Features and scope of GVL

One of the most popular modern materials for interior decoration today is considered to be GVL. This abbreviation stands for gypsum-fiber sheet, which is a dense finishing material of gypsum and cellulose. It is a durable material that is commonly used for wall cladding and floor screeding.

Special features

The main feature and advantage of gypsum fiber is strength and ductility. The homogeneous composition of the plate GVL even allows you to hammer nails into it, like in a tree. A special microclimate is maintained in a room finished with GVL-sheets, since the material is able to absorb excess moisture or give it away. Thus, gypsum fiber is a natural moisture regulator.

Gypsum board can be processed in different ways. For example, the mark "W" on the package means that the sheets are sanded, and "NS" - unpolished surface. When choosing GVL is not for rough finishing, but for painting or wallpaper it is more often to choose sheets with a polished surface, but if you need to glue some additional finishing material (panels or tile) over GVL, then a slab with a non-polished surface is best.

If it is necessary that when finishing there were completely invisible joints of GVL-sheets, then it is necessary to choose packages marked “FC” - sheets with special chamfers for an inconspicuous joint. If ordinary sheets are used, then the joints must be puttyed using a special reinforcing tape.

Gypsum fiber does not combine well with silicate dyes and paints based on liquid glass. Any other paint can be used - alkyd, dispersed and so on.

Most manufacturers are interested in the high quality of the manufactured building material, so when you purchase a GVL, you can safely demand GOST certificates of conformity and other documents confirming the quality of the products.If there are no documents, then it is better to refuse the purchase - the material may turn out to be of poor quality.

Advantages and disadvantages

Gypsum fiber boards have many advantages over gypsum board and other finishing materials.

Consider the advantages of this material in more detail:

- the material has excellent thermal insulation and noise insulation qualities, therefore it is suitable for the use of interior decoration of country houses and installation of interior partitions in them;

- high fire resistance, as evidenced by special certificates;

- the plates are hygroscopic, that is, they are able to absorb moisture from the air, and, if necessary, give it away;

- moisture resistance of gypsum-fiber boards is better than that of drywall or fiberboard;

- high-strength plates, very dense, but also flexible at the same time;

- no deformation of the material due to temperature changes do not threaten you;

- it is an eco-friendly material, containing gypsum and cellulose;

- it is easily mounted both on a wooden frame and on a metal one;

- the joints of the plates are easily masked;

- even the house master can use plates in construction and finishing;

- no significant waste, dust or dirt.

GVL canvases also have disadvantages, but there are quite a few of them:

- the plates are rather heavy;

- GVL is more expensive than drywall;

- if the GVL installation rules are not followed, the material may crack or break during further operation;

- special tools for mounting or cutting plates GVL do not need.

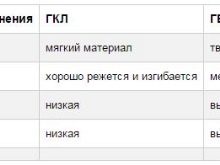

What is the difference from GCR?

GVL-plates are similar to drywall and glass-magnesium finishing materials, but have their own characteristics.

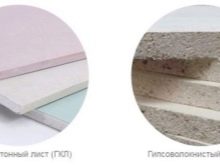

- Drywall is a "sandwich" of two layers of cardboard and a gypsum layer, and sheets GVL - whole, as the cellulose fibers are added to the gypsum mixture, pressed and dried. That is why GVL stronger gypsum.

- Glass-magnesium finishing materials (MFL) differ from GVL with greater fire resistance, but are inferior in “naturalness”, as they contain, in addition to binding components, magnesium oxide and magnesium chloride, and the fibers present in the composition of GVL - the product of recycling waste paper.

- GVL is a durable material, therefore, unlike GCR, it will be good to withstand accidental damage. Anyone who has dealt with drywall knows that even an occasional gentle blow can damage this material.With GVL-sheets, you can be sure that neither a random champagne cork, nor an unsuccessfully thrown children's toy will cause serious harm to the wall. Since the differences between GVL and GKL are connected precisely with strength, It is important to note that gypsum-fiber boards can be used when leveling the floor., and drywall is not suitable for this. When choosing a sheet of drywall, you have to take into account the size of the room and the height of the ceilings, since the wall, finished with one sheet, is much stronger than finished with several. The wall of gypsum fiber may consist of several elements, it will not violate its strength.

