The process of insulating the ceiling in the bath

Any bath needs high-quality insulation of the ceiling, since warm air easily leaves the room if there are no obstacles in front of it. Fortunately, today in the shops you can find a variety of insulation at different prices - to choose the best option is not difficult.

Today we will look in detail at the process of warming the ceiling in the bath.

Special features

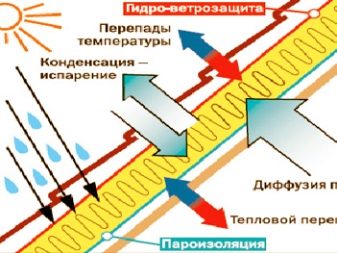

Not only residential buildings, but also baths need good insulation. If we neglect the installation of heat-insulating material, a comfortable temperature will not be maintained in such a structure. Warm air, so necessary in the conditions of the bath, will simply leave the room. However, the problem of leaving warm air is not the main one.Also without insulation on the ceiling in the bath will accumulate disastrous condensate. Because of him, unpleasant drops will fall on people from above, which can be very annoying.

Moisture leaving together with heat will negatively affect ceilings. Under the influence of such external factors, the structures risk to rot and deform. Further repair of the bath will require free time and money.

Today, the market has a large number of manufacturers producing high quality insulation materials. Thanks to this, every consumer will be able to choose suitable insulation materials.

Warming the ceiling in the bath is quite possible to do it yourself. You do not need to be an experienced master or have an appropriate education. The main thing in this case is to strictly follow the instructions and use only high-quality materials.

To insulate the ceiling in the bath, you need to use materials that have the following important characteristics:

- they must be fire-resistant and not flame-proof;

- insulation must be environmentally friendly and absolutely safe for human health;

- The material must be resistant to moisture and moisture, which are unavoidable in the bath.

Fortunately, in modern retail outlets it is quite easy to find materials that meet all the listed requirements. In the bath may be present ceiling with attic space or without it. In both cases, the structure will need reliable insulation. The only difference is that in the absence of an attic space, you will not have so many ways to install thermal insulation material.

It is also worth considering another important feature - if your bath is built of wood, it will literally need the perfect weatherization of the roof. Making mistakes in such a case is disastrous. This can lead to rotting and deformation of floor structures.

Of course, you can fluff the wood with special moisture-proof and anti-fungal impregnations to prolong the life of the material and to hedge in case of improper installation of insulation. However, these tools are not omnipotent. Even if you put them on the ceiling structures, they will break down under the constant effect of steam and the bath will have to be repaired.

Experts say that if you comply with all technologies for the installation of thermal insulation materials, you can avoid serious mistakes. The main thing is not to neglect any of the necessary stages of work. In this case, the result will not disappoint you.

Material selection criteria

Suitable insulation for a Russian bath should be chosen according to the following important criteria:

- The possibility of combining with other building materials. Heat-insulating coating should be combined with other materials, without affecting their specific qualities.

- Resistance to accumulation of condensate. The heat-insulating material in no case should accumulate excess moisture in its structure - this will necessarily have a negative impact on the design of the ceiling, especially if it is made of wood.

- Minimum moisture absorption. Choosing insulation, pay attention to the fact that it has the minimum value of water absorption

- Certificates of quality and safety. When buying a heater for a cold roof in a bath, you must require from the seller all the necessary quality certificates. The material must meet sanitary and fire requirements.

If the material chosen by you for thermal insulation of a bath suits all the listed criteria, then inside the steam room and the dressing room it will be not only warm and cozy, but also safe.

Materials

To date, the market is replete with insulating materials. They are made from different raw materials and have their own distinctive qualities. Let's take a closer look at the most popular and sought-after heaters that are in demand with most homeowners.

Mineral wool

Most often, people choose the good old mineral wool as a heater for baths. Despite the fact that there are many good alternatives to this material on the market, many users continue to buy it.

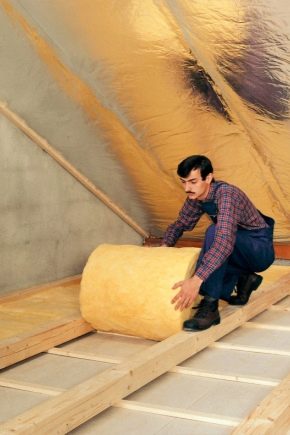

This insulation is sold in rolls, plates and cylinders. For the insulation of the roof and ceiling, roll materials or plates are most often chosen.. They fit easily and quickly. Minvatoy in the cylinders are usually insulated pipe base.

