Mastix cold welding: characteristics and scope of application

Mastix cold welding is well known to the domestic consumer. Due to its high performance, the composition is deservedly in consumer demand and is widely used in industry and in everyday life.

Specifications

Welding Mastix is a plasticine material made in the form of a rod consisting of two layers. The layers are separated from each other by packaging and are mixed only immediately before installation. The structure of cold welding includes amine and epoxy resins, metal fillers and mineral additives.

The material is highly resistant to extreme temperatures, which compares favorably with many analogues. The composition is able to withstand temperatures from -60 to +150 degrees, while maintaining its operational properties and the original volume.Welding in a soft package weighing 55 g is produced. The storage temperature is 30 degrees, and the “viability” of the finished mixture does not exceed 7 minutes.

Field of use

Mastix cold welding is often used as an adhesive, but the main functional feature of the composition is the ability to create various parts from it. Due to plasticity and the ability to take given forms, the material can be used to recreate worn mechanisms and parts to them. The tool is often used to eliminate cracks and chips, indispensable for the repair of pipes and batteries.

The material copes with the repair of furniture, interior items and household utensils, and by creating an airtight connection it can be used for gluing aquariums and stained glass. Despite the fact that welding is sufficiently resistant to moderate vibration loads, strong mechanical effects can damage it. Therefore, it is not recommended to use the material for the repair of products exposed to shock.

Mastix perfectly connects metal, wood, plastic,stone and glass bases in any combination, which, together with a wide range of temperatures in which the glued parts can be used, further increases the popularity of glue.

Advantages and disadvantages

High customer demand and a large number of approving reviews about Mastix cold welding due to a number of indisputable advantages of this material.

- Ease of use and convenient form of release allow you to easily prepare the mixture and carry out installation on their own.

- Consumer accessibility and reasonable cost make the material even more in demand.

- Wide range of. In the model range of Mastix there are compositions of different purpose and technical characteristics. Along with adhesives of narrow specialization in the lineup, there are also universal types.

- High bond strength, heat resistance and moisture resistance of the seam allow welding to be used in any temperature and humidity conditions.

The disadvantages of cold welding Mastix include a slightly increased hardening time and the probability of lump formation. The first is due to the presence in the composition of epoxy resins, and the second is due to poor mixing of the components during the preparation of the mixture.

Species

Cold welding is available in several versions, each of which has specific performance characteristics, designed to work in certain conditions and with specific material.

- Welding for metal products. A series is intended for repair of bathroom equipment and pipelines. The composition of the mixture includes a metal filler, which ensures high strength of the joint and ensures the durability of the seam. Glue is not afraid of excessive moisture, so it can be used on wet surfaces without prior drying. Models of this series are divided into several types, each of which specializes in gluing a certain material. For example, a special compound “Fast steel” has been developed for working with steel bases, and for mounting aluminum structures there is a mixture containing aluminum fillers and designed exclusively for this metal.

- Universal option. This type of welding is the most common. It is distinguished by the strength of the joint, it is quite effective on any surfaces.

- Heat-resistant composition has a red color packaging.It does not lose its performance when the temperature rises to 250 degrees.

- Plumbing mixtures are designed to repair metal and porcelain elements. They are distinguished by high waterproof properties and durability of the connection.

Popular formulations

Among the wide variety of modifications the most popular is the Blitz Batyr series of universal means. Glue is intended for the connection of any materials, including ferrous and non-ferrous metals, plastics, ceramics, wood and glass. With it, you can restore a defective part or eliminate a leak in the tank. Glue is very convenient in application and does not require thorough preparation of working surfaces (installation can be carried out on wet, dirty and oily bases).

Welding "Blitz Batyr" consists of epoxy-Dianova resin, plasticizer, amine hardener, kaolin, chalk, dioxane silicon and iron oxide pigments. Welding production is governed by technical conditions 2252 023 90192380 2011 and meets all standards.

No less popular "Batyr" with a steel filler. The composition of the adhesive is represented by epoxy resin, an amine hardener, a plasticizer, a hardening accelerator, kaolin, chalk, silicon dioxide and steel powder.The composition can be used at a temperature of 0 degrees.

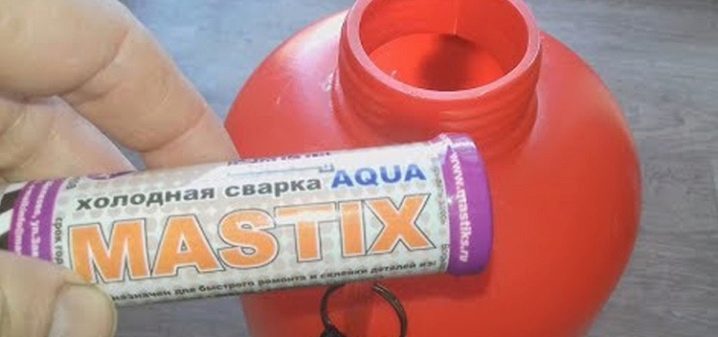

Instructions for use

Before preparing the composition, the work surfaces should be prepared. Bases are cleaned of rust and mechanical debris, wiped dry and degreased (if necessary). Then you need to cut off 1/3 of the rod and thoroughly mix both components with wet hands. An indicator of a properly prepared mixture is the color of the material: it should become uniform, without inclusions and stains. Then the resulting composition must be applied to both parts, then connect them together and fix.

The fixing time must be at least 15 minutes. When working on oily, wet or contaminated substrates, it should be remembered that the bonding strength of problem areas is reduced by 25% compared to dry and degreased surfaces. If the installation is carried out at low temperatures, the composition must be further heated in the hands for 3-4 minutes, and then quickly applied to the substrate.

When warming up the material, it should be remembered that the time of its “viability” is 7 minutes, so the installation should be done quickly, and the mixture should be prepared exactly as much as you plan to use during this period.The initial setting time depends on the environmental conditions and the temperature of the working elements. The higher the temperature, the faster the solidification will be, and vice versa, as the temperatures drop, the solidification time may increase. To use the repaired products, and also to subject them to loading and it is possible to process after one and a half hours. The composition is not recommended for bonding items that have direct contact with food.

Due to its high performance, Mastix cold welding is an indispensable repair tool. That is why it is widely used in various fields of human activity.

For information on how to use cold welding, see the following video.