Tips on the device ventilation in the bath

The positive effect of regular bath procedures on the body is invaluable. At the same time, a bath is not just healthy, it is also a spiritual pastime, rest and gatherings. However, all the benefits will easily override the difficulties that will certainly appear if there is no effective ventilation in the bath.

Importance of the system

Even in the old days, architects understood that the lack of fresh air in a bath can quickly cause the onset of dampness, mold, spores of fungi, which inevitably leads to the destruction of the structure. That is why, even in ancient times, builders left small cracks between the logs - they contributed to the improvement of air exchange and high-quality ventilation.Nowadays, these primitive technologies have been replaced by modern efficient systems that require the expenditure of effort, time and money for planning and installation.

Some homeowners skip this stage of work, but this is a very big mistake, because after a couple of years, such buildings simply become unusable due to constantly high humidity, and if the bath is built using frame technology, then its service life will be even less. The first sign of the beginning of the destruction will be a musty smell, which will be most noticeable at the time of the kindling of the stove. This will negate any pleasure from the procedure. Being in such a steam room is not only unpleasant, but also quite dangerous to life and health, because carbon monoxide accumulates in the air, fungal spores and molds that provoke the development of dangerous diseases of the bronchopulmonary system.

Effective ventilation in the bath must necessarily meet the basic requirements and principles of safety:

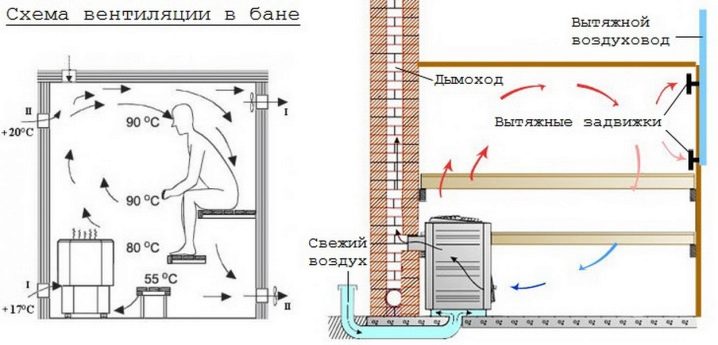

- Proper redistribution of air masses. As is known from the school course of physics, high-temperature air masses rush upward, and cold ones, on the contrary, fall.Therefore, the flow should be directed so that the legs do not freeze, and on the loungers was a comfortable temperature.

- Maintaining a given level of heating in the steam room. Ventilation under no circumstances should not violate the functionality of the steam room, that is, air cooling is unacceptable.

- The use of hydro-resistant materials. For the arrangement of steam rooms and the organization of ventilation in them it is necessary to use materials that are resistant to humidity and elevated temperatures.

The main difficulty in creating an effective air exchange system is that it faces the task of quickly removing hot humid air from all parts of the bath, but it is necessary to prevent the temperature in the hot room from falling; therefore, modern systems usually use an installation allow blowing cold air from the street. The presence of such systems is of fundamental importance for buildings equipped with solid-fuel and gas furnaces, since such schemes require a large amount of oxygen to maintain the combustion process.

How it works?

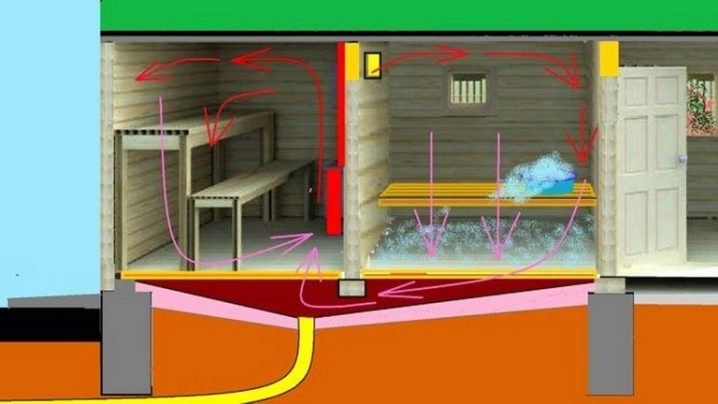

High-quality ventilation in the steam room consists of ventilation and complete drying of all functional areas, as well as walls, floors, attic and the entire under-roof area.Exhaust holes in the attic are carried out in the form of small windows, as well as aerators or spotlights - this largely depends on the type of roof and materials for its manufacture. If the building is insulated, then an additional lattice is mounted, which allows for ventilation between the layer of thermal insulation material and other layers of the roofing pie. It is also installed to ventilate wall structures, which is very important to prevent the formation of condensate in the bath.

