How sealant seal joints in concrete?

During the pouring of the concrete floor, special expansion joints are made to avoid cracking the coating. They need to be protected from dust and moisture. Manufacturers produce different tools, so the question arises - how to seal up joints in concrete with a sealant. This topic may be of interest to those who carry out repairs, eliminating cracks in the concrete pavement.

Purpose of expansion joints

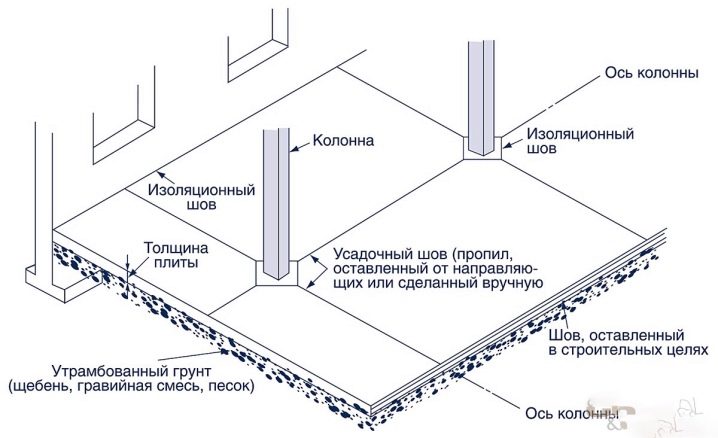

Concrete is not a plastic material, so it can crack due to temperature fluctuations, during shrinkage or due to contact with any structures of the building. To avoid this, make deformation slots.

They may have a different purpose.

- Structural - separate areas, filled in on different days.It is not always possible to fill the floor in the whole room in a day, therefore it dries unevenly, which can lead to cracks in the places of contact between different zones.

- Shrinkage - needed to eliminate the effects of shrinkage of the floor after drying. To do this, make special grooves or use the insert during the fill.

- Insulating - separate the screed from other structures of the building - walls, columns. Different materials may have their own operational features, so additional insulation is carried out between them so that the surface is not affected by excessive pressure in the joining zones.

Classification

Means for sealing seams can be divided into the following groups according to the method of exposure:

- surface - create a protective film that eliminates the contact of concrete with moisture;

- penetrating - act deeper, close the pores from the inside and prevent moisture from penetrating into them.

The composition of sealants designed for concrete, may differ due to existing components.

Among the most common are the following:

- acrylic - suitable for indoor use, give a good grip;

- polyurethane - create a stable protective layer due to the elasticity of the dried means;

- Tiokol - tolerate temperature drops, chemical effects.

Sealants may have other active ingredients - silicone, bitumen, rubber.

Despite the difference in composition, these funds are subject to such requirements as:

- high adhesion not only with concrete, but also with stone, brick, iron, glass;

- the presence of water repellency;

- resistance to sunlight;

- the ability to withstand temperature extremes;

- easy application.

The compositions may be ready to work, then they are called one-component. Some of them need to be pre-mixed - these are two-component sealants.

Means are classified according to a number of other criteria related to their properties:

- type of hardening;

- application method;

- elasticity indicator.

All sealants used for concrete floors comply with the general requirements that apply to them, but may be intended for internal or external work, have a higher adhesion to certain materials or have other individual properties.Therefore, before starting work, you need to find a suitable tool, taking into account the existing conditions.

Acrylic

Acrylic sealant is better suited for interior work, since it is less resistant than others and resistant to temperature and humidity changes. In addition, it is the most environmentally friendly of all types of products. Most often acrylic sealant is a one-component composition. It can be used during repair to seal gaps in concrete and where individual areas do not require serious protection. It has a good vapor permeability.

The product is easily diluted with water and poured into the hole; a smooth surface forms on top. Until the final setting, the sealant is easy to clean. It is well leveled, so it can be used to align and smooth the joints between the walls and the floor or ceiling.

Since there are no solvents in the composition, after hardening the surface can be painted or varnished. Among the well-known manufacturers are Stiz-A, Tektor and Ekorum.

