Pergolas made of polycarbonate: the pros and cons

Various extensions, summer kitchens, gazebos allow you to make a country plot or a dacha more comfortable and comfortable. The latter are increasingly made of a material resembling glass, but more durable, practical and affordable. It's about polycarbonate.

Special features

Polycarbonate is a modern material for construction, including gazebos. It is a lightweight, soft and flexible material that allows you to create structures of unusual shape, simplifies and reduces the cost of transporting the material and its installation.

Polycarbonate is a type of polyester-based plastic. Features of the composition and production and provide lightness and plasticity of the material, as well as its good thermal insulation qualities.

Visually, the material is similar to glass (transparent, attractive), but it is much lighter and stronger. A polycarbonate sheet withstands a blow from a stone thrown at close range. Objects from it resist even with squally wind and under a layer of snow. Polycarbonate is usually combined with a metal frame.. Among modern projects are increasingly you can see wood, hollow stone and brick as the base. Such an arbor can have various dimensions and design.

The peculiarity of the material is its light transmission ability; therefore, gazebos do not visually block up the site, but rather dissolve into it.

Advantages and disadvantages

The popularity of carbonate due to many advantages.

Here are the most obvious ones:

- plasticity, flexibility of the material, which allows to obtain unusual structures of various shapes, including dome and arched;

- the aesthetic appeal of the finished objects - arbors are obtained as if airy, thin-walled, let in light

- durability and reliability of the design, due to its resistance to moisture, temperature changes and UV rays;

- low weight, which simplifies the delivery of the material to the construction site and its installation - it does not require foundation preparation;

- ease of installation, also related to the fact that the material is easy to cut with a saw, without forming a large amount of dust, sharp particles;

- affordability;

- high light transmission capacity of 80% (the same amount of light passes through the glass), so it will be light and cozy in the gazebo;

- compatibility with other materials - metal frame, wood, brick;

- high heat-insulating qualities (it is not for nothing that greenhouses are built from cellular polycarbonate) make it possible to operate the object from early spring until late autumn, in a closed structure it will be warm and comfortable enough;

- suitable for areas with high humidity, can coexist with trees, shrubs and climbers, without fear of their dew;

- fire resistance - fire safety class of NG material.

The disadvantage of the material is its low resistance to ultraviolet radiation, which is leveled by the application of a special protective coating. However, even the slightest damage to the latter will lead to a rather rapid deformation of the whole structure. It is impossible to restore the damaged layer, you only have to completely change the sheet.

Compared with other materials (wood, brick), polycarbonate has a short lifespan - up to 10 years for products of European quality, 5-7 - for cheaper Chinese counterparts.

Projects

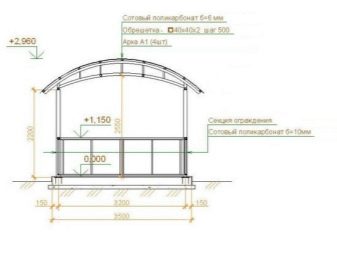

Deciding to use polycarbonate as the basis of the gazebo, you should make a preliminary draft of the structure. At this stage, you need to decide on the dimensions of the object and make a drawing.

Usually (to reduce the amount of waste and simplify installation) when choosing the size of an arbor, they are guided by the size of the carbonate. For each species they are their own: for cellular - 210 by 600 cm, for monolithic - 203 by 305 cm. Dimensions are determined by the number of users: the family gazebo, as well as the one in which large companies gather, should be spacious.

If a small number of users is supposed, for example, it is an arbor for the dacha, for the retired spouses, then, most likely, a small structure is enough.

It should be understood what form the canopy will be, whether it will be an open or more closed structure, and choose the material for its base.

At the design stage should also determine its location in the yard.Usually the building is located near the private house.

If you want to make a more closed structure in which you can relax at night, without fear of dew, as well as in the rain, it is recommended to lift the structure above the ground.

Of course, without a small porch in this case is not enough. Another option is to arrange a gazebo near the barbecue area.

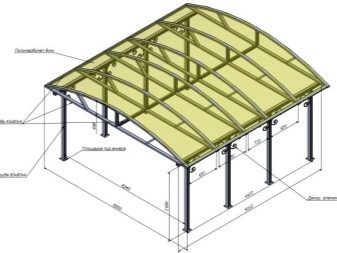

All types of projects can be conditionally attributed to one group or another:

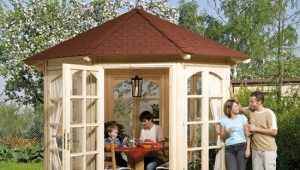

- by type of construction - open and closed (the first usually represent a canopy on the supporting pillars, while the second may have the form of mini-houses with walls, doors and windows);

- by installation method - stationary and mobile, collapsible (the latter is usually - this is the summer house construction, which the owners dismantle for the winter);

- in form - in this criterion it is impossible to list all possible forms, the most common square, rectangular, round and hexagonal structures, as well as arch-type objects, a gazebo - a barrel;

- by degree of difficulty - this parameter directly depends on the functionality of the arbor, the type of construction. A pergola can only be a shed or serve as a summer kitchen, a small extension to the house, etc.

