Subtleties of choice of MDF-panels for furniture

You do not know what material to make furniture for the kitchen, corridor, bedroom, office and other premises? In this case, you should pay your attention to medium density fiberboard (MDF). This versatile material today is actively used for the manufacture of various pieces of furniture. This is due to its undeniable performance, a large palette of colors, various sizes and availability.

How is the manufacturing process?

MDF production is a high-tech process based on modern technologies. In the manufacture of used natural material - wood chips. This suggests that the final product is absolutely safe for human health.

The production process itself consists of several stages.

- The formation of the workpiece.They take massive peeled logs, which are placed in specialized cutting machines.

- Preparation of the fibers. After grinding, the resulting mass is mixed with lignite and various resins with binding properties.

- The formation of plates. The prepared components are sent for drying to remove residual air, and then loaded into special molding equipment. After it turns out a sheet of the desired width with the edges already trimmed.

- Pressing. This is done to remove possible air residue and give the finished product durability and reliability. Next, the plate is cut to the required size, then cools for an hour.

The front part of the resulting plate can be used for finishing or lining.

To do this, use the following decoration options:

- PVC film application;

- painting with abrasion resistant enamel;

- shponirovaniye under a natural tree;

- plastic lining.

Special features

Simple machining and uniformity of the material makes it possible to use it to create the most diverse furniture: facades for kitchen sets, doors for cabinets, profiled worktops, basis for children's beds, etc.

Some features make MDF even better than wood.So, this plate can be bent at any angle in the process of its manufacture, having received aesthetically attractive furniture.

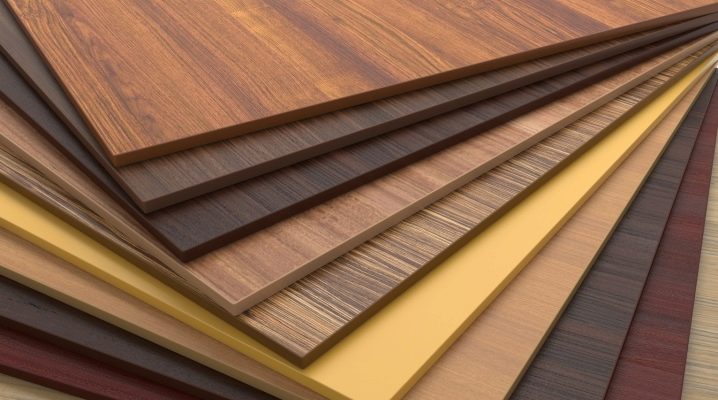

The most popular today are laminated panels. They are covered with a special PVC film of various colors. And also such products can imitate the structure of natural wood. The surface repels dust and increases the resistance of the wood-fiber sheet to mechanical damage.

As for the cost of MDF slabs, it directly depends on how the material will be decorated. For example, plastic front doors for the kitchen will cost you more than film. Compared with chipboard, of course, higher. But all this is offset by excellent performance (strength, durability, durability), as well as diversity.

Advantages and disadvantages

In its segment of MDF can be called the best wood material.

It has the following advantages:

- making sheets of any size and shape (even curved);

- high level of strength;

- resistance to wear, moisture, temperature, mechanical damage, aggressive detergents;

- variety of color shades;

- similarity with the facades of furniture made of natural wood;

- long period of operation;

- small weight;

- resistance to fungi and other pests;

- excellent level of noise insulation;

- the plate perfectly holds furniture fixing materials;

- environmental friendliness;

- affordable price.

The negative aspects of the material include:

- long period of manufacturing furniture - more than 3 weeks;

- panels coated with laminated film are not resistant to moisture;

- painted plates are difficult to clean and are also sensitive to some cleaning agents.

Options

MDF boards come in the following sizes:

- thickness - 3, 4, 6, 7, 8, 10, 12, 16, 18, 19, 22, 25, 28, 30 and 60 mm;

- length - up to 3.66 m;

- width - from 1.5 to 207 cm.

Depending on the purpose for which the MDF panel is needed, use its specific size. Thus, products with a thickness of 3-4 mm are suitable for creating plastic facing profiles - furniture facades and corners. Ceiling and wall panels, curbs, plinths and other are made of slabs of average thickness (6, 7, 8, 10 mm). Often they are made shelves, small cabinets, used as a door lining.

Products having a thickness of 10, 12 or 16 mm can be used for rough finishing: the construction of partitions, leveling the floor, linen and walls, as well as sound insulation and insulation.

Furniture for residential and public premises is manufactured from MDF plates from 16 to 30 mm thick, and also packages for the transportation of fragile goods are manufactured. And the thickest plates (60 mm) are used in the repair and decoration of large-sized premises according to the design idea.

In addition, when choosing, it is worth paying attention to such a parameter as the density of MDF panels. As stated in the established state standards, the average value of the indicator should be in the range from 720 to 980 kg / m3.

Tips for choosing

Choosing MDF, you first need to pay attention to the fact that the surface of the plate was homogeneous and smooth. There are no knots and rottenness on the panel of good quality, it does not dry out, its surface is not covered with cracks. In addition, a good product does not lose its commodity appeal and with various types of processing.

The most important thing to focus your attention on is the finishing option. The choice of this or that material depends on personal preferences, the design you are planning to create and financial possibilities. Refers here and the selection of the optimal color shade.You should purchase MDF panels in proven and reliable companies that are very popular and can provide an official guarantee for their products.

Do not be lazy to ask the manufacturer for a certificate of quality. This is the only way you can be sure that the products you buy are environmentally friendly. If you plan to use furniture from MDF indoors with a high level of humidity, then you should buy a special moisture-proof panels.

You will learn more about the installation of MDF panels from the video.