Properties of epoxy glue and rules of its application

One of the most used adhesives can rightly be called epoxy. It is widely used both in everyday life and in industry. The pledge of its popularity lies in the high adhesion with the vast majority of building materials, the durability of bonding and the special strength of the frozen composition.

Special features

Epoxy glue is a composition that is highly in demand among production workers and home craftsmen. Despite the fact that the modern construction market constantly offers consumers options for stronger compounds, the demand for epoxy does not decrease - it is still widely used where it is necessary to glue hard materials.

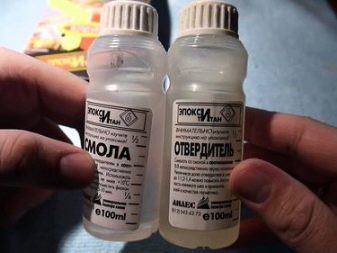

As the name implies, the main component of the substance is epoxy resin, to which a hardener is added. For the first time epoxy resin hit the market in the 40s of the last century.Since then, the technology of glue has undergone significant changes, modern bonding techniques and truly unique materials have been developed.

In the construction segment, you can find a variety of epoxy compositions that work in a significant temperature range and allow you to achieve a compound of increased strength and durability.

Both components are classified as low molecular weight polymers., when they are combined, the process of complete polymerization begins, in other words, small molecules are combined into larger ones. In this case, the polymerization takes place simultaneously throughout the composition; therefore, we can safely say that the glue in the hardened state is a single huge polymer molecule. In this case, the resin acts as a mass-forming substance, and the hardener is responsible for the passage of the polymer reaction.

It is very important that both substances react strictly before making the adhesive composition, since the curing of epoxy is an irreversible process that cannot be stopped and the resin returned to its original state.

In industry, polymerization can be accelerated or slowed down. In the first case, the temperature is increased, while in the second, on the contrary, it is lowered, and also the concentration of the hardener is reduced.

As a primary hardener, as a rule, use di - and polyamines, as well as aminoamidesin addition, the desired effect can be achieved by adding modifiers (rubbers or silicone resins), anhydrides of various organic acids, some technologies involve combining the resin with complexes of Lewis acid solutions with esters, as well as amines.

The content of primary or secondary amines in the structure of the adhesive usually does not exceed 7-20% of the total resin, and the proportion of tertiary is much lower - no more than 5%. If you use excessive concentrations of these components, it can cause a chemical reaction, as a result of which polyesters are formed from epoxy resin.

Necessary to use substances as an effective adhesive composition characteristics can be obtained by using maleic or phthalic anhydride, all other reagents are introduced into the adhesive in an amount not higher than 0.85 mol per mol of epoxy resin taken.

Sometimes dyes are added to the glue.

Epoxy adhesive has high adhesion to most types of surfaces. It perfectly glues the surface of metal, plastic, porcelain, as well as plaster, glass, wood and ceramics. Due to the liquefied consistency and uniform type of solidification, this composition is often used for the impregnation of various fillers (sawdust, metal shavings, fiberglass, paper, etc.), as well as for repairs in everyday life, automotive and aircraft building, modeling and other industries.

A distinctive feature of epoxy glue is its water resistance, so the solution is widely used in waterproofing.

Glue is considered an excellent dielectric, which leads to its use in electrical engineering. It is noteworthy that at the end of curing, the glue can be subjected to further processing, namely: grinding and painting, it can be drilled and even sawed. If necessary, pigments are introduced into the glue before hardening; this makes it possible to impart necessary properties to the frozen layer. The production of epoxy compounds is carried out in accordance with the established GOST 10587-84.

Advantages and disadvantages

The combination of all the components of the adhesive gives the output of the composition, which has extremely high performance parameters.

Among the advantages of glue there are several.

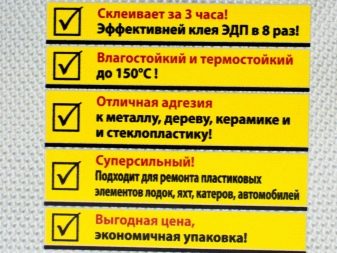

- Resistance to high temperatures - glue can transfer heat up to 250 degrees without changing its user characteristics.