Materials

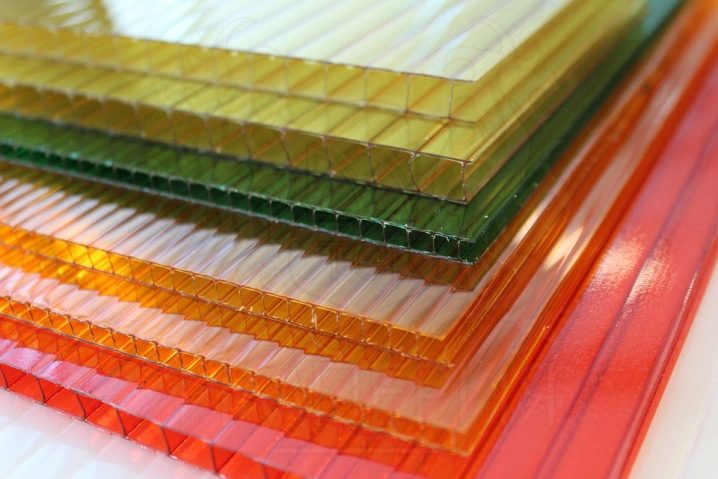

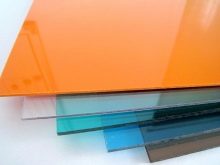

For the construction of arbors can be used one of the types of polycarbonate.

- Monolithic. Visually resembles glass, it is characterized by a high degree of transparency. However, unlike glass, is a more durable and lightweight material. The products are smooth and perforated, transparent and colored. Usually monolithic polycarbonate is used as separate decorative elements, which is associated with its higher cost. However, its strength is enough to build an object only from a monolithic modification of carbonate. The arbor will turn out very beautiful and respectable.

For construction, you should choose sheets with a thickness of at least 4 mm. For the roof, the material thickness can be increased up to 6 mm.

- Cellular. If you look at these sheets from the side, you can see that they consist of 2 or 3 layers, interconnected by original lags. These lags, or lintels, are stiffeners, which ensure the strength of multilayer sheets. The result is a “pie”, resembling a honeycomb. Cellular polycarbonate does not look so impressive, but it has less cost and differs from monolithic even in lower weight. Glazing with this material is made in the same way as monolithic, but at the same time cellular sheets are much cheaper, which affects the cost of the project.As already mentioned, it can consist of 2 or 3 layers. The difference between the products - in their strength and cost (three-layer safer, but more expensive). The thickness of the cellular carbonate for an arbor should be at least 8 mm. Depending on the raw materials used in manufacturing, polycarbonate can be of primary or secondary origin.

For the construction of gazebos (as well as any street object) it is permissible to use only the material of primary production, analogues from recycled materials are not suitable.

In addition to polycarbonate, other materials are used in the construction, in particular, for the manufacture of the base.

Consider the most popular:

- Wood. It is characterized by availability, low weight, special authentic appearance. However, it should be noted that the attractiveness of wooden elements depends on the quality of care for them - it should be regular. Despite the presence of special treatment, wood remains a fire hazardous material, prone to decay. This leads to a shorter lifetime.

- Metal. The use of metal profiles as the basis of the most widespread.It has a higher cost compared to the tree, but less whimsical in care, more durable and durable.

- A rock. Under the stone refers to the framework of concrete, stone (artificial or natural), brick. They are the most durable and durable material, but they are characterized by high weight. This necessitates the creation of a more solid deep foundation, increases the cost and complexity of the process. For an arbor on the basis of a metal frame with a polycarbonate "top" it is better to use as the basis of a square cross section tube.

The use of a profile pipe with a rectangular section is permissible only at points with a small load (for example, along the perimeter of the arbor).

Installation

Because of its lightness, polycarbonate does not require foundation preparation. Enough to dig into the ground metal poles. To do this, dig a well 40 cm deep and place a pillar in it, observing its verticality. After that, half fill the hole with concrete solution, and fill the rest with rubble.

