Bath of blocks: the pros and cons

Today you rarely find a private house without a bath, sauna or swimming pool. Depending on the region of residence, our compatriots choose to fill their site for themselves and their preferences. Construction of the bath today is one of the most popular processes.

It is quite laborious and complex. But even a novice builder will be able to build a decent construction in his area, if he follows the basic recommendations and step-by-step instructions.

Special features

Previously, the main material for building a bath was considered a tree. Houses were also built from it. Today, the situation has changed somewhat. New generation materials are resigningly entering the construction market. Among them - a variety of building blocks.Bath with porous walls - sounds, at first glance, very strange.

After all, for this construction is very important hydro and thermal insulation. Otherwise, it is not a bath at all. But the main feature of such a building from blocks can be called a unique opportunity to build an almost monolithic house with smooth walls in a matter of days.

Blocks are most often designed for use in the construction of low buildings. The maximum that they can do is a one-story house with an attic. To accurately determine the material for the future bath, pay attention to the positive and negative sides of the block structures.

Advantages and disadvantages

Enumerate the advantages and disadvantages of blocks in the bath walls can be a long time. Everyone will find his quality differences in this material, both in a good and in a bad way.

Still, it is more pleasant to start with the pros:

- foam blocks have no shrinkage at all;

- the bath is ready for operation immediately after construction, external and internal design and installation of the furnace;

- minimum term of construction;

- the cost of the finished structure is two times lower than a wooden log or brickwork;

- the absence of harmful chemicals in the production of concrete blocks and, as a consequence, the absence of unpleasant odors;

- low weight of the material, which makes it easy to lay and use the simplest foundation;

- possesses high heat-repellent qualities;

- not subject to mold, fungus or other microorganisms;

- the thickness of the walls is pleased that you can use only one block at a time, this will be enough to create a warm, comfortable room.

But in a barrel of honey often put a spoon of tar. Therefore, we note the disadvantages:

- If the blocks are not treated with a special hydrophobic solution, they can easily absorb moisture. She in the winter, even under the condition of double insulation, can harden and spoil the walls of the bath. The design can simply crumble.

- When using concrete blocks in such a building with high thermal performance, there is a problem of condensation on the walls.

Most of the deficiencies of foam blocks can be corrected and avoided by resorting to additional means of steam and waterproofing. And also choose the type of material with a minimum number of pores in the structure.

Types of materials

The number of various building blocks today is simply huge. It seems that manufacturers are competing with each other, creating more and more new varieties. Let's try to understand this variety, choosing the most popular.

Aerated concrete

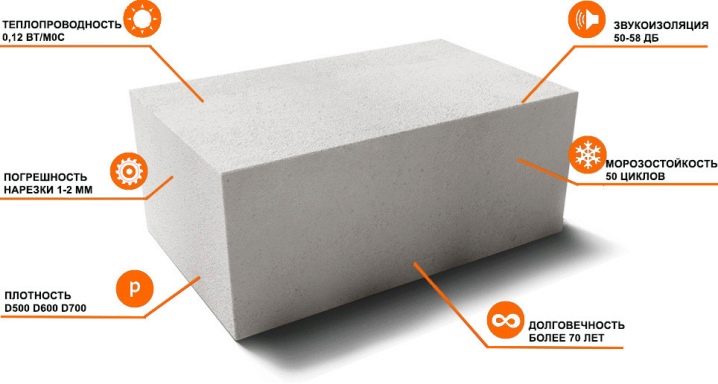

It is a concrete block with a porous structure. Its components: cement, silica sand and foaming agent. Durable foam blocks of aerated concrete are a convenient material for the construction of low-rise houses.

The most famous manufacturer of gas-blocks in Russia is the trademark “Insi”. They characterize their material as a qualitatively new, practical and versatile sample.

Another distinctive feature of the gas block can be called the fact that aerated concrete is still very often used in the construction of intra-house partitions.

Its sound-proofing qualities, of course, are a little inferior to bricks, but they are much stronger than those of drywall.

