Bath of logs: the pros and cons of designs

In Russia, traditionally, the bath was built from a single log. Most often used for this conifers. Over the centuries, the existence of this construction builders have improved it to the smallest details. And at the present time there is nothing better than a log bathhouse, in which it is easy to breathe and steam.

Special features

It looks simple and uncomplicated wooden house with reliable and thought out.

This material has the ability to create in the construction of a unique microclimate. The main requirements for the type of wood from which the bath was planned to be built are water resistance and the ability to breathe easily..

Pine and cedar give a resinous atmosphere. Larch logs are practically not subject to rotting and unusually strong. Aspen is the most “airy” breed - in the bath of its logs it is easiest to breathe.

The main feature of the tree - it does not prevent the movement of air, while the steam stays where it should be - in the steam room. Excess moisture is derived itself.At the same time, wood is an excellent natural heat insulator. In addition, it has a positive effect on human energy and destroys pathogenic flora.

This "Russian bath" can not be built from plastic or sandwich panels. Only a tree is suitable for it.

Today, it is possible to build a bath from a log in hundreds of different variations: two-storey, with an attic, with a garage, with a pool, with a veranda - everything depends on the owner’s imagination and, of course, on the time and money he is willing to invest in construction.

Advantages and disadvantages

The first and main advantage of a solid log bath is its naturalness, organic, ecological (there can be many names, but the essence is the same). Wood is the best material for building a bath complex, this is especially true for people with respiratory diseases - they actually recommended a visit to such a sauna. It is difficult to overestimate the special atmosphere that is created and maintained in the woody steam room.

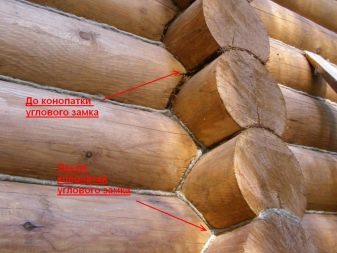

When building a bath from a log, the most common method is cutting “into the bowl”. Its essence is that a semicircular hole is made in the upper log.In size it should be the same as half the height of the log under it. When using this method of construction, the structure has a minimum property of heat loss.

The ends of the logs, protruding 25-30 cm beyond the boundaries of the walls, protect the building from winds and rains. Construction time is minimal, since logs are easily joined to each other. The bath is very durable: the parts do not move and are tightly fixed by the “bowl”.

The log building is easily and quickly heated, it warms up well. Properly treated wood will last a long time without losing an attractive appearance.

It should be noted and cons of such buildings. They are few, but they can become very significant.

- Cost Well-dried whole logs can cost a large amount to the owner.

- Due to the cutting "in the bowl" there is a large waste of material due to the protruding parts. This, in turn, will further increase the final price of the building.

- Obligatory impregnation with antiseptic from rotting, burning, fungus. Not any composition is suitable for this, because a bath is a building in which, due to the release of steam, any chemical substance will get intoair and breathe man. Therefore, the composition should be as natural, harmless, which is also not cheap.

Types of logs

The material necessary for construction is harvested in advance, as it needs good drying. It is best to choose a pine log for a log house.. If you prepare the material in the winter, it will have high moisture resistance.

The diameter of the logs to be used for the construction of the bath complex should be in the range of 18-25 cm. The difference in diameters of each log should not exceed 3 cm.. Otherwise, they will not fit snugly together.

Wood should be not only of one species, but also preferably grown in the same climatic zone. It is preferable to choose trees grown in forests of northern latitude, as they are less susceptible to the effects of temperature and humidity fluctuations.

Logs can be divided into several types:

- Rounded (calibrated). Processed on a special machine. Therefore, they are given the same perfectly round shape and equal diameter. Thanks to it it is very simple to stack them.But when cylindering, not only the bark, but also the upper layer, bast, which protects the tree from environmental influences, is removed from the log. That is, a calibrated log, although it is more budgetary in cost, and it is easy to build a structure out of it, but it is subject to rotting, cracking and even deformation. Therefore, for the construction of the bath is better to choose a different material.

- Planed - these logs are not processed by the machine, as calibrated, but with an electric planer. As a result, the loss of the upper layer is not so significant. Planed log is not as smooth as round, but the diameter difference is insignificant. However, manual construction is required when building a log house.