Let's get acquainted with the main advantages of mineral wool, which make it popular:

- This material is characterized by high rates of thermal insulation, which is especially important for a bath.It can be installed in almost any conditions. However, it should be borne in mind that when installing it, other insulators will be required.

- Mineral wool is a waterproof material. High-quality glass and basalt cotton wool contribute to the transmission of steam and do not absorb excess moisture. Due to this quality, mineral wool can be safely used to protect structures against the appearance of moisture.

- Mineral wool has good air exchange. This insulation will promote air circulation. The base will "breathe" and will last much longer.

- Also, this heat-insulating material boasts quite good sound-proofing qualities. Being in the bath, insulated with such a coating, you will not be distracted by extraneous sounds coming from the street.

- Minvat is not afraid of aggressive chemicals. It is not destroyed by the action of acids and alkalis.

- Minvat is a fire-resistant material, which is very important for a bath. Moreover, in contact with fire, this heater does not emit acrid smoke.

- Similar material differs in long service life. High-quality mineral wool can last from 25 to 50 years.

- Many consumers choose mineral wool, as it is environmentally safe.

However, this material has some disadvantages:

- The quality of mineral wool is significantly affected if it absorbs too much water. Under the influence of such a factor, this material may not act as effectively.

- Another disadvantage of mineral wool is considered to be a fairly high level of dusting. In this insulation there are very fragile fibers, and their fragments are sharp and thin. If they get on the skin, they cause severe itching and irritation. It is possible to work with such insulation only in special protective clothing and glasses.

There are several types of mineral wool:

- stone (or basalt);

- slag;

- glass wool.

More affordable is the budget glass wool. It has a special fibrous structure and a yellowish tinge. Such material is made from cullet, borax, sand, soda, limestone and dolomite.

Glass wool has good thermal properties. In addition, it seamlessly transfers strong vibrations.When compressed glass wool reduces its volume by almost 6 times. Glass wool is the softest kind of insulation of all subspecies of mineral wool.

It is recommended to lay only on those bases which will not be subjected to serious loads.

Not so long ago, glass wool in slabs appeared on the market, which is often used to insulate facade foundations. Such material is more durable and reliable. but It should be borne in mind that glass wool is not only the softest, but also the most prickly insulation. It is necessary to work with it very carefully. For this special protective clothing must be worn.

Basalt wool is very popular among craftsmen, as it is durable and keeps its shape.

The similar heater can be made from:

- diabase;

- basalt;

- gabbro.

Components such as dolomite and limestone are also added to these components.

Stone wool is good because it can withstand severe mechanical stress. In addition, this material does not burn or absorb moisture, which is decisive characteristics for the bath.

Often basalt wool is made with a special substrate of foil or fiberglass.To make the material more durable and reliable, it is additionally stitched with special glass threads. Instead, they sometimes use wire.

This material is used a little less than the others, as it absorbs moisture. For this reason, it is better not to use slag wool for warming the sauna ceiling - it will quickly fail and require replacement. In addition, this material is not designed for any load.

Ecowool

Ecowool is another popular insulation that is chosen by many craftsmen.

This material is made from the following raw materials:

- residues from the production of corrugated packaging;

- defective products that appear in the process of issuing printed publications;

- production waste cardboard products.

This common material has the following advantages:

- It is distinguished by a high level of sound insulation. Due to this quality, ecowool is often used in recording studios and stadiums.

- This material is economical. To insulate the ceiling in the bath you will need quite a bit of eco wool.

- As part of this insulation there are no toxic and toxic components.

- Ecowool blows seamlessly into any problem areas.

- This material is seamless, therefore its thermal qualities only strengthen from this.

- Ecowool is inexpensive.

And now we will consider what disadvantages we have with ecowool:

- Over time, the heat insulating ability of ecowool decreases, especially if it is located in a room with high moisture content.

- To install ecowool, you need to use special expensive equipment, which, as a rule, only professional teams have.

- Independent installation of ecowool will not be possible not only because of the requirements for equipment, but also because of the complexity and specificity of the work. Their implementation should be entrusted to professionals.

- From ecowool there is a lot of dust in the installation process. If you use a wet installation option, then it will dry for a long time.

- Ecowool can not boast a sufficient level of rigidity.

