Garage swing gates: types of materials and stages of installation

Garage doors are permissible to install various types. Motorists choose from their own preferences, as well as from financial opportunities. Of all the options the most profitable - swing garage doors mechanical. In most cases, they are installed when constructing a separate garage. One of the advantages of this type is that the structure can be assembled on its own.

Special features

Before embarking on a job, it is worth examining how the design is appropriate for your particular case. For convenience, most modern doors are equipped with automatic systems. But these are difficult to build by yourself: you need a drawing, although they are distinguished by their merits compared to the mechanical versions.

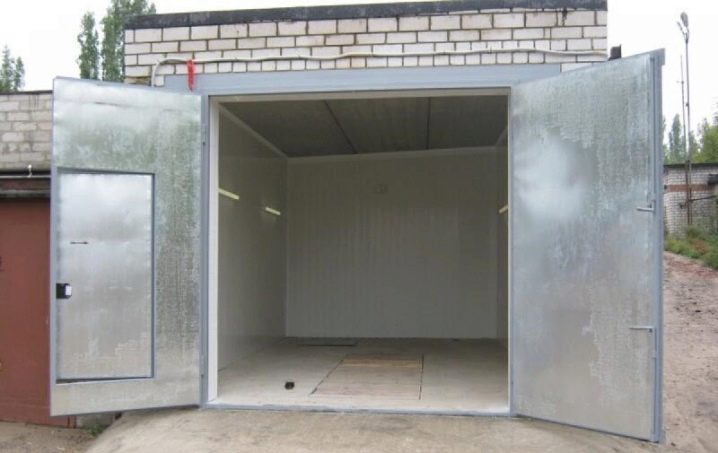

Swing gates conventional device easier to manufacture, are available from simple materials. For example, the most popular gates made of metal. Forged elements or reliable professional sheets are often chosen as the basis for them. The supporting part is made of durable metal.

The main feature of all hinged modifications is wide opening of doors, which requires free space, which is not always possible to achieve in conditions of dense building. Good functioning of the garage door requires enough space for the doors to open fully.

Savings can be achieved by considering all existing options for swing gates: single-leaf, double-wing and the same options with an additional wicket. But at the gate, as a rule, no one saves.

Of the other features worth highlighting:

- wide range of models;

- special coating profile that serves as corrosion protection;

- external attractiveness of designs.

Advantages and disadvantages

Types of swing gates differ depending on the installed or not installed automation. Conventional garage doors have such advantages as:

- constructive simplicity;

- relatively low cost;

- undemanding in operation;

- duration of use

- reliability;

- unlimited choice of solutions and forms.

The disadvantages include the cumbersome design and inconvenience during operation.: it is necessary to ensure that the doors do not accumulate debris, do not contain foreign objects. Cloths form a large sail, so they are not safe to use in windy weather.

Swing gates are often supplied with automatic systems. They are of several types. Simple systems are opened with a conventional button, which is controlled by the driver. Sophisticated systems are equipped with sensors, protection, identification devices.

The main options are:

- drive mechanism with an electromechanical pusher;

- automatic systems with alarm elements;

- devices with a protective owner identification system.

As shortcomings in the process of installation of swing structures can be noted:

- the expenditure of forces on the assembly of the gate, since this requires digging holes to a greater depth;

- installation of pillars, which will take a lot of time;

- purchase of multiple actuators for opening the double-leaf design.

Material

For the construction of the garage doors are more often used steel sheets of different colors. Differences are also allowed in their thickness. It takes into account the characteristics of a particular model. For example, design features and design.

For the case of swing gates, steel or aluminum panels are often selected. The latter are often supplied with polyurethane foam filler. Lightweight construction does not contain a seal. In general, for sale garage doors are:

- metal;

- from a professional flooring;

- wooden;

- sandwich panel;

- steel;

- forged.

If you have decided on the material of manufacture and do the job exactly, prepare everything you need, including the tool.

In the list of necessary electric and simple tools for the construction of garage doors:

- Bulgarian with threaded discs and grinding discs;

- welding unit with electrodes;

- tape measure or building level;

- hammers, shovels, trowels.

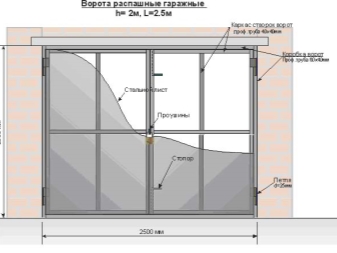

Sizes of materials are standard. For example, the frame is constructed from a 60x40x15 shaped tube. Size for racks, choose based on the size of the finished gate:

- if the weight of the structure is 150 kg, choose a pipe 80x80x4;

- if the weight of the structure is from 150 kg and higher - the pipe is 10x100x5;

- with a weight of a design more than 300 kg - a pipe 140x104x5.

It is important to correctly relate the weight of the web material to the weight of the pillars. At the same time, it is permissible to install brick, concrete and wooden poles as racks.