- Lafet (Norwegian cutting). This type of log is obtained by sharpening and sawing from opposite ends. According to its properties, the carriage is close both to the log and to the bar. It is subject to cracking, but less than a calibrated and planed log. If it is good to treat the carriage with antiseptic and other compounds, its service life is rather long. Its cost is higher, but for the structure of the mast does not require interior decoration, which means that you can save on it.

- Sculpted - these are the most durable logs.They are treated in the following way: first, debarked logs are made, then the bast is removed manually. Then chop the log house and grind it in draft. Gather it at the right place and grind again - the last one. If you comply with this technology, then only the top layer of bark will be removed from the log, and all the properties of the tree species, including tar, will be preserved. Even if it is not treated with antiseptics, the scrubbed log house will last for a very long time. If to make impregnation, the bath will serve one hundred years. However, fitting a log to a log will take a lot of time, since each of them retains its own knotty, shape, curves, and everything else.

- Square beam. This is the most budget option. Bath from it will have smooth and smooth walls. But to construct such a construction is not easy - it will take very careful adjustment of the elements of the log house to each other.

- Simple, sanded. The most commonly used type of material. Due to the fact that the upper layer is not disturbed, it is little susceptible to rotting and destruction. Still needs to be impregnated with appropriate formulations.

When choosing lumber, you need to consider a number of factors:

- the lowest air temperatures in winter at the construction site;

- frequency of the planned operation of the bath;

- building area;

- technology applied during drying.

If it is planned to operate the bath only in the summertime, logs with a diameter of 18 to 20 cm are quite suitable. For such a structure does not need a strong foundation.

In the case of the construction of a bath for use throughout the year, logs of larger diameter are needed - from 24 cm. The foundation will also need more powerful: a monolithic or strip foundation is well suited.

On how the wood is dried, depends on its humidity. In turn, humidity affects the degree of shrinkage of the structure:

- material obtained by hand cutting, shrinks 15 cm or more;

- thick logs grown in the forest, felled in winter and dried in a natural way, are prone to shrinkage by at least 4-6 cm;

- Rounded logs, dried in the chamber, shrink 3 cm.

These indicators must be taken into account when developing a bath project to calculate the correct height and the required amount of lumber.

When purchasing and harvesting logs you need to follow a number of rules:

- No item should be affected by insects.

- The trunks should be straight, without curvature. The allowable difference in the diameter of the ends is 3 cm.

- None of the logs should have any kind of damage.

- The greater the thickness of the logs, the harder they are to build, and the higher their cost.

- Independently harvest timber should be in the winter.

- Choosing a tree, to the calculated value of the diameter should be added 1 cm for further processing.

- If the cutting was done by means of a benzo or electric saw, the cut of the log becomes “ragged” and more susceptible to rotting. To avoid this, you need to clean the wood clean with an ax. Pre-cut it between cross-cut.

- Construction lead from svezhespilennogo material. It is easier to process, it is less prone to cracking and deformation in a folded log house.

- Peeled logs need to be stacked, laid with bars to ensure the movement of air. From above the stack is protected with a shed or dense cellophane to avoid both the effects of precipitation and direct sunlight. To dry the logs need for two weeks. After that you need to start felling the log house.If the lumber is too dry, it is difficult to handle.

- To make the logs less cracked from the front part of the structure, the saws are made on each of them with a depth of approximately one quarter of its diameter. This is done in order to compensate for internal stress and in the future to avoid the appearance of cracks. It is important to know that files should be made only from the side opposite to the longitudinal groove.

If all recommendations are followed, the bath will be beautiful, warm and reliable.

Project

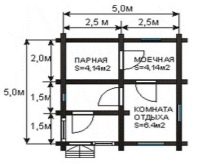

Before starting the construction, it is necessary to think over and decide what the bath will look like and what tasks the owner assigns to it. Currently, a project of a 5x5 m bathhouse with a chopped terrace and a mansard is very popular. This is a small structure, but it will comfortably accommodate a company of 5-7 people.

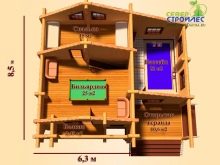

Bath 6x6 m is not less popular. It may be a one-story structure or a two-story one. It can be equipped with a rest area outside (summer), in which there will be a brazier or a barbecue.

