Plaster net: the pros and cons

Repairs are a complex set of works that help to make something beautiful, stylish and comfortable out of a regular room. To achieve the best results, it is important to use the materials correctly and choose the ones that are best suited for a particular type of work. The use of plaster grid is becoming more frequent, because you need to know all its advantages and disadvantages.

Special features

Modern repair does not do without the use of plaster, because the walls, floor and ceiling in finished form must be completely flat, be warm and soundproof, serve for a long time and reliably. If a layer of plaster is not applied to the draft wall, the desired effect cannot be obtained. In order for the layer of plaster to hold securely, not to crack and not collapse, it is important to reinforce it. That is the fastening mechanism is the grid.

If earlier, more primitive and inconvenient materials were used to strengthen the surface under the plaster, then with the advent of a grid of new materials, it became much easier and faster to work. Plaster mesh can be made of different materials, have a different cell size, its shape, as well as the weight of the canvas. All this causes a different result from its use.

If it is necessary to revet the outer wall, then a reinforced mesh with large cells is often taken, in some cases a chain-link is used.

Almost every construction store now has a choice of grid for plaster, which have different lengths, which makes it possible to choose the optimal amount of material needed for the work. The principle of working with it is quite simple, which makes its use more popular for the repair of all the rooms in the house, apartment, office, obtaining excellent final results.

Plastering mesh is a very important element for repair work, because with its use, the finishing wall finish easier, and the result lasts much longer.After plaster using a grid, the wall will not change its properties, and therefore the wallpaper will not be threatened by tearing at the joints or along the canvas itself. Painted walls are most susceptible to shining through the flaws that appear on them, therefore, choosing such a method, it is important to take care of the reliability of the wall and its strength.

Any type of lining will be much more confident to attach to the surface, which is properly processed, and its service life will increase several times if the surface has been strengthened and protected from all sorts of influences and unpleasant environmental factors.

Kinds

Due to the great popularity of the material, it was necessary to create a certain number of options that would allow spackling on different surfaces as convenient and efficient as possible. So, there are such types of mesh as:

- Grid for masonry - This is a building variety, which is best to go to the laying of brick. The material is polymer, and the cell size is 5 to 5 mm.

- Universal - a small cell is used to reinforce the finishing and plaster mixes.It is convenient to use it in any areas due to the optimal cell size, which is 6 to 6 mm.

- Average universal. The material is polyurethane, as in the previous case, but the size is different - by 13 by 15 mm.

- Large universal - cells have a size of 22 by 35 mm and with its help you can easily reinforce a large area. It is convenient to make repairs in buildings with large dimensions.

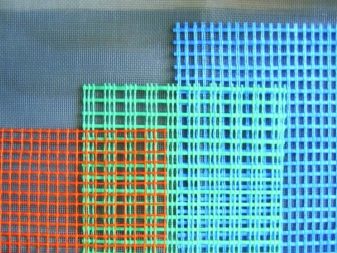

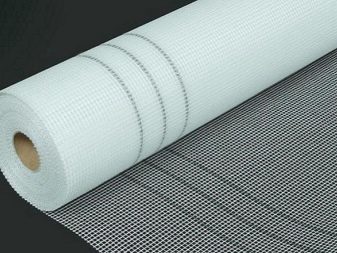

- Fiberglass. Its composition is fiberglass, which is processed in a special way. The size of the cells is not large and is 5 to 5 mm. This option easily tolerates the temperature difference, the impact of chemical elements, while it has high strength and can withstand a large weight of plaster. This option is most often used in work, because it is lightweight, convenient and has no particular contraindications to use.

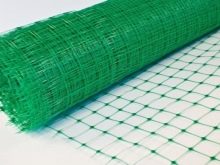

- Plurima - Polypropylene biaxially oriented mesh with a 5 by 6 mm cell. This option is also convenient in work, because it is not exposed to chemical effects, light and used both indoors and outdoors.

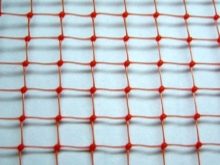

- Armaflex - polypropylene type of mesh, in which reinforced knots are provided. The cell in this case is quite long and is 12 by 15 mm. The mesh has high strength, because it is most often used where the layer of putty is very large.

- Sintoflex - polypropylene version with a cell 12 on 14, 22 or 35 mm. The lightness of the material and the lack of reaction to chemicals allow you to work with the grid both indoors and outside.

