next, you need to lay out the stones and carry out the installation of the door and the portal in the furnace.

A very important point for the proper arrangement of the steam room is the discharge of the chimney. For the furnace of any material, you can use a metal pipe. The main thing that the lower part of the pipe was more heat-resistant.

You can cook a metal furnace with your own hands as follows:

- As a basis, you can take a pipe of large diameter, which must be cut so that one part is slightly larger than the other.

- On the longer section of the pipe a hole is cut that will serve as a blower.

- Similarly, a hole is cut for the firebox.

- Next to the pipe you need to weld the hinges. Then the doors of the fan and the fuel chamber are hung on them.

- In the side of the stove is also cut a hole. It will be made platform for the location of stones. Under it are well suited rods of metal.

The result is an efficient and mobile round oven frommetal. In some cases, it can be further impose a brick. But in this case, it will not be mobile.

Manufacturers

Today on the market there are a huge number of manufacturers of sauna stoves. Below is a ranking of leading brands in Russia, based on an analysis of customer reviews and manufacturers' reputation.

Furnace "Termofor Geyser". "Termofor" - one of the leading manufacturers of sauna stoves. This model is a classic sauna stove specifically for the Russian sauna. It is made using heat-resistant alloy steel, which makes it very reliable and wear-resistant. A feature of the heater is the presence in it of a two-stage system of vaporization, that is, it is both an open and closed system. In the furnace there is a convenient system for dispensing water that enters the heater. To do this, it has a special valve that delivers water in measured portions. The furnace is suitable for small baths, and for larger rooms. Main advantages:

- it warms up quickly;

- the vaporization system gives the room an easy pleasant steam;

- strong body walls;

- large volume of the stove, which allows you to install it in both large and small steam rooms;

- attractive and stylish appearance of the stove.

"Sahara 24" from "Teplodar" is an excellent oven, characterized by the adjustment of modes. The power of this furnace is quite large and is suitable for rooms of any size. The stove quickly warms up the room, for example, the average area of the steam room will heat up to more than 100 degrees per hour. The furnace does not need special care, it is easy to clean from the products of combustion. Main advantages:

- fast warming up even large rooms;

- moderate level of humidity;

- Kamenka high volume;

- extremely simple device of the furnace;

- ease of care.

The Hephaestus PB-01 furnace manufactured by the manufacturer Hephaestus is deservedly one of the best cast iron sauna heaters. Its enormous capacity allows to warm up large rooms of up to 45 cubic meters. The furnace has the ability to withstand the strongest temperature drops. A quick warm-up of the room and light steam make the rest in the bath pleasant and comfortable. The only drawback is the rather large weight of the furnace, as, indeed, other designs made of cast iron. Main advantages:

- quick warming up of the steam room;

- high level of wear resistance;

- ability to heat up very large rooms;

- the duration of the preservation of heat in the room.

Also excellent cast iron models are ovens "Vesuvius Legend Suite". This model, unlike the previous one, warms up smaller rooms. But she has a lot of positive qualities. It is worth noting that this design of the self-cleaning system has a glass surface, which significantly reduces the hassle of care for the stove. Main advantages:

- high level of efficiency;

- durability;

- easy care;

- long-term heat retention.

In addition to the main leaders of sales, there are other popular brands of sauna stoves, which are slightly inferior to the main brands.

Harvia firm has long established itself in the market as the release of quality products. Basically, this company produces sauna stoves. But in her catalogs you can pick up and heaters for a traditional Russian bath.

The company "Ermak" is one of the leading domestic manufacturers of sauna stoves. The products of this company are distinguished by their compactness and the possibility of supplementing the furnace with various functional devices.The pleasant design of the Yermak stoves gives the steam room an aesthetic appearance. Most of the products of this manufacturer are made of quality steel.

The Finnish company Kastor also has long been actively involved in the sales of sauna stoves. The company's products have a very original and exquisite design, which gives the steam room a rather creative appearance.

The stove of the “Locomotive” brand is very relevant for Russian baths, where intense and high-quality steam is appreciated. The name of this brand speaks for itself. The stove is capable of producing a large amount of high-quality and useful steam thanks to a powerful steam generator.

