Two-component polyurethane adhesive: pros and cons

In the construction and repair sector can not do without special adhesives. A special place among the rich range is polyurethane glue. Recently, the demand for products of this type has increased significantly.

Given the wide range of applications, two-component formulations have become particularly popular. The solution is compatible with a variety of materials that differ in density, texture and nature of origin.

Special features

Polyurethane adhesive solutions are one- and two-component. Products differ in specifications and composition, respectively. The main difference of this type of product from a similar product on the market today is a wide temperature range of use.But also note the resistance to increased moisture and other external factors.

Among the advantages, experts emphasize the use of indoor and outdoor use., as well as versatility, durability and reliability. For the manufacture of 2-component glue hardeners and polyesters are used. During the work with structure it is necessary to carry out procedure of mixing of two components.

Many manufacturers add special catalysts. With their help, you can accelerate or, conversely, slow down the polymerization of glue. Today, products of this type are offered by domestic and foreign brands.

Advantages and disadvantages

To evaluate the range of possibilities of 2-component compositions based on polyurethane, It is necessary to get acquainted with the list of weaknesses and strengths of the product.

- Using. Glue is actively used when working with various materials, whether raw materials of synthetic origin or natural. Products are used when working with wood, metal, rubber, plastic (PVC), stone and textile material. A large scope of work made the product popular and in demand around the world.

- Temperature. Quality product is not afraid of sudden changes in temperature. Even with constant fluctuations, all performance characteristics remain unchanged.

Wear resistance is maintained at low and high temperatures.

- Wear resistance. A layer of adhesive composition maintains density and practicality even when exposed to water, oil or gasoline. But it is also worth noting that the product is not afraid of dampness, mold and mildew. Due to the special components in the composition of the breeding of bacteria on the surface of the layer is impossible.

- Reliability. Glue firmly and permanently connects various materials. It can be used for horizontal and vertical surfaces. With proper use of a certified product, you can be confident in the reliability of fastening. As well as the composition boasts high mechanical properties.

- Additional features. When working with MDV panels or PVC (plastic) structures, a two-component product plays the role of a practical and durable sealant. High-quality sealing of seams will help preserve the heat in the room, as well as reduce noise.

Polyurethane adhesive is particularly widely used in regions with harsh climatic conditions.

- Benefit. At the expense of favorable consumption, the composition is economical to use. This characteristic is especially important if you plan to repair a large object.

- Wide scope of use. On sale you will find a huge variety of products focused on a specific front of work. Glue is used for the installation of parquet, structures of various types, vehicles (boats), shoe repair, sealing and other things.

- Excellent result. Deformation of the layer in the process of laying an array or parquet is excluded. Given the individual technical characteristics, the material is recommended for use to beginners who do not have adequate experience in the field of repair, installation and construction.

The above characteristics have only certified products.

Among the huge range of such popular compositions are:

- Alu 2-component (Cosmofen Duo) - a universal product;

- Uzin MK 92 S - effective glue for laying parquet;

- Molefix 8325 is a professional product with a wide range of applications.

This type of product has one major drawback. Two-component adhesive has a long drying time. This feature is not all experts believe a disadvantage. This feature can be called an advantage. The master has more time to carry out specific work. In addition, this minus fully compensates for a number of advantages.

Specifications and use

If you use a two-component composition, it is not necessary to take into account the level of humidity in the room or outside the building. The compositions are designed in such a way that they are able to withstand even the highest rates without problems. These are waterproof solutions that firmly connect various compounds.

Products retain a number of specific properties that apply to pure polyurethane. It is resistant to various chemical compositions and sea water.

We should also note the high temperature indicator of ignition, which totals 200 degrees Celsius.

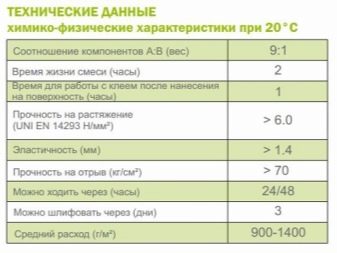

Layer sticking occurs in an hour, provided that the air temperature is 20 degrees Celsius above zero. The process of complete solidification takes from 1 to 2 days, depending on the microclimate.

Before applying the adhesive to the base or structural element, you must first clean, degrease and dry it. Be sure to use gloves to protect your hands. Particles are removed with acetone. This is done until the product is completely dry, otherwise it will have to be mechanically cleaned.

How to choose?

Most polyurethane adhesives are universal, but when choosing an adhesive it is imperative to pay attention to the area of application. This information must be indicated on the packaging.

Products are ideal for laying “warm” floors, given the high upper limit of permissible temperature. Given the fact that the layer does not shrink during operation, the compositions are recommended for use for the installation of flooring.

The material will be securely fixed after installation and will remain in this position throughout its entire life.

Some types of compounds can be used at sub-zero temperatures. Glue retains the necessary elasticity due to special elements.Depending on the impurities, the color of the product is gray, white, brown or amber.

A separate product segment - two-component solutions for sealing seams and joints of various designs, regardless of material. This type of glue is sold in compact containers and is mixed in a ratio of 1 to 1 before work. Together with the product the package comes with a hardener.

For the preparation of the solution used metal or plastic buckets.

Security measures when using structure

Even experienced craftsmen are required to adhere to the instructions for using two-component adhesives.

- To put structure it is necessary in rubber gloves. When mixing components, protect your eyes with special work glasses.

- If the glue gets on the open skin, it is necessary to immediately treat the affected area with warm soapy water. If particles of the composition hit the mucous membrane of the eye, you should quickly seek help from a doctor.

- Optimal conditions for work - ventilated room. Otherwise, be sure to use a respirator. Individual elements of the solution volatilize during application and dilution.

Inhalation of vapors is undesirable.

Parquet two-component composition

This type of product has individual characteristics:

- high adhesion;

- layer time varies from one hour to two hours;

- the glue layer has excellent elasticity;

- the solution retains its properties after mixing for 30 to 90 minutes.

The process of curing components occurs due to chemical reaction. Due to its practicality, simplicity and convenience, the adhesive method of laying floor coverings is widespread.

You can learn how to make an adhesive mixture of polyurethane two-component glue from the video below.