Features of adhesive sealant

The final touch of the repair work is the design of the joints with glue-sealant. Filling gaps with this tool will protect and ensure the cavity is watertight. The aesthetic appearance of the room and the duration of wear of individual objects depend on this stage.

Special features

Silicone adhesive sealant first appeared on store shelves in the 1970s and became one of the multifunctional universal construction tools that is still used today to seal joints and in many other construction works. He is preferred by professionals and ordinary home craftsmen who started repairs. After all, there was always a need to polish the joints, seal holes or seams, and therefore they invented glue-sealant to help.

Previously, to perform such repair and construction work, various mastics, various putties and bituminous mixtures were used, the work with which did not bring the desired quality and satisfactory result.

Glue-sealant is applied on numerous surfaces and has the following properties:

- resistance to temperature difference (atmospheric pressure is not scary when applied from the outside of the room);

- heat resistance in conditions from -50 to +300 degrees;

- plastic;

- clutch with different parts;

- up to 100% elasticity;

- holds the form and does not flow when applying a thickness of less than 1 centimeter from vertical surfaces;

- polymerization shrinkage is zero;

- filling gaps and cracks;

- solid and durable structure;

- different temperature range;

- after application it does not emit harmful and toxic substances - this construction material provides complete environmental safety, and the presence of a slight odor does not indicate the harmfulness of the product.

The substances that are used in the manufacture of adhesive sealant are as follows:

- rubber;

- plasticizer;

- element to give plasticity and the necessary strength;

- vulcanizer (there are several types of vulcanizers to impart viscosity to the tool);

- a material that allows silicone to adhere to the surface.

It is hard to believe, but those very elastic sealants with an adhesive effect are released from silicon under the guise of sand or quartz, and silicon extracts are the basis of the composition. By consistency, they are a plastic substance that will never burst even on a moving structure, but rather, on the contrary, will stretch.

The quality of the adhesive sealant is affected by additives that are used during the production phase. To reduce viscosity include a number of specific components.

These include the following:

- components with natural bases;

- chemicals for the destruction of mold and fungi;

- viscosity additives;

- fungicides - antifungal antiseptics;

- mechanical additives for adhesion and chalk;

- quartz dust and glass;

- fungicides that prevent the development of all types of microorganisms;

- dyes - silicone during the work is not subjected to further painting, the creation of color occurs at the production stage.

Temperature resistance and adhesion significantly affects the quality of the adhesive-sealant. It should be easily applied to coatings of wood, ceramics, iron, concrete and plastic, and its aging after drying serves as a guarantee of longevity. Adhesive sealants remain resistant and durable to the effects of the external environment, as well as destructive factors. All of these listed options are universal in their own way and help to achieve high results in various areas of adaptation.

It should be noted that the composition is quite interesting, and the principle of operation is based on the fact that on contact with moisture, which is always in the air, hardening occurs. It distinguishes the remedy among the mainstream products.

Scope of application

In the modern world there are many areas in which not to do without adhesive sealant. This tool will be indispensable for various repair and construction works. One of the popular types of mortar is a silicone-based adhesive sealant. Its main actions begin to occur under the influence of moisture, which is contraindicated for many of the usual means of use.Based on this, the scope of application is quite extensive, simple and diverse.

Polyurethane adhesive sealants made of synthetic elastomer have also gained considerable popularity. With it, they close up cracks, combine individual sheets or vulnerable roofing materials, and allow for other repairs.

The general area of use of adhesive sealant is as follows:

- when sealing concrete floors;

- in civil engineering;

- in the construction of bridges and airfields;

- in the invention of double-glazed windows and installation of windows;

- in the automotive industry;

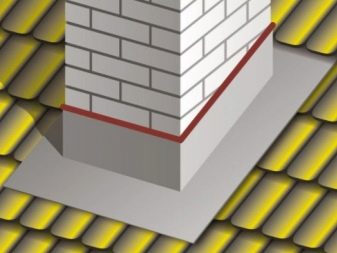

- at roofing joints of pipes, gutters and parapets.

The modern market provides buyers with a wide range of choices.

There are several types of sealant that are used in different areas, namely:

- universal use for outdoor areas (the elimination of window and door drafts), it is considered to be quick-drying and heat-resistant;

- neutral is more suitable for mirrors, at the same time it can serve as antifungal and quick-setting agent;

- heat resistant (installation) is used for various installation works, besides its main advantages are frost resistance (up to -50 ° C) and heat resistance (up to + 285 ° C);

- aquarium will work with showers, washing machines and ceramics;

- bitumen sealing is not afraid of temperature changes, perfectly cope with cracks and damage to the foundation, slate, tile, its application is possible with other various surfaces;

- sanitary (liquid rubber and nails) quickly sets to glass and enameled surfaces, it is necessary to strengthen the gaps between the sink, washbasin and wall;

- roofing rubber is used by builders to process chimneys and fixed joints;

- glass is well coupled with both porous and smooth coatings, perfectly tolerates temperature variations;

- electrical insulation has dielectric properties;

- low-modular used outside the building to fill between the panel joints; for work with stone, it is applied to stone, polyvinyl chloride, glass, because it does not perceive UV rays, it tolerates weather changes.

