Foam blocks bath projects

Currently, many owners of country houses dream of their own bath. But while not everyone knows what material is better to choose for its construction. Today we will talk about bath rooms from foam blocks.

Special features

Today, experts can offer many different projects of foam blocks baths. This material is a foam or lightweight and cellular concrete. He is of different kinds.

Foam concrete

Such a material is made by adding a special frother to the cement mortar. Then the resulting mass should be divided into forms and wait until it hardens. Foam concrete can be made independently at home. It is most often used in the construction of baths.

Aerated concrete

This material is made by mixing cement mortar with a special aluminum powder. After that, you need to wait until the mass is completely hardened. Do not make aerated concrete at home. It is produced with the help of special technical equipment. Such products are produced with exact geometry, so it is sufficiently convenient for the design of baths.

Silicate concrete

This type of building material is created using lime. Silicate concrete is white. It is highly hygroscopic. Despite this, this type of foundation is also often used in the construction of sauna rooms.

According to many people foam concrete is the most reliable material for a bath. Therefore, many people choose it during construction. And although this material has a high hygroscopicity, it can be used in the design of such buildings. However, in the manufacture of its necessarily treated with hydroprotective substances.

The foam block is an artificial material, but it has the same characteristics as natural bases. At the same time, it has a lower, affordable price for everyone.Therefore, at present, most people choose such products for exterior decoration of baths.

Pros and cons of the material

Foam blocks can boast a considerable list of positive qualities. We note the main.

- High level of thermal protection. Even with high temperature fluctuations, foam blocks are not destroyed, they remain in their original form.

- Environmental friendliness. This material is manufactured using safe components, it is completely harmless to human health.

- Resistance to decay and rust. When creating such products, they are pre-treated with special building solutions that counteract the formation of fungus and mold. In addition, these compounds protect the structure from rodents and corrosion.

- Light weight This property greatly simplifies installation work.

- Easy styling. To install the foam block can almost anyone. On some types of such material there is a special lock, which further simplifies the process of laying.

- Affordable price. Unlike natural bases, foam blocks can boast of low cost. Buy it can anyone.

- Fire resistance. House-bath from the foam block is quite resistant to fire. He can counteract him for two hours.

Despite the large list of advantages, foam blocks have certain disadvantages. They must be subjected to additional treatments.

Can be used in the construction of baths only after impregnation with special compounds that counteract moisture. Otherwise, the material will quickly lose its appearance and may collapse.

Although the foam blocks themselves are not notable for their high cost, their installation will be expensive. Between themselves, they can be connected using a special construction adhesive, which is expensive. During the construction of bath structures made of foam blocks, it is imperative that insulation be carried out. This is necessary in order to once again protect the material from the harmful effects of moisture and temperature fluctuations. Otherwise, the blocks may completely collapse.

Subtleties of design

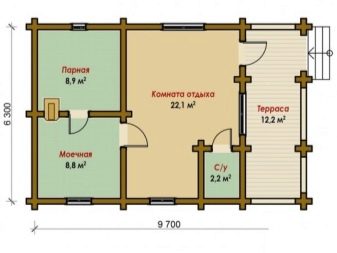

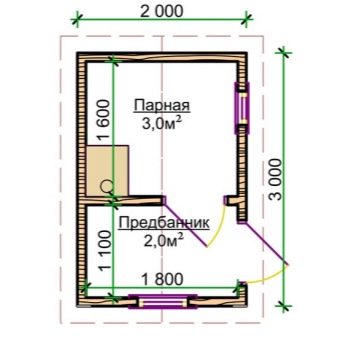

When developing a drawing of a future bath, it is necessary to take into account its size. Only knowing the exact scale of the structure, it is possible to properly design a project of such a room.In addition, additional buildings located near or under the same roof should be taken into account. Currently, you can find a lot of bath projects of size 3x4, 4x4, 5x4, 4x6 m.

This scale is small, so you need to be careful when designing these rooms. The design should simultaneously contain the steam room, washing room, and often the shower room with the dressing room. As a rule, in these cases, most of the space is separated for the steam room. Often in such baths there is a window.

There can even be two openings (in the washroom and steam room). They act as necessary ventilation. Often the projects of such small premises are combined with other residential buildings (garages, guest houses) to make the constructions look more beautiful and solid.

Tambour at the construction of a small bathhouse (for example, 6x4 m) is better not to use, because it will take a lot of space. If you decide to include it in the project, you will have to install a partition and move the door.

