Ceramic tile for fireplaces

Fireplace is an attribute of many houses, allowing you to create an atmosphere of warmth and comfort in them. Today, ceramic tiles are increasingly being used as the main material for decorative finishes. They select it not only according to technical parameters, but also to the external design, which makes it possible to give the design originality.

Ceramic properties

The facing tile is made of various materials, but only heat-resistant products are suitable for finishing stoves and fireplaces. They are able to withstand high temperatures without disturbing their structure. In addition to the previously mentioned parameter, ceramic tile for fireplaces has a number of properties characteristic of these types of materials:

- Water absorption. Ceramics for furnaces should absorb a minimum of moisture, since water can simply tear it apart when heated. Therefore, high-quality tiles used for such purposes are characterized by a water absorption coefficient of not more than 3%.

- Heat accumulation. This indicator is rather difficult to measure, since it depends not only on the thickness of the tile, but also on its internal structure and density. Therefore, buying this product, you should first of all consider this value and the conditions of its operation. The thickness of heat-resistant materials should be at least 8 mm, which contributes to the effective accumulation of heat.

- Environmental friendliness. The high-quality heat-resistant tile does not emit toxic substances when heated into the air. Special certificates of quality should testify to this.

Tile classification

Ceramic tile for finishing fireplaces has many characteristics, which are the basis for its division into the following types:

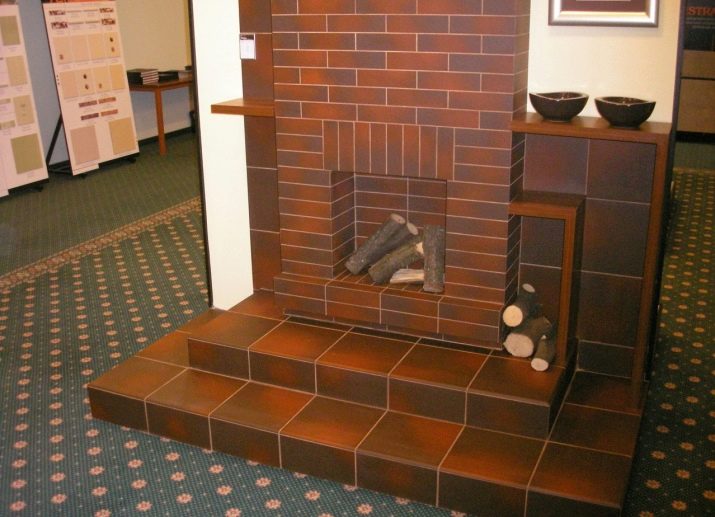

- Terracotta. Such a cladding material is obtained from dense clays that can be pressed. The outer side of the tile is rough, and the structure itself imitates materials such as natural stone or brick. Terracotta is a high-quality, durable and fire-resistant product with good heat transfer performance.

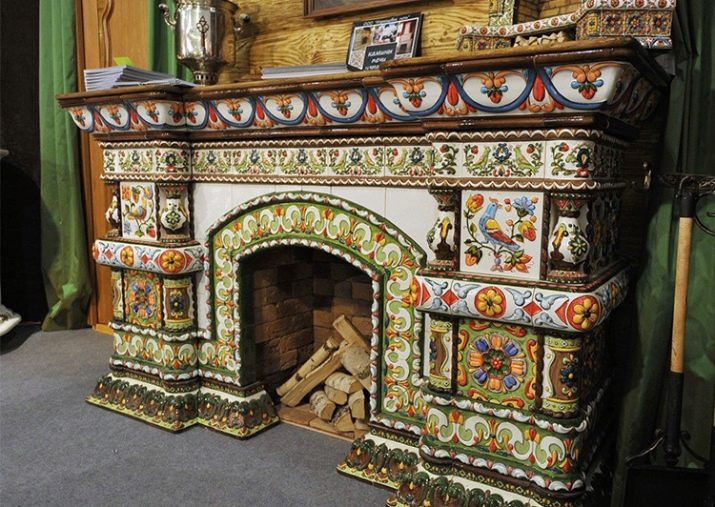

- Majolica. Such a product is obtained by firing clay.Externally, this tile is covered with a layer of glaze with a variety of decorative patterns. It should be noted that the painting at the same time applied by hand, so the cost of this product is much higher than that of its other counterparts.

- Clinker tiles. The process of its manufacture involves mixing chamotte powder and slate clay. Also in the composition can be added other products that allow you to slightly change the properties of the material. Clinker differs from the previous two types of higher density, so it absorbs much less moisture and is resistant to frost. The optimal environment for the use of clinker tiles are constant temperature changes.

- Tiles. Tiled tile in its structure resembles a box, and externally is smooth and embossed. To protect the product is covered with several layers of glaze or enamel. Tiles are handmade materials, which also affects its value. It should be noted that tiled substances are completely safe for humans and have excellent heat transfer performance.

- Chamotte tile is a product of the combination of natural clay and stone flour, which mix and fry at temperatures of about 1300 degrees.This product practically does not crack, it can withstand high static loads and therefore it is possible to revet with it not only the fireplace, but also the stove.

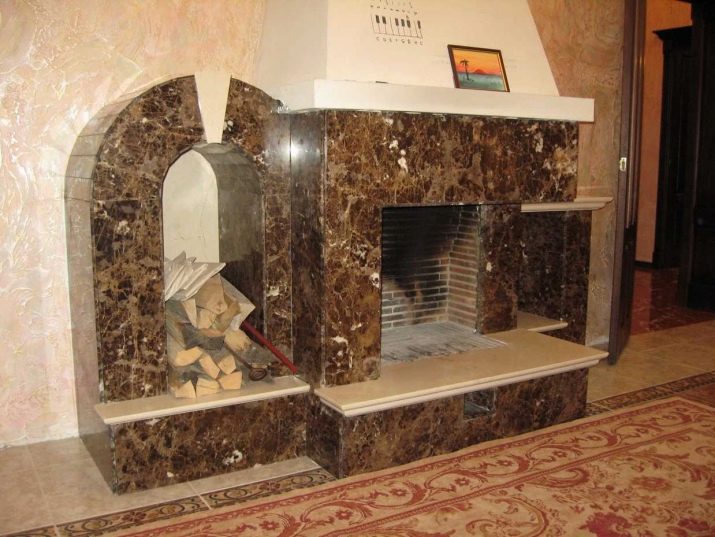

- Porcelain tile is a durable material, which is obtained from quartz sand, clay, marble chips and oxides of various metals. This type of tile is resistant not only to high temperatures, but also to low temperatures, which makes it possible to use it outside.

Cladding technology

The process of external decoration of the fireplace is carried out in several successive stages:

- Surface preparation. This process involves cleaning the brickwork from the old finish, removing dust and dirt. Also at this stage, surface plastering is performed with special solutions based on conventional cement. For additional reinforcement, a fiberglass mesh with small cells can be attached to the frame.

- At the second stage, wall cladding is performed. For this purpose, an adhesive solution is initially prepared according to the recommendations of the manufacturer. Fastening the tiles start from the bottom row, which is the main one. Glue is applied to the surface of the cladding material, and not on the fireplace itself.Then the tile is simply applied to the base and leveled.

The technology of pasting is no different from the standard application of other similar substances. Only here special heat-resistant grouting is used, and not the usual formulations.

Selecting ceramic tiles for the fireplace, you need to first assess its technical properties, and only then give preference to any particular design or type.