Foam concrete

This material has a similar structure to the previous one. But it has less weight and improved thermal insulation. Another very important and big plus of foam concrete blocks is increased water absorption, which is especially important for building a bath.And also has a lower price compared to the cost of aerated concrete bricks.

Claydite

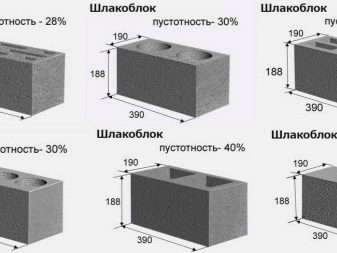

One of his name says about its own composition. It has a low thermal conductivity, that is, it makes it an excellent tool for building the external walls of a building. It has the most dense structure and low mass. It is made with cavities, niches inside the body of the block.

And a few more materials:

- Manufacturing process gas silicate blocks allows to produce them absolutely equal from all sides, of the same size, which brings joy to true perfectionists. The composition also includes lime, which paints the blocks in white, compacts the structure. This type of blocks requires mandatory waterproofing treatment.

- Using another very popular foam material at one time - cinder block - Experts strongly do not recommend. Under the influence of elevated temperature, this raw material begins to release toxic gases.

- The presence of wood shavings in wood concrete blocks It gives this building material high thermal insulation, but completely deprives moisture resistance.Like wood, they need to be treated with antiseptic and make enhanced waterproofing. Otherwise, large sawdust, which is part of wood concrete blocks, may begin to rot.

Today in the construction used a large number of various materials. The most popular ones are described above.

- I would like to separately note more properties sandblockwhich consists of a mixture of sand, cement and water. By its qualities, it is a bit like the solution used to make a strip footing for a low building. Quite moisture resistant, inexpensive and easy to use.

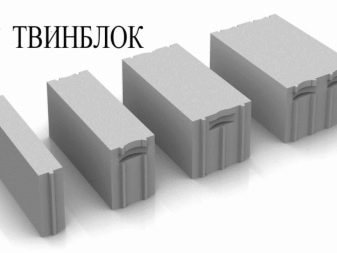

- Particularly noteworthy is the relative of the gas silicate - twinblock. It is one of the most environmentally friendly materials for the construction of residential buildings. The composition of the twin block includes: water, portland cement, lime, aluminum powder and ash. Its convenience lies in the light weight and the presence of mortise locks, which maximally bring the structure closer to the solid.

Project

As with the construction of any other building, the design of the bath should be approached scrupulously and responsibly. The first step is to make a plan of your project.The convenience of the construction of the blocks is that they are suitable even for the smallest - two-or three-room bath.

At the same time, the increased thermal insulation of the building blocks allows an extension to the main house or to the country house. So do not be afraid to have a bath next to the garage. They do not interfere with each other at all.

So, before you start building, consider the most common and successful drawings of standard sizes.

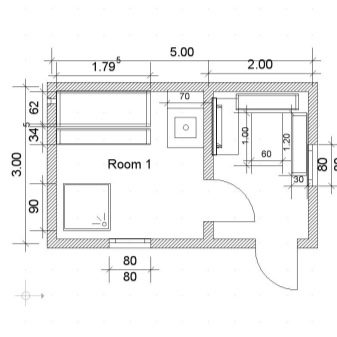

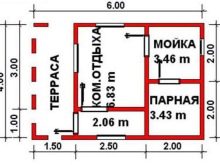

- To accommodate a small design with maximum convenience, you need to do everything right. At the same time, both external and internal planning is very important. The minimum size of the steam room is considered to be a 4x3 m house. Here you can make a project of a small two-room house, where the steam room is quite successfully located complete with washing room, and the rest room can also be used as a small corner for storing bath accessories. Such a project is distinguished by high functionality, despite its small size. Bath 3x4 m can be built even on a small plot of land or attached to the cottage.

