Glue for wood: varieties of compositions and selection rules

Wood refers to natural materials that people constantly use for construction, the manufacture of various structures and objects used in everyday life. To ensure effective work with wood, you need a reliable and durable composition for fixation, which is glue, which is represented on the market in a wide variety of species.

Specifications

New types of adhesive compositions for working with wood are constantly appearing on the modern market, and products that have been used for a long time are being improved in order to occupy a leading position in the line of these products, along with new products. When choosing an adhesive, one should dwell on the characteristics of the product; in addition, an important factor is the type of materials with which the work is to be carried out. Based on these nuances, the compositions may differ significantly.

It is also necessary to take into account the conditions in which the product or structure will be further exploited, since there are no universal products ideally suited for all types of gluing wood without exception.

It is necessary to highlight a number of characteristics of the adhesive:

- Product moisture resistance - this material property is indicated on the label with the letter “D”. There are several options for water resistance of the composition - class D2, D3, D4. The higher the value, the better the glue performance.

- The composition must be non-toxic.

- The level of strength of the formed compound. In most cases, high-strength material is necessary for working with wood.

- Density of products.

- Adhesion to various bases - wood can be reliably fixed not only with similar raw materials, but also with concrete, glass, rubber, cloth, mirror, tiles, there are compounds for gluing wood and metal, as well as products used in shipbuilding, etc. d.

- The term full cure of the substance.

- Heat resistance products.

- Resistance glue to the development of microorganisms.

- In some cases, a very important point is the color of the substance - the composition can be transparent or repeat the color of the tree, in addition, there are products of white and black.

Composition

Given the composition of products it can be divided into two groups:

- one-component compositions for bonding;

- two-component materials.

The first category is glue, which is realized in liquid form, already fully prepared for application to the working substrate. You can also find the composition in the form of glue-foam. The second group of products includes formulations that require dilution and mixing of two ingredients to obtain a substance for bonding materials. As a rule, such a product is a polymer composition, which is labeled accordingly - the first component is denoted by the letter "A", the second - "B", the last is hardener.

The composition is prepared immediately before work, strictly following the specified instructions for breeding. For mixing, a special tool is usually used. After complete dissolution of the components of a two-component adhesive, an elastic and uniform contact product is formed. Products may be different in color.

Kinds

Based on the purpose and ingredients used to make wood glue, a wide range of products is on sale.The most popular type of composition is PVA, it is familiar to everyone since childhood. This substance allows you to glue paper, wood and wood-containing materials. Its main requirement is the moisture absorbing ability of raw materials. Eco-friendly composition is a thick consistency liquid of white color, which becomes colorless when solidified. The main characteristics of the product include the fact that the glue dries quickly, is sold ready to work, the composition is easily removed from the base if necessary, it can be diluted with water. On sale you can find various types of products that vary in scope.

Epoxy adhesive refers to two-component products. freezing composition occurs without participation in the reaction of air. This product can be used not only for gluing wood, the material is often used to work with other types of raw materials. During the preparation of the composition it is necessary to strictly observe the proportions, since errors in dosage will result in a foaming mass that is unsuitable for bonding.The period of hardening of the substance varies depending on the brand of product.

Glue BF has not so long ago belonged to the group of the strongest and most durable products for work with wooden bases. The scope of use of the composition includes the bonding of wood, iron, PVC, polyurethane foam and other raw materials. There are several types of this composition, but moisture-resistant BF-2 or BF-4 is best for fixing wood. The products are distinguished by a rather specific material processing technology, which is reduced to applying a layer, drying and then compressing the elements with each other - this technique is necessary for the strength of the splicing line.

Compounds that are resistant to different temperatures are represented by synthetic substances and varieties of materials of the epoxy group. Among the list of products belonging to this category, we can distinguish the composition, which is implemented in the form of a rod. Work with him with a gun. It is used to repair furniture, when modeling various designs.

Joiner's adhesive composition is considered furniture, since it is in demand in this particular area of production.In addition, the products are used for the repair of musical instruments. The reason why this product has not received wide popularity is the difficulty in work, because it is sold in a dry form, which requires a number of works to prepare it for use.

It includes several varieties - sturgeon, mezdrovy, bone glue. These are organic products that are made from organic matter. Products are sold in granules, and glue is also produced in the form of grains. Fish glue is mainly used as a professional composition for repairing a musical instrument. The latter relates to gelatinous products. The main feature of such wood glue is the ability to soak the compound in water, as a result, the elements will move away from each other.

Synthetic compound is necessary for fixing the tree with the tree. It is a home-made product that contains sugar, hydrated lime and carpenter's glue.

Polyurethane glue is a super strong material that possesses high quality characteristics, refers to expensive products.Among the indisputable advantages is to highlight the moisture-and frost-resistant nature of the products, so that the composition is recommended for working with wood both indoors and outdoors. Moisture and frost-resistant composition has the effect of filling the plane, ensuring the protection of materials and their junctions. Expanding composition is allowed to work in the temperature range from -30 to +100 degrees. Can be used for solid wood.

Casein wood glue has a completely natural composition. Such products are sold in the form of granules or it can be prepared independently at home. The structure is used for MDF, a chipboard, DVP, for a parquet, in printing house and painting. With the help of a casein composition, luxury furniture is made.