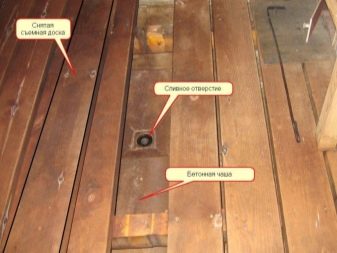

Depending on the capabilities and wishes of the owner inside the bath, you can make a pool. It is set up both in a separate room and in the steam room - under a removable floor.

The bath can be both a part of the house, and an independent structure. We need to take care that it was convenient to bring communications to it. It is better if the bath is not too far from the house.

In addition to the desires of the owner, you need to take into account many natural factors: the nature of the soil, the level of groundwater, the evenness of the landscape. It depends on what foundation is required for a bath.

And you also need to calculate how much material is needed, what kind of material it will be (from what kind of logs it is planned to build), how to cut a log house.

After all calculations, you need to draw a sketch that will contain a bath plan. It is important to immediately decide where the stove will be located.

How to build?

It is not easy to cut a log bath with your own hands from scratch, but this is possible with certain skills. And you also need to understand that to do it alone is unrealistic, since even in order to raise a log, it takes at least two, and preferably three. Therefore, it is better to still find yourself intelligent helpers.

Construction of a bath begins with the foundation. It can be of three types:

- tape

- shallow;

- columnar.

The type of foundation depends on the soil on the site.

If the earth is heaving, the best option would be to have a shallow depth. If the building is planned to be small, then it is advisable to stay on the column foundation. For a large bath (this also applies to the two-story building), only the tape version with a depth below the ground freezing level can be considered.

After the selected type of foundation has been constructed, a waterproofing layer is put on it. It may be a ruberoid.

After that, proceed to the construction of the log house itself. The first crown is called a closet. It is made of logs of the greatest thickness, best of all from oak.. It is laid on a layer of roofing material. Before laying, he is being hemmed down and treated with an antiseptic impregnation.

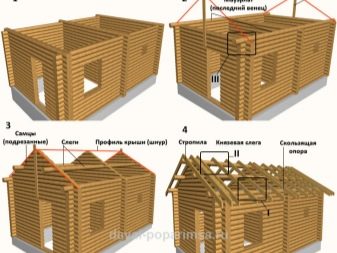

The frame is put in ways "in the bowl", "in the flash" or "in the paw" (this is the most laborious of them). Before installing each element, it is fitted (only calibrated logs are not fitted, they can be used to form a frame immediately).

When building immediately lay a layer of insulation - moss, hemp, tow or other material.

The upper crown of the frame is called Mauerlat.He is a support for the rafters, so his choice should be treated no less carefully than the choice of salary crown.

After the log house is assembled, it needs to be dug. For this purpose, moss, linen tow, felt. Caulk must start from the bottom of the crown and go round. If you make a cauldron on one wall, the bath will be twisted.

The finished log house from the calibrated logs is assembled according to the instructions attached to it. In it not only the sequence of actions is indicated in stages, but also the rules to be followed during assembly.

It is important to accurately fulfill all requirements to ensure a high-quality and tight fit of the elements to each other and to avoid distortions of the structure.

After the construction of the log house is over, it is necessary in the same year to bring it under the roof. It does not matter whether it will be a roof under a temporary scheme or permanent. For bath complex most often use a simple gable roof with the equipment under it cold attic. For this step rafters take equal to 1-1.5 m. If the attic is warm, the width of the step rafters is calculated based on the size of the insulation material slab.

The feet of rafters cut into the power plate. The tops of the legs hold together. After that, the rafters are lined with crate, and a layer of waterproofing is placed on it, it can be roofing material. As for the roofing, it is better to choose it at will: make the roof of slate, metal, corrugated board or ondulin.

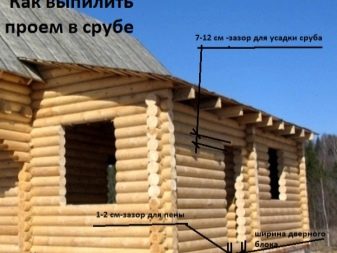

Window and doorways are cut in the already erected and insulated log house. Strengthen them okosyachkoy, and fasten it with window frames and door frames.