Locks are allowed to choose mechanical, electromechanical. It may be useful paint, which will need to cover the rack or outer skin. Any material is allowed as a plating. Choose the ones that you can afford.

Automation swing design is and to anything. By the way, you can install it later. The style and technical characteristics of the garage doors you construct are permissible to choose any of your own preferences.

How to make and install?

Self-made swing gates will certainly turn out beautiful, betray the characteristics of the owner and provide one hundred percent durability. The main thing is to follow the sequence of all stages associated with the installation:

- installation of posts for fastening the web and frame;

- installation of the gate itself.

If the work began with the assembly of the structure, consider the time required to secure the mounted racks.Therefore, it is better to start the installation of garage doors with racks. While they will be fixed, while waiting, you can do the welding of the structure.

As indicated above, it is most convenient to use pipes as racks of garage doors. About the dimensional characteristics stated above. It is also permissible to install concrete pillars and wooden beams. The latter should have a cross section of 100x100.

Install the pipe most quickly - drive the rack to a depth of about half a meter. With this method, there is no need to pour concrete. The main thing is to maintain the correct level, to avoid the gate skew. The negative quality of this method is the need for brute force, as well as the availability of suitable soils.

Mounting pillars for gates requires:

- Dig a pit with a depth of 1 meter, diameter - 20 cm, if the cross section of the pipe is 100x100;

- create a sand-rubble cushion under the concrete base, height - 150x200mm. It will not allow the deepening of the rack and will serve as the basis for the concrete;

- install the pillars and align them with a building level.

Only after these stages are completed, concrete is prepared, and a rack is poured.

The assembly of the door leaves will require the following parts:

- iron sheet;

- accessories - guides, hinges, locks;

- corners and profiles.

The general scheme involves marking, assembling and welding the frame. Then proceed to the welding of sheets, and then to install the frame.

Frame

Measure the gate opening. Leave marks on the corner and start cutting out the frame components. Level the design with a leveling device. Start joining the workpieces by welding. Sand the resulting seams. Attach the levers at the corners.

The frame will consist of two halves, for the connection of which an iron profile is required. Align the cut parts, weld and grind.

Next, weld the hinges. One of them is mounted on the sash, and the other on the frame at the top. Attach the workpiece to the mounted slopes of the garage. Special pins will be useful for this job. Weld the ends of the pins, and grind the seams. Paint the gates with paint on the metal.

Tips and tricks

When installing, consider the following nuances:

- Let the concrete pillars stand for about seven days. During this period, do not forget to wet the frozen concrete liquid. This will prevent cracking during slow curing, which means that the foundation will not need to be repaired.

- If not a pipe, but a brick or concrete was used for racks, the depth may be about one meter.

- For high-quality arrangement of the rack is allowed to reinforce. Reinforcement mortgages are displayed in advance. They are needed to secure the loop.

Consider that when cutting a web, a larger amount of one part than the second. The indentation may be approximately twenty millimeters.

- To make it more convenient, it is better to start welding the web and frame from the bottom. To increase the rigidity of the canvas along the edge of the horizontal, weld a corner made of metal.

- For the strength of welds, weld a strip of metal, its thickness should not exceed 8 mm. Attach this strip to the top of the hinge and to the sash.

- Proceed to install the gate only after the assembly. Prime the construction to prevent corrosion.

- If the garage is planned to be warm, you should pay attention to the heat insulating materials. For a garage with a wicket, double-wing insulated doors are best suited.

As a heater foam plastic, assembly foam is more often used. Polyfoam differs in lightweight, is a qualitative insulator.It is cheap and non-flammable, as well as moisture resistant.

Polyurethane foam is also a good heat insulator. It is fireproof and environmentally friendly. Differs negative characteristic - dries in the sun. To eliminate this factor, it is used in conjunction with such additions as polyethylene or other means of protection.

Successful examples and options

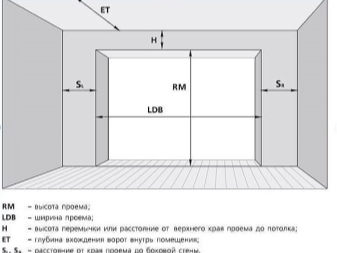

The design of homemade doors can have a high level of comfort and resistance to the penetration of negative external factors into the garage. With independent production, you yourself take into account the dimensions of the opening in height and width.

Swing gates can be a universal system, engineering features allow you to operate models in northern latitudes at low temperatures.

Installation of swing gates is simple. The construction will work for a long time in an uninterrupted mode if high-quality metal canvases, cast hull structures and furniture components are selected.

Terms of installation of garage doors may vary depending on weather conditions. On average, they are:

- production of materials - up to seven days.

- assembly of the gate with the preparation of the opening - about two days.

- Welding and assembly design - will be delayed up to three days.

Do not be afraid of difficulties, self-installation and installation of garage doors - this is an additional skill of craftsmanship.

For information on how to install garage swing gates, see the following video.