The choice of the foundation depends on the dimensions of the gazebo and the materials used.If only metal profiles and carbonate (possibly wood) are used, then the foundation of the above technology is sufficient.

For objects with heavier surfaces (concrete, stone, brick) erect tape or slab shallow-deeper foundation. The second one is usually applied on unstable moving grounds, as well as when facing the floor. In this case, the base plate becomes a floor on which it is enough to fix the tile.

The next step is to assemble the metal base according to the project. For fastening elements it is better to use welding. - get stronger and more reliable. However, if you plan a collapsible gazebo, the metal elements are fixed with bolts.

If an arched structure or a tent-shaped gazebo is being built, then the corresponding metal elements should be arched. This is done with a pipe bender. Then follows the “glazing” of the finished metal structure. Sheathing polycarbonate sheets produced using screws with thermal washers. The material is applied to the profile, after which the screws are screwed.

When using metal profiles, you can turn them into arcs using a vice. To exclude the deformation of the profile will allow slots in the shelves, made in advance. The distance between the slits is a few centimeters.

Start laying with the roof. Depending on the project, it can be arched, single or gable, and can also be characterized by complexity of the form. On the sheets of polycarbonate should mark up, if necessary - cut them, drill holes for screws.

Neglecting the pre-drilling of holes for screws, as well as the use of nails, causes cracks in the material. When assembling sheets, it is important to ensure that the stiffeners are vertical. Otherwise, moisture will accumulate in the carbonate sheets.

When installing it is important to bear in mind that polycarbonate tends to expand and contract depending on weather conditions. In this regard, a gap of a few millimeters should be left between the fastener heads and the polycarbonate sheet.

The floor in the gazebo made of polycarbonate can be made concrete and revetted.Sometimes a wooden floor is laid, which is installed on the logs. Naturally, when using wood, it should be pre-treated with antiseptics and antipyrineto extend the life of the floors.

Concreting, of course, must be carried out before the construction of the frame and covering it. Under the concrete floor, remove the top vegetative layer of soil, level and compact the soil. Then a gravel layer of 10 cm is laid out, on top of which is a layer of concrete mortar of the same thickness.

If the gazebo lighting is planned, the cables should be laid on the gravel, enclosing them in special protective plastic tubes.

Since all the steps during installation should be phased, when pouring the concrete floor, the procedure will be as follows:

- preparation and marking of the site under the gazebo;

- removing the top layer of soil, leveling and tamping the resulting site;

- falling asleep gravel "pillows";

- installation of support pillars around the perimeter of the site under the gazebo (the number of supports is determined by the dimensions of the object, in any case, one column should be installed in the corners of the structure);

- mounting of horizontal and vertical beams to the supports;

- lining the resulting frame polycarbonate sheets.

The ends of the gazebo should be sealed with a suitable composition. Only the lower parts of the fixed fragments should not be covered with sealant - the resulting gaps are necessary for the removal of moisture.

When building a closed stationary structure window openings should be made of monolithic sheetswith a strong resemblance to glass. For roof glazing, you can choose tinted material options.

Installation of a gazebo made of polycarbonate is not difficult, you can handle it with your own hands and even do the work alone.

It should be borne in mind that in the construction of objects of complex shapes still need an assistant to bend, hold the sheets in a given position, etc.

Tips and tricks

Despite the fact that working with polycarbonate is quite simple, it has its own characteristics, the ignorance of which can complicate the installation process. For example, in the wind, the material begins to behave like a sail, so it is better to first get acquainted with the weather forecast and plan installation on a windless day.

When using cellular carbonate after drilling, sawing chips remain in it, which should be removed immediately after the sheets are installed. Otherwise, they will arrive for a long time in the gazebo, interfering with rest, as well as spoil the appearance of the object.

Drilling cellular polycarbonate should always be between the edges, retreating from the edge of the sheet at least 4 cm.

Usually, a gazebo assumes the presence of benches, it is also more convenient to make them on a metal base, which is welded to the frame at the assembly stage. After the arbor is assembled, the metal base of the bench is sheathed with a lath or eurolining, painted, varnished.

Fireplaces and barbecues should also be collected before the arbor frame was made.. Moreover, if we are talking about heavy stoves and fireplaces, an individual foundation is made for them (slab or ribbon).

It is important to take care of the exterior - convenient paths should be led to the gazebo; lights should be installed around it, select appropriate flower beds, return the lawn removed during construction, or sow a new one.

When choosing furniture and decor for an arbor, it is important to remember that the material from which they are made should be designed for outdoor use.

The stated advantages of having only high quality polycarbonate from a reliable manufacturer. Experts do not recommend to buy products, if its manufacturer specializes in the production of carbonate less than 5-7 years. The trust of consumers is enjoyed by products of such brands as Borax, Polygal, Makrolon.