- Drywall when sawing often crumbles, and you can not be afraid of this with gypsum fiber - no crumbling or chipping during cutting will be. Gypsum fiber can be cut as required. It is necessary to say only about a large amount of dust when cutting, so all work is best done with glasses.

- Even if the plasterboard is wet, then it will not lose its properties - for some time it will just become more plastic, and after drying it will return the standard strength. By the way, if you are going to glue the surface with wallpaper, then remember that the plasterboard can absorb glue.

- The difference between these two materials allows them to be used for structures with different purposes.

- It is much more difficult to bend gypsum-colored slabs, than drywall, so the interior with bends and indirect lines is better to perform from drywall.

- Gypsum fiber differs from drywall more resistant to temperature extremes, in particular, to freezing.

- For installation of gypsum sheets and GVL-slabs need a frame. And those and other building materials require the preliminary manufacture of the supporting structure of metal or wood. For GVL-slabs, the frame structure must be stronger, and the profile must be at least 0.5 mm thick, since the plates themselves are rather heavy.

Due to the high weight of gypsum-fiber boards, it can be difficult for one master to work with them. If you have to rely only on yourself, choose small versions of GVL-sheets.

Specifications

The composition of the material (waste products and gypsum) gives a white and gray color to all sheets of gypsum plasterboard. The ratio of gypsum and cellulose fibers for gypsum-fiber boards is about 80% to 20%.The density of the gypsum-fiber panel is approximately two times less than the density of red brick.

The tensile strength of GVL-sheet is very high: on bending, the index will be 53 kg / cm2, and in compression - 100 kg / cm2. The thermal conductivity of the material reaches 0.36 W / mK and is similar to the thermal conductivity of expanded clay. The material is warm to the touch.

Sound insulation GVL-plates at a good level - sound absorption comes to 40 dB and depends on the thickness of the material.

There are waterproof GVL and ordinary. GVL swelling in water will be 1.5% in a day.

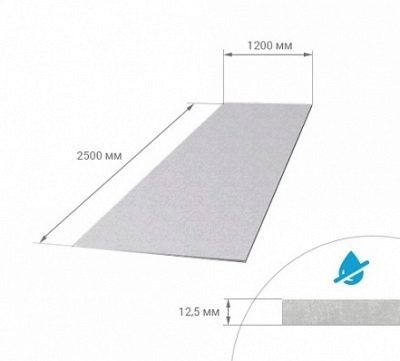

GVL-plates come in different sizes, but most often on sale we find sheets in the form of rectangles from 2 to 3 meters long and from 60 centimeters to 1.5 meters wide. Sheet thickness can be 10, 12, 14, 16 or 19 mm. When interior decoration is usually used material of the following parameters: 10 or 12 mm thickness, 2500 mm by 1200 mm. The larger and thicker the GVL plate, the more it weighs.

The first place in the Russian construction market is occupied by Knauf GVL-plates, therefore, we will be guided by them in determining the standard ratio of the size and weight of one panel.

The ratio of size and weight for ordinary sheets GVL:

- plate 250x120x1 cm - 36 kg;

- plate 250x120x1.25 cm - 45 kg.

The ratio of the size and weight of sheets GVL for dry floor screed:

- plate 120x 120x1 cm - 17.5 kg;

- plate 120x120x2 cm - 17.5 kg.

GVL-slabs - fire-resistant material, incapable of self-ignition. Flames do not spread over the surface of the material. On the packaging of the material and in the certification documents the fire resistance category G-1 (slow-burning) is indicated.

Moisture resistance and resistance to deformation provides a special treatment.

In order to increase moisture resistance and resistance to deformation, the gypsum fiber is impregnated with special latex compounds right in the process of its production. Such a water-repellent treatment will not only increase the water resistance, but also provide optimal adhesion to other finishing materials and painting.