A sealant with an adhesive effect is often used on wooden surfaces, namely:

- in the absence of deformation, it is ideal for wooden parquet or plinth, decorative wood elements and fixed joints;

- with a high level of deformation, it is considered a means for housing construction - embedment of beams, logs in wooden houses and for the prevention of freezing.

For wooden coatings it is worth using a transparent type of adhesive sealant. To work with the floor (parquets, laminates) it is recommended to choose darker tones, which after drying will not be noticeable.

Glue-sealant is often used for the following exterior works:

- impermeability of metals;

- repair work with materials that depart from the base of the surface (stones, tiles, metal, vinyl cladding, and others);

- restoration of ceramic and stone materials;

- seal cracks in buildings;

- sealing window frames (joints, seams);

- for work with parts heated to a high temperature.

This tool can also be used for the following interior works:

- for working with PVC (for threaded connections and polypropylene);

- joints between drywall and ceiling;

- filling empty cracks and areas;

- sealing windows, balconies and loggias;

- sealing of joints of natural or artificial stone (parquet and laminate);

- installation of bathtubs, plumbing, washing machines, sewer pipes;

- sealing metal and parts with high thermal stress.

Important: for sealing gaps in the windows is perfect glue-sealant for the appearance of work, as it is waterproof.

Adhesive sealant suitable for use in rooms with high levels of moisture. It is used for drawing on cracks in window sills, during plumbing works and for an aquarium. As is known, in the presence of high humidity after a certain time a black bacterial plaque forms on the surface. Water becomes the first cause of unpleasant formations. If you do not follow the simple rules, then mold and fungus will be formed, which can cause respiratory diseases, allergic reactions and skin rashes.

If fungi multiply, they should be removed immediately, as they represent a great danger.. It is not recommended to use antifungal, as well as antimicrobial agents, if you have to work with the use of products in the field of kitchen and food zones. In order to avoid the development of this problem, it is worth using a fungicidal sealant. Neutral glue-sealant with fungicidal additives is used just for working in wet areas (kitchens, toilets,bathrooms) and prevent the appearance of unwanted microorganisms. Thus, the price of the goods will depend on the fillers, solvents and any other factors. The buyer can choose the tool for different applications, the necessary material and color.

Advantages and disadvantages

This adhesive sealant is one of the most commonly used building materials. Reviews, the main differences, disadvantages and advantages will help in the future selection.

Sealant with adhesive effect has the following advantages:

- strength and durability;

- high level of elasticity;

- compatibility with different materials;

- resistance to chemicals and ultraviolet;

- high level of heat resistance;

- freezes quickly;

- changes in air humidity do not affect traction;

- high temperature resistance;

- bonding with different surfaces (stone, ceramic tiles, concrete, metal and glass surfaces);

- eliminates the development of microorganisms (mold, fungus);

- moisture insulation;

- resistance to environmental factors;

- ease of use;

- affordable price;

- retains basic properties for decades.

Among the shortcomings are the following:

- there are a number of surfaces, the connection with which performs its function poorly, for example, polyethylene or fluoroplast;

- appearance before application should be washed and degreased with special means, it is thoroughly cleaned and finally dried;

- there is a deterioration in the interaction of properties when applied to a wet plane, as regards only non-water resistant types;

- in the absence of impurities is not subject to further painting;

- when cured badly stained;

- may fade when applied to external sources;

- poor bonding with plastic coatings;

- there is a peculiar smell that disappears after a while;

- the process of hardening depends on temperature changes, sometimes this process is too long;

- Not the fastest recycling process.

Kinds

In addition to the silicone base, there is an acrylic adhesive sealant. They differ in the characteristic composite components. Silicone-based rubber is used, and acrylic acid is used. The universal variety is acrylic adhesive sealant,after applying it can be easily polished to create a completely smooth coating, which can later be prepared for painting, which is unacceptable with rubber.

Rubber sealants with an adhesive effect are used in the repair of bathrooms and swimming pools. With the impact on water resistance, it has become relevant in places with high humidity and the probability of formation of a fungus.

Sealants with an adhesive effect on the composition are viscous substances, and are divided into one-component and two-component types.