Kutkin brand furnaces are distinguished by a wide variety. The designs of this company can be both gas and wood, and even working on diesel fuel, which not all manufacturers can boast. The combination of original design and efficiency make the Kutkin stove an excellent choice for steam room heating.

Furnaces of the domestic company Berezka are distinguished by their democratic prices and high quality workmanship. The company produces a fairly large number of furnaces of various models, among which you can choose any, depending on individual preferences.

The domestic company "Svarozhich" supplies the market with exclusive furnaces with a wonderful design. Furnaces from this manufacturer are distinguished by the fact that they have the ability to control modes. This stove can even operate in the sauna mode. It has a large furnace, and the door has a forged finish.

And completes our "oven" rating manufacturer Troika. These are quite reliable and efficient stoves at reasonable prices. A distinctive feature of the products of this company is their fastidiousness in the care, ease of installation and operation.

IziStim brand furnaces are notable for their high prices, but are not inferior in quality to global brands. These are quite powerful models with an attractive design that will become a real decoration for the sauna, and not just a structure for warming up the room. High-quality materials give the furnaces of this company a long service life and high reliability. This is one of the exclusive products that does not enjoy mass popularity.

Customer Reviews

The smallest number of comments and complaints from customers were received by the products of the Hephaestus, Teplodar and Termofor brands.These companies have long been engaged in the production and supply of sauna stoves to the world market, so they have extensive experience in the production of heaters and monitor their reputation. The furnaces of the brand "Troika" and "Vesuvius" were marked by a long service life and effective performance of their tasks.

Brand "Birch" buyers noted for low cost and good quality, but, according to many users, such stoves are more suitable for the sauna. Products of the company "Ermak" most users say as with a compact, but at the same time roomy stove. Also, many buyers of this model were pleased with the panoramic glass on the firebox door and the handle with self-cooling.

Safety

To rest in the bath was not only useful and comfortable, but above all safe, It is imperative to observe some important safety instructions:

- When buying a stove, you need to pay attention to the brand of the manufacturer and carefully read all the certificates of compliance with fire safety and quality. When self-fabricating, you need to familiarize yourself with the requirements of the fire brigade and carry out the furnace in strict accordance with them.

- It is worth buying a stove whose body will not heat up so much as to cause serious burns if there is a sudden contact of open skin and the surface of the stove.

- The main component of the heating in any heater is the stones themselves. Therefore, their choice should also be given special attention. Stones should not crack from high temperatures. To place them in the grooves should be very reliable and stable, so that they do not fall out of the melted furnace.

- Adding water to hot stones should be extremely dosed, because even a large amount of steam can cause burns.

- In the steam room itself, the ceiling, walls and floor should be protected from excessive overheating. This is especially worth doing in the place where the furnace itself is located, because the temperature there will be the highest, which can lead to damage to the walls.

- Increased attention should be paid to the installation of high-quality chimney. This is one of the main safety rules in the bath. A good chimney must promptly remove smoke from the furnace and prevent it from entering the room. Also, do not overload the stove with firewood.Firstly, the chimney can not cope and part of the carbon monoxide starts to get into the steam room, and secondly, the stove can be heated to extremely high temperatures, and then it will be simply impossible to stay in the steam room.

- Ensure safety is necessary not only in the bath room. Attention should be paid to the attic, through which the chimney goes. Near the chimney, and it is better not to store objects that may catch fire from high temperatures above the entire room of the steam room. It is also recommended to ventilate the attic in order to avoid excessive heating.

Consideration should be given to a ventilation system for constant inflow and circulation of fresh air.

- It is not recommended to visit the bath while intoxicated, because it causes stress on the whole body and the wellness procedures will only act to the detriment. Also, do not visit the steam room pregnant women.

- If a person has a tendency to fungal diseases, then visiting the bath for them is highly undesirable. This may cause them even greater harm and cause the risk of disease in other visitors to the steam room.

- Do not heat the bath to high temperatures, to be in which will be uncomfortable. Excessive overheating causes dizziness, vomiting and even loss of consciousness. Therefore, even with a small suspicion of heat stroke, it is best to leave the steam room. From a lower temperature immediately noticeably feel better.