But for the best drying of floors, they use a salvo ventilation system or arrange a ventilated floor. Such options should be foreseen at the planning stage of construction work. To do this, lay the rough floor and pour concrete at an angle, then lay the boards in such a way that there are small gaps between them, through which excessive moisture is removed.

It should be noted that absolutely all bath rooms need airing: a steam room, a sink, a rest room, as well as other rooms. In order for the ventilation to be most effective, it is necessary to select in advance such a scheme that will correspond to the peculiarities of the bath and the conditions of its operation.

Experienced builders do not advise to conduct complex ventilation systems and recommend to give preference to the simplest and most familiar techniques.which may be suitable for each case. Here it is 100% true that the simpler the better, and at its cost this option will be much cheaper.

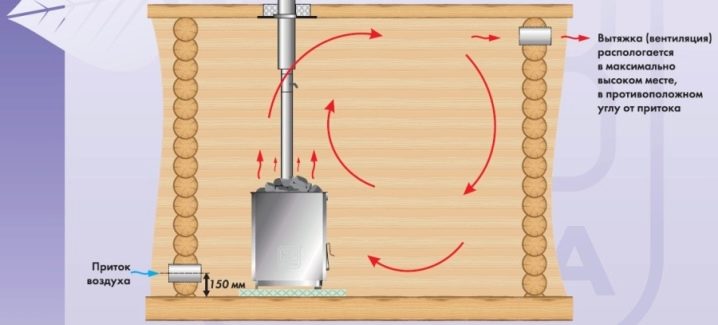

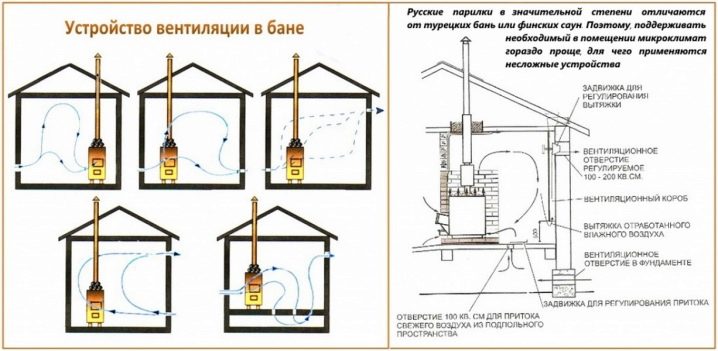

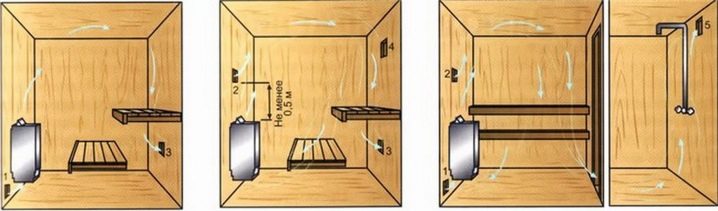

The principle of ventilation is based on the laws of physics. As a rule, 2 windows are cut out in such rooms: one of them is responsible for the intake of fresh outdoor air, and the second allows you to get out of the overheated and humid outside. On how these windows are located in relation to each other, it depends largely on which zone of the complex and with what intensity the air heated from the fire chamber will penetrate, as it moves under the influence of cold air masses coming from the street. This explains the fact that in some baths, instead of a single outlet, two are cut out, which makes it possible to redirect heat flows in the desired direction.

Of fundamental importance are the dimensions of the windows, as well as the availability of the possibility of full or partial adjustment of the lumen.To do this, they fix the special valves, allowing you to cover up any open slots.

It is very important to make the correct calculations of the window, taking into account the size of the room. If the windows are too large, the steam room simply will not be able to warm up to the required temperature and will have to spend more electricity. And if the windows turn out to be too small, then the intensity of the flow will be reduced and a full glut of air with water vapor may occur.

The size and location of the ventilation windows primarily affects the entry and uniform mixing of air, as well as its removal from the overheated room. As for the uneven distribution of temperatures in different areas of the steam room, this phenomenon cannot be completely avoided, but it is possible to ensure that the effect is not noticeable to the visitors of the steam room and washing station and does not cause any discomfort.