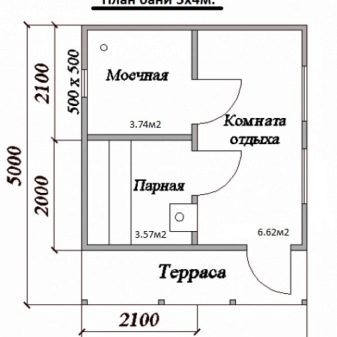

- The next popular block-bath size is slightly larger - 3 by 5 meters.Only two rooms are also present. As in the first embodiment, the steam room is adjacent to the sink without a partition and occupies an area of 9 m². The entrance hall is just 6 squares. At the same time, the bath is equipped with everything you need: a shower with a drain, a stove with a hot water tank and shelves, as a rule, bunk beds.

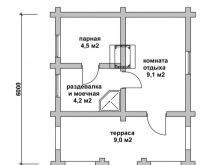

- Another project of a bath of 3x5 m. Here you can already make three rooms, despite the small space. Consider how this was achieved. There is a comfortable waiting room - a rest room. Now it is given under 9 m². Steam room and sink have dimensions of the area - 4 and 2 square meters, respectively.

- The example of a square bath 4 by 4 meters allows you to arrange everything in places and is absolutely geometric exactly. The same three rooms, as in the third version. Only the steam room and the sink this time have the same area of 4 m², and the waiting room with the guest area is located on 8 squares. A block bath of 4x4 m modern masters manage to do even with a mansard. But it is worth taking care of this at the stage of laying the foundation for the appropriate height of the building.

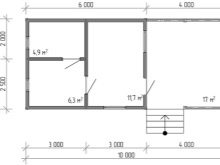

- Baths, large in size, do - a pleasure. For example, a comfortable size of 5x4 m.Here you can walk up to the open or closed terrace, as well as more safely plan the attic floor with the placement of a sleeping area on it.

- 6x4 m - the best option for a bath on a large plot. This design looks great as a separate room. The main thing is that all the main communications are brought to it and work as smoothly as possible. Consider a project that can easily accommodate a company of 6 people at the same time. The bath is also equipped with an outdoor terrace. All rooms are isolated. Washing and steam room - 4 square meters. Guest area + waiting room - 8 m², and a terrace - 8 squares. In the warm season you can stay almost in the lap of nature after active soaring.

For baths from blocks of large areas, original and roomy projects are provided. For example, a square building with an area of 6 to 6 meters can be considered a full-fledged house for outdoor activities. A bath of 10x4 m can be safely arranged in such a way as to accommodate more tiers of shelves.

Having paid special attention to the design of the future building, we proceed to the organization of the internal space.It is also very important at the design stage to decide on the filling of the bath and the location of all the important components of the interior.

Design

The aesthetic component in the interior decoration of the bath is certainly important. The design, made in strict accordance with the wishes of the owner, is not only the pride of the homeowner, but also a condition of comfort during operation. However, when planning for certain internal content, general recommendations should be taken into account.

The most common finishing material for any bath is wood. For the interior of the steam room, it is customary to use varieties of lining; linden and larch boards are most preferable.

It is not recommended to use pine, fiberboard or particleboard, linoleum, since these materials emit toxic substances when heated.

Sink and a waiting room can be executed from any raw materials.

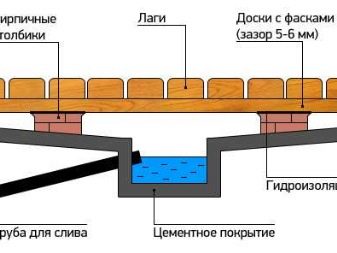

When arranging the internal space is recommended to start from the floor. First of all, boards are processed and laid. Consider the properties of this material, as the oak on the floor in the steam room, for example, will contribute to sliding.And it is very traumatic, especially if the steam room is small. The floor itself must be lifted from the concrete screed centimeters by 10. This will keep the heat in the steam room.

Next, set the tiers of the shelves. In this case, the lower of them should be 10-15 cm above the furnace. Depending on the area and the height of the room, set from two to four tiers.