- Frost resistance - the composition does not lose its consumer properties with regular frosts up to -20 degrees. Coupling can also withstand one-time short temperature drops to a lower level, so wide glue is used for the repair and installation of street structures.

- The glue seam does not collapse under the influence of adverse atmospheric influences, retains its strength when in contact with aggressive substances of the gasoline and oil series.

- Moisture-proof - bonding provides maximum sealing, and at the same time does not lose its physical and technical characteristics under the influence of moisture.

- High adhesion with the vast majority of materials used in construction and finishing works and in everyday life. Epoxy can even connect iron with cement, not to mention such “low-demanding” surfaces as plywood, plastic, glass and so on.

- Glue does not decompose with regular exposure to all kinds of cleaners and other household chemicals.

- In the frozen state, the composition is nevertheless somewhat elastic, so that in the case of displacement of parts, the connection should not break.

- The adhesive is resistant to cracks and surface shrinkage.

However, the composition has its drawbacks.

- To begin with, it should be remembered that epoxy glue is absolutely unacceptable to use to create and repair things that in any way can come into contact with food, since even a small amount of substances in contact with food can lead to poisoning.

- Epoxy does not stick polyethylene, Teflon and silicone, moreover, the composition of these substances acts in a destructive way, changing its structure, shape and size.

- The glue hardens very quickly - many consider it an advantage, but in some situations this property is considered more likely as a shortcoming, because in the case of any deformations and errors of the connection of the parts, it will not be possible to make changes. Therefore, a specialist with extensive experience who is able to do everything as required the first time should work with glue.

- In case of contact with glue on the skin, it will be quite problematic to wash it off.Therefore, when working with resin, it is recommended to use protective gloves - such a measure will minimize the risk of contact of the resin with the outer covers of human hands.

Kinds

Epoxy based adhesives can be classified according to three basic parameters: according to its composition, final consistency and hardening variant.

By structure

According to this parameter, the glue is subdivided into one- and two-component:

- Single component epoxy It has a transparent structure, it contains a liquid resin or a resin-containing solvent. The mixture is packed in small tubes and does not require special preparation before use. One-component adhesive is widely used for effective bonding of small parts, as well as for reliable sealing of the joints of water pipes and all kinds of gaps.

Most types of glue do not require pre-heating for effective hardening, but some brands “seize” only under the influence of high temperatures.

- Two component adhesive - This is the most common version of the adhesive composition. This glue goes on sale in the form of packaging from two tubes - in the first resin is contained directly, and in the second - a hardener in a liquid or powdered state.Before use, both components are poured together and mixed with a small spatula - the prepared composition needs to be applied to the surface within 60-120 seconds, otherwise the composition will harden, and the necessary adhesive properties will be completely lost.

Consistency

Epoxy glue goes on sale in the form of a paste or in a liquid state:

- Liquid glueAs a rule, it is squeezed out of a tube; its advantage is cost effectiveness and the ability to apply a point, it allows to glue small parts together. Such a composition can be produced in syringes.

In addition, the composition is sold ready-to-use, and therefore does not require any preliminary preparatory work, it allows you to save time and effort of the master.

- Paste It is a plastic mass, which in texture resembles simple clay. In order to use it in work, you should cut a small piece, knead and slightly moisten with ordinary water at room temperature, diluting to the consistency of thick sour cream. The prepared composition must be applied to the bonded base.

By type of curing

For this parameter, all types of glue differ in three options - their difference is due to the parameters of the base hardener in the structure of the adhesive:

- Mixtures that include diluted resin, aliphatic polyamide and various plasticizers can reach full hardening rather quickly, they can be dried for 1-3 days at a temperature of about 20 degrees. At the same time, the structuring of such compositions lasts much longer. To increase the strength parameters, these types of glue are advised to additionally be subjected to slight heat treatment. By the way, the places of adhesion, which freeze without exposure to temperature, are distinguished by an increased resistance to the effects of acid-base solutions.

