Knauf Fliesen tile adhesive: features and specifications

It is not so easy to choose the glue for tiling: the modern market is literally littered with a wide range of offers for different tastes and budgets. However, among all this diversity, professional craftsmen often choose Knauf Fliesen tile adhesive. To understand its relevance, it is necessary to get acquainted in more detail with its features, advantages and disadvantages, as well as technical characteristics.

Special features

Knauf Fliesen tile adhesive is a product of the domestic manufacturer and is designed for indoor and outdoor use. This is a facing mixture for breeding, which is suitable for laying wall tiles of a small size (no more than 30x30 cm) with water absorption of more than 3%.In addition, the composition is designed for laying floor tiles, as well as porcelain tiles with the dimensions of dies up to 60x60 cm inside buildings.

Wall cladding can be done inside and outside buildings, including over tongue-and-groove tiles.

The composition has a gray tint and, depending on the variety, is characterized by a minimum layer thickness, which distinguishes it from other analogues. He is able to glue to the surface even heavy material with a high degree of adhesion. However, in order to achieve maximum strength after laying tiles using this mixture, it is necessary to maintain a temperature in the room of about + 20 ... +25 degrees for at least two days.

The main components of the adhesive are cement and fine sand. The composition of the product has special additives based on polymers that increase the degree of adhesion with the treated base. Each type of adhesive brand has a certificate of quality and compliance with regulations. The formula of the composition is designed in such a way as to prevent the formation and spread of mold and fungal infections of the surface.

The composition of the product is intended for fixing moisture absorbing tiles on a relatively flat base.In working with tiles, you can use special primer compositions of the same brand. For tiles that do not absorb moisture well, the company recommends using other lineups. The mass is not applied immediately to the entire wall, as long as each fragment is installed in its place, it can begin to dry, reducing its adhesive properties.

When working surface gypsum screeds and places of direct contact with water should be isolated waterproofing. When working with screed layer must be monolithic. You can work with the composition using the minimum set of inventory. To do this, you need a plastic container, a mixer, a notched trowel and a trowel. However, due to the special strength and petrification during drying, the manufacturer strongly recommends removing glue contaminants immediately, without waiting for the mortar to harden.

Advantages and disadvantages

Tile adhesive brand has a wide list of advantages. For example, it can be used in working with different types of bases. It is suitable for lining concrete, cement, brick, stone and other bases (GKL, GVL, GGP, SML, TsSP). To carry out the lining with this glue can be on the cement plaster.In addition, the composition is easy to prepare: if you follow the instructions on the packaging of the product, it will not be difficult to prepare it.

In addition, it is easy to work with him, which is especially important for any master and even a beginner.

This composition is plastic, which allows its use when finishing the base with a height difference of up to 2 mm per 1 m2. The diluted mass is comfortable, does not flow and does not slip from vertical planes, therefore it does not increase the degree of the angle of inclination of each upper stacked row. The solution is characterized by a long life cycle, due to which there is no need to dilute it in small portions.

The adhesive of the company is resistant to high dynamic loads. It can be used for laying not only ceramic tiles and porcelain tiles, but also for tiles, mosaics in the form of separate fragments and on the grid, natural and artificial facing stone. This is a modern glue that allows you to veneer surfaces on a professional level. Convenience for buyers is the availability of modifications, due to which you can choose a special type of glue for a particular material.

At the same time there is no need for preliminary soaking of a tile. Due to the high ductility, the solution not only lays well on the base, but also makes it possible to correct its minor irregularities. It will cover the small pits and relieve the cracks from microcracks. This is a material with a long life. With the observance of the technology of breeding and laying, facing of surfaces with brand adhesive will last more than a decade without needing to be repaired.

Due to the high resistance to moisture, the mixture can be used for finishing rooms with a high coefficient of humidity. Glue is a waterproofing of hygroscopic and mineral floors. An additional advantage is the fact that this composition is suitable for laying on previously installed tile. In addition, pleases every buyer and the price of the material.

However, with a lot of advantages, glue has its drawbacks. For example, it will not keep the lining well, if the base is not prepared properly. In addition, if you do not withstand the temperature during operation, it can affect the quality and durability of the coating. If the air in the room is too dry, the life cycle of the finished solution will be reduced.

At the same time, the adhesive mass will dry out quickly, and the time for correcting an incorrectly installed element will be reduced.

Kinds

Today, the brand offers Fliesen glue in three modifications: “Universal”, “Plus” and “Max”. Each type of mixture has its own differences. For example, mixtures have a different field of application, as well as the thickness of the adhesive layer, which allows using different in weight and size materials for laying wall and floor tiles. Thus, the option "Fliesen Plus" is a product with a reinforced formula.

It can be used not only for decoration of walls and floors of buildings. It is suitable for cladding the facade of the house and even the base. The total weight load of such an adhesive is 1 square meter. m lining is 50 kg (tile weight + glue). Fliesen Max is distinguished by the possibility of thick-layer application of the working solution.

For example, the maximum thickness of the layer under the tile when laying with this solution can be 3 cm. This feature allows you to lay the elements on the base with simultaneous alignment. Maximum permissible weight load per 1 sq. m of such facing is 50 kg. However, this composition is incompatible with the “warm floor” system, which is its disadvantage.It is not intended for finishing the basement, although it is considered universal, suitable for interior and exterior use.