It is important to remember that in accordance with the provisions of fire safety equipment, the entrance door must open to the outside. These requirements apply to any door in the building.

Inside, the steam room and the dressing room can be lined with clapboard, board. When covering, it is imperative to follow the rules of thermal insulation and not to disturb the movement of air.

How to warm?

Properly insulate a bathhouse - one of the most important stages of construction. Otherwise, water treatment will become uncomfortable. Heat should not leave the room through the walls or through the ceiling. Ensuring proper air circulation is very important for maintaining a healthy microclimate inside the building.

The optimal type of insulation is not easy to pick up.There are several ways to protect the walls.

In order to warm a log bath, it is better to choose a natural material, for example, mineral wool. For insulation of the same log cabin there are few options, since irregularities and surface roughness are not suitable for most heaters. Nevertheless, it is important to treat the joints of the logs in such a way that heat does not go through them.

Different materials are used for this:

- Tow - the most commonly used insulation. Available in rolls. With its help, you can avoid drafts, it retains heat and soundproof the room. But like any organic matter, it is short-lived: it attracts both birds and rodents. Therefore, to ensure good warming baths every 2-3 years will have to caulk again.

- Another natural material is moss.. You can not buy it, and collect it yourself. Moss perfectly retains heat, moisture resistant, dense. But he is exposed to the moth, even with appropriate processing. Over time, the moss is destroyed, it will have to be updated.

- Fiber from flax and jute - also natural rolled material. It is more expensive, but at the same time its service life is much longer.The fiber is not subject to rotting, rodents and birds are not interested. This material is the best, than it is possible to warm a log bath.

Whether the building needs warming from the inside, or just external caulking is enough - everyone has their own answer to this question. Opinions on this score are different.

In the case of internal insulation, the usable area will decrease. Natural material, whether tow or moss, needs additional protection with a waterproof film.

This can not prevent the formation of condensation between the wall and the layer of insulation. This will cause damage to the wood, will begin the process of decay. therefore warming from the inside is used infrequently.

Instructions for the insulation of the log house is simple. Work begins simultaneously with the assembly of the log house. Then it will be very uncomfortable to push the insulation into the seams. Prior to this work, all logs should be treated with antiseptic and flame retardant: from rotting and from ignition.

Stages of insulation are as follows:

- laying of material between the crown crown;

- caulking cracks - can be carried out no earlier than six months, when the wood and insulation is finally seated.

The steam room is first covered with a waterproofing film.On it fix basalt insulation, produced in rolls. It is covered with foil film. On top of it is crammed with wood, then the whole structure is closed either with clapboard or other material.

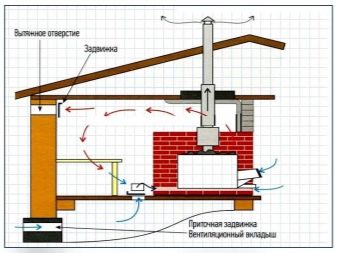

Ventilation

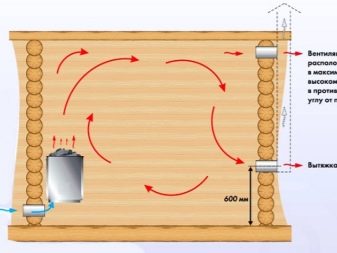

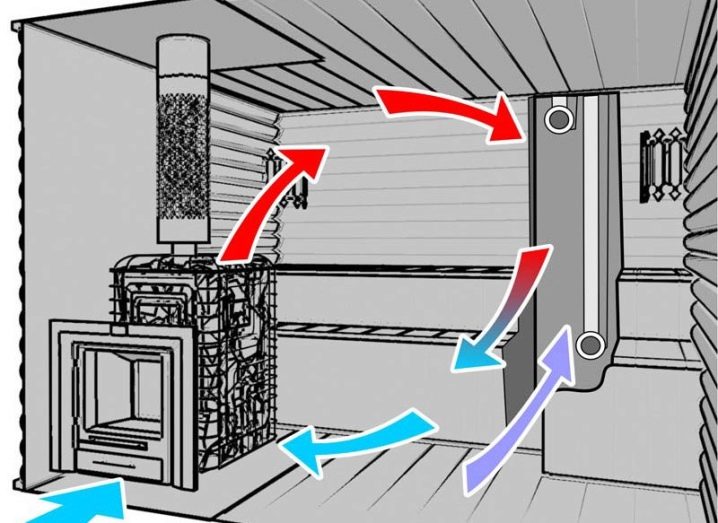

The construction of the bath provides for many different activities. Not least among them is the ventilation device. Strangely enough, even experienced specialists often discourage owners from exhaust equipment, vents and openings, because “steam will be lost,” and natural air circulation is sufficient.