However, their strength significantly deteriorates with prolonged exposure to moisture, this is especially important when it comes to gluing wood and other hydrophilic materials.

- Modified versions of epoxy have a temperature range of hardening from +60 to 120 degrees, they are used to combine metals, are characterized by impact strength, as well as increased resistance to oils, gasolines, liquid fuels and other organic solvents.

- High-temperature heat-resistant extremely durable composition - this category includes adhesives, for hardening which requires maximum temperatures: from +140 to 300 degrees. Such compounds differ in electrical insulation and heat-resistant parameters.

Manufacturers

Among the most popular brands of epoxy glue, which are in high demand among consumers, there are some.

Moment

“Moment” - this epoxy glue can be found in any building and hardware store at a quite affordable price. This composition is implemented in small tubes, the weight of which does not exceed 50 ml, as well as in bulk packages - such adhesives can be used many times.

Glue "Moment" can be used for bonding a variety of basesIt is implemented in several variants: “second” - of instant action and “standard” - the curing period of which is approximately one day. And in fact, and in another case, the clutch is strong and durable.

After opening the glue tube should be stored at a temperature not higher than 25 degrees.

Contact

Contact adhesive is the second most popular epoxy compound,which is optimal for repairing products operated in high humidity conditions - for example, for reliable sealing of sewer and water pipe joints in a bathroom or kitchen, as well as for fixing light shelves in a shower room.

This glue hardens pretty quickly - in just a couple of minutes.

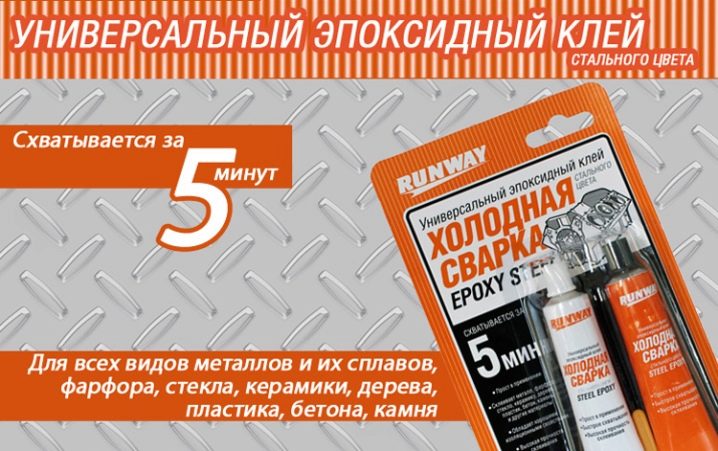

Cold welding

Cold welding - this subspecies of epoxy glue literally in a few seconds glues the surface of the metal, and the degree of bonding in its reliability is not inferior to the strength of heat treatment. When in contact with the glue, the corners of the metal sheets are not subjected to deformation, moreover, thanks to the glue, it is possible to join together such alloys that are not subject to welding.

EPD

EDP is another popular brand of epoxy, which is used to work with a variety of surfaces: from porcelain to metal. Consumer reviews clearly distinguish this type of glue as optimal, in terms of price - quality, and versatile in terms of scope. This glue has been used in everyday life, as well as for the repair of automotive equipment, the elimination of cracks in all types of plumbing, modeling and the like.

Users also note the high quality epoxy compositions of the “Class” and Ultima brands.

Scope of application

Universality of epoxy glue exceptional adhesion to a wide variety of surfaces causes it use in the most various industries and segments of the industry.

- In construction, this composition is used to fix reinforced concrete bridges of bridges, as well as three-layer panels, glue is used to fix ceramic panels, connect concrete with various metals, and the like.

- In mechanical engineering, glue serves as a mandatory participant in the technological cycle in the manufacture of abrasive tools, as well as for technical equipment, fixing brake pads and the production of plastic elements to metal coatings. Glue is commonly used to repair the gas tank, as well as to perform body work, eliminate defects in the gearbox and any skins.

