Cork floor in the kitchen

Cork flooring is a relatively new and not very widespread phenomenon in the market of finishing materials. In the kitchen, and in other rooms, cork cover can be found not very often. This is explained by the fact that not everyone knows the pros and cons of this material.

Experts in the field of building materials claim that this type of flooring is environmentally friendly, therefore, it is recommended for use in residential premises. Such a floor will be especially appropriate in children's rooms and the kitchen - in fact it is there that most often something falls, breaks, flows and gets dirty.

Merits

- Natural material that does not cause allergies. Cork flooring is made from the bark of cork oak, which is grown exclusively for the purpose of obtaining its valuable bark.

- Excellent sound insulation - the cork floor perfectly muffles the sounds. This quality is especially important for those who have small children, who are known to be very active, and not all neighbors like this.If you like to listen or play loud music in the kitchen - cork floor will reliably protect you from the discontent of your neighbors.

- Thermal insulation. This quality of the floor, many estimate to the full during the off-season, when the heating is already turned off, but the street is already or still cool. Cork floor is always warm. It is nice to walk barefoot on it.

- The ability to recover from deformation. As the reviews of those who have a cork floor in the kitchen, if the traces of the furniture and remain, they are restored in a short time.

- Cork floor has amazing shock absorbing properties. Try for comparison to go through the wooden floor and then through the cork. And you will immediately feel the difference and understand the advantages of this coating. Walking on this floor is akin to physical therapy - the load on the entire body is significantly reduced.

- All kinds of insects - pests and rodents are absolutely indifferent to the taste qualities of the cork floor. Therefore you can safely stack it even in a country house.

- Cork floor does not slip. He has a rough surface.

- For such a floor is not afraid of dirt and various chemicalswhich are abundantly used in the kitchen, if they do not contain acid.

- The cork is not electrified, therefore, dust does not sit on it. It is easy to look after a pith floor - it is enough to do wet cleaning periodically.

- Cork tiles are easily cut, so they can be composed of compositions of any complexity. There are two types of cutting tiles - thermal, in which the edges of the tiles can melt, and cutting with water when the tile is cut with a thin stream of water and folded into patterns according to the type of mosaic.

Manufacturing technology

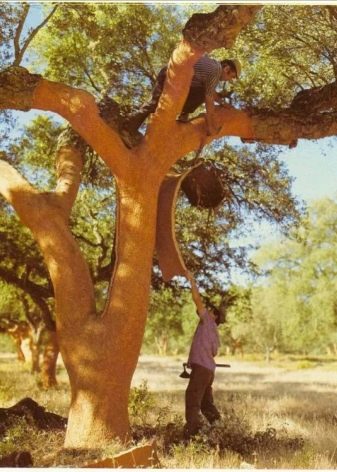

As mentioned above, the material for cork tiles is oak tree bark. It is removed after reaching the oak 25 years of age. At the same time, they remove it at the moment when the crust itself begins to fall away, so participants in the “green” movement can be calm - not a single tree will suffer in the process of creating cork cover. In addition, oak bark has the ability to recover after 9 years. The process of removing the bark is done manually, without the help of a saw and jigsaw, therefore, quite laborious.

Next, the crust is crushed, heated and pressed. As a result of heating, the particles of the crust stick together and it turns out a certain cellularsubstance, which serves as a substrate for the base, consisting of resin wood sawdust. Then put the face layer on the base. It can be made of various types of wood and varnished in several layers. This stove is more resistant to mechanical damage, there are practically no traces of furniture on it. This variant of cork coating is called decorative veneer and is a whole layer of bark, removed from the tree. Each of the collections of such cork coatings is carefully selected by color.

A more economical coating option is cork agglomerate. It is based on cork crumb heated and pressed into sheets.

Mixed version - a combination of veneer and sinter. This is a kind of compromise of attractive appearance, price and quality.

Kinds

- Technical traffic jam. It is used as a lining for linoleum, parquet, laminate and other floor coverings to create a noise-suppressing and insulating layer. It is made in the form of plates or rolls.

- Cork floor mounted to the floor with glue. In this case, the adhesive should be used as recommended in the instructions.It is produced in the form of tiles, impregnated with a protective layer, and therefore can be used in rooms with high moisture - for example, in the kitchen. The design of such a coating is varied, so you can add various floor ornaments from them. Glue tiles can be laid on any flat surface - cement screed, chipboard, linoleum, etc.

- Floating floor or, as it is called otherwise, cork flooring. The basis for such a floor are MDF plates on which the cork coating itself is attached. The advantage of such a floor is that it is easy to disassemble and replace the plates in case of repair. Panels fit one to one on the principle of laminate. This type of cork is afraid of moisture, so it is hardly suitable for a bathroom or toilet. Lay such a floor on the substrate, which partially hide the small irregularities.

disadvantages

- High price. Since the process of its production is quite laborious, therefore, the cost of cork floor is comparable to the cost of high-class parquet.

- Low tensile strength. If heavy furniture with a wide surface does not leave marks on the floor, then marks from thin studs, knife stabs and other sharp objects will leave a memory for themselves for a long time.

- The upper protective layer of the cork in areas of heavy traffic is gradually erased, so it must be periodically updated - remove the entire lacquer layer or change the entire cork coating.

- Since the cork has a rough surface, it contributes to enhanced wiping of woolen socks, soft sneakers, as well as thin nylon stockings and other shoes.

In order to smooth the surface of the cork, it is covered with several layers of varnish. If there are too many such layers, the floor becomes slippery. Elite cork varieties cover with oil for wood. It favorably affects the person.

Therefore, before choosing a cork covering for a kitchen or for another room, you need to take into account all the details and, if possible, foresee all possible consequences.

How to choose

When buying, pay attention to the manufacturer. Companies from Portugal are considered favorites in this type of production - it is there that the cork oaks grow.

Particular attention when buying cork in the kitchen should be paid to the appearance of the tile. All tiles must be absolutely flat at the edges and the same size.If the structure of a tile is heterogeneous, with extraneous impregnations, it means that there are sawdust in its composition. This floor will be worse to absorb noise and keep warm.

For living rooms - bedrooms, nursery, living room, it is better to choose the castle floor. But in the kitchen and hallway, it will not work. Here it is better to take a tile with a glue base. If the floors in the room are uneven, it is better to choose a tile with beveled corners - it will visually smooth out possible differences in the height of the base.

As for the classification of traffic jams, in rooms with low traffic, it is enough to lay 31 class. For the living room, where the permeability is average, 32 class will suit, but for those rooms where the movement is very intensive - in the kitchen, in the hallway, in the nursery - it's better not to spare money and fork out for 33 class. The optimum thickness of cork coating is 4-6 mm. With this thickness, the tile is very durable.