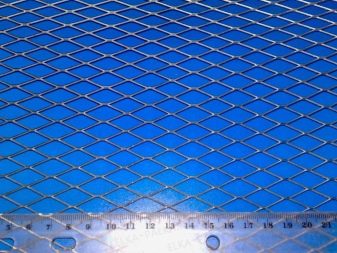

- Steel option - These are welded steel rods. The size of the cells can be very diverse. Used for interior decoration, because under the influence of precipitation steel will not serve for a long time and will begin to rust.

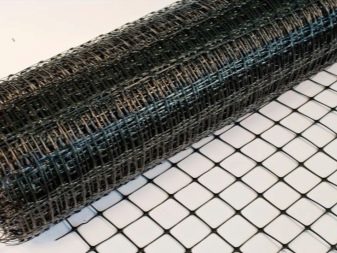

- Galvanized version involves the interweaving of galvanized twigs among themselves, which is then soldered. It is a durable material from which you can level the surface in any conditions, both indoors and outside.

- Reinforcing wall decoration assumed the use of metal nets, which have certain variants of the device design - it is welded, plexus and expanded metal of the variety.Cells can be of different sizes, due to a specific task, for which rods with different thicknesses and types of their joints can be used. The resulting mesh has high strength and physico-mechanical characteristics. The wire mesh is used indoors, because it does not tolerate an increased level of moisture and metal corrosion may begin under its influence.

- Galvanized version it has been used for external works for a long time and very successfully, allowing you to reinforce quickly and efficiently The size of the cells can be very diverse, and the type of their attachment - welding.

- Reinforcing mesh (which is also called the chain-link) is used in case the leveling layer is very thick and complex. During work with the cement wall, you can use any solution, because for such a material there are no special selection criteria, which indicates its versatility. Often, brick, concrete, stone walls are trimmed with a rabbit, but it can also be applied to aerated concrete and wooden surfaces.

- Metal grid Expanded metal can be made by any method.Due to the lack of welding places, the resulting product is durable.

Use the grid for plastering the inner surface of the walls, where the layer of material is not more than 30 mm.

- Steel mesh It has its advantages, but progress does not stand still and new material has come to replace it. Plastic mesh refers to the modern types, it is used on aerated and brick walls. In this case, it is advisable to choose a small cell, because a large one is more suitable for working on facades and a plinth. This material has no problems with a large temperature range, it can even be used for arranging the insulating layer.

- Glass cloth variation It consists of glass, in which there are no alkali impurities, but aluminum is added, which helps to increase the strength of the resulting surface. Chemical effects are not terrible to this material, the processes of decay are also avoided, because this type is used most often and is considered the main one in work.

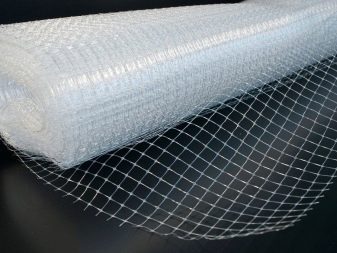

- The polyurethane version is also universal.. It is very convenient to use it in large rooms.But biaxially oriented polymer mesh is the newest material of all existing in this industry. Due to its elasticity and the absence of contraindications to its use, it is a universal means for communications that conduct current when working on various facades.

Polypropylene mesh is very durable and can withstand a lot of weight on itself, because it is recommended to use it to strengthen bridges and roads.

- In addition, there is also serpyanka, with which it is very convenient to seal cracks in the walls. Due to its fiberglass composition and the ability to self-stick to the surface, this material is now indispensable for the repair of walls and their puttying.

The installation grid for plaster is a very convenient invention, which made the repair process simpler and significantly improve its results. Varieties of grids with different cell size help to choose it correctly for a certain type of wall.

Thanks to the possibility of choosing between metal and synthetic versions, it is now possible to use the grid both indoors and outdoors,which significantly improves the result of repair and extends the service life of an object.

Which one to choose?

If we consider the metal type of grids, then there are some criteria by which you need to make a choice in the direction of one or another option. These include:

- The quality characteristics of the raw material, which is taken for the manufacture of rod or wire. It is desirable to have information about the grade of the alloy of steel from which the mesh is made, which will show how high-quality the product is.

- The cost of stacks will be higher for small traders, so for large batches should be addressed to the companies that are engaged in this. Large product turnovers make it possible to pay for it, which means not to set prices too high.

- The quality of the rods themselves, the presence of galvanized coating. Non-galvanized mesh can be used for interior work, but if it is used for exterior and not covered with a special compound, then it will soon rust and traces of corrosion can reach the outer layer of the finish.