The next stage is the walls, which are sheathed with wooden boards or clapboard. When facing you should not forget about the intermediate layer - vapor barrier. And only after this work is done with the ceiling.

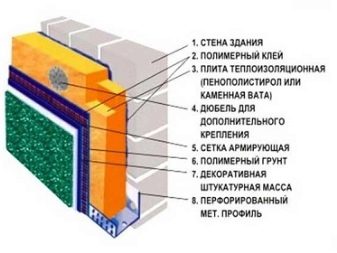

It is not so critical to approach the issue of exterior decoration, but it is still worth remembering the need for additional thermal insulation. Of course, blocks, as a rule, have a high index of this indicator.

In order to avoid condensation on the block walls in winter, when using a bath, it is better to take up this issue closely. Sheath steam rooms are usually PVC siding, brick or even ceramic tiles.

How to build?

It is much easier to build a bath of blocks with your own hands than to do the same process out of wood.

First you need to familiarize yourself with some detailed step-by-step recommendations:

- First: The construction of any building always begins with a project. If everything is ready here, you can immediately go to the second step.

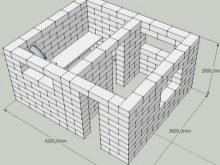

- Second: even such a light construction as a block bath must be laid on the foundation. The choice towards a certain type of basis for your building is made based on the quality of the soil under it.

Versatile is a recessed or non-recessed columnar foundation, consisting of ready-made concrete blocks. Its main disadvantage is that it is not possible to warm the base and the floor, respectively. The columnar pile foundation is suitable for ground prone to subsidence or landslides. It is also difficult to insulate the underground space.

Ribbon foundation - the most suitable basis for a block bath in almost any soil. To make an even and strong tape base, you need to make the correct markup. Dig out the required width and depth of the trench along the perimeter of the future building and partitions inside it. Further mounted formwork. At the bottom of the trench, a layer of sand is compacted to a maximum of 15 cm.

We lay on the sand reinforced base (mesh, rods, etc.). Having prepared the solution, we fill it with formwork, filling all voids. After 7 days, the support can be removed. The foundation is continued to stand, wetting periodically with water to avoid cracking. Putting blocks on top of the base is possible only in a month.

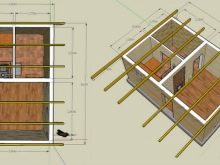

- Third: block masonry. From above on the dried and insisted foundation waterproofing is done. Despite the fact that the blocks are stacked with a special glue, the first two rows are recommended to be stapled to each other using standard cement mortar. The laying begins with the corners of the structure. In addition, each corner block should protrude beyond the basement by 0.5 cm. It is desirable to check each row by level. Do not forget to lay reinforcement every 3-4 rows. And also in the openings. So the design will be stronger.

- Fourth: when the walls are rebuilt, you can begin to design floor screed.

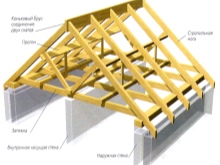

- Fifth: fully immersed in the installation of the roof and the laying of the roof. This process is very important. Since it is at this stage, all the necessary actions are taken to bring the furnace chimney out to the outside, so that gases and vapors do not accumulate, so that a fire does not happen, and so on.And also to keep everything warm in winter through the roof, it is warmed.

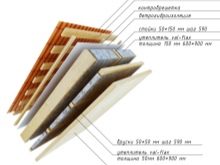

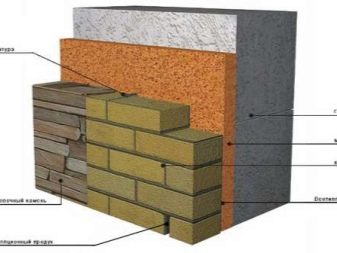

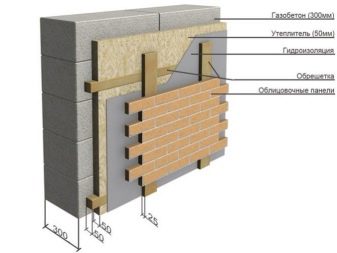

- Sixth: one more important point in the process of building a bath from blocks is its facing from the outside. The walls are insulated. On top of this, the host chooses siding, tile or wood panels to his taste. Inside, only a vapor barrier is produced, which prevents the formation of condensate on the inner wall of the block structure.