Single-component, as a rule, are divided into these two main groups:

- neutral - emit part of the composite solution, which does not oxidize in contact with the material, this list includes materials such as PVC, copper, metal surfaces and wood;

- acidic - this group oxidizes the above-listed surfaces and does not guarantee a coupling along the entire seam.

Important: it must be remembered that when using an acidic and neutral species a substantial odor is formed. When working with this sealant, it is advisable to use a protective mask on the nasopharynx and in safety measures it is best to leave the windows wide open after the end,to fully ventilate the room.

Two-component formulations are less common and are used more in industrial applications. The polymers of these types in a solidified form form an elastic compound. Since they have a stable heat resistance and are well glued to many building surfaces, their range is quite wide among builders and ordinary users who have undertaken a major overhaul or redecoration.

It is worth paying attention to the expiration date before the purchase itself, the integrity of the package and for which areas of use it is intended. The final result of the work will depend only on how correctly and precisely the glue-sealant will be selected.

Colors

Sealant on adhesive basis has gained considerable popularity among users and thus caused the need to expand its advantages in composition and in color. It must be remembered that the adhesives-sealants are not painted, there are finished colored goods that you can buy. Means of black, white, gray and brown shades are acquired most often. But there are extraordinary colors, such as silver and gold.

Adhesive sealant can be represented by such tones as:

- transparent glue is used when installing furniture and plumbing to avoid moisture;

- color tone is required to work with building materials already with a certain name;

- white color is designed for plastic balconies and windows;

- black tone is often used in cars;

- Colorless version is considered universal, with no restrictions in use.

The newest fashionable technology is a contrast method of selection of glue-sealant. This combination will give the design uniqueness. For the selection of the combined color is to consult with the seller.

How to use?

When starting to work with glue-sealant, it is important to make sure that all the necessary materials are already prepared. Protective clothing in this list will come first. It should protect the entire body, including the skin of the hands. To protect the skin of the hands, you can use construction gloves, and to work with more aggressive in composition means you should use a mask.

In further work with adhesive sealant, the following materials will be useful:

- working clothes;

- paper napkins;

- soft rags;

- special cylinder gun;

- spray;

- soap solution;

- alcohol to degrease and clean the instrument after work;

- spatula to shape the silicone.

Further, it is necessary to focus on the instructions for use, which is indicated on the package itself. The manufacturer gives all the necessary information and everything you need to know the worker. To avoid poor quality outcomes, overdue products should be avoided. Before applying it is important to prepare and clean the surface. Alcohol can be used to prepare the site, but you should make sure that it does not harm the surface.

It is necessary to moisten the cotton with a small amount of degreaser to clean the place and thoroughly wipe the surface itself. A normal adhesive and sealant will not stick to a wet place, with the exception of a special type that is intended for use in a moist environment. Skipping the line of application, on the top and bottom of the seam should be glued mounting tape.

After completion, you need to remove the masking tape and wipe all the tools with alcohol or acetone, which will allow you to achieve the perfect result and a precise straight contour. In addition, this will save time because you will not need to spend it on rubbing out unnecessary frozen media.To strengthen the adhesion after applying the glue-sealant to the surface, it is recommended to moisten with soapy water, so it guarantees a strong adhesion for many years.

After application, it must be leveled using scrap materials or special tools. It is very important not to level the applied mass with your fingers, but to purchase a special spatula. The substance is chemical and corrosive, which can later cause an allergic reaction of the skin of the hands or slight discomfort. If you get money on your hands and nails, you can remove the excess with soapy water.

The duration of the drying of the adhesive sealant depends on the thickness of the layer that was applied to the surface. Full hardening of the agent occurs after 24 hours, and initial solidifications after engaging with the agent are already visible after twenty minutes. To accelerate drying will help the technique of applying a thin layer in small quantities. After hardening, it looks like rubber and becomes elastic. It should be remembered that a professional and quality product under all circumstances should always remain elastic.

Remove excess material will help construction knives and liquid solutions. You can try to clean it with a spatula or a knife, but it hurts the surface more than cleans it from the hardened mass. There are several ways to wipe off a surface without further damage. In advance, you must purchase a special solution for washing the product, for example, white spirit. Penta-840 is a good cleaning swab. Antisil is another effective means for cleaning the surface from the adhesive sealant. Most often, a similar remover is used by an automalor; you can buy it from sellers selling car accessories.