- It is necessary to choose the type of nets. If it is welded, it will be better to keep plaster on yourself than twisted.This is important when work is carried out with a brick wall or from aerated concrete outside the house, where the layer of plaster can reach significant sizes.

- The rods must have a clearly normalized thickness of the rods; therefore, when choosing a grid, it is necessary to pay attention to the GOST standards in each package.

The plastic version of the grid for plaster is not inferior to any of the above options, it can be used on any surfaces, inside or outside, for the socle and facade. The only case where it is worth referring to the metal grid is the presence of a thick layer of plaster, which has considerable weight, in all other situations modern grids will be much more convenient to use.

The use of the plastic option also implies the choice of the desired cell size, which is often reduced to 6 by 6 mm, but you can choose another option depending on the wishes and ease of operation.

Dimensions

Since there are a lot of options for applying plaster, there is a certain amount of cell sizes for each of them. Despite the large selection, there are norms,which are best suited for each type and determine the size of the cell. Here they are:

- For the masonry variety of mesh the most convenient cell size is 5 to 5 mm. The main production material is polymers.

- For universal type There are several options - from a small cell 6 by 6 and an average 13 by 15 to a large 22 by 35 mm. The material for the manufacture is polyurethane. It is used for interior decoration.

- For fiberglass The optimal cell size is 5 to 5 mm, and it is produced from glass cloth matter.

- Plurima characterized by the same size of the cell, but it is made of polypropylene and it can be used for various types of work.

- For metal mesh there is no clear cell size, it is chosen for a specific type of activity, but due to its composition, it can only be used indoors.

- For galvanized mesh The optimal cell sizes are 10x10 and 20x20, but if necessary, you can find more overall dimensions. This grid is made of rods, which are connected by soldering, which ensures a long service life and reliability of the finished surface.

- Armaflex Most often it is made with cells 12 by 15 mm and is used in cases when a thick layer of mortar is used in the work.

- Sintoflex A sufficiently large range of cells that can be used in work is 10 by 10, 12 by 14, 20 by 20, 22 by 35. It is made of polypropylene.

- For steel mesh the size of the cells may be different, but the most popular is 20x20 mm. It is made from rods made of metal, which are soldered together. For fixing on the surface, you must have a corner.

- For plastic mesh There are no defined cell size standards. It is most often used for fixing foam and put it on the glue, and then treated with a finishing putty. After this process can be considered complete.

It is important to choose the correct mesh for repair and pay attention to the GOST indicated on the package. It is this material that will make it possible to make a good repair and guarantee the durability of the coating, otherwise you can expect any result from the repair work on the plaster of the grid inside and outside the room.

Installation

Since there are quite a few varieties of plastering mesh, there are also several ways to fix it. The most popular of them are:

- putting mix for plaster;

- the use of screws;

- use of dowel-nails;

- fastening with screws.

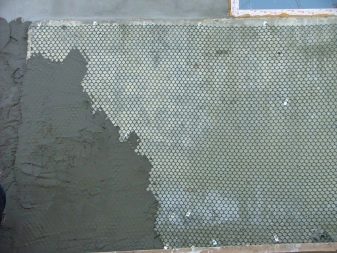

If the first layer of plaster is applied, the mesh is simply pressed into it. Such actions can effectively level the wall and get a strong coating. But for decoration it is necessary to fix the selected canvas with fasteners. If such a zone has small dimensions, then it can be applied to certain areas. A small layer of mortar is enough for a painting grid.

If we talk about fiberglass, then to use it, you need the correct sequence of actions:

- marking for fastening of lighthouses;

- making holes for dowels;

- screws are screwed to a certain depth so that the caps are on the same level;

- drawing solution on the necessary site;

- over the plaster you need to immediately fix the grid, passing through the heads of the screws;

- mix pad for a new section;

- attach the next piece of the grid must be overlapped by about 10 centimeters;

- it is necessary to gradually cover the entire room with a solution and impose a grid on it;

- after that beacons are installed;

- The subsequent work is already underway exactly on the beacons in order to get a flat surface

The process of smoothing the mixture on the grid goes from the middle to its edges. If the thickness of the putty is small, then you can use the staples to fix the mesh, and then apply a new layer of putty from above.

If we are talking about a metal grid, then the sequence of works is different:

- de-greasing, rinsing and wiping with a damp cloth;

- separation into pieces of the desired mesh size using metal shears;

- preparation of holes for dowels at a distance of 30 cm from each other;

- in the dowel with screws and mounting tape you need to fix the grid on the wall surface;

- a new section of the grid is laid with an overlap of 10 cm;

- after that, the installation of beacons and work on them.