Considering these recommendations, the rest in the bath will be pleasant and comfortable, and its result is wellness and relaxing.

Tips and tricks

For the heating of the bath, you must use well-dried firewood. They should be stored in a designated place on the site, which will not be available for rain. It is recommended to leave small gaps between the wood, so you should not stack them too tightly to each other.

In no case should firewood be covered with plastic films. In this case, there is a greenhouse effect, due to which the wood will not only dry out, but also become more moist.

Today, a bath is not only a place for healing and washing, but also a universal room for spending time in good company. Therefore, the bath interior is also paid a lot of attention. Leading styles today are:

- high tech differs conciseness and strict colors, clear shapes and lines;

- retro is the best for lovers of old;

- country music involves the implementation of a bath in a certain rustic style.

In the old days, baths were heated only “in the black way”, but even today this method is popular. For this method of firebox can be divided into several positive aspects:

- such a bath warms up many times faster;

- moist and heated wood emits a pleasant characteristic odor;

- The construction of the “black” bath is extremely simple and can be easily made by yourself.

Bath procedures have a good effect on human health. High temperature cleanses the skin, removing harmful substances from the body along with sweat. A visit to the steam room hardens the human body and increases the level of immunity, as well as stimulates the work of almost all internal organs, especially the heart and lungs.

It is very important to properly heat the bath. It would seem that there is nothing difficult in simply putting firewood in the furnace. But here there are some peculiarities. Firewood in the furnace should be laid, observing the small gaps between them.As you know, the fire can not be without air, and these gaps will ensure its circulation, so that firewood will quickly begin to inflame. For high heat and quick warm-up, you can slightly open the oven door, but for safety reasons, it is better to use a specially designed for this purpose blower. It will not only be safer, but much more efficient.

In no case should the valve in the chimney be completely closed when the stove is working, otherwise the emitted carbon monoxide will begin to fill the room. Birch, aspen and alder are traditionally considered to be the best wood for heating. From them there is practically no dirt and soot inside the furnace, which will reduce the effort to clean the chimney and ash pan.

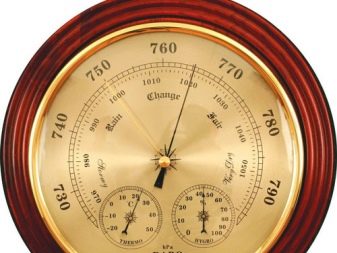

It is advisable to install in the bath some instrumentation that will help regulate the whole process. The most famous and simple device for a bath is a thermometer. Today it is available in almost every bath, which allows you to monitor the rise or fall of temperature in the steam room.

It is important to visit the steam room dosed and spot a comfortable time for yourself in it. Therefore, in the bath, you can set the timer time.Often used for this hourglass, which are sold in stores bath accessories. On such a clock marked time scale. Usually it is 10-15 minutes. This time is enough for a single entry into the steam room.

Quite an interesting device is a hygrometer. This device monitors the level of humidity in the room, which is quite convenient, because a comfortable rest depends on the favorable balance of humidity and temperature.

Even in the bath, you can install a special barometer that will measure the level of pressure in the room. Today they can be both mechanical and electronic.

Materials manufacturing such devices should be resistant to high temperatures and elevated levels of humidity. The body must be completely sealed and should not be heated to a high temperature. In modern stores you can also find integrated measuring devices, which will include various devices.

Furnaces operating on electrical grids are much more compact and mobile. Almost all processes in such furnaces are automated and have the ability to set individual temperature parameters,humidity and steam levels when visiting the steam room. For these furnaces do not need to spend a lot of effort on the abstraction of special ventilation and chimney systems. A big plus of electric heaters is the complete absence of combustion products, debris, dust and ash. Also, such a furnace is extremely simple in operation and maintenance.

So, a comfortable, useful and safe rest in the bath for the most part depends on the correctly chosen stove. Modern manufacturers offer a lot of different models, among which you can choose a furnace for any individual requirements, given the appearance of the furnace, its material, functionality and price.

If necessary, the furnace can be made independently, using the above tips from experienced craftsmen.

How to choose the best stove for a Russian bath, you will learn from the following video.