However, it is precisely forced ventilation that is required in most cases, otherwise the bath will simply be dangerous to operate. Indeed, in a hot steam room or sauna, the higher a person sits, he inhales oxygen and exhales carbon dioxide. At temperatures above 60 ° C, if there is no normal circulation, it is easy to get angry.

In order to ensure a constant flow of air (and oxygen), it is necessary to equip forced ventilation.

In the classic Russian bath there is always an outlet - a hole for the movement of air. Ventilation can be arranged in a natural way - in the lower rims of the tab is free, and leave a gap in the door around the perimeter.

However, for a large family or company of friends this may not be enough. It is better to take care of full-fledged forced ventilation. Especially if the operation of the bath is planned year-round.

In the absence of normal air circulation in the bath, a number of unpleasant consequences are possible:

- The lifetime of the structure is reduced, because the wood dries out badly. This is fraught with the rapid development of rotting logs.

- Due to temperature changes, high humidity inside the bath, and especially the steam rooms, bacteria and microbes can multiply. This leads to "stale" smells of various kinds, and to mold, bugs, cockroaches, as well as the rapid rotting of logs. As a result, it will be impossible to enter the bath, not to mention taking water procedures, because it is impossible to influence chemicals on all these things, and there is no other way to get rid of them.

- It is very easy to catch a disease: both a fungus and various kinds of allergic reactions. People with respiratory diseases are especially susceptible to this.

What kind of ventilation device will be correct - let's try to figure it out. The main rule is this: in an hour, the air in the bath should be fully updated three times.How this will be achieved - the owner decides.

The exhaust must not interfere with and violate the temperature regime., that is, the air should not be cooled due to the action of ventilation. Only exhaust air saturated with carbon dioxide can be removed from the bath.. All oxygen should linger in the bath. The appearance of drafts is unacceptable - neither in the steam room, nor in the sink.

The hottest, hottest air should be under the ceiling.

Experts identify three types of ventilation, each of which can provide full air circulation:

- Natural - the movement of air masses occurs due to temperature differences, different pressures and other physical phenomena.

- Mechanical - air moves thanks to fans and extracts.

- Combined - combines elements of the first and second types.

It must be remembered that it is necessary to ventilate not only the steam room, but also all the rooms.

Placement of products on the ceiling is unacceptable. This is fraught with weathering heat in two or three minutes, and then it will take a long time to warm up the bath.

Floor ventilation is also necessary, you need to think about it during the construction phase. Otherwise, floors and floors will rot over several years.Holes for ventilation can be arranged next to the foundation, and in order to avoid the penetration of mice and rats, install metal grids on them.

Valve-valve can be installed under the ceiling, but the lion's share of time it should be closed.

When installing the stove, you need to consider that the floor must be slightly higher than the blower.

You can also install a special exhaust box opposite the door to the ceiling or directly on it. This will require certain skills.

Design

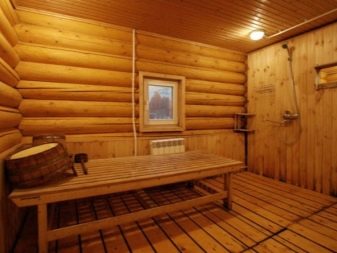

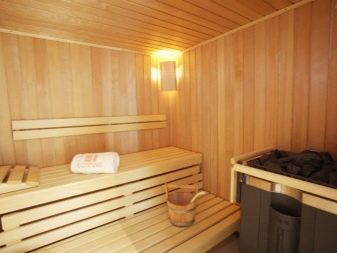

Traditionally, the Russian bath is built as a hut. Inside it is divided into a waiting room and steam room.