Kinds

High-quality ventilation of the bath rooms extends the use of the steam room to 50 years and even more. The variant of the ventilation system in each case is selected individually and is largely determined by the location of the building and the materials that were used in its construction.All the ventilation arrangements that have been developed to date, according to the basic principle of operation, are divided into natural, compulsory, as well as combined.

Natural ventilation assumes that the change of air is carried out due to the unobstructed inflow of flows from the outside, their mixing with air layers of double rooms and the removal of waste through special openings.

Forced The system is based on the use of fans. As a rule, they are installed on the hood and much less frequently on the inflow. Usually, fans are installed not only in the steam room, but also in the washing room, as well as in the rest room.

Combined option as the name implies, includes elements of natural and forced ventilation.

Among the most popular scheme is the most common "strike". It involves the formation of a small hole with an adjustable gate that works on the inflow and is usually located behind or below the furnace.

As additional elements above the stove, vents are being equipped which are controlled by means of a valve and a valve - it is through them that the air enters from the outside through the airways from the subfield.Usually, the opening of such a box remains closed for a certain period, however, as soon as there is a need to reduce the humidity level in the bath, both exhaust valves open. This scheme could be considered ideal if not for some of its limitations. Unfortunately, it is far from suitable in every case, therefore, in some situations, the installation of an exhaust system becomes the preferred ventilation option - for this, a fan is attached to the bottom of the box. If you install it in the air inlet behind the stove, you can get air supply type of ventilation.

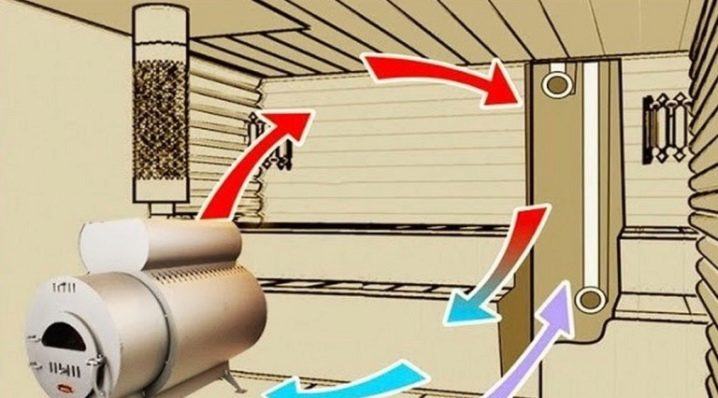

There is another scheme that is often used in steam rooms - with it, humid superheated air is discharged from the room through the upper and lower holes, equipped with valves, and fresh air flows through vents in the floor under the furnace. From the outside of the building, such openings are interconnected by a special ventilation channel. Less often, an exhaust hood is installed in the baths, in which a single channel for the entry of air jets and one for their removal works, and both are equipped at the same height from the floor level: one is located behind the furnace and the other is opposite on the opposite wall.This system requires mandatory installation of forced ventilation.

The most unfortunate way involves the arrangement and flow and exhaust on one side opposite the furnace. In such a system, fresh air, penetrating from the street, looks for a way to the furnace and, during its movement, stumbles upon the soaring feet. This creates a draft, which significantly reduces the level of comfort from being in a steam room. However, this arrangement also occurs quite often, when there is no technical possibility to make holes from different sides of the room.

Materials

The choice of the ventilation system of the bath is largely influenced by the type of structure and the material from which it is made. If the bath is equipped in a separate building, it is quite simple to plan and install the most preferred type of ventilation. But if the bath has a common wall with living rooms, then the ventilation must be taken very carefully to prevent overwetting and rotting of the wall.

The ventilation system in the baths of the second type can only be forced, that is, it must necessarily include a fan, which will contribute to the effective drying of the wall.The ventilation of the bath can be connected with elements of the general house ventilation or independently go outside. The ventilation channels in the frame buildings are settled directly in the walls, and later brought to the roof or even higher. For maximum air flow, install functional airways in the foundation or install a vent valve.

The peculiarity of the buildings according to the frame technique is such that the walls in them are covered with a large number of insulating layers, which completely excludes the possibility of arranging natural ventilation. That is why the best option here is to create a supply and exhaust ventilation system. In order for air exchange to be of the highest quality, two channels are used: one is placed near the floor and is supplemented with a fan, it is used for inflow, and the second is used for exhaust air discharge - it is mounted slightly higher. The openings of such openings are closed with flaps.

