How to make a bench for a bath?

The traditional Russian bath with its unchanged attributes has long been popular with most people. The healing and rejuvenating effect of bath procedures is known to every lover. Undoubtedly, such results are achieved only due to the correct finishing of all zones in the bath, and first of all the steam room. Wood plays an important role, of which the benches are made.

Special features

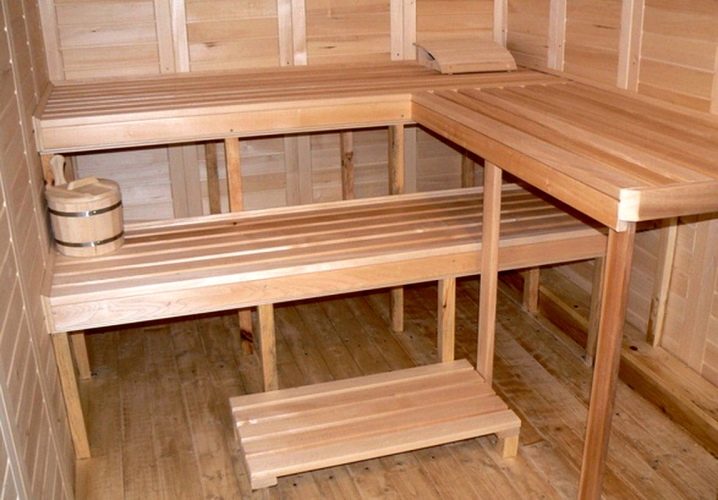

Bench for a bath has many distinctive features. Since the product is used in a room with high humidity, special attention during its production or selection should be given to the material from which it is made, its properties and characteristics. For a compact room, for example, a small country steam room, the model may be angular.

Distinctive features of the wood material used for the production of furniture for baths are high strength, durability, low thermal conductivity. The material should not absorb a large amount of moisture and deform when heated.

For fixing the components of the construction should use special strong and reliable fasteners.

There should be no metal parts on the bench surfaces. To ensure the reliability of the connection of individual parts of the shop in the assembly process, special screws are used. Such constructions are not recommended to be treated with paint and varnish compounds. For processing and impregnating furniture, you need to use special tools, which include only environmentally friendly and safe substances. When heated, such agents do not emit harmful vapors to human health.

It is not recommended to install the structure close to the wall - you should leave a small gap for draining water. In the manufacture of benches, special attention should be paid to the processing of wood: the more carefully polished, the less risk of injury or splinter. All of the above features relate to shops, located directly in the zone of high temperatures and humidity. But, for example, in the locker room you can put quite a normal bench.

Material selection

The choice of wood for a bath is a very important and crucial moment. Not all tree species are suitable for the production of furniture for bath rooms. The material requirements are many: increased density, low thermal conductivity, strength, a small amount of knots, and so on. The best options for the manufacture of shops are oak, birch, linden, poplar. These tree species are characterized by high strength, resistance to moisture and heat.

- Linden. Working with this type of wood is a pleasure. When heated, lime products exude a unique aroma and substances that are beneficial to human health. The disadvantage of this material is that the product darkens after a long stay under the influence of high humidity.

- Larch. Durable and durable wood look. Products made of larch have a long service life. Possess the increased resistance to humidity. Minus - the high cost of the material.

- Maple. Maple has a high strength and is able to withstand moisture for a long time. The surface of the product from the maple board does not crack and does not darken.A distinctive feature of this type of wood is its low thermal conductivity.

- Oak - durable, high strength and reliable material. Oak furniture is distinguished by the natural beauty of natural wood and will even adorn a room such as a bath. It should be noted that oak products have a rather high cost.

- Aspen. The budget version of the material for the manufacture of furniture for baths. Aspen products create a special microclimate in the bath due to the natural structure and its properties. It is worth noting one significant drawback of this wood species - a short service life. Aspen products are very quickly subject to the appearance of rot. Despite this, lime boards are often used by specialists in the manufacture of various pieces of furniture for baths.

- Abashi. The cost of this type of wood is quite high. It should be noted that structures made of such wood are distinguished by durability, strength, resistance to moisture and heat.

- Birch tree It belongs to the heaviest tree species with high density.The presence of certain properties of birch wood gives it special characteristics and durability. With regular temperature differences, the material is not deformed and does not lose its shape.

The best option for the production of furniture for paired branches are hardwood trees. Coniferous species, when heated, emit a large amount of resin, so benches from similar types of wood are not recommended to be used in the bath to avoid burns.

However, in other bath rooms - with lower temperatures - the use of pieces of furniture made of pine and larch is an ideal option. Pine and larch have one special property: under the influence of moisture, these materials become stronger and harder.

Forms and sizes

The shape and size of the benches are completely dependent on the size and purpose of the room. The best option for the pair office is the use of multi-tiered shops. This will allow visitors to select the appropriate air temperature. For the washing compartment and the dressing room use small mobile benches without a back.

Three-tier bench model is most suitable for large steam rooms. The upper shelf has the largest dimensions: its length is about 180 centimeters, width - about 60 centimeters. The distance from the ceiling to the upper tier should not be less than 120 centimeters. This is necessary so that visitors can be placed on the top shelf, both sitting and lying down.

The second and third tier should be located at least one meter away from each other. Lower shelves are smaller.

Bunk designs are used in medium sized couples. It is necessary to install such benches near a blank wall, without windows and hoods, in order to avoid drafts. It is important when installing to maintain a safe distance to the furnace. This is necessary to eliminate the possibility of accidental burns. For convenient lifting on the upper tier, the installation of a ladder is additionally provided.