Comparison with other analogs of the line

If we compare all the modifications with the compositions "Flex" and "Marble", then "Marble" is distinguished by the presence in the composition of the mineral filler, as well as white. It is this factor that determines its purpose, since it is the only option from the entire range of Knauf adhesives that does not distort the color of glass and translucent mosaic, translucent ceramic tile. The varieties in question cannot protect the color of a similar lining from discoloration. Therefore, they can be used for stacking more traditional materials, and nothing more.

With regards to the comparison with the analog Flex, it is worth noting that this composition is more relevant for lining industrial facilities. In addition, it differs in that it is suitable for the treatment of unstable bases. These are deformable overlappings to which tongue-and-groove plates and a chipboard, and also a tree belong.

The reinforced version of “Fliesen Plus” is designed for fixing low-porous granite plates.

Specifications

The main physicomechanical characteristics of a dry mix look like this:

- the life cycle of the finished solution is not more than 2.5 hours;

- adhesion to concrete - not less than 0.6 MPa;

- time for the adjustment of the element - up to 10 minutes;

- the thickness of the adhesive layer is from 2 to 6 mm;

- grouting can be done a day after laying;

- walking on the floor facing is possible after 24 hours;

- full weight load on the finished finish is possible after 7 days;

- working t of work is from +5 to +25 degrees;

- the composition is compatible with the system "warm floor" in the modification "Fliesen Plus";

- frost resistance is not less than 50 cycles;

- shelf life should not exceed one year, provided the integrity of the package.

Brand adhesive tile is quite elastic, which simplifies the veneering and adjustment of individual elements. The composition dries on the floor quickly enough, while the glue is resistant to cracking.

Forms of release

To date, the composition is produced in standard bags of 25 kg. Less often on sale can be found packing of 10 kg. Regardless of the variety, powder glue should be stored strictly in dry rooms on wooden pallets.In the presence of damage to the composition is recommended to use first.

How to calculate the flow?

According to experts, the consumption of Knauf Fliesen tile glue, depending on the variety, is from 2.2 to 2.9 kg / m2 for the modification of Fliesen and from 1.7 to 3.7 kg / m2 for the analogue of Fliesen +. An important aspect in determining the rate of consumption is the height of the teeth. For example, when laying dies with dimensions of 10x10 cm per 1 square meter. m can take no more than 1.8 kg of the working solution, provided that the length of the teeth of the notched trowel is 4 mm. If the length of the tooth spatula is larger (6 mm), the flow rate will increase to 2.3 kg or more.

You can calculate the number of bags by the formula. To do this, you need to know the size of the cultivated area (S), the length of the trowel teeth (L) and the base flow rate (H) indicated on the marking. The formula is as follows: (S * L * H) / 2. For example, with an area of 18 square meters. m with a base consumption of 2.2 kg / m2, packaging of 25 kg and a height of teeth of a spatula 6 mm will need (18 * 2.2 * 6) / 2 = 118.8 kg or 5 bags (round 4.75 to an integer) .

Using

Before laying the tile or other facing material, it is necessary to properly prepare the base. This implies not only removing the crumbling old coating.It is necessary to remove any dirt and oil stains, get rid of lime, if it is on the surfaces of the floors.

After that, you need to remove dust from the surface of the future lining.

Following on the overlay cause primer deep penetration. It will strengthen the base, align its structure, bind the remaining dust particles and microcracks. After application of the primer, the surface is leveled with a cement-based rough plaster mixture, then trimmed and again treated with a primer. And only after that you can perform facing.

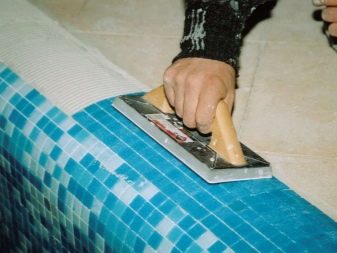

Glue diluted with clean water at room temperature according to the instructions indicated on the labeling of the bag. In this case, a construction mixer is used so that the working solution has a uniform consistency. After the initial mixing, it is left for a few minutes, then mixed again and used. In the process, use a conventional spatula for applying glue to the working surface, as well as a gear tool for normalizing the amount of glue.

Apply glue to a part of the surface, spread it evenly, then remove the excess with a notched trowel. They take a die, spread glue on it, after which they pass through the solution with a notched trowel in a direction perpendicular to that on the plane. So it will be possible to distribute the glue correctly, and also to carry out the work as accurately as possible. After the element is pressed down slightly to the base.

So put all the dies. For the identity of the gaps between the tiles used plastic crosses or special clips. Excess composition is removed with a rag. You can not scratch it with a tile or other material, because the aesthetics of the lining will suffer from this.

One day after laying, the crosses or clips are removed, and the voids between the fragments are filled with a special trowel. After it dries and hardens, the remnants of the grout are removed with a dry sponge, passing it over the entire facing area. You can treat the surface with a special spray. Do not grind if the tile adhesive is still dry.

Violation of the technology of laying can lead to detachment of the material from the base.

Reviews

Knauf Fliesen is considered a high quality tile adhesive. This is evidenced by the reviews of those who worked with this solution.And often familiarity with the mixture begins with the recommendation of professional craftsmen in the field of construction and repair. According to the available comments, the mortar is easy to use, the tile keeps tight, dries optimally quickly. The material is valued for plasticity and economy in work. It does not slip from the base and the elements themselves, has an optimal setting time and, most importantly, does not crack.

A comparative test of tile adhesives awaits you in the next video.