The details of the manufacture of arbors from the profile pipe

The summer cottage has long ceased to be the only place for planting vegetables. Many cottage owners seek to arrange the territory in an original way in order to enjoy a good rest in the fresh air. In order to most comfortably spend time in the family circle, as well as to arrange gatherings with friends on the street, many gardeners install gazebos.

Special attention deserve the construction of metal pipes. They are quickly assembled, harmoniously combined with any landscape design, are reliable and convenient to operate.

Main characteristics

The gazebo from the pipework is a modern construction, which can not only serve as a great place to relax, but also become a real decoration of the villa territory.

The framework of such arbors is constructed from a profile pipe, thanks to which they have a number of advantages.

- Low weight.Since the pipes inside have a hollow structure, the structure is much lighter than buildings made of wood and other materials.

- Simple assembly. The design can be both folding, and welded from iron pipes. For many projects, the floor and the foundation casting are not required; therefore, installation work is carried out quickly.

- The possibility of cooking inside the gazebo. Garden arbors of metal are characterized by a high melting point, so they meet the requirements of fire safety. Inside these structures, you can put a barbecue or grill.

- Strength. Metal constructions reliably serve not one ten years. For their repair it is only necessary to periodically paint the frame. This helps to increase the service life and protects the metal from corrosion.

- Affordable price. Profile pipes are inexpensive, and given that they are used only for the manufacture of the frame, this gazebo is a budget option.

As for the drawbacks, the buildings of this material quickly heat up in the sun, they require good attachment during installation. Also, they need to be periodically processed with paint.

Garden designs from a profile pipe are most often equipped with roofs from the massif or a metal tile though the carbonate well is suitable for this purpose. It is considered the cheapest building material, has a translucent appearance. Roofs from carbonate in the hot and sunny days create an excellent shade, so they are chosen for the construction of facilities in open areas.

The roofs of metal, in turn, are very hot, and wooden look massive.

The walls of the building can also be made of various materials, ranging from bricks and wooden planks to metal forging or polycarbonate. The frameworks sheathed by a dense grid on which walls plants are started look beautifully. Compositions of woven grapes or ivy will not only decorate the pergola itself, but also harmoniously fit into any design of the site.

Depending on the wishes of the owner, the gazebo can be both monolithic and portable. The welded structure is considered more practical and reliable, since all the details of its frame are fixed by welding. Folding models consist of four panels connected by mounting bolts and a removable roof,which is fixed with pins.

Portable arbors are recommended to be put on rarely visited summer cottages, where there is no security. In this case, the possibility of parsing the facility will protect it from unauthorized persons.

The choice of design and design

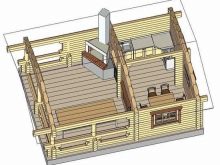

Before starting the installation of a garden gazebo from the pipework, it is necessary to create a project in which the type of construction and its layout on the land plot should be indicated. Today, hexagonal and round arbors are very popular, but if the dimensions of the summer cottages allow, then it is possible to assemble a volumetric construction of a square shape.

Regardless of the appearance, the structure is equipped with a roof consisting of two or more ramps. For country plots intended only for summer holidays, it is recommended collapsible type of gazebos.

If the family has small children, it is best to put a solid monolithic structure.

When developing the design of the structure, it is important not only to provide for its size and shape, but also to take into account the following points:

- interior design and the number of pieces of furniture in the interior;

- availability of additional equipment in the form of a brazier, stove or cauldron;

- the location of the gazebo and the type of its foundation;

- exterior finish and components of the future structure.

Only after all the drawings and calculations of the materials are ready will it be possible to proceed with the construction.

Necessary tools and materials

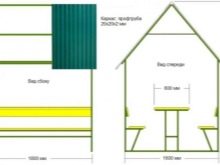

For installation of garden arbors of this type, as a rule, they are used with different diameters and lengths, but more often they prefer products 40 × 20 mm. At the same time, decorative partitions are made of pipes of 20 × 20 mm, and a material with a size of 50 × 50 mm is chosen for strapping.

For the skin of the frame, wood is mainly used, but the arbor can also be decorated with polycarbonate.which is widely used for roofing. Polycarbonate is characterized by excellent performance properties, but on strength it is not inferior to Ondulin and tile. Both materials have a long service life and are resistant to environmental influences. In addition, the tile is represented by a wide range of colors, which allows you to quickly find the right fit for any landscape design of the site.

In addition to the basic building and finishing materials, a primer, a mortar for pouring the foundation and a floorboard will also be needed to create an arbor.The installation is carried out using a simple set of tools consisting of a shovel, a screwdriver, a drill, a grinder, a grinder and a welding machine.

Stages of work

Installation of arbors from proftruby - simple process, so it can be done independently, without the help of experts. To do this, make the necessary calculations, make a project of construction and prepare tools with materials. After that you should make a clear plan of action.

As a rule, the installation of such arbors consists of:

- foundation casting;

- frame assembly;

- plating and decorating.