The sequence of works with adhesive sealant includes the following steps:

- preparation of materials and workwear;

- site preparation;

- to simplify the application you can use a mounting gun;

- it is not recommended to put a layer of 5–10 millimeters, with a thinner layer;

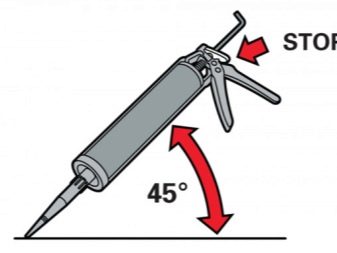

- in order to economically and uniformly apply the product to the surface, the tip of the balloon should be trimmed along the oblique;

- it is necessary to apply weight from a cylinder under a certain inclination (angle of 45 degrees);

- after completion, it is necessary to carefully remove the remnants with a spatula, it is necessary to guide the tool, without taking it from the seam and pressing it slightly.

In work with glue-sealant there is nothing difficult. It is worth buying a gun, in which you need to install a cylinder before use. Then you need to put the nozzle, and to adjust the flow to use trimming the dispenser of the required thickness. To squeeze the tool out of the gun, use a lever on which in the process of work you need to gently press and immediately put in place. It is important to remember that the balloon itself must be kept at an incline of 45 degrees.

When buying it is important to consider how much material will be consumed from start to finish. The capacity of a standard cylinder is approximately 300 mm. You should try to expend the necessary material so that at one time the required mass is evenly distributed.

The selected product option depends on the task, which is in front of the adhesive-sealant. The main thing is to follow the correct sequence of actions. If done correctly, the work will be quite easy, comfortable and relaxed.

Manufacturers

Success in work is a reliable manufacturer of building materials. After all, the quality and durability of the repair done depends on the used goods.There is a huge amount of quality and low-quality sealants with an adhesive effect on the market. Of course, there are also defective batches in production, but they are not so common. In most cases, a poor-quality product was made this way initially, usually some composite materials are replaced by cheap organic matter (kerosene, oils, and other components). Such additives significantly degrade the product and the effect of its components - the heat resistance, elasticity, color, strength and many other properties promised by the manufacturer disappear.

As a rule, the life of these materials is much lower than promised on the package. In order not to face an undesirable purchase, one should give preference to manufacturers that have been proven over the years. Modern companies provide a wide range of products, among them are some of the most popular.

- "Moment" used for exterior and interior installation finishes, sealing glass doors and windows, walls and floors. Joints and seams retain their strength and remain elastic for many years.

- "Latch 3" Designed for quick-drying fixation of metal pipe threads.Sealant with adhesive effect is used in systems of heat-resistant and cold-resistant water supply, gas supply, hydraulic fluids and heating.

- The company "Titan" Presents Polish professional high-quality product based on rubber and acrylic. Its main task is the treatment of seams in various areas. This adhesive sealant is waterproof and most often used for work in rooms with a high level of moisture.

- Soudal - is a professional all-purpose adhesive sealant. Its strength is useful in the work of concrete foundations, drywall, ceramics, natural stone and other materials.

- Penosil - it is a quick-drying one-component agent that will help seal the inner and outer seams. It has a good level of coupling with metal and glass surfaces.

- Firm Macroflex provides products of excellent quality with high performance, which takes a good place among users of building materials. In the assortment there is a huge selection of goods with reasonable prices and good quality.

- Ceresit - It is a sales leader with a wide range of building materials, dry mixes and various chemicals.Glue-sealant has a powerful antibacterial protection.

- Belinka is a high-class company that does not use toxic substances in the composition of the adhesive sealant and produces an environmentally friendly product. Every year, the quality of the goods is noticeably improved and promoted, therefore Belinka is the leader in sales among construction materials.

- "Second" in most cases serves as a sanitary measure. There are also special options with a heat-resistant effect, which are useful in parts of the glue and exposed to high temperatures. Sanitary options are designed to combat fungal microorganisms that appear on frozen silicone.

Tips

As already known, the range of sealants with an adhesive effect is so extensive that sometimes it seems impossible to choose the necessary one. When buying, you should contact the consultants, because they will help determine the choice of means depending on the surface to be processed. Do not be afraid to ask the seller documentation on the presentation of the brand goods. The shelf life is usually 18 months from the date of production.Storage should be tightly closed, while it is necessary to adhere to the temperature indicated on the vial.

Before buying you need to focus on the percentage of components, which should be the following:

- silicone - at least 25%;

- rubber mastic - from 3 to 5%;

- acrylic - 4–5%;

- polyurethane - 3-5%;

- cement mix content - not less than 0.4%;

- epoxy resin - 2%.

Important: the density of the adhesive-sealant should not be less than 0.8 g / cm ³.

You should pay attention to the time of manufacture of adhesive sealant, its quality, as well as to avoid such products:

- with damaged label;

- low cost, which causes suspicion;

- with a note that the silicone is 100%, because absolutely all manufacturers use additives;

- with lightweight tuba;

- with the lack of information on the cylinder and composition;

- with the absence of the seller copies of the certificate of quality.

In the next video you will find a detailed review of the universal adhesive sealant company Soudal.