In no case can this heater be installed in places close to open sources of combustion. Being close to the flame, ecowool begins to fester.

Penoplex

Penoplex is considered to be the material of a new generation, despite the fact that it was invented 70 years ago.

Its main advantages are:

- high hydrophobic properties;

- low weight, which makes it cheap to transport and easy to install;

- good strength characteristics;

- composition with anti-corrosion components;

- the ability to install penoplex in almost any conditions;

- does not cause allergies;

- does not attract insects and rodents.

Of course, Penplex, like the other heaters, There are its weaknesses, which include:

- susceptibility to burning;

- fear of contact with solvents (when interacting with them, penoplex dissolves);

- high price.

Inside the structure of this insulation there are foam and air. Due to this feature, this material is not subject to corrosion, destruction from time to time and is not afraid of interaction with moisture.

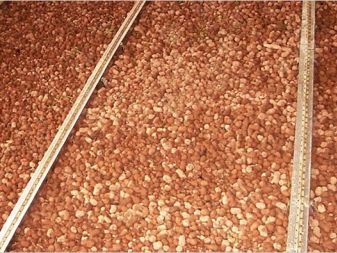

Expanded clay

Expanded clay - a material of natural origin, so it is environmentally friendly. However, this is not the only plus of this heater:

- Expanded clay is inexpensive - everyone can afford it.

- Such insulation will last for many years and will not cause any hassle.

- Expanded clay does not emit toxic and hazardous substances.

- This material has high thermal insulation properties.

- Expanded clay - heat-resistant material. He is not afraid of fire and does not melt at high temperatures.

- This insulation has a low weight, so does not exert loads on the base.

- Not afraid of pests.

- Universal application.

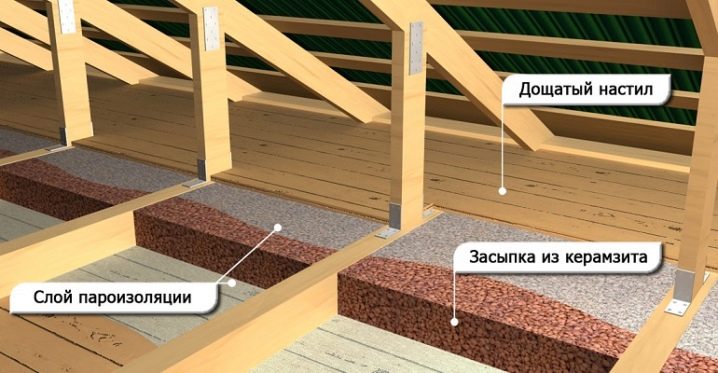

It should be borne in mind that working with such material is not too easy. When laying expanded clay to insulate the ceiling in the bath, it is very important to provide the base with additional vapor and waterproofing.

Clay

The ceiling in the bath can be insulated with clay. But do not think that this process will be very simple and accessible. In pure form, this material is not recommended to be laid.

It has long been combined with:

- sawdust;

- ground straw;

- tree bark;

- sand;

- expanded clay.

Most often, clay is combined with straw, sawdust and sand. It is advisable to use claydite only if you are laying the clay mixture in layers.

Sawdust

If you decide to insulate the ceiling in the bath with sawdust, then you should take into account that such material is the most fire hazardous. In this case, does not help the flame retardant. In addition, sawdust is quite dirty, and in the event of a draft, they gradually scatter throughout the bath.

However, this material is environmentally friendly and completely safe for human health.It does not cause allergies and other similar reactions. Most often sawdust for insulation combined with clay or cement. Sometimes sawdust from above is covered with earth.