You can see the approximate device layers of insulation of aerated concrete slabs in the bath can be in the photo.

Tips and tricks

Reviews of the owners of the block bath is usually positive. Especially those who built it themselves. Most often, buyers emit aerated concrete and foam concrete from a wide variety of blocks. Pointing out that these materials fit better, they have the very same blocks in shape and size, they do not shrink at all and are pleased with their simplicity when working with them.

As for the construction of the bathhouse from the blocks, the specialists willingly share their tips and recommendations, paying attention to the most basic of them:

- Place under the steam bath must be selected, after weighing all the important nuances.The building should be well removed from the well, so as not to contaminate drinking water. And also to avoid even the smallest possible fire, the bath should be located away from the apartment building. And equidistant from each tree on the site (the approximate sufficient distance is 10-15 meters).

- At arrangement of drains it is obligatory to dig up a separate drain hole for a bath. Experts do not recommend combining it with the general, because the bath emissions are quite large and powerful, which can adversely affect the state of your total drainage well.

- All sewer and water pipes for the bath are placed on the sand pad in the same way as the strip foundation.

- Under each porous material for the walls of the bath is important its own size of the base. For example, cinder blocks and expanded clay concrete are the best and most stable on the foundation 50 cm high from ground level.

- For all types of foam concrete blocks, a hinged ventilated facade is best suited. It has a beautiful appearance. It also eliminates the problem of condensation between the wall and cladding.

It is very important to remember that starting the construction of a bath from the blocks yourself, it is necessary to carefully and thoroughly examine all the necessary information.This will be the key to the construction of the original and simple building, which will be comfortable and pleasant to rest.

Beautiful examples

Neat interior trim steam room with a small area. The walls, floor and shelves are made of wooden wall paneling. The height of the ceiling in the bath of the block is sufficient to make three tiers of shelves. Thus, it can accommodate sitting up to 6 adults.

An example of a spacious bath of blocks with a small terrace and PVC siding lining. It has a gable roof, low strip foundation, also hidden by plastic, imitating stonework, darker in color than the main building.

The original design of the exterior cladding makes you believe that before us is a wooden bath. However, this is our familiar block design. The walls are covered with a board that is impregnated with an antiseptic. There is a small terrace for evening or afternoon gatherings in nature.

A bold combination of interior trim steam rooms in the bath. Walls, floors, shelves and ceiling are made of clapboard. The furnace is framed in the form of a cave in the rock. Three-tier shelves. At the same time, the first of them is practically on the floor, and not 10-15 cm above the stove, as recommended by professionals.

This photo looks very beautiful brickwork as the outer lining of the bath.The building itself is very spacious. It will quietly accommodate a large steam room, a guest room, a washing room, and you can also install a separate internal bathroom.

Another brick facing, but a smaller bath. The roof will be with a guest bedroom - attic floor. The foundation is tape. For construction used aerated concrete blocks.

Beautiful and gentle bath with ceramic tiles. It has a small open terrace. Details are painted in the dominant color. There are two windows. Small - goes to the washing room, large - in the guest.

When choosing a project to build your own bath of blocks, you should focus not only on your taste and your wishes. The ultimate success of an enterprise depends on many component factors that we sometimes do not even look at. Starting from the location of the bath on the site, continuing the process of laying the foundation and solving the issue of interior and exterior design.

Finishing the roof of the roof and installing the main attribute of the Russian bath - the stove. Do not worry or be shy to contact the experts who will not only advise and prompt, but with pleasure and will help on their own and with their example.

In this video you will find a review of a small bath from the blocks in the country.