In the interior of a Russian-style bath there is a minimum number of decorative items. It has only the most necessary.

- In the steam room - oven, bench or other seating surface, water tank, large deep wooden tub for bathing and brooms.

- In the dressing room - table and chairs (or benches), it is better if they are made of solid wood, perhaps deliberately roughly treated.

The main designer decoration can be carved frames on the windows. Traditionally, the window (or windows) faces the south-west side so that you can see the sunset.

Another element of the decor, which can diversify the design of the bath, is lighting. It is better to choose lamps in the traditional style: carved wooden crates or lampshades harmoniously fit into the atmosphere of the Russian izba. It will look good forged accessories, especially if it is supported by other elements of decor.

It should be remembered that metal parts are permissible everywhere except for a steam room or a sauna - there they are subject to strong heating, you can get burned about them.

It is not necessary to limit the layout of the bath to the waiting room and steam room. It meets the pool, shower, lounge with a pool table or card table. An interesting design solution can be a steam room or a sauna with a removable floor, under which the pool is hidden.

Inside the walls of the bath have a different texture, as upholstered with clapboard or other material. Outside due to logging, the walls are semicircular or, in the case of application for the construction of a square beam, straight.

Inside the boards do not varnish or other chemical composition, they are subjected to thorough grinding.

Tips

For the construction of a wooden bath is best to use conifers.You need to take only the prepared material. If it is rounded logs - they must be the same size and diameter. If the log has curvature or irregularities, it is rejected. And also specimens with dark spots, with an excessively large core, knotty, having cavities where the knots are located, are not to be used for construction.

- The cut of the log should be neat, not “tattered”. Its surface should be yellow (light or dark shade). If the material is not overdried, then when it is hit with an ax butt, it rings.

- In order for the building to be strictly horizontal, the first crown must be grasped. This means that you need to make it perfectly flat in height.

- In the southern regions for the construction of baths is better to take oak wood.

- By tradition, the logs are laid on the foundation with annual rings outside. Because it is this part of them that withstands temperature fluctuations and the negative impact of the environment.

- In the transition to the insulation of the bath it is not necessary to allow one wall to be completely caulked. Otherwise, the log house will warp.

- When erecting a structure from otsilindrovanny logs, they must be treated with antiseptic and fire retardant, as they do not have an outer layer.

- Between each layer of logs must be placed a layer of insulation - tow, moss, or flax. Insulation is fixed on the bracket.

- Each subsequent crown is controlled by level. This is necessary to avoid skewing the structure.

- In order to prevent door and window frames from collapsing, the openings are framed with a casing block. Its gap is 3 percent of the height of the entire opening. The gap is filled with insulation.

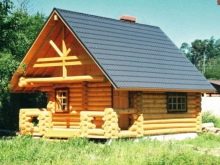

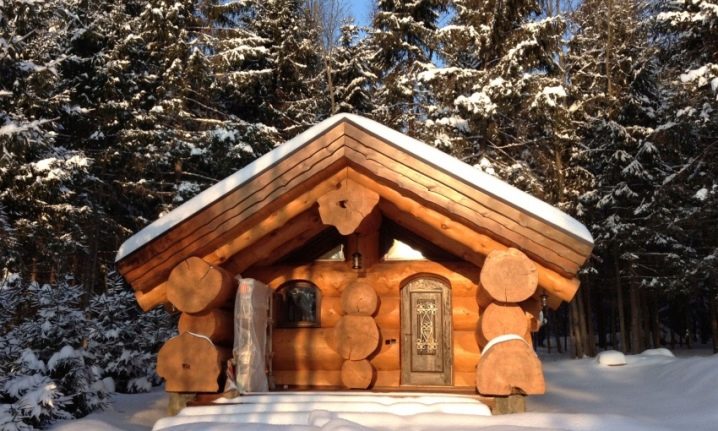

Beautiful examples

Here is a small photo gallery of beautiful design options for baths.

- A bath with a mansard made of a rounded log is installed on a concrete foundation.

- Bath in the old Russian style of logs with a very large diameter.

- Bath with a loft of logs with a small diameter and small columns of wood.

- A two-storey sauna with a brick oven and a massive concrete foundation. The original three-leaved windows on the facade and small balconies make the design extremely attractive.

Review of the bath of the log, see the following video.