In the baths, built of gas and foam blocks, due to the individual characteristics of the material equip galvanized ducts.For this purpose, ready-made pipes are being purchased, some even make them from simple sewer pipes. Some craftsmen create a ventilation channel independently of galvanized leaves, first giving them the necessary configuration and reliably sealing the joints. As a rule, in such buildings, air ducts are laid over the side walls.

The easiest way is to arrange ventilation in a Russian classic log bath. It makes sense to equip a natural exhaust system. If the wood is breathable, gaps are formed between the logs from the floor to the bottom edge, and there are windows in all the rooms of the bath, then additional ventilation structures will not be required. However, often there is the problem of creating optimal proportions between incoming air from the outside and air going outside. In order to prevent the occurrence of drafts and not to “heat the street”, experts recommend that the bath should also be well insulated and equipped with small openings with special valves inside the insulating material that serve to admit and remove streams.

In buildings made of wood often use the method of salvo ventilation, in which all windows and doors are opened at the same time.

Brick buildings do not initially provide for the possibility of air exchange, therefore any natural extract is absolutely excluded here. Because of this, ventilation should be planned at the stage of drawing up a construction project. At the same time, it is important to accurately understand how many bath rooms the bath procedures will take. If the bath is being built for a small family, then you can simply arrange a small inlet near the furnace and an exhaust under the ceiling, and if the building is oriented to a large company, then preference should be given to compulsory options.

How to make yourself?

In order to create comfortable conditions in the steam room and other sauna rooms, it is necessary to properly equip the ventilation system. You can hold it in the bath both on your own and with the help of specialists. This will require a project of works, materials and tools, as well as a little time and effort.

What is needed?

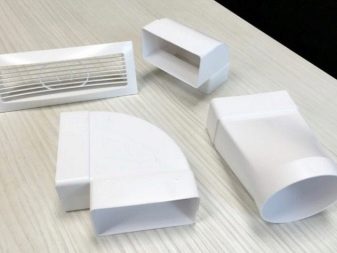

For the installation of ventilation ducts in the bath need training. The work will need components:

- several vent valves;

- gate valve;

- metal grill;

- anti-mosquito net;

- ventilation box;

- corrugated duct;

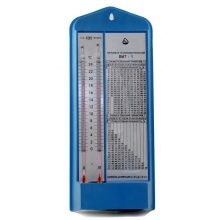

- hygrometer;

- fan;

- thermometer;

- metallized adhesive tape;

- clamp;

- foam assembly;

- sealant;

- fasteners;

- decorative plates for facing inlets and outlets.

By the way, the latter are widely represented in any store in a wide variety of colors and textures, so buying the best option will not be any problem. Vent valve installed on exhaust and air inlets. They may differ in shape as well as in size and material of manufacture. Gate valves are used to quickly open or close openings. They are made of a variety of materials, and some home craftsmen even make them with their own hands, and in terms of strength and fixation, they are not inferior to the store options.

A grid with a net, like in ordinary houses, is necessary in order to create a barrier in the way of insects and rodents, whose presence is extremely undesirable neither at home nor in the bath. Most often they are made of metal, but there are options made of heat-resistant plastic.

The box is usually fixed from the outer wall, but if there is no technical possibility for this, it is simply laid on top. This arrangement is typical for buildings of aerated concrete. Some make the box on their own, using corrugated tubes. Keep in mind that plastic options are not suitable for double rooms, because under the influence of high temperatures, most types of plastic begins to deform.

The fan in the steam room is used both on the supply and exhaust air. Optimally, if in the room it will only work in the general direction. Such a device should be purchased in a heat-resistant version, which is specially made for Finnish saunas and baths. Thermo and hygrometer are used to make the use of the bath as practical as possible. For example, in systems with forced ventilation, thermal sensors are often installed that analyze the actual state of the air and, depending on its performance, open the intake valve or run the hood.

Planning during the construction of the steam room

Optimally, if the entire ventilation system is thought out in advance, even at the design stage of the building.To choose the most suitable design, it is worthwhile to focus on some of the nuances of installation work. The ventilation system, as a rule, is laid during the construction phase of the bath, it is at this time that all the necessary channels are laid and openings are formed into which they will be immured later or to which they will be attached. The adjustable windows themselves are fixed only after the decoration of the complex has been completed.

