Glue for aerated concrete blocks: types and characteristics

For fixing building materials, not only familiar fasteners (nails, screws and other types of products in this category) are used, but also various solutions, mixtures and adhesives. They are selected on the basis of the characteristics of raw materials and the scope of further exploitation. As for aerated concrete, it is not an exception and also needs high-quality and reliable adhesive for installation work.

Special features

The material used for the construction of the walls of buildings should have high performance characteristics, since this directly affects the quality of the entire structure. As for the aerated concrete blocks, reliability and durability during installation and further use depends on adhesive compositions that fix similar structural elements.

Such products as aerocrete, has become quite popular in recent years. This tendency is due to the presence of a mass of advantages for the material. For the laying of raw materials, experts recommend using special glue and abandon the usual cement-sand mortars.

Such compositions provide a strong and small thickness joint, and the adhesive itself for aerated concrete blocks, most often, is sold as a dry mix, which is allowed to be used for both exterior and interior work.

Among the main uses of the composition are the following:

- wall leveling;

- laying blocks made of foam concrete, aerated concrete, brick or cinder block;

- laying tiles.

With regard to the positive features of the use of masonry adhesive mixture for aerated concrete blocks, we can note the following nuances:

- high level of plasticity of the composition;

- small thickness of the joint in comparison with the usual cement mortar;

- good adhesion to building material;

- no shrinkage after curing;

- frost-resistant mixtures are present among the types of glue;

- the water-holding components of the product exclude the formation of dampness, mold and fungus on the material;

- due to the absence of "cold bridges" the level of thermal insulation of the building increases;

- freezing composition occurs in the shortest possible time;

- aesthetic appeal of the masonry due to the small thickness of the layer and the appropriate color range;

- due to the low consumption of the composition in comparison with the cement-sand mortar, the cost of work when using glue will be less;

- products increase the strength of the entire structure.

The only drawback of products is the demands on the correct geometry of the building blocks.

The adhesive composition has the following main characteristics:

- full cure time is about 2 hours;

- moisture resistance of the mixture - 95%;

- grain size of the filler is 0.67 mm;

- block adjustment time - no more than 3 minutes.

Composition

Glue for gas blocks consists of several important ingredients:

- Portland cement - acts as a binder;

- sand;

- polymers - provide plasticity and help to increase the adhesive properties of the mixture;

- modifiers - are responsible for retaining moisture inside the composition, thereby eliminating the cracking of the connecting joints between the blocks.

Kinds

Today on the market there are two types of adhesive mixture for aerated concrete. Material classification is based on the color of the product, as well as the temperature range of its use.

- White glue. It is also called the summer composition, as it is recommended for use in the warm period. Among the advantages of this type is worth noting its color, similar to autoclaved aerated concrete blocks. Performing laying on such glue, you can save on interior decoration, because the base after work gets a uniform light color, due to which there is no need to resort to additional processing of seams.

- Gray adhesive composition is considered a winter mixture. However, the product has a universal purpose, so it can be used at any time of the year. The main feature of the material is the presence of antifreeze components, due to which the mixture becomes resistant to negative temperatures.

Products are allowed to use at a temperature not lower than -10 degrees. In the process of laying blocks in the winter, the structure additionally protects against external factors with a tarpaulin.In addition, it is very important to monitor the temperature of the composition itself - it should not be below 0 degrees.

Professional builders note a number of recommendations regarding the use of frost-resistant mixtures:

- it is necessary to work out the entire volume of the prepared composition in 30 minutes;

- it is prohibited to perform work during the period of precipitation;

- building blocks should not be wet or frozen;

- Storage and dilution of the solution is carried out in a warm room.

Forms of release and appearance

The adhesive composition for aerated concrete blocks (normal and frost-resistant) is realized in a dry form. Package weight in the bag is 25 kg. Such packing is very easy to use and transport, since the purchased products can be transported without using a truck in a regular car.

In addition to dry mixes, glue-foam is on sale, which is also recommended for laying blocks of aerated concrete. Products are manufactured in a balloon, which facilitates its application to the substrate. The base for the foam is polyurethane. According to the reviews of experts, the products are notable for a rather small expense and strength of fixation of the material of the structure.In addition, polyurethane is resistant to negative temperatures.

However, despite the mass of positive characteristics, it is worth noting the lack of this type of adhesive composition - it includes the sensitivity of the substance to sunlight: during the contact of the composition with UV rays, the deposited material may be destroyed. Therefore, when choosing such products should take into account this feature.

Manufacturers Overview

Among the presented range of adhesive compositions for aerated concrete blocks from domestic and foreign manufacturers It is worth highlighting the products that have proven themselves on the positive side:

- Ceresit CT21;

- Knauf;

- Kreisel 125;

- "Moment";

- AEROC;

- Betolit;

- Volma;

- YTONG glue.