Step models found application in rooms of the small size. The upper shelf of these designs is wide and long, and the bottom is narrow. The lower shelf is often used as a step for climbing the upper tier.

Single-tier constructions of benches are used in small premises. These models have a mobile design for more convenient movement, repair and maintenance. The location of the benches in the bath rooms should be thought out in advance.

When installing multi-tier structures, the upper tiers should be made removable, and the lower shelves should be made stationary.

Subtleties of manufacture

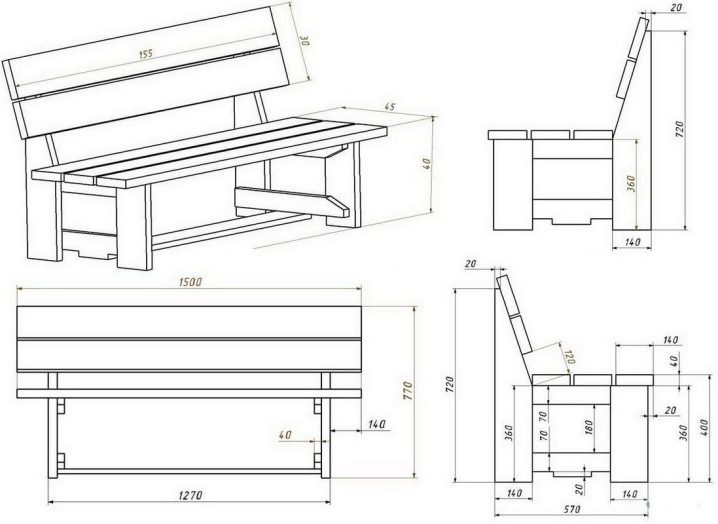

It is possible to make any design of a bench for the bathing room easily and simply with your own hands. To do this, just study the instructions and show a little imagination and ingenuity. Before you start manufacturing, you should consider and decide on the dimensions of the product, choose the material, prepare the tools. The construction of the simplest model of the shop consists of crossbars, cut, seat and legs. Having decided on the parameters and shape of the bench, you can begin to manufacture:

- First you need to prepare all the ingredients of a certain size;

- all prepared parts must be carefully sanded using special emery paper;

- then on each leg you need to make a groove of the right size, on the crossbars, therefore, spikes are made;

- the legs are connected to the crossbeams with a special construction glue and nails made from wooden blanks.

The final step in the manufacture of the bench will be fixing the seat. It is attached to the structure with special screws. To avoid the appearance of rot, self-tapping screws should be slightly deepened. The place of deepening fasteners must be covered with a special putty. That's all - a great shop for a waiting room is ready. The process of making a bench for a steam room is somewhat more complicated and takes a little longer.

In order to slightly simplify and speed up the process, you should prepare a scheme, drawing in advance. After that you need to prepare the necessary materials and tools. Following the drawing, all parts are cut out strictly according to size, and then carefully polished, after which you can proceed directly to the assembly of the structure itself.

First you need to make the frame of the product. Then to the frame you need to attach the prepared, polished slats at a distance of about 1 centimeter. The gap is very important, because, firstly, when interacting with water, wood will slightly expand, and, secondly, it will allow water to flow to the floor. To connect, you can use wooden nails, pins or screws.Designs in several tiers are made in a similar way.

Modern manufacturers of various means for processing and impregnation offer a wide range of diverse compositions. Therefore, in order to extend the life of the structure and protect it from moisture and rot, you can use a special composition based on vegetable oils. Carefully treated and impregnated with such a special tool furniture will be more resistant to various negative influences.

For a waiting room, you can make a shop in a certain style. In this case, you only need to put a little effort, patience and follow the instructions and advice of experienced craftsmen. For example, to make a design in the style of country will not be easy. To do this, it is enough to strictly follow the instructions:

- the design must be pre-treated with a brush on the metal;

- carefully polish the surface of the bench until the natural structural pattern of natural wood appears;

- then a layer of translucent blue is applied on the surface;

- the coating is thoroughly dried, and a second layer of the composition is applied;

- after the coating is completely dry, use a hard sponge to carefully and gently remove the top layer of azure;

- if you are satisfied with the result, you can treat the structure with a colorless varnish.

After thorough drying, the product is completely ready. The design is ideal for use in the waiting room. Stylish and original shop, made in country style, will decorate the room. It should be recalled that the use of such a structure in the steam room is not recommended, since when heated, the varnished surface of the bench will release substances harmful to human health.

Care instructions

Furniture for bathing rooms is not recommended to be coated with paints and varnishes, since under the influence of high temperatures substances harmful to human health will be released. All components of the structure should be carefully polished, while paying special attention to the edges. This will help avoid injuries and splinters. When producing furniture for the steam room, conifers should not be used: under the influence of high temperatures, such wood produces resin.

This is not to say that the resin is harmful to human health, but heated resin may cause a burn if it gets on the skin.

To join parts, it is necessary to give preference to nails made of wood. Regular airing and drying of the bath after a visit will help prevent the occurrence and reproduction of mold and mildew, as well as significantly increase the operational period of furniture and premises. For better ventilation and drying, you need to leave a space between the floor covering and the bottom shelf.

These measures will help prevent the appearance of decay, mold and wood destruction. With some effort and a little imagination and ingenuity, you can make yourself beautiful, durable, high-quality pieces of furniture for the bath and not only.

To learn how to make a bench for a bath with your own hands, see the next video.