Among the minuses of production, the hygroscopicity of the material should be noted, as well as the possibility of the formation of mold on its surface, but with proper storage of unpleasant situations with the composition does not arise.

Pasty adhesive materials are used as assembly products for sealing small voids that prevent the ingress of moisture. They are heat-resistant and tolerate cold.The heat-resistant product for gluing wood is used infrequently, but for work with uneven bases, the product will be an indispensable tool.

Manufacturers Rating

For wood, ready-made synthetic-based adhesives are more in demand. Among the brands that have proven themselves in the market for such products from the positive side, it is worth mentioning several manufacturers.

Titebond - compositions which are issued by the American company. Product specialization is the manufacture of furniture from wood and wood-containing materials, working with flooring, including tiled ones, and finishing various designs with wooden elements. The compositions include artificial and natural components, do not contain solvents and resins, which provides a high level of adhesion of the bases among themselves. In the product review of this manufacturer, Titebond ii premium product should be highlighted, which is recommended for fixing paper products, wooden elements, is in demand for the manufacture of doors and window blocks, chairs and other furniture. Products are allowed to operate for work outdoors and indoors.With the help of such adhesives, facade decoration with wooden fittings is performed.

"Moment" - products of the German concern, is widely used in the industrial and domestic sphere, the composition is relatively cheap, therefore it is convenient for small and large repairs. Quite often, with the help of this product, kitchen utensils are repaired - waterproof glue sticks mugs, cutting boards, etc.

"Titanium" - the composition of the universal purpose, quality glues wood, glass, plastic and paper. It is realized in different capacities - from 60 g to 1 l. It is possible to distinguish glue-mastic among the assortment, which is used for repair and finishing works with wood.

Application

To ensure a high level of strength of the connecting seam, you should correctly approach the preparation of elements for fixation. Wood must be well sanded, remove sawdust, as well as remove dust or pollution. If you plan to work with wood and porcelain, or with glass, acrylic surface or plastic, the material must be degreased. Acetone is well suited for this.

According to the recommendations of most manufacturers, one or the other part needs to be processed with an adhesive compound. If the work is performed with BF glue, then gluing is performed in two sets with an interval of 10-15 minutes.

A two-component polymer product involves several options for applying - in the first case, the compositions are mixed, forming a homogeneous composition, in the second embodiment, each ingredient is applied to one of the materials, after which they are fixed with each other.

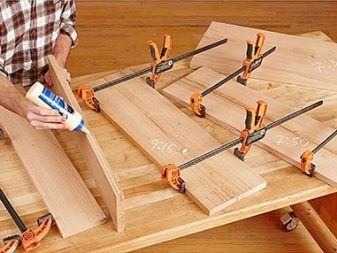

Varieties of wood glue for wood are applied in two layers, giving the previous one a bit to harden. For flat elements, you can apply one layer, evenly distributing it along the arrangement of fibers on the material. For a more efficient connection, the elements must be put under a press or pressed against each other in some other way.

Quick-drying compositions do not need additional pressure. However, attention should be paid to the leakage of the substance at the junction - all surplus must be promptly removed from the grounds.

An important nuance when working with glue are safety measures, since even organic or one-component products can causehuman allergic reaction. Consequently, care must be taken to protect the skin and eyes.

Which is better to choose?

There are a number of points in which It is worth to focus your attention when buying products:

- For gluing wooden components forever it will be better to give preference to the composition on a synthetic base.

- Gluing elements of the structure, in which it may be necessary to dismantle the fixed parts, should be performed with adhesive compositions on an organic basis.

- For light wood varieties "Joiner" is most suitable. Based on feedback from experts, casein formulations darken over time, which will make the connecting seam expressive against the general background. This option is not suitable for carpentry work in most cases.

- When buying PVA it is worth checking its uniformity. The separation of the composition into several fractions will indicate that the products were stored or transported with violation of the conditions, as a result of which the glue was at a minus temperature and was frozen. Use this composition in the work is no longer possible.

It will be much easier to decide on the type of products required for gluing wood, knowing which materials need to be combined. For work only with wood, any of the adhesives described above are suitable. To glue the small elements that are present when creating models of any structures for decoupage or handicrafts, it will be more correct to purchase a cyanoacrylate quick-drying composition. Strong bonding will provide PVA when processing large areas that relate to fixing the floor covering to plywood or wooden floor, for skinning furniture items or fixing leatherette on wood.

For gluing elements of the street structure, where the operating conditions suggest temperature fluctuations, you need a cold-resistant BF-4. These can be stairs, tiles laid on a wooden surface, bases of aluminum, etc.

How to do it yourself?

There are traditional time-tested recipes for the preparation of adhesive compositions at home.

Such substances include the following wood glue options, which can be made from the products available in every home:

- Casein - a tool made on the basis of a low-fat curd mass. It is soaked in soda solution, and then washed with water. Further, according to the instructions, the product must be dried so that it becomes like a dry powder, which is mixed with water for subsequent use. Boil like glue is not necessary.

- Kleister - is a contented demanded adhesive composition that you can weld yourself. The composition includes a solution of flour (at the rate of 6 tablespoons per 1 liter of water), which must be diluted in boiling water to obtain a homogeneous mixture.

In the next video you will find an interesting acquaintance with wood glue.