Heat-resistant drywall for fireplaces

Fireplaces are operated under the constant influence of high temperatures, which can lead to a fire. To reduce the likelihood of such an occurrence can be through various types of cladding. Among all this diversity should be distinguished heat-resistant drywall for the fireplace.

Material Features

On the market today there are several types of such a product, which are distinguished by their technical properties. Fireproof drywall differs from other analogues by a number of properties:

- Visually, it is externally covered with pink cardboard, which testifies to its specific purpose.

- The composition of drywall includes a special layer, which contains clay and reinforcing fiberglass. This can significantly increase the resistance to temperature and reduce the likelihood of destruction.

- The structure of the leaf core also includes crystallized water.which is an additional obstacle to the spread of fire. The amount of this component in some cases can reach 20% of the total mass.

When buying heat-resistant drywall, it is advisable to check all certificates for this product, confirming its belonging to this group of products. All the specific characteristics of the material are already described in detail, which will make it possible to select only a high-quality and reliable substance.

Heat-resistant drywall consists of several main components:

- Two-water gypsum, filament yarns and several types of organic substances. The percentage of these components in the structure reaches 93%.

- Cardboard coating (6%).

- Moisture. The amount of this product often does not exceed 1%.

Specifications

Heat-resistant drywall is an indispensable material for the construction of fireplaces and other similar structures, as well as resists fire. In comparison with other types of this substance, it is indestructible under the influence of temperature of about 45 minutes (moisture-resistant types of sheets can withstand only about 20 minutes).

The material is marketed with standard surface dimensions:

- 2.5 * 1.2 m (area);

- sheet thickness is standard and is 12.5 mm.

The weight of a separate structure is approximately 25 kg. It should be noted that the heat-resistant drywall also "breathes" as well as its counterparts, which allows it to be used instead. On the market there is a material with a thin and unfinished edge, which plays an important role in direct installation. If you acquire substances of the latter type, then you will have to cut a part of the end by yourself about one third of the total thickness. Due to the unique features, a drywall sheet costs about 2 times more than its simple counterpart.

Scope of use

The universality of fire-resistant drywall makes it a very popular product. This substance is used to solve several specific types of tasks:

- Arrangement of ventilation ducts. It is not used for the formation of chimneys, as it is not able to withstand prolonged temperature loads.

- Sheathing almost all types of baths (Russian, Turkish and Finnish).

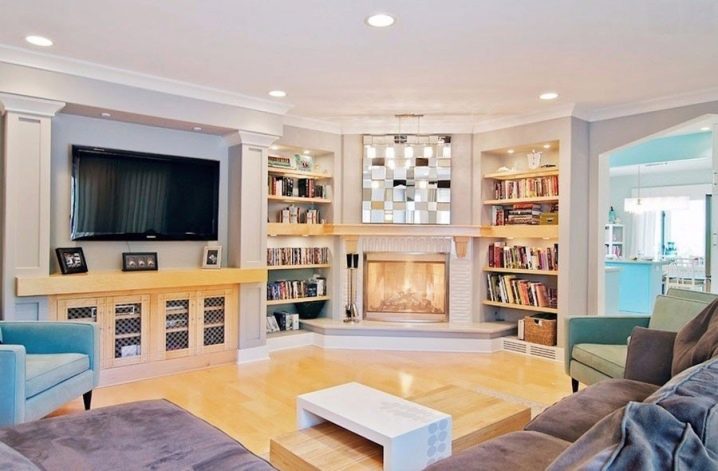

- Facing fireplaces.Often drywall here acts as an intermediary between the hot surface of the frame and the main wall.

- Internal lining of light industry shops, etc.

As already mentioned, drywall can be used to form the framework of fireplaces, but it should take into account a few nuances:

- It is not advisable to veneer fireplaces with the help of this material designs, which are made of stone, refractory bricks, etc. These substances themselves are excellent insulators. Plasterboard cladding is often made only fireplaces made of steel or cast iron to further protect them and give them a certain decorative look.

- This material is desirable to use in cases where the furnace is installed directly in a niche wall.

- When covering fireplaces between drywall and its walls, it is imperative to have special heat insulators that will reduce the effect of temperature on the product structure.

It should be understood that heat-resistant drywall is not a brick and it is not a reliable protector. It only prevents the possibility of fire for sometime, but does not exclude it with prolonged exposure to high temperature.

Some nuances of editing

Finishing fireplaces drywall is made according to a special technology, which involves mounting sheets on a special frame. Please note that such operations are carried out only with the help of metal constructions, and the use of wood or other highly inflammable substances is not allowed.

Fastening of sheets is carried out on special self-tapping screws, whose pitch is approximately 12 cm. All joints of elements are additionally covered with metal corners. If necessary, various heat insulators are placed inside the structure. It should be noted that the use of polystyrene for such purposes is strictly prohibited, since it ignites very quickly and emits harmful substances.

When installing fire-resistant sheets of plasterboard, only heat-resistant binders (glue, sealant, etc.) are used. This allows you to get a solid and reliable system that will serve for a long time and without failures.

Exterior finish

Frames of such sheets are often located in residential buildings, which requires additional decoration.When finishing the fireplace, drywall can be covered with special decorative materials, such as fire-resistant tiles. The technology of its application to such a surface is practically no different from pasting to another material.

To do this, use a special heat-resistant glue, with which individual tiles are fixed on the surface of the fireplace. Thus, by combining these two materials, you can create a very beautiful decor.

When buying heat-resistant drywall should be preferred only to quality products. On the market today, one of the most popular products are several manufacturers:

- LAFARGE.

- Knuf.

- Velma and many others.

Heat-resistant plasterboard is a universal solution for fireplaces, which are created not only as a decorative element, but also are heating systems.