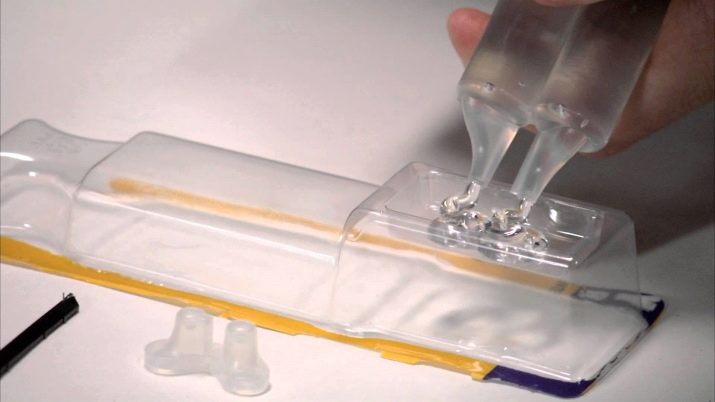

- In the aviation industry, with the use of glue, it becomes possible to form glue-welded joints when creating aircraft, as well as to create solar cells and the formation of external and internal thermal protection.

- In shipbuilding, adhesives are used to assemble floating devices made of fiberglass, as well as to form reinforcement units with increased load and create a waterproof barrier. Glues are used to make the hull cover of boats and yachts with fiberglass reinforcement.

- In addition, epoxy used in radio and electrical engineering, in the manufacture of glass and other industries as a means of impregnation. The use of resins significantly increases the strength of the material and the quality of adhesion, and also creates moisture protection.

High melting point resins are used as reliable waterproofing of walls and floors in rooms with high humidity, such as swimming pools, baths and shower rooms, as well as in basements and cellars.

Glue is truly indispensable in the repair and decorationSince the resin gets solid, it is relief and keeps its shape, it can be polished, sawn and cut, so you can give the composition the necessary shape and texture. Glue is also used in needlework.

The reason for such popularity of epoxy is obvious - it is a consequence of the universality of the adhesive, its availability in use, ease of use and high efficiency.

How long does it dry?

Separately, it is worthwhile to dwell on the temperature regime, which withstands epoxy glue and keeps its physical and technical characteristics working. Even for normal work with the material it should be heated, the temperature of use is about 70 degrees.

The maximum allowable temperature for epoxy glue is 250 degreesand the minimum is at -20. Such resistance to heat and frost was one of the main reasons why the composition based on epoxy resins is used not only in everyday life, but also in construction, industry, aircraft and ship modeling.

Usually, epoxy dries for about 24 hours, however, the rate of hardening largely depends on the correctness of the technology of glue preparation. Before starting work, it is very important to understand how to dilute the resin and all the additional components in its structure so that the resulting composition meets all the required technical standards.

As a rule, the resin is quite thick, so it is not easy to mix it with a hardener., first you should put the tube in a container with hot water, while you need to make sure that the liquid does not come into contact with the resin.After heating, you can begin to dissolve the glue - while the proportions of the resin and hardener used are usually indicated on the packaging and are 5 to 1 for some products, and 10 to 1 for others.

If you do not follow the recommended proportions, then the curing period increases significantly, and the adhesion strength, on the contrary, decreases.

Tips

Any contact with epoxy compounds should follow the safety guidelines. The standard precautionary measures will be the use of protective masks with carbon filters that will protect against dangerous fumes.

It is recommended to wear rubber gloves for people with high skin sensitivity, however, they can be worn anyway, since the glue caught on the skin is cleaned with great difficulty.

All work should be carried out in the open air or indoors with good ventilation.

Do not leave the glue open, as it emits volatile substances that can harm the health of children and adults.

Avoid getting glue in your eyes. If this happens, seek qualified medical attention, as it is impossible to wash the glue out of the eye.

Glue should not be used to repair products that will come into contact with food, otherwise resins and solvents will enter the body, which often leads to poisoning.

More details about the use of epoxy glue will tell the following video.