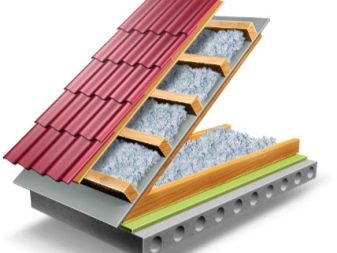

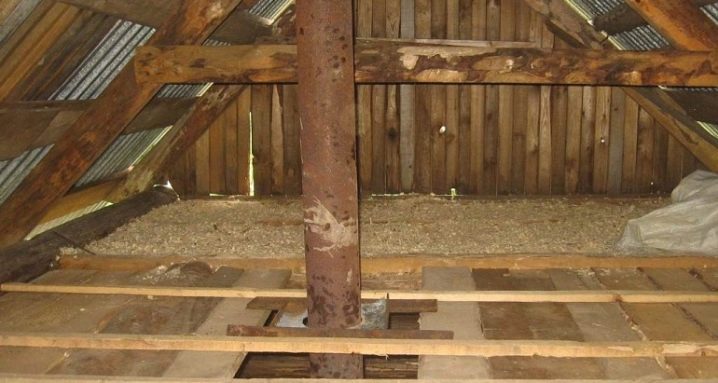

Internal and external work

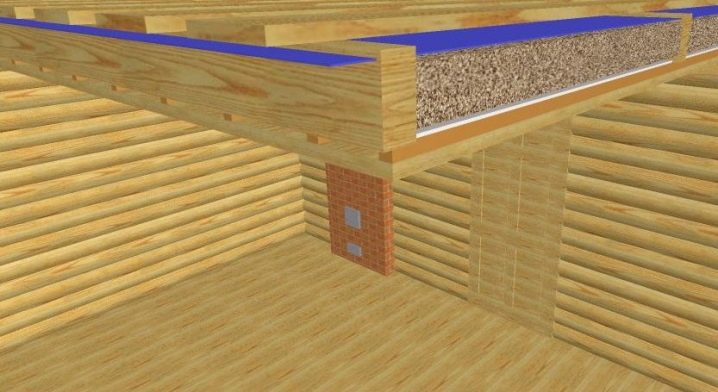

Thermal insulation of the bath is permissible to produce both inside and outside. The second installation option should be addressed if there is no attic in the building. It is best to use insulation in the form of flooring. Podshivny same designs make the ceiling more reliable and strong.

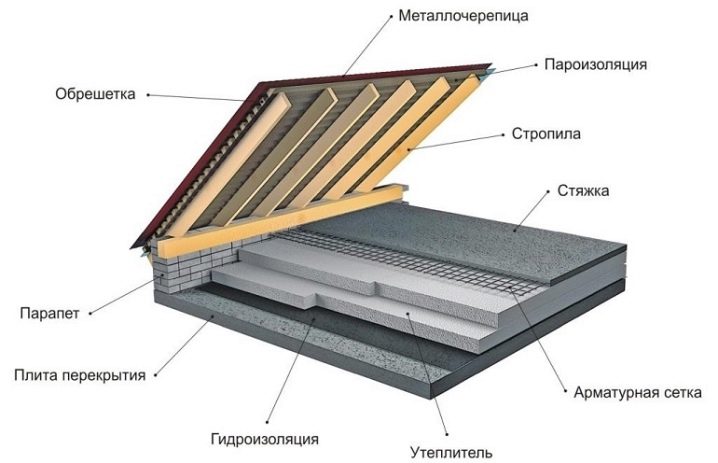

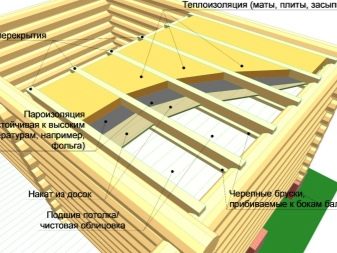

In this case, the boards are attached to the beams from the inside of the room, as well as from the attic. In this case, multilayer insulation materials must be laid between the floorings. If you have a good two-story bath (attic), then the laying of multilayer insulation begins from the bottom floor.

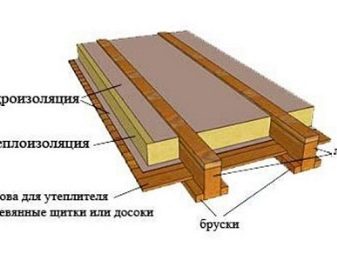

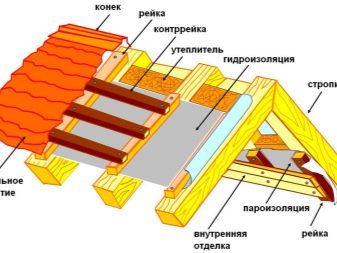

First, a steam insulator is mounted, followed by a heater, waterproofing material and a floor covering on the second floor.

Warming scheme

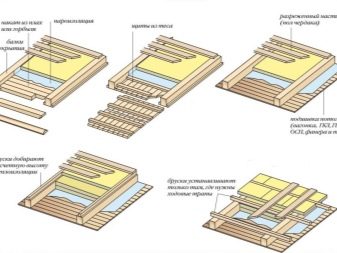

In order to decide on the tactics of conducting thermal insulation works, it is necessary to find out whether the ceiling base itself is a hemmed or flat. In the case of a hemming base, a board is stitched onto the installed support beams (at the bottom). In this case, the bars from the inside are closed and left only in the attic area.