All ventilation ducts are usually of identical size, while if there is a task to increase the degree of air outflow, then the exhaust window is made slightly larger than the inflow, but in no way the other way round. The formation of an exhaust hole with a diameter lower than that of the inlet is strictly not allowed, because such a design can pose a threat to the life and health of users.

Certainly, flaps and valves should be provided in the system, the latter being considered the most preferable option, since they allow to close the openings with the greatest tightness without the formation of any gaps. Adjustable valves are also important because the air flow depends not only on the size of the window, but also on the season. In winter, when negative temperatures prevail outside the window, cold air masses penetrate the sauna room more intensively, which is why windows open partially in the autumn-winter period, thereby delaying the flow of large amounts of frost air masses.

As for the ventilation window, the size of its cross-section is calculated based on the volume of the steam room. A provision is conventionally adopted, according to which the window area should correspond to 24 cm2 for each cubic meter of space. If the calculations are made with violations and deviations in one direction or another, then the room will be too much ventilated or vice versa.

Even at the design stage of the bath should be remembered that ventilation windows should not be exactly opposite each other at the same level. In this case, the warm air masses will not have normal circulation and will not be able to cover all the required warm-up areas. Holes for exhaust should be located slightly below the ceiling. This is due to the fact that warm air rises. If there is an outlet for superheated air streams in the system, they are effectively brought out,and if the openings are low, the exhaust air can not find a place for breeding and the general microclimate in the room becomes uncomfortable.

Separately, the floor should be ventilated, since with constant contact with water, wooden surfaces lose their performance characteristics after 3-5 years, therefore important requirements are imposed on the ventilated floor:

- To form the possibility of a flow in the basement, it is necessary to build small vents;

- the floor should be laid in such a way that between the boards there would be cracks up to one centimeter in size;

- finishing floor must be laid without fail above the level of finding the blower, which contributes to the fact that the furnace starts to work as an additional hood;

- after taking bath procedures, leave the front door completely open until the floor dries out.

As for the waiting room, it is easiest to equip ventilation here, because there is no direct contact with water in such a room. As a rule, a combined or natural method of ventilation is formed here,when the cool air through the intake channel enters inside, and is removed using the exhaust mechanism of the steam room, which gets under the action of the fan.

In addition, installation of ventilators is allowed here, which may require connection to the electrical current network and exit to the street .. As for the washing room, forced ventilation is usually constructed here, and air exchange is performed using an electric motor.

We organize the hood in the already built bath

Even the ancient architects, far from the laws of physics, invented a method of ventilation, which was based on the creation of natural thrust. Depending on how the bath was heated in a black or white way, it depended on where the heated air was removed. In the first case, the stove did not function during direct soaring, therefore, open windows and doors were used for ventilation. The white scheme provides for the construction of a chimney. As already mentioned, to lay the basic elements of the air exchange system should be at the construction stage, however, there are options when there is a need to equip the hood in an already constructed building.

To do this, it is necessary to pierce the holes directly in the walls and add them with special plugs. One hole makes its way in the area of the stove blowing, and the second - near the ceiling on the opposite side. Of course, this is easiest to do if the bath is built of logs. If the building is built of aerated concrete and especially of brick, then it will be much more problematic to form holes and equip the hood, because during such works the integrity of the walls can be completely different from where it should be, and the risk of destruction of the bath as a whole is quite large. That is why you should not independently do the ventilation in the already operated baths. Entrust these works to professionals who have the necessary skills and special tools. But if you still firmly intend to do all the work yourself, read the walkthrough.

Recommendations

In conclusion, it should be noted once again that the basic principles of creating an effective ventilation system largely depend on the dimensions of the bath and the materials from which they are made. However, in any case, there are a number of requirements that must be met regardless of the specified parameters.Each steam room must have at least two openings. One is used for inflows, the second is for the removal of air masses. If you plan to exhaust in advance in the bath under construction, you will be able to avoid serious problems with the installation of the ventilation system, which can cause violations of the air exchange in the steam zone.

It is absolutely unacceptable that installed ventilation creates the following problems:

- violated the required humidity threshold in the bath complex and temperature conditions;

- inefficiently redistributed the flow of fresh and exhaust air - coolness is allowed only near the floor, and towards the ceiling the degree of heating must necessarily increase so that the shelves maintain a sufficiently high temperature;

- left dangerous to life and health of carbon dioxide.

Review the correct ventilation in the bath, see the following video.