Closers for kitchen cabinets

Closers are special mechanisms whose function is to prevent blows of moving furniture items on the main frame of the structure. This allows not only to reduce the likelihood of external damage, but also significantly extend the life of the kitchen unit.

Operating principle

Closers for kitchen cabinets consist of a special frame, a spring and a certain fluid that creates resistance. As such solutions, oil or silicone fillers are often used.

The work process of the closer can be described in several successive steps:

- The movement of doors or other elements begins with a certain physical impact, which often acts as a push.

- During this process, a certain pressure is produced on the mechanism of the closer, which promotes the movement of fluid into the capsule case.

- After that, the expansion of the special adjustment element is performed, which leads to a decrease in the speed of movement of the door or other similar design. It should be noted that such systems can be simply adjusted by changing certain parameters of the product itself.

Gas closers have an identical principle of influence, only here a certain volume of gas is used as a regulating solution, and the movement slows down only when a certain distance to the frame is reached.

Advantages and disadvantages

Before you install the closers in your kitchen or in another place, you should study their basic technical parameters and understand the principle of their work. It should be noted several fairly weighty advantages of such systems:

- Closers prevent damage to furniture when the doors, pedestals, etc. are suddenly closed.

- With the help of such a mechanism it is possible to achieve complete closure, eliminating the need for human visual control.

- Closer faults do not affect the appearance of the furniture, as the oil does not leak and remains inside the case.

- The systems are quite versatile, which allows them to be installed for both small and massive door designs.

- Closers are easy to install, and their service life is limited only by the quality of the materials used to make them.

- On the market, you can find many varieties of such systems that can be selected both in terms of functionality and design for specific human needs.

But although closers are universal products, they still have certain disadvantages:

- Installation and adjustment must be carried out strictly by the manufacturer’s instructions, since failure to comply with it may be the reason for the rapid failure of the mechanism.

- Closers do not always fit harmoniously into the interior, as they have a specific structure.

- The operation of oil-based products may deteriorate slightly at low temperatures, since they contribute to an increase in the viscosity of this solution.

Species

Such designs can be operated with various furniture sets, but often people use them for the kitchen. Closers can be divided into several subtypes according to certain criteria:

- By the principle of action they can be divided into gas and oil. A distinctive feature of such structures is the use of a specific environment, which allows for the smooth movement of the mechanism.

- According to the purpose closers can be divided into door and drawer mechanisms. They differ mainly in design features and principle of action.

- By way of installation, the structure can be divided into several categories:

- direct mounting on hinges;

- installation on the case of kitchen furniture;

- mount between loops.

We make an independent installation

Installing closers is not particularly difficult, but requires compliance with the recommendations of the manufacturer of specific products. Therefore, before embarking on such operations, it is advisable to examine the documentation for these products. The installation process of such structures can be described in several successive steps:

- First of all, you need to get or remove a specific furniture box. It is necessary to put this element in such a way as to have full access to the fixing point of the closer.

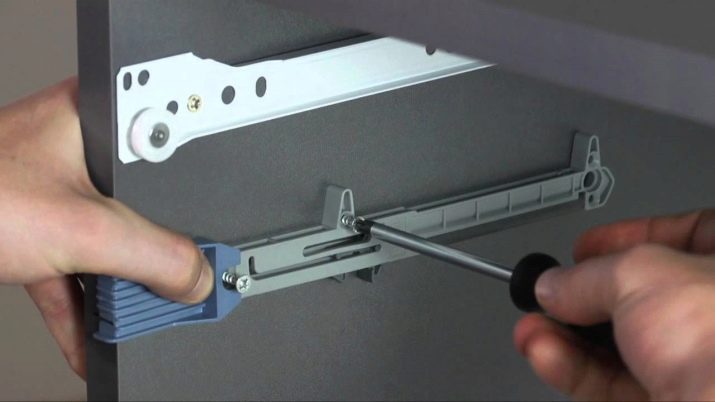

- Then, the holding part of the mechanism is fastened, which is somewhat longer than the other elements of the body. For fixing use special loops and screws with which the frame is screwed.

- At this stage, the markup of the future location of the closer case is performed. To do this, use a regular pencil, which mark the attachment points on the doors.

- After that, this part of the door closer is screwed to the furniture with screws. To simplify this operation, many experts pre-make small holes in the locations of fasteners.

Setting up the mechanism

Closers are relatively simple, but allow you to adjust several basic parameters:

- slip speed;

- door closing speed;

- the density of the fit to the frame.

It is possible to adjust all these characteristics with the help of a special screw, which must be present directly on the door body. To do this, simply twist or twist it a few turns. Do not try at the same time to perform similar operations at maximum speed, as often you can achieve optimal movement by turning the screw in one or the other side for one or two circles.Before performing such operations, be sure to consult with a specialist or carefully read the instructions.

To extend the life of the door closer, experts recommend proper maintenance of them. To do this, follow a few simple rules:

- In case of squeaks, all fastening screws on the retaining hinges must be tightened.

- Fittings and rails are periodically cleaned with soap and napkins. It is not recommended to use for such purposes soda or other mixtures in which the granular compound is present.

- The hinges are also intermittently lubricated.

To prolong the operation of such systems, one should not intentionally push the doors. Allow the construction itself to do this, because in another case, you can break its functionality, which will lead to the replacement of its main parts.

Popular manufacturers

Closers are fairly common elements of a modern kitchen set. There are quite a few varieties of such products on the market today, among which there are several quality manufacturers:

- Austrian company Blum produces one of the highest quality products of this kind. The cost of such components can vary in a significant range, depending on the specific purpose of the door closer.

- Vauth Sagel. German products of this kind are distinguished by high reliability and popularity, which led to their distribution almost throughout the world.

There are many other manufacturers of kitchen closers, which allows you to choose the optimal ratio of price and quality to solve specific problems. If you are not sure which products should be preferred, then entrust the choice to experienced professionals.