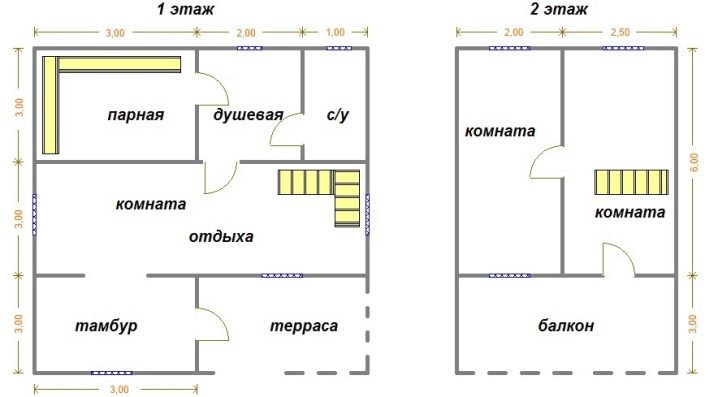

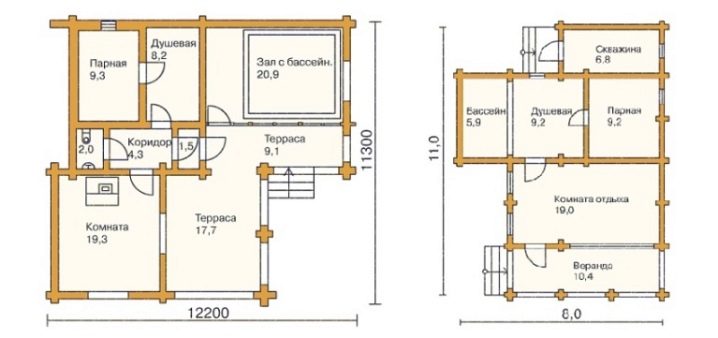

Many experts in this case strongly recommend making such areas outside the room. Today a considerable number of projects for the design of larger baths have also been proposed. Their size is 6x6 m, some designs may be larger (+ 2-3 sq. M).All the necessary rooms (shower room, changing room, washing room, vestibule, steam room) can easily be accommodated in the premises of such an area. In addition, in such buildings are often placed small recreation areas for the owners.

In these types of baths is to install window openings. Their size should correspond to the dimensions of the room itself, since large structures require good ventilation. It is better to place windows in several rooms at once. Often, such large-scale baths do two-story. Moreover, the second tier also make a rather big size. Most often it is diverted to a pool or a large rest room.

On the second floor you need to place at least one window opening as ventilation.

The second floor of such premises is not necessary to additionally warm. Warm steam from the first tier will penetrate into the room, warming it. Due to the uniform distribution of heat, the temperature of the upper zone will not be too high, it will remain optimal. Experts and designers do not recommend combining them from the outside with other buildings when building two-story bath rooms.After all, they will be able to completely spoil the beautiful appearance of the bath, to make the structure too overloaded. Therefore, all other additional facilities should be placed separately.

With swimming pool

Often in the construction of baths from foam blocks they place pools. But it should be remembered that they should be installed only in buildings with a large area. Otherwise the design will be cumbersome and will bring considerable inconvenience. If you are building a two-story building, it is better to have such an element on the second tier.

In a room with a swimming pool there must be at least one window for ventilation.

Today, in the building materials market, any person will be able to see the various options for swimming pools for baths. They can be of very different shapes (round, rectangular, square, semicircular). The choice of a suitable option depends on the internal layout of the building. In this case, we must not forget that the design of such premises with a pool will cost the owners expensive.

With terrace

Often you can find projects baths with a veranda. It can be included in the projects of small structures. According to some experts and designers, the terrace can perfectly fit into any type of decoration, regardless of size.If you build your bath from foam blocks, the veranda can be made from this material. But there are options in which the terraces are made from another base (wood, metal, plastic, decorative stone).

Many say that the structures made of wood look particularly impressive.

Some designers recommend placing small pieces of furniture on the terraces (tables, sofas, chairs). It should be remembered that it is impossible to overload the veranda. Otherwise, it will look ridiculous. If you are equipping a two-storey bath, then such structures should be placed on the upper tier.

Small buildings

Today, experts can offer bath projects of foam blocks with sizes smaller than standard ones. In such rooms often include only washing and steam room. Other zones in such constructions may turn out to be too small or cannot be accommodated at all. Often, the owners build a second floor of the same scale to increase the area of a small bath.

On the upper tier, you can arrange a shower, a rest room, a small pool. If you do not want to build another floor, remember that it is better not to load such structures with verandas and other additional elements. Even in small bath rooms you need to place window openings.For these structures, two small windows will suffice. In small scale baths this will be enough for ventilation.

How to build?

Bath of foam blocks can be made with their own hands, without the help of professionals. Before the construction of the building you need to build a foundation. However, most builders recommend immediately warming it. Then you need to install the walls of the future bath. To do this, the foundation must be laid foam blocks of a certain size.

You can only connect them with a special construction adhesive. When laying these parts should pay special attention to the seams. They should be quite thin. After installing the walls you need to make a rough ceiling of the boards.

It is necessary to make the rafters that are needed for the installation of the ceiling covering.

As a rule, the top of the roof is covered with other material. Most often they are profiled. During construction in the roof should be made holes for ventilation. Then be sure to cover the material from the inside with a special insulating film or hydro-protective composition. After that, you can lay the wiring. However, it does not require special insulation in foam concrete.

Ready examples

Today, anyone can meet many different options for the design of baths from foam blocks. Since the foam itself is not a beautiful finish, it is better to cover it with decorative elements. Many designers offer to decorate the outer surface of the stone.

In the building stores, any buyer will be able to see a rather large selection of various decorative stones.

- Many people choose for their baths similar elements of small size with a rough surface. The color range of such material may be very different. Her choice depends on the personal preferences of the owners. Often these elements trim the entire construction completely.

- The roof for the bath can be made from the usual sheeting. It is also possible to have a terrace. It can also be decorated with decorative stone. According to most people, this type of design is beautiful and interesting.

- Often, you can see projects in which foam concrete baths are finished outside with siding. In this case, the color palette of the material is diverse. Roof and all openings more profitable and practical to draw in dark shades.

- If the project includes a veranda, it can be made from siding in the same color scheme as the room itself. Often with this type of design make a small ladder. It can be covered with a decorative coating of wood.

Allowed to use a small amount of stone during construction.

On how to build a bath of foam blocks with your own hands, you can find out further.