If the overlapping method is flat, the board is fixed on top of the bars. Thus, in the attic flooring is created. The bars themselves remain on the territory of the steam room.

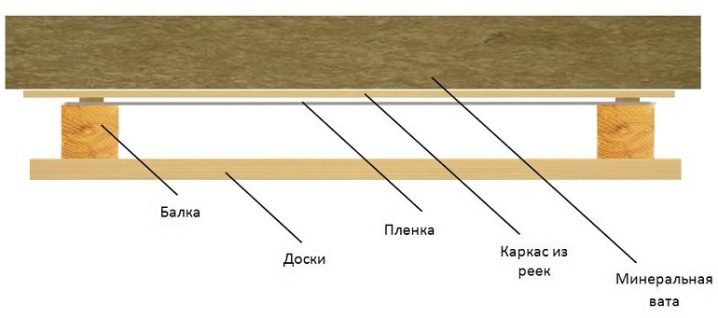

If there is thermal insulation from the inside of the forged ceiling, then the scheme of work will be as follows:

- First, on the floor boards, you need to fix a waterproofing film with perforations that can pass steam;

- further, a frame / lathing of wooden bars is formed, taking into account the pitch for insulation mats;

- next in the installation should be insulation (it should be laid out between the bars);

- This is followed by a waterproofing material, but in the bath it is recommended to use not foil, but foil cloth;

- Further, according to the scheme, there is a rake that needs to be sewn over the bars.

If we are talking about the insulation of the ceiling inside the ceiling, then the layout of the materials will be as follows:

- first on the boards, located on the side of the attic stack vapor barrier;

- then heat insulation is placed on it (if it is mineral wool, then its layer thickness should be about 200-250 mm;

- Next comes a vapor barrier;

- at the end the floor in the attic is covered with boards.

How to warm?

When you have studied the scheme of insulation and the type of construction of the ceiling, you can go directly to its finishing with mineral wool, penoplex, clay or other materials. So that the result did not disappoint you, and the bath became warm and comfortable, you must follow the step-by-step instructions when installing the heater. For a start, it is worthwhile to consider in detail the guide to the insulation of the flooring ceiling.

Finishing such a framework is carried out from the outside.

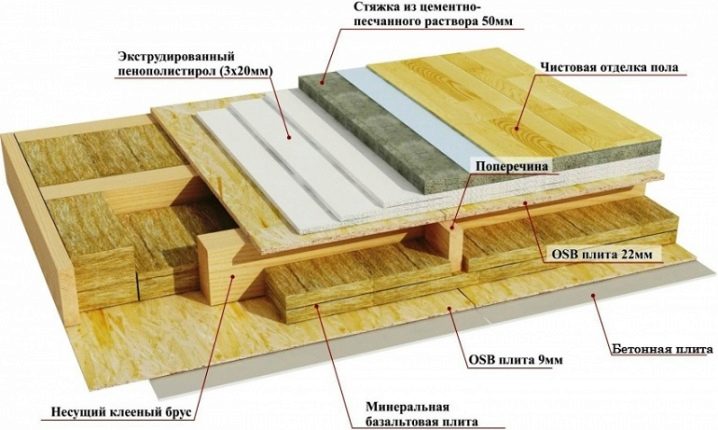

Stages of work:

- First you need to lay paroizoliruyuschy material on the flooring. It can be fixed with a construction stapler or nails.

- On top of the vapor barrier film you need to put the insulation itself. If you are using bulk material, such as expanded clay or sawdust with clay, then a side should be nailed around the perimeter of the base, which will prevent the insulant from spilling.

- The resulting "pie", consisting of several layers, you need to close the waterproofing material.

- As a rule, insulation is pressed against the boards, which were laid in 40-50 cm steps.

