Standard sizes of MDF panels

Today, MDF panel is gaining popularity as a budget, reliable and fashionable type of decoration. Their indisputable advantages include ease of installation and a variety of colors, which allows you to translate into reality any design idea. MDF panels are an excellent choice for internal or external work. It remains to understand why this sought-after finishing material is so good.

Special features

The MDF panel is a medium density fiber board, which is based on wood waste in the form of chips and sawdust. Raw materials are crushed, dried and processed under the influence of high temperatures. The result is a homogeneous mass, which is held together by paraffin and lignin (the latter is formed when wood dust is heated). Cut wall panels are made similar to natural wood with a melamine film and then painted.

MDF boards significantly pressed chipboard, plywood and even panels of compressed sawdust. There are a number of reasons for this related to the quality of this material. Thus, MDF-panels are more dense, which contributes to reliable retention of the doors of lockers, door handles and other elements. They are environmentally friendly, allowing you to apply them even when finishing children's rooms.

MDF boards are an affordable material that can be purchased in any city at an affordable price. Installation does not take much time, and everyone can cope with it alone. MDF panels allow to improve the heat and sound insulation properties of the room, and the imitation of the wood pattern will not leave anyone indifferent.

However, this wonderful material has several disadvantages. For example, MDF panels are mounted on a frame that occupies a certain area of the room. For owners of spacious apartments, this drawback is not so critical, but the owners of small premises have something to think about. The material has a low fire and water resistance, so it should be kept away from direct hits of water,and wall sockets and switches "pack" in metal pozoroztniki.

The panels are characterized by low durability of the laminating layer, which is difficult to restore.therefore, they are changing every five-year period as wallpaper familiar to everyone. And, finally, among the shortcomings of MDF panels are the limited design possibilities, believing that for the realization of ideas you need to choose only texture and color.

Scope of application

MDF panels are widely used for interior decoration. They trim floors and ceilings, make furniture from them and even transform entrance doors. Such popularity is not accidental, because MDF plates allow not only to hide the unevenness of the walls, but also to improve the interior in the shortest possible time and without unnecessary dirt. They can be mounted in any direction, it is convenient to “hide” wires and communications behind them. In terms of cleanliness, it is enough to wipe their surface by taking a damp cloth, while chemical agents are not used.

MDF wall plates can be lath (long and narrow), externally resembling wooden wall paneling. Tiled rectangular or square are similar to tiled tiles, and sheet are wide smooth sheets.Due to the variety of forms, you can modify the room, visually narrowing or expanding the room.

Depending on the application, the installation of MDF-sheets has its own characteristics.

- Because of the unevenness of the walls, panels are often mounted by attaching to aluminum profiles. If the walls are smooth, it is permissible to use the adhesive method. The adhesive should be thick and retain plastic properties after drying, which will not allow the plates to deform or shrink.

- If the ceiling is planned to be decorated, the panels for it should be distinguished by ease and simplicity of fastening. The best solution would be the use of rack panels, which use liquid nails, a special adhesive solution or a construction stapler as connecting elements.

- The material is customized in length with a jigsaw or a circular saw, and you can fix it alone. But for the installation of tile or sheet MDF will require at least one assistant, which is not always convenient.

- Thick moisture-proof sheet panels are laid on the floor. If sheets are laid on a subfloor, it is worth using slabs whose thickness exceeds five millimeters.If the installation is done on logs, you should choose MDF from ten millimeters thick.

- In any case, before work, the base should be leveled and cleaned, and then lay the plates "in a run-in." The clearance of the panels from the walls is 2–4 millimeters, and the distance between the panels themselves is 2–3 millimeters. Along the perimeter of the panels should be installed fasteners in increments of 10-15 centimeters. Then proceed to the grinding of surfaces and putty joints, and only then to painting. The basis from MDF can be used both under a laminate, and under any flexible finishing material.

- As for furniture, MDF panels often decorate the facades: these plates are easy to deform and make various intricately curved shapes. MDF will improve the doors and door slopes, and fit the plates of any shape. Do not forget that these panels do not “love” shocks and scratches, so doors and furniture with MDF-surface require careful handling.

The design of the front side of MDF panels is also very diverse. In addition to the usual flat products obtained in the process of pressing, there are plates with a relief surface.The three-dimensional pattern, obtained as a result of stamps, stickers or milling, looks original, but is quickly contaminated, and such panels will have to be cleaned much more often.

On top of the decorative films, laminated plates are glued with transparent glossy or matte polymer coatings that protect the panels from mechanical damage. Veneered faces of the plates reproduce the natural wood pattern, and matte or glossy shades of painted surfaces will become a stylish interior decoration.

If you want to realize any unusual design idea, you should pay attention to the panel with a smooth, untreated surface. At home, you can clean it yourself, pierce it, close the pores, smooth out irregularities, and then prime and color it with the desired color. MDF is “afraid” of water, but the bathroom or kitchen, loggia or veranda can be finished with moisture-resistant MDF panels protected by a laminating layer from the outside and inside. It is only necessary to ensure that they are protected from direct contact with water.

