How to cut PVC panels: the choice of tool

Undoubtedly, tile is considered to be the classic material for finishing the bathroom, but PVC panels have an increased mounting speed, and additional care for this material will not be necessary, because neither soap nor water is deposited on their surface. Initially, plastic panels are well proven because of their ease of installation. To carry out such work does not require assistance from professionals and complex tools.

Use of panels

In the process of plating, you must initially decide on the tool used for cutting plastic panels. This material is widely used in the decoration of balconies or bathrooms, because it has an excellent set of properties. We must not forget about its practicality, which makes it even more popular. Plastic panels attract buyers also low cost and beautiful appearance.

Each owner can independently at home and at his discretion make the finishing of the bathroomBecause there are so many options for panels that can be used for this. All PVC panels are manufactured with a standard length of 3 m. It is not always practical, because it is required to cut it into pieces to get the desired size.

Cutting rules

For safe work, you must clearly follow the following rules:

- When working with panels that were brought from the cold, you must wait a short period of time. This action is necessary in order to warm the material. If you do not obey the advice, the plastic panels will break during the cutting process, thereby losing their neat appearance. Often there are cases when cracks appear on the surface that is cut along.

- In order to get several strips of the same length, it is necessary to lay them at least 2 supports. In this way, protection against sagging or shifting occurs. It is recommended to rest the edge of an element that is not subjected to cutting to the wall.Thanks to this action, you can be protected from their shift.

- You can facilitate the process by making a markup with a pencil or felt-tip pen.

- Properly cutting the inside of the panel should be done downwards, because during processing under load, the profile of the bar changes and causes some inconvenience during the installation process. Often there are microcracks on the front surface, which appear in the future.

- When using power tools, you need to use protective glasses and gloves that can protect against fragments and sawdust flying in different directions during the cutting process.

What is needed?

Currently, a huge number of tools have been created, thanks to which it is possible to shorten the length of a particular material. When working with plastic panels it is necessary to take into account many factors, among which the main ones can be called practicality, cutting speed, surface quality, as well as ease of operation.

Cutter

This tool has proven itself because of its low cost. It is perfect for working at home.

The tool has excellent characteristics, and the surface, which is amenable to cutting, looks exactly. It should also highlight the fact that it does not require much physical effort for cutting. A huge advantage can also be called its compactness, in which it does not have much space when storing it.

The disadvantage of the tool is the ability to cut only in a straight line, they will not be able to round the edges.

Hacksaw

A hacksaw is considered more practical to use, and it doesn't matter if it is for metal or wood. The only requirement when using a hacksaw is the presence of small teeth, which should not be divorced, because this is how the surface of the material that needs to be cut into pieces is destroyed. Such a tool is often used for cross-cutting.

The advantage of this tool can be considered the possibility of simultaneously cutting multiple panels. For this operation, you will need to stack the material.

For convenience, when carrying out cutting, it is better to have the planks facing the performer.Subjecting a decrease in the length of the panels, you need to take care not to put tremendous effort when pressing on the tool, because you can break PVC sheets in this way.

Thanks to the plasticity that the material possesses, it does not take much effort to cut off the extra part of the panel.

Jigsaw, circular and grinder

These tools greatly accelerate the process of changing the length, and also give an excellent view of the cut edge at the exit. These devices proved to be excellent if you need to quickly cut the panel lengthwise.

In no case should we forget that when working at high revolutions of rotation of the cutting tool on the surface that is being processed, the appearance of defects in the form of melted edges is possible. At the same time, unpleasant odors and substances harmful to health are released into the work area. It is necessary to decide how to make treatment. In view of this fact, all work must first be performed at low revs. With the help of the grinder, you can get not only straight cuts, but also figured ones.

Experts recommend to get a high-quality surface,as well as increased productivity as a tool used when cutting, use a regular jigsaw. In this case, it turns out a great smooth edge, which has no creases, and is also very practical in the process. The tool proved to be excellent both for longitudinal cutting and for cutting across the bar.

Using a jigsaw need to remember that it is necessary to use a file with a fine tooth. Particular attention should be paid to the cutting mode - the minimum speed is selected and the pendulum motion is turned off. This tool is well proven when cutting multiple panels at the same time.

Knife

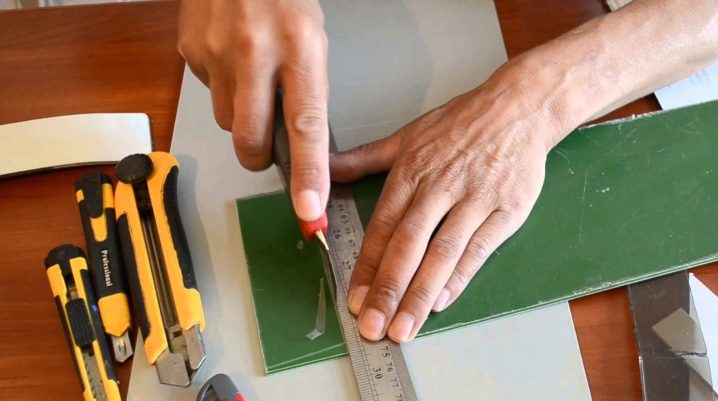

This tool has proven itself if you need to cut a small number of plastic panels. Applying it, you only need to know some little things that can help and facilitate the process of changing the length.

The least suitable for such works ordinary kitchen knife, which can be found in any kitchen. Difficulties in working with this cutting tool arise from the width of its blade.Even being perfectly sharpened, the kitchen knife will not cut the wall panels.

The contractor will have to spend a lot of time if he does not have the opportunity to use another tool. In this case, the installation process will be longer in time.

Office knife is considered a more suitable tool., because using it, the material is not completely cut. After holding on the front surface of the material, a groove is obtained. Turning over the bar and pressing the edges, the PVC panel clearly breaks off along it, and the resulting small fringe, which covers the surface of the fracture, doesn’t harm the appearance of the room, because it will be hidden either under curbs or under the plinth.

A bread knife made of ceramic can also be used for such work. It will perfectly cope with plastic panels due to the presence of a wavy cutting edge. Working with such a tool, it will not be difficult to get an element that fits perfectly into the interior of the bathroom.

For cutting PVC panels, you can use different toolseach of which has its own advantages and disadvantages. There are also specialized professional devices to speed up and facilitate cutting.

To learn how to cut a PVC panel with a stationery knife, see below.