Kinds

Gypsum-fiber materials differ from each other depending on two criteria: size and purpose.

By appointment stand out:

- Standard GVL plates used for construction and finishing works in rooms with standard humidity indicators. Durable, safe for human health materials, widely used for the installation of internal partitions and other repairs.

- Moisture resistant GVLV plates. They can withstand high humidity for a long time, so they are used in the decoration of kitchens, bathrooms, even saunas and baths. Moisture resistance is acquired through the processing of the material with special water-repellent compositions.

- Plates GVL- "superpol". Produced by Knauf. Very strong and reliable plates, ideal for working on a dry floor screed. The “superfloor” plates are two welded sheets of gypsum fiber board, while they are slightly offset relative to each other to facilitate installation and to obtain a reliable quality surface with excellent strength indicators. Dimensions of GVL-sheets are determined by the requirements of GOST, while, as mentioned above, some material characteristics will depend on the size:

- Standard 1200 × 1500 mm plates are used for finishing or construction of any surfaces. They align the walls.

- Small format slabs. Dense and heavy slabs are usually used for flooring. Usually they have a folding system (“in lock”) when connected to each other.

Scope of application

The scope of GVL is very wide and is becoming wider.Over the past two decades, the volume of “dry construction” has increased dramatically in our country, that is, without the use of mixtures, so the demand for gypsum fiber has steadily increased. So, GVL materials are used:

- in the construction and repair work of residential and public buildings;

- for wall decoration in industrial enterprises, as well as in trading floors and hangars;

- when covering any frame structures and building walls;

- for installation of partitions indoors;

- for decorating when the walls need to be leveled;

- when installing flooring;

- as finishing wooden and other walls in country houses;

- in sanitary rooms (in the bathroom, shower or toilet) for subsequent tile finishing;

- when facing technical rooms - storerooms, attics, etc .;

- when finishing basements with standard and high humidity;

- in the decoration of the balcony and loggia - as an independent or draft finish;

- for decoration of premises with special requirements for fire safety, for example, lift shafts and evacuation corridors;

- due to environmental friendliness, it can be used in the decoration of school and kindergarten premises (the natural background radiation is three times less than that of the widely used brick);

- for installation of flooring in sports and dance halls;

- when installing warm floors, as GVL-sheets have good heat capacity;

- in rooms where it is necessary to place a hanging closet, shelves or heavy doors on the walls - gypsum fiber easily withstands even very serious loads;

- when creating cabinets and ducts to conceal plumbing and other communications;

- gypsum fiber impregnated with antifungal agents used in construction and repair work in medical institutions and swimming pools.

In general, it is safe to say that gypsum-fiber materials allow you to perform high-quality construction or finishing work in almost any room, while the owner of the room can count on their durability and strength.

What to cut?

When performing construction or finishing works with their own hands, it is often necessary to cut GVL-slabs. Professionals point out that, in general, this work is similar to drywall cutting, but some features need to be remembered. So, gypsum fiber bends much worse than drywall.Therefore, if you unsuccessfully position the sheet before cutting (for example, if the edge of the blade will sag heavily down from the cutting place), it may crack or break.

Tools that can and should be used when cutting plasterboard materials include construction knife with replaceable blades (the blades must be at least 12 mm thick) or a special hacksaw that allows you to cut GVL with almost no dust (you can also use a regular sharp hacksaw, but in this case dust will be necessary).

Can be used grinder or circular sawHowever, this method, although considered the fastest, is the most dusty and noisy. Of course, if the room is easily ventilated, it makes sense to use these tools, be sure to protect the respiratory tract with a respirator and special glasses - vision.

Professionals often use electric jigsaw with built-in vacuum cleanerbut the spread of dust still cannot be avoided - the vacuum cleaner does not have time to absorb all its volume. Use a standard file for a jigsaw for woodwork with a tooth pitch of at least 4 mm and do not forget about protective eyewear and a respirator.

When working with any instrument, you should follow safety precautions, and it is recommended to prepare GVL material. So, the sheet is recommended to soften before you start to cut it. So the dust will be less, and cut it will be much easier. To mark a markup line, use a rule or a ruler.

