Brick Corner Fireplaces

Today, brick corner fireplaces are considered to be among the most practical and versatile heating facilities. They allow you to heat the room, give the room a more elegant look. Moreover, some types of such fireplaces are designed so that they can be used to cook food. Let's find out what key features these structures have and how to create them.

Specifics

Such heating structures can have a different design, so that they can perfectly complement any interior. Such fireplaces are relatively simple to build. Their device allows you to heat one or several rooms at once. The timing of such a fireplace can be different: this work can be done immediately while building a house or during repairs; also, the construction of the heater is allowed after the completion of all major works. But despite this, experts recommend laying out the fireplace before installing the flooring,so then again not to engage in the arrangement of the floor.

An important advantage of such structures is their compactness. As they are being erected in a corner, most of the usable area of the room remains free. This allows you to furnish the room at any discretion. In addition, there is no need to think through the installation of a complex chimney system (as, for example, in the case of fireplaces located in the center of the room). The chimney can be built on top of the whole structure, which saves time and resources.

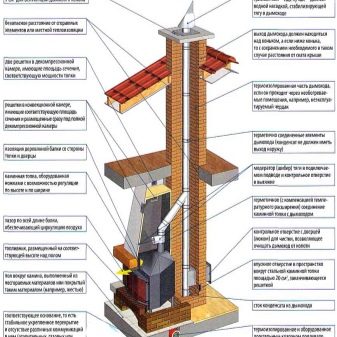

Arrangement of a chimney pipe

High-quality construction of the corner fireplace can not be done without taking into account the dimensions of the chimney. This part of the heating structure is considered to be one of the most important, because it provides the output of carbon dioxide formed during combustion. In fact, the safety of the inhabitants of a house depends on this element.

When building a chimney pipe, special attention should be paid to its dimensions. They should be selected on the basis of the power of the entire heater: the higher it is, the more smoke is emitted, which means that the pipe should be wider. If the pipe diameter is insufficient, smoke will accumulate and leak into the house.This is fraught with tragic consequences.

Another important fact is that the chimney will be very hot. Because of this, when building it, you need to use a special type of brick.

Features of the cap

The base part is called the element of the fireplace installation, located under the firebox. It is a kind of pedestal on which the whole structure is located. As a rule, the thickness of such a pedestal is 3 bricks, although these values may be different (they depend on the design of the fireplace and its intended power).

Thanks to the basement part, the stability of the entire structure is ensured. In addition, it protects the floor and surrounding elements from fire. Many experts consider the base to be the most important part of the fireplace, because the future operation of the entire heater depends on the correctness of its calculation. Therefore, when it is being erected, it is necessary to keep a close eye on the level (it should be ideally horizontal).

To provide greater convenience when cleaning the fireplace, the base can be equipped with a niche into which the ashes will fall. In this case, over the basement niche should erect a ceiling of steel mesh.With this structure, wood ash, formed in the fuel compartment, will fall into a niche, from where it can be taken out with an ordinary scoop.

Fuel compartment

The second most important element of the fireplace design. Its creation is considered the most difficult, because requires consideration of many factors. It is not difficult to guess from the name that it is here that the combustion of fuel (wood, coal) will take place, which means that an extremely high temperature will always be present inside this compartment.

Because of the high temperature regime, the fuel compartment must be laid out of a special brick by a special technique. As a rule, chamotte brick is used for such work. The joining of brick components is carried out using a so-called warm joint with a thickness of about 3 mm. Often, the fuel compartments are laid out in 2 layers, with the second layer being constructed from a simple brick. It is here that the whole importance of the warm seams of the inner layer is manifested: they protect the outer skin from excessive heating, so that it is not deformed, and the person does not burn, touching it.

Fireplace portal

In terms of design, this is the most important part of the heater. That it gives the whole design an elegant look. For this reason, when laying out the portal, you should think over how the finished fireplace should look. A pre-built project containing the drawings and diagrams of the entire structure can help in this.

In principle, the design of the portal and its dimensions may be different, but there is one detail, the presence of which is mandatory. This is a special steel ceiling, located at the bottom of the partition. Such an element makes the structure more stable and provides more efficient heating. It is important to take into account the fact that this overlap must be located outside the working area of the fuel compartment. Otherwise, it will prevent the smoke from entering the chimney.

Auxiliary items

When building a wood or coal fireplace, additional components can be equipped. These components can make heaters more beautiful or perform some function. For example, to give the ideal option would be a mini-fireplace with oven. The structure of such a fireplace is standard, but a niche is created between the fuel compartment and the main portal, in which you can bake different dishes (from bread to your favorite pizza).Constructing such an “oven”, it should be remembered that it should not completely block the fuel compartment in order not to interfere with the smoke getting into the chimney.

An elegant decoration of a corner fireplace can be an arch, located above the portal. Building such an ornament is a rather difficult process. It is recommended to perform this work according to a professional project, where the order is detailed (the procedure for laying out brick components).

How to calculate the optimal size?

According to the standard, the ratio of the area of the combustion chamber and the area of the room is 1:50. As an example, consider the following values:

- if the room has an area of 15 square meters, then the area of the combustion chamber should be 0.3 square;

- with a floor space of 20 squares, the area of the firebox will be 0.4 square meters.

It should be remembered that such calculations are only suitable for houses with a standard ceiling height. If the ceilings are too low (or high), it is recommended to consult a specialist.

What is required for work?

In order for the corner fireplace to serve as long as possible, and its operation was safe, it is necessary to use 2 types of bricks: chamotte and earthen baked calcined.The connection of all components should occur with the help of a special clay solution. Such a solution is made as simple as possible: you need to mix sifted pit sand and clay. To the solution was more durable, you can add Portland cement brand M300 and above.

It is better to equip the foundation with crushed stone and chamotte chips. To create a portal jumpers better to use steel corners.

As mentioned above, the inner part of the fuel compartment must be built of fireclay bricks. The outer lining of the firebox and chimney can be made of red clay brick. When erecting the street part of the chimney, you can use the usual finishing brick, because It tolerates the effects of precipitation.

The working process

Work on the creation of a corner fireplace to give or at home can take place in different ways. But usually the following actions are required:

- Dig a pit to fit;

- tamp the bottom of the pit and put in a 10 cm layer of gravel;

- on top of the gravel, install the formwork, and then fill the space with large stones;

- fill the gaps between the stones;

- knead cement-sand mortar;

- pour the resulting solution into the formwork (about 10 cm layer);

- give the foundation a day to dry;

- after that, on top of the first layer of the foundation fill a layer of broken brick and rubble;

- fill these components with concrete;

- carefully align the foundation layer;

- then remove the formwork;

- cover the foundation with two layers of roofing material;

- after that, start laying bricks, relying on the design order;

- during operation, pay special attention to the arrangement of the base and the fuel compartment;

- carefully align the seams between the bricks.

After completing all the work, give the construction a day so that all the connections are securely seized.