Before buying, you need to look at the cut sheet. If it has a bluish tint, then the material is covered with a layer that protects against ultraviolet radiation. In the absence of this sign from the purchase should refrain. The surface of the sheet should be smooth, without sagging or blotches.

The latter indicate that the product is based on recycled raw materials, and this affects its carrying capacity and durability.

Often, buyers can not decide - to choose colored or transparent sheets. Reviews allow us to conclude that colored gazebos, although they look more attractive, heat up more than usual. They are not recommended to be used for gazebos located on the hillocks, southern and eastern sides, as well as a roof structure. Interesting projects are obtained, where transparent and colored sheets are combined.In this way, a balance between practicality and aesthetics can be achieved.

Do not choose too heated zones for the gazebo, as well as areas where the wind is always walking. It is impossible to call the neighborhood with large trees, as well as shrubs with a strong branched root system, useful for them. Growing up, the roots of trees can damage the concrete floor or the base of the arbor.

To maintain the attractive appearance of the building will allow proper care. In process of pollution of a surface of an arbor wash water from a hose. When heavily soiled, you can use soapy water, washing it clean. It is forbidden to use detergents containing abrasives, alkali, chlorine, salts. They negatively affect the protective layer of polycarbonate, which makes it resistant to UV light. Do not use metal brushes and scouring sponges.

Beautiful examples

The most simple and practical version of the gazebo is an object of transparent cellular polycarbonate on a metal frame.

However, even such a laconic design can be turned into a cozy place with the help of climbing plants, hanging pots, and textiles.

Arbors with wrought iron elements look more elegant, although the presence of the latter significantly increases the cost of the project.

The budget option - an open gazebo with a canopy on 4 pillars, adjacent to the main building. A wooden grid is used as the outer wall. On it you can put grapes or other climbing plant, making the gazebo more comfortable.

A great option for a country house on a slab foundation. It is better to build such an arbor nearby with a summer kitchen or near the house in the part where the kitchen is located. It is desirable that the latter had a separate exit directly to the gazebo. In addition to the furniture for the meal, you can install garden swings, wicker furniture. As a canopy, you should use special fabrics that have a moisture-resistant impregnation or mesh, collecting them in beautiful folds.

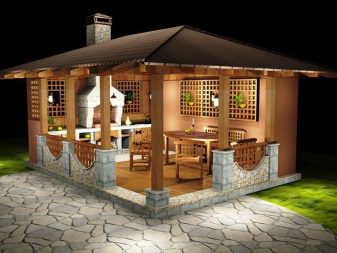

Gazebo can have the appearance of a real house. In this example, it has a stone base, an unusual hexagon shape and a tent-shaped roof. The construction of such an object requires knowledge of applied geometry and the preparation of a more solid foundation.

As a rule, gazebos that are closed and more complicated in design, provide fireplaces or barbecues, turning it into a summer kitchen.This is very convenient because the owners have the opportunity to roast meat even in rainy weather.

So that while the barbecue inside the arbor does not accumulate smoke, you should carefully calculate the thrust. Coming out of the chimney smoke has a very high temperature. To prevent the melting of polycarbonate allows facing of the breathing brick with bricks, as well as the use of special heat-resistant sealant at the joints of the polycarbonate and the elements of the barbecue.

Pavilions made of polycarbonate can be made in any style. Most harmoniously they look in the so-called village styles - country, Russian style, chalets, design in the style of an American ranch. Such objects are characterized by an abundance of greenery and flowers, bright textiles, and simple, exquisite furniture.

The minimalism inherent to the oriental styles and unusual forms are implemented in this project. It is no coincidence that it is located near the reservoir - in such a place you can relax, be alone with yourself. From the decor is quite low benches, small pillows. The bench can be replaced by a low podium.

A small pergola-canopy in the classical style, for which elegant conciseness, simplicity and clarity of forms, the use of expensive natural materials are inherent.The lightness and weightlessness of the design ensures the minimalism of its execution. To avoid coldness allows plastered wall, entwined with ivy, which is adjacent to the gazebo.

The high-tech gazebo is the original structure, usually rectangular in shape with tinted inserts, original multi-stage lighting and modern furniture. An excellent "filling" will be a fireplace, bar counter and high chairs.

Due to its moisture resistance, a polycarbonate gazebo can be located by the pool or pond. In this case, it can be equipped with sun loungers, a hammock, a table for drinks. It is better to revet the floor tiles.

Installation of gazebos made of polycarbonate, see the following video.