Along the line of marking it is necessary to carry out several times with a construction knife (it is necessary to carry out more than once, but until the sheet indicates a deep groove - at least 2/3 of the sheet thickness). We put a special rail under the cut line and sharply crush the material. Leaf we crack up, not down!

Such a difficult task, as cutting gypsum-fiber sheets, is compensated by the formation of a smooth and even edge of the cut GVL-plates, which do not need additional processing.

If, however, you didn’t succeed very smoothly, then the fitting can be performed using a conventional roughing planer, and a knife-cutter or chisel will help to prepare the fold.

Subtleties of installation

At installation of GVL-plates for walls and a floor there are subtleties. Nevertheless, these works can be done by hand.

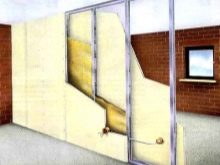

Installation of GVL-slabs to the walls in stages:

- prepare sheets GVL (sawing, marking);

- prepare the surface (cleaning, leveling);

- markup for profiles;

- put a special sealing strip on the profile;

- Attach profiles to walls using screws; If necessary, use dowels;

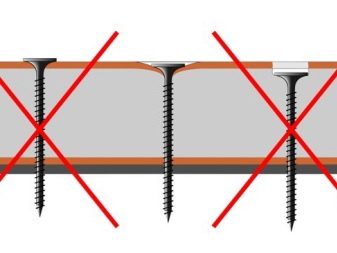

- fix gypsum-fiber sheets on profiles with the help of special screws, use only GVL screws !;

- the screw head “sinks” about 1 mm into the sheet, while it is important to ensure that the screws enter the material at a right angle, and the fixing step should not be less than 25 cm;

- we work out joints and screws with a putty, after which we ground them.

Gypsum panels can be fixed to the walls and using mounting glue. In this case, the frame is not needed, and the technology of the work is as follows:

- prepare sheets GVL (cutting, marking);

- prepare the base wall (cleaning and leveling the surface);

- carefully read the instructions for applying construction glue, as there are types of glue that are applied around the perimeter and strips in the center (mesh) with a notched trowel, and there are types that are applied dotted;

- Apply construction glue on GVL-sheets;

- press the panels against the walls;

- Seal the joints with a putty and prime.

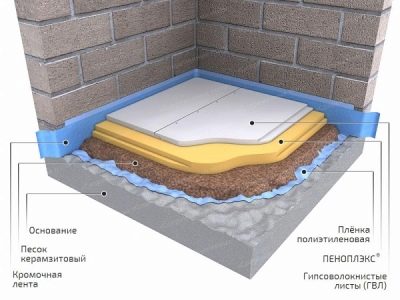

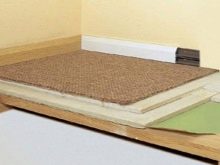

GVL mounting on the floor is used before laying laminate and other finishing materials. Gypsum fiber helps to level the floor, strengthen it, make it moisture resistant and fireproof.

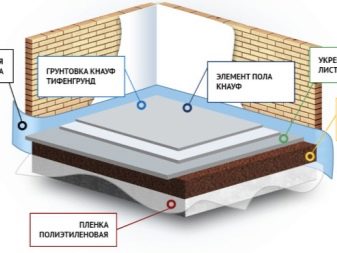

Technology installation GVL-plates on the floor as follows:

- If necessary, dismantle old flooring, including old logs.

- Remove debris and dust.

- Eliminate the gaps in the old floors. For this you can use alabaster, mounting mixture or fast-hardening cement.

- Layout the backfill level using the water level. It is desirable that the difference in the marks you set be no more than 6 cm. Be prepared for the difference to be anyway, since the unevenness of the floors is a common thing.