Standard sizes

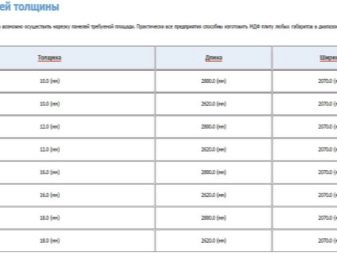

Depending on the scope of MDF panels experts identify several standards.

- The length of wall panels should be 2.62 meters, and the width can vary between 100–900 mm.

According to the last indicator, the panels are divided into the following types:

- P-1 corresponds to 100 mm;

- P-2 - 125 mm;

- P-3 - 150 mm;

- P-4 - 175 mm;

- P-5 - 250 mm.

- The thickness of a flat, painted, laminated or embossed wall panel ranges from three to thirty millimeters. The standard thickness of the veneered panel reaches sixty millimeters.

- Wall MDF panel must have a specific resistance with a normal separation of the coating is not less than 0.4 MPa, and the index of abrasion resistance is in the order of thirty turns.

- The length of MDF plates should be about one and a half meters, width - 190 millimeters, and thickness - 6, 10, 18 and 24 mm.

- For the manufacture of furniture fronts choose panels that correspond to the dimensions of kitchen sets, dressers and cabinets. But here you can deduce a certain standard. Thus, plates 16 mm thick, 140–934 mm high and 296–596 mm wide are considered the best option.

- Decorative aprons, made of furniture panels, have the following characteristics: 3000 mm in length, 600 mm in width and 6-10 mm in thickness.

- The length of the tabletop subjected to a regular dynamic load should be 1000 mm, width - 600 mm and thickness - 28–38 mm.

- For the manufacture of doors should be taken MDF-plates with a thickness of 35–45 millimeters, a height of 190–200 mm and a width of 70–90 centimeters.

These standards vary depending on the products of a particular manufacturer.

- Polish company Kronospan produces a wide range of MDF 260 cm long, regardless of the application. The panels of this manufacturer differ only in width and thickness, and the width varies from 15.3 to 20 cm, and thickness - from 7 to 14 cm.

- German company Hdm specializes in the production of moisture-resistant MDF, designed for finishing kitchens, loggias and bathrooms. The range of the company is famous for the variety of textures that imitate natural wood, the beauty of natural stone and other natural materials. The established standard lengths for HDM panels are 130 and 260 centimeters with a standard width of 19.8 cm and a thickness of 600 mm. The choice of the size of the MDF panel depends on the type of repair work: 130 cm length is enough to finish the wall in half. If you want to sheathe the wall to the ceiling, you should choose a longer panel.

- MDF-panel domestic manufacturer "Union" have the same dimensions: their length is 260 cm, width - 23.8 cm and thickness - 0.7 cm.High quality, rich color palette and the ability to purchase panels individually for the same price found a high response from buyers.

In addition to the listed companies, the products of a number of firms engaged in the manufacture of MDF panels are on the market, but it is better to give preference to a proven manufacturer from Russia, Poland, Sweden or Germany. This will avoid disappointment, realize the dream of a perfect home and enjoy the result for a long time.

Tips

Regardless of preference, you should make sure that a quality product is selected before purchasing.

To do this, you should pay attention to the following nuances:

- the surface of the slab should be smooth, without chipping, grooves and tubercles;

- MDF is odorless;

- sheets of the selected texture should be the same color;

- upon contact with water, the material should swell by seventeen percent (this information is contained in the characteristics of the panel);

- it is easier to work with thin panels because they weigh little and take up little space; however, they are fragile and break easily;

- thick panels are durable and reliable, but they are not recommended to be used for finishing small apartments, as they “eat up” an already small space;

- in search of the original pattern of MDF panels, intermediary firms should be avoided, reselling products purchased from manufacturers; this will help the specific wording of the Internet request, for example, "the official website of MDF wall panels Nizhny Novgorod."

MDF panels quickly become obsolete psychologically: in 1-2 years, most likely, they will want to update the situation, making it more fashionable. In this case it is permissible to paint the panels. MDF should be painted with emulsions containing polyurethane resins, nitro-paints of the NC category, acrylic, oil or alkyd based aerosols. This is a rather troublesome, but quite feasible procedure.

To get the best result, you should observe the following sequence of works:

- you need to prepare the dye by mixing paint with hardener in the ratio of 1: 9; the composition should be mixed regularly to avoid solidification;

- it is necessary to grind the panels and treat them with a primer, the layer should be 100–140 microns, and allowed to dry for 2–6 hours;

- then you need to start painting: paint should be applied in several layers, the thickness of which is not less than 80 microns; it is necessary to polish the finish layer to give the surface a glossy shade.

- at the final stage of work, the freshly painted panel is left to dry for 8–12 hours at room temperature.

For how to install the MDF panels on the walls, see the following video.