The grid installation technology is suitable not only for walls, but also for the ceiling. The main thing is to knead the solution correctly, because for the ceiling work the mixture is needed not too liquid, otherwise it will not stick to the surface.

The use of reinforcing mesh for the ceiling has its own characteristics. It is applied in cases when many small cracks appear on the surface, which cannot be removed in the usual way. In order to carry out work on the installation of reinforcing mesh onceiling, you must:

- remove all lagging areas from the surface;

- primer with penetrating mixture;

- dilute the PVA glue to a liquid state and apply it with a roller to the cracks;

- Immediately apply a piece of fiberglass to the place smeared with glue and apply PVA on top;

- each new layer of fiberglass must have an overlap of at least 5 centimeters.

Work is being carried out until the entire ceiling is plastered, after which you need to wait until the surface is completely dry and begin to finish using any convenient method. Following the above rules, you can easily and correctly make the repair of any room.

Tips and tricks

The choice of mesh depends, first of all, on the thickness of the plaster layer. If it is less than 3 cm, it is recommended to use a fiberglass version, which is placed on the solution. It dries very quickly, which helps strengthen the wall and fully work with it.

If the layer of plaster is more than 3 cm, then it is better to use a metal grid that will easily cope with such weight and will help to strengthen the surface of the wall. Usually this type is used for outdoor decoration.

If the work is carried out in a bathroom or a swimming pool room, then it is important to choose reinforced material for work, otherwise the net will be covered with rust from moisture, which will tread on the surface of the wall, ruin its appearance and break the strength.

If you need to make a plaster finish, then the best option for this would be a plastic grate. In the process of finishing it is important to use a stack with a minimum diameter of cells. In the event that on a wall or ceiling it is necessary to get rid of the crack and seal it, the most convenient and practical option is to use serpyanka.

To work with slopes, it is important to use a metal grating in the case when a thick layer of plaster is applied. For a thin layer, you can do with fiberglass, but any work with slopes must necessarily be using reinforcing mesh.

In the case when you need to finish the stove, in the course is a massive mesh, which is called a chain-link. It is fixed on the composition of cement and clay, after which fiberglass is applied on a thin layer. Then the finishing process goes to the finishing stage.

There are cases when you can do without the use of reinforcing mesh. But it is still better to use it:

- in the presence of joints of various materials - walls of plasterboard and bricks, the construction of partitions adjacent to a different material;

- on the angular parts of the rooms where the bearing wall is connected with the interior one;

- in the presence of a monolithic concrete surface, which is not yet five years old;

- there are places where plaster has been lying for more than 20 years;

- in case the mixture has a greater degree of shrinkage;

- when working with drywall;

- if the surface is painted, wallpaper will stick to it or decorative plaster will be applied.

If the work with the painting grid is for the first time, you need to know how exactly it should be applied to the surface. The sequence of work in this case is reduced to:

- preparing the base for the mesh;

- the application of the base layer of putty on the area where the grid will be applied;

- installation of the grid itself;

- indentation of the mesh into the putty;

- leveling the grid with a spatula so that there are no irregularities or folds on the surface;

- coating a new layer of putty paint mesh.

After that, it is necessary to dry the surface until it is completely dry and apply the finishing layer of plaster, finally leveling the surface.

If reinforcement is necessary, then the grid is located not end-to-end, but with an overlap of at least 10 centimeters.

In order to properly use the grid, it is necessary to be able to choose it, and for this it is important to know the difference between the main types of grids for repair.

- Putty net - a material similar to the fabric, whose cell is only 2 to 2 mm, and the density of 60 g per m2. If, however, a mesh with a 5 by 5 mm mesh is taken for operation, then surfaces can be reinforced using a coarser solution. Such a grid can be used both indoors and outdoors.

- Serpyanka the structure has the same appearance as the 2x2 spackling mesh, but differs in size, because it is made in the form of a strip. This strip is small in thickness, and the length can vary from 12 m or more. An important feature of such a coating is that one side has a glue base, with which it is possible to reinforce cracks on the walls.

- Spider web - a material that is not similar to a cloth, but a large amount of fibers obtained as a result of a press. In the professional environment has the name fiberglass. Buy it can be in the form of a roll, the width of which may be different.The minimum is 2 cm and the maximum is 2 meters.

A variety of putty nets allows you to use them in a wide variety of situations - both for repairing the premises inside, and for finishing outside, when working in the bathroom, etc. Each case has its own grid variant that will perfectly cope with its task.

For how to fix the plaster grid, see the video below.