- Install the waterproofing material. The first layer is dense polyethylene, glassine or tol (the material must be selected depending on the purpose of the room and remember that this layer serves as a vapor barrier). Polyethylene or other material overlap, and glue the edges of the mounting tape. Waterproofing is placed so that its edges went on the walls (making a kind of bowl) above the waterproofing level marks. The edges of the film must also be glued to the wall. The second layer - insulation / waterproofing. Many masters give preference to expanded clay, as it has good performance characteristics. Wooden or reinforced concrete base stack layer of waterproofing material.

- Smooth clay. For these works, use the beacons of the guide metal profile and level, paying particular attention to the corners of the room and the space around the walls.

- If your room needs additional sound insulation, then use foam polystyrene sheets for this, laying them between expanded clay and GFL slabs.

- Between expanded clay and GVL you need to lay all the necessary communications, for which you need to use special corrugated tubes.

- Start the installation of gypsum fiber materials. Installation of the base floor of gypsum-fiber plates of medium size. This is a simple and fast process, representing the laying of plates of small and medium sizes, which need to be fastened to each other by folded edges. If the ends of the plates are not folded, then simply lay the plates in two layers so that the joints of the plates of the first and second layers do not coincide. The most commonly used plates with a thickness of 1 to 2 cm, rectangular 1.5 mx 1 m.

- Underfloor heating, which is becoming increasingly popular today, is mounted between the GVL-plates and the finish.

- After GVL-plates are laid, you need to putty seams and places where the screws are screwed. In kitchens and bathrooms, the joints between the sheets need additional waterproofing.

- A day after the completion of works with GVL, you can begin the final finishing of the floor, including laying the tile.

For work, you will need the following tools and materials: a knife or handsaw, tape measure, mounting glue, various spatulas (notched and common), sealing tape, construction tape, level, self-tapping screws, special screws for GF, dowels. Lighten and speed up the jigsaw and drill.

Tips and tricks

We present the most current recommendations from experienced masters on installation of gypsum fiber board:

- All calculations on the amount of materials need to be done in advance, this will help to avoid unnecessary expenses, because GVL sheets are not cheap stuff.

- Before buying plates, we recommend inspecting them for cracks and chips. Sheets with cracks can not be used in construction, and chipped will give you a lot of trouble when fitting the plates to each other.

- When buying glue, make sure that it is suitable for use with GVL. Otherwise, the material can be spoiled.

- If tiles will be laid on the floor covered with GVL-slabs, we recommend that you take a three-day break between the installation of the gypsum plasterboard and its laying.

- Before cutting the seam edge adjacent to the walls, be sure to follow the slab taping.

- Valuable advice - glue seam connections with glue, so the "lock" connection will be much more reliable. If there is too much glue and it “crawls out” of the seams, then try to remove the excess as soon as possible - you can use a sponge or dry cloth.

- If GVL-plates are laid on the floor in two layers, then we recommend to take small-format plates for the lower layer, and standard ones for the upper layer. This floor will be more reliable and strong, will not "breathe."

- Tile glue, which you will put on GVL-sheets, dries very quickly. Do not immediately coat the entire surface!

- If you use GVL for a tile floor, it is advisable to prime the floor before laying the tile. After priming, check if the surface is “breathing”.

- If there is no possibility to use expanded clay for insulation, then give preference to mineral wool.

- Hard putty "Fugenfyuller GV" is best suited for fine-tuning the seams of gypsum-fiber boards.

- Wet rooms require the installation of only moisture-proof GVL-sheets. Ordinary plates, of course, will also last for some time, but this will be a temporary measure, and soon they will have to be changed.

- If the main floor is complex and uneven, then sometimes you have to put not two, but three layers of GVL-plates. However, in this situation, you need to think about the additional installation of the lag, because the floor will become much harder.

- Construction and repair works using GVL, including repair of floors, can be carried out in private and in apartment buildings.

- GVL slabs can be an excellent substitute for a traditional wooden floor.

- GVL-sheets for the floor are great for building warm water or electric floors.

- The seams between the panels in the bathroom or kitchen must be treated with high-quality waterproofing mixtures, as the water falling on the floor should not fall between the plates.

- GVL-plates are suitable for pouring the popular "liquid floor", as they are able to withstand a serious load.

In the next video you will find more information about the features of GVL.