If the gazebo is mounted on the foundation, then first of all clean the area from debris and remove the fertile layer of the earth to prevent grass from sprouting under construction. Then pour the foundation.

As a base, a traditional strip foundation is good, in which the entire contour of the arbor will be filled with concrete. To do this, around the perimeter of the future structure digs a trench, equip it with formwork, and then fall asleep with a layer of gravel and sand.Concreting can be performed without reinforcement, as the weight of the structure is usually small and does not require additional reinforcement. It is worth paying attention to the fact that the depth of the foundation should exceed the depth of soil freezing by 20 cm.

A good option for the base of the gazebo can be a columnar foundation. It is the cheapest and rational, since for installation it is enough just to drive a few pillars into the ground and fix the structure on them. Supports should be made of the same shaped pipes as the frame. Also, they must be treated with solutions that protect the metal from corrosion. For such a foundation, a pit digs in a similar way, then the supports are fixed, and the embedded stands are welded to them.

If in the project of a gazebo, the foundation is not foreseen, then after cleaning the site, the soil is carefully leveled, eliminating all irregularities and bumps. This is necessary so that the floor can be laid on flat ground. Installation of a stationary structure without foundation is carried out by means of concreting the metal profile. This is the basis of the future structure. Each pipe digs into the ground to a depth of at least 70 cm.

As for the portable folding arbor, it does not attach to the ground. This is a huge plus of such projects, although such structures are unstable.

After everything is decided with the base of the arbor, it will be possible to start assembling its frame.

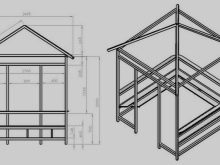

To do this, perform the following steps:

- cut pipes of a certain length and grind their cuts;

- weld the pipes around the perimeter, forming the lower and upper strapping;

- attach additional pipes to strengthen the structure and install decorative crossbars.

Upon completion of work, all metal parts of the frame must be treated with a special primer.

The next stage of installation is plating. First cover the roof. Then fix the side walls and floor. In this case, as a flooring is better to use wooden boards. According to the design features of the arbor, the slope of the main rafters of its roof should be at least 10-15 degrees. To further strengthen the roof, you can put the crate, using the profile pipe size 20 × 20 mm. A step of 40 cm is made between them.

The walls in the garden gazebo are made, as a rule, from small-diameter profiles (30 × 30 mm).They are welded to the supports along the entire perimeter of the structure at a height of 90 cm from the ground. It is important to control the layout of the railing of the building. They must be placed strictly horizontally. All fasteners should be checked level.

One of the central sides of the structure is not sheathed; it will serve as the entrance to the gazebo. The harness is usually carried out with profiles of 30 × 30 mm, it needs to be done under the roof along the entire upper perimeter. If desired, you can further strengthen the bottom of the frame near the ground.

For the installation of the railing, as a rule, about 14 m of pipe is required, and for the lower and upper trim, 15 m each. It is important not to forget to cover all metallic elements with anti-corrosion paint.

As for the flooring, it can be completely filled with concrete solution, forming a high-quality screed. It can also be laid out with wooden boards or paving tiles.

If the last option is chosen, the area intended for the tile should be well aligned. Then the inside of the gazebo is filled with a small layer of sand (10 cm), the level is checked.If there are irregularities and slopes in the center, re-leveling is done, otherwise water will be collected in the central part of the building. Then they lay out the tile, stamp it well and press it tightly, checking the horizontal level. Sticking up the elements should be hammered into the hammer and sprinkled with sand.

After the tile is laid, temporary wooden borders will need to be replaced with concrete ones. It is important to adjust the level of the sandy substrate. This can be done with a sledgehammer. Then the finished floor is re-covered with fine sand, distributing it in such a way that all the gaps between the plates are filled with it.

Excess sand is swept with a broom, the tiles are poured with water from a hose. It is worth using an average jet head, otherwise the sand will not be moistened, but washed.

The final stage is the arrangement of the finished arbor. When the floor is dry, it will be possible to conduct electricity, bring furniture and decorate the walls with a decorative grid or climbing plants. If the roof of the structure is made of polycarbonate, then inside the arbor, you can install the barbecue. Polycarbonate is resistant to fire and does not need increased attention, so open fire will be safe.

It is also necessary to pay attention to the good illumination of the structure, using both traditional lighting devices and their combination with LED strips. Thanks to such a backlight, it will be possible to adjust the light level, making it brighter or dimmer.

Building care

Despite the fact that structures made of shaped tubes have high strength and reliability, they need proper care. This will extend their life.

To maintain the aesthetic appearance of such gazebos, it is necessary to periodically cover with a protective paint and primer with anti-corrosion effect. It is recommended to renew the protective layer at least once every 5 years. In addition, the design should be regularly cleaned from dust and dirt. To do this, it is washed out of hoses and wiped dry with a rag.

To learn how to make a gazebo out of the pipe yourself, see the next video.