Ceresit products are recommended for external and internal work with blocks. The mixture contains cement, as well as high quality organic and synthetic fillers.

The adhesive composition "Knauf" offers the consumer universal, as well as specialized mixes for aerated concrete. Products specifically designed for use with cellular building materials.

The composition of Kreisel 125 can be used for laying foam concrete, aerated concrete, as well as polystyrene foam blocks.

The composition "Moment" stands out among similar products with a high level of adhesion with building blocks. The products are non-toxic, therefore it is allowed to be used for work both inside and outside buildings.

The AEROC trademark produces adhesive compositions for aerated concrete for both winter and summer jobs.

Bonolit is a product that has recently appeared on the construction market, however, experts distinguish it from other adhesive mixtures due to the presence of antifreeze additives.

Clay "Volma" is represented on the market in the form of a frost-resistant composition with a good level of adhesion to porous building materials.

YTONG. The mixture is widely in demand for stacking blocks due to the advantages that relate to the strength of the formed connecting seam between the blocks, however, the products have a considerable price compared to similar mixtures of Russian manufacturers. In addition, according to some consumers of this product, it takes more for work than indicated by the manufacturer in the consumption rates.

How to choose?

Selecting the adhesive composition for aerated concrete, you should first get acquainted with the characteristics of the existing products.

It is best to pay attention to the following qualities of the material, on which the reliability of the masonry directly depends:

- material consumption per 1 m3 and 1 m2;

- grain size of the filler;

- masonry correction time;

- freeze time;

- operating temperature range.

The combination of the above parameters of the adhesive will give the most complete picture of the properties and characteristics of the product, starting with the specifics of the preparation of the mixture and ending with the technology of masonry blocks on the composition.

It is also worthwhile to pay attention to the manufacturer: it is best that the aerocrete and adhesive mixture are made by one company.

However, studies of the most popular brands of glue for aerated concrete blocks showed that the mixtures are characterized by almost identical performance indicators.

How to calculate?

The consumption of masonry glue may depend on a number of factors:

- dimensions of the building material;

- surface states of blocks;

- the presence of defects in geometry;

- specialist qualifications.

To calculate the dry powder consumption, you can use the following formula.

L + HL * H * d * 1,4 = P, where

- P - the amount of glue per 1 m3;

- L is the block length;

- H - block height;

- d is the thickness of the seam.

As a rule, on average, about 1 bag of the mixture leaves for 1 m3. To avoid overspending, you should strictly follow the instructions for breeding. You need to pay attention to the fact that the mixture is gradually introduced into the water, and not vice versa. The specified consumption rate was obtained from the calculation: the thickness of the adhesive layer will not be more than 3 mm.

How to use?

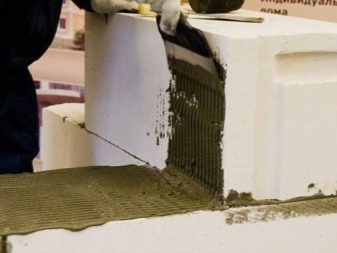

To most effectively perform the laying of aerated concrete blocks on glue, You will need the following tools for application:

- measuring container for adding powder;

- capacity for stirring;

- drill with nozzle or mixer;

- the application of the prepared composition is performed with a notched trowel or carriage.

Dilute dry powder at the rate of 5-5.5 l of water per bag of mixture. Water should be warm, but its temperature should not exceed +60 degrees. After mixing, a homogeneous mass is formed in the container - avoid the presence of clots in it, which will adversely affect the adhesion to the base during the application process. The product is suitable for use within a few hours, so the composition should be prepared in small portions.

Before you start working with glue,care must be taken to keep the blocks clean. - it is necessary to remove dust and other pollution from them. The thickness of the applied adhesive layer should not exceed 4 mm. The surpluses that may protrude along the edges of the block must be promptly removed, otherwise they will have to be cut off - as a result of such work there is a risk of damage to the gas blocks. The alignment of the geometry of the masonry is carried out by tapping on the top of the material with a rubber hammer - this will contribute to a better grip of the composition.

When working with the mixture do not forget about the measures of individual protection - work on the preparation and processing of the composition should be performed in protective glasses and gloves. In some cases, you may need a respirator.

Professional Tips

During the laying of aerated concrete, experts recommend taking into account external factors, such as humidity and air temperature. Such nuances have a huge impact on the ability of the mixture to seize with the material. In addition, they depend on the speed and time of solidification of the composition.

For example, an increased level of moisture may adversely affect the rate of solidification of the composition., therefore, work in rainy or snowy weather should not be performed.Too high temperatures will contribute to rapid hardening, as a result of which the seam may crack. In winter, the composition will take longer to polymerize.

As practice shows, the optimum temperature of the already diluted adhesive solution is 10 degrees. In addition, the time of application of the product on the material should not exceed 10 minutes, so for working with glue will require some skill.

For information on how to properly knead the glue for laying a gas block, see the following video.