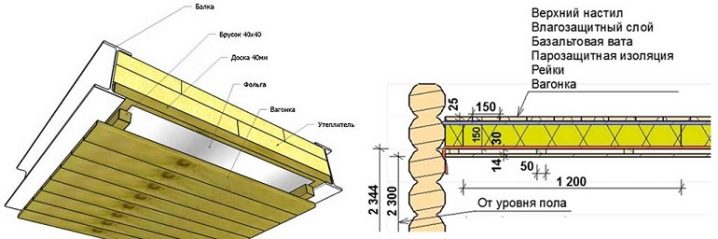

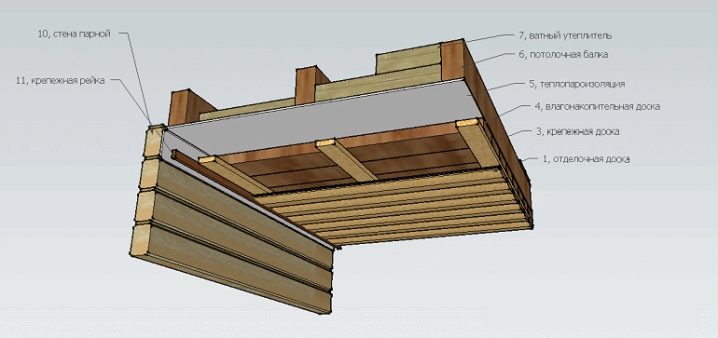

Now it is necessary to consider how to warm the ceiling hem:

- First, on the beams on the ceiling, a vapor barrier is nailed.It is recommended to use canvas in which one of the sides is foil. Vapor barrier should be installed with a small overlap of 10 cm (a similar approach should be done on the walls).

- Next to the beams you need to nail the wall paneling or edging. These materials should be pre-treated with antiseptic agents so that they do not rot.

To make the ceiling more robust and reliable, it is recommended to use tongue-and-groove lumber, which has a groove and a comb.

- Further, from the attic in the space between the beams you need to put insulation. Note that the material must be laid correctly to create a dense layer without gaps and gaps.

- Ensure that the height of the insulation material reaches the top of the beams by 3-5 cm. Thus, the necessary space for ventilation will be formed.

- Then the insulation is covered with a waterproofing film. It must be put with an overlap of 10 cm.

- In conclusion, you should perform the flooring of the boards.

If your ceiling in the bath is panel and consists of separate shields made of planks and bars, then you will have to act differently:

- For 2 beams arranged in parallel, you need to nail the boards with a length of 60 cm. Before this, the tree is very important to process with antiseptic compounds.

- On all sides, the board should be issued by 5 cm. During the docking, the resulting gaps will be closed with insulation.

- Next, on the inside of the panel, you need to fix the vapor barrier material.

- The resulting structures must be put on the crate, fixed at the bottom of the floor beams.

- Insulation resistant to moisture should be installed in the panel joints.

- At the final stage you need to lay a plastic wrap - it will protect the finishing of the attic floor. On the crate at the bottom of the ceiling, you can fill the lining.

Tips

If you decide to independently insulate the ceiling in the bath, then you should take into account that you should be especially careful with the steam room. If the ceiling has at least the slightest flaws, then the heat will definitely leave the room.

When working with vapor barrier films or foil, you should be as careful as possible. These materials can be accidentally torn, which will negatively affect their quality characteristics.

If you want to correctly lay down the material, then it is better to do it a little below the walls, so that you have enough free space for backfilling of bulk materials or laying the same mineral wool. In case it is not possible to do this, small sides should be filled around the perimeter of the ceiling under the roof.

If you decide to insulate the ceiling with a mixture of clay and sawdust, then you need to consider that when using the bath in the warm season, the optimum layer thickness may be 50 mm. If you are going to bathe in it and in the winter, it is better to put a heater with a layer of 150 mm.

If the overlap is built of logs, then from the side of the bath it is necessary to construct a crate. At the same time, it is necessary to cover the logs with vapor barrier, cover with a layer of sand of 20 cm on top and then carry out the insulation in the usual way.

If we are talking about the skull boards, then they can be mounted on the top of the logs.

If you do not want to spend money on the purchase and installation of steam and waterproofing of the ceiling, then you should use a high-tech insulation, which is made on the basis of mineral wool and has a foil layer. With such a coating laying steam and waterproofing is not needed.

Do not use such material as polystyrene for insulation of the ceiling in the bath.despite its cheapness. When heated, it releases toxic substances that have a negative impact on human health.

Do not save on thermal insulation materials and do not look for too cheap copies, unless, of course, the insulation of the ceiling with clay or sawdust is expected. Suspiciously low price may indicate not the best quality insulation.

In the next video you will find an example of insulation of the ceiling in the bath with mineral wool.