Polyurethane

These tools are waterproof, they are used as a seam sealant to ensure strength and increase the life of the screed.When applied, the tool will not flow over the surface, but will immediately set, therefore a construction syringe is used to work with it. Due to its resistance to constant exposure to moisture and the ability to withstand significant temperature differences, such sealants can be used on the street to work with the facades of houses and foundations. After application and curing, the surface may be subject to high mechanical loads. Polyurethane means well maintain contact with oils, acids, alkalis. The compositions can be one-component and two-component, but the latter are demanding compliance with the dosage, they should be prepared exactly according to the instructions.

Among the manufacturers of polyurethane sealant stands out the company Rustil, Soudal, Sazilast.

Silicone

Such agents give better protection against moisture. They are of two types - sour and neutral, the first option for concrete is not suitable. During contact with the acidic sealant, the cement stone emits soluble salts, which degrade the surface quality and may lead to corrosion in the future, so you need to choose a neutral composition.Many silicone agents have antifungal components and can be used in places of constant exposure to aggressive substances, for example, to seal the septic tank from the inside to protect the joints of concrete rings.

When working, pre-priming of the surface is obligatory, since without this the silicone agent will not give good adhesion. They do not contain solvents, differ in elasticity, resistance to various influences. The material has dielectric properties. Famous manufacturers are the company "Avtogermesil" and "Tektor".

Thiokol

The basis of this group of sealants are polysulfides, characterized by elasticity, high resistance to chemical components. Most sealants of this type are two-part. After mixing, they turn into elastic rubber that does not shrink. They are suitable for use in conditions of temperature drop and contact with aggressive media. They protect the coating from dynamic and static deformations.

The manufacturer of thiokol sealants is Sazilast.

Silane-modified

They are usually single-component, solvent free, and therefore suitable for protecting wet surfaces. Moreover, they can maintain their properties even under water. Such tools are flexible and well bonded to the surface. After completion of the work, they can be painted. They are compatible with bitumen. Almost immediately after application, sealants give maximum adhesion. They are more expensive than other types of sealants.

Popular manufacturers include Viladex, Sealant.

Cost of

The most affordable are acrylic compositions, the prices of which start from 150 rubles per 1 kg. Two-component polyurethane cost from 172 rubles per 1 kg. Tiokol means cost from 192 rubles per 1 kg. Silane-modified sealants are available in tubes, the price of one - from 695 rubles.

The specific cost depends on the manufacturer and the store in which the product is sold.

Sealing

First you need to prepare the surface for work, because the adhesion strength depends on it. The concrete coating must be dry, clean, oil stains, traces of foreign substances, corrosion are not allowed.If the gap is narrow, it is pre-expanded, and also treated with primer and primer, although for some types of sealants it is not needed. After that, you can proceed to sealing. One-component preparations are not required, they can be applied immediately. Two-component sealants should be mixed according to the enclosed instructions, where permissible proportions are indicated. You can add during the preparation of gasoline or white alcohol, if you want to increase the fluidity of the solution.

A certain ratio is observed: 80 grams of solvent per 1 kg of sealant. For operation, the cylinder with the substance is inserted into the building gun, or a suitable application tool is selected - a brush or a spatula. It is necessary to evenly fill the gap along the entire length of the seam, so that there are no voids and gaps. After applying the composition is leveled with a spatula, previously soaked in soapy water. The excess should be removed immediately so that they do not harden. When drawing two layers they need to be leveled in opposite directions.

The rate of hardening depends on the composition of the product. Acrylic sealants seize faster than others - in 15 minutes, within an hour after their application can be removed, with the full polymerization takes 2 weeks.Polyurethane products form a film in 1–2 hours, the total curing time is 7 hours per 1 mm of the finished layer. Calculations need to be done on the basis of thickness. Thiocol sealants harden for several hours, but when applied with a thick layer, the process can take about a day.

During and after work, the room must be ventilated.

See how to seal the expansion joint in the concrete floor in the next video.