PVC panels "under the brick": the pros and cons

Brick is considered one of the traditional finishing materials. It differs in environmental friendliness, durability, durability, solid appearance. However, brick has always been distinguished by a high price, so not everyone can afford such a finish. Decorative panels "under the brick" - one of the excellent alternatives. On the pros and cons of such facing, read this article.

Special features

Polyvinyl chloride is a popular material used today in many industries, including the construction industry. PVC panels with imitation of brickwork have received wide popularity and numerous positive feedback from consumers. First, this is due to the excellent aesthetic qualities of the material. Secondly, such panels are incredibly functional and practical.

Many have already managed to get used to the plastic lining of the interior. This trend appeared relatively recently, but building materials of this type have already been recognized as one of the best on the market. PVC panels are ideal for anyone who wants to create a beautiful interior, but at the same time is limited in budget.

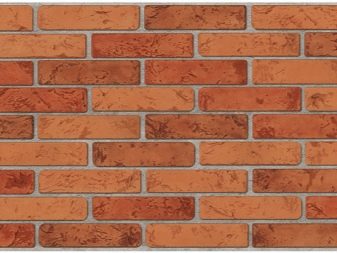

PVC panels are produced with the addition of special softening components using molds, which allows you to exactly repeat the brick texture and give the product a natural volume. After that, they are subject to staining or pasting with a special film with imitation of brick color.

The following types of material are on sale:

- rack and pinion;

- plates;

- leafy.

Vinyl panels are considered affordable and convenient to use. They are safe, resistant to damage, not subject to peeling and flaking. Cheap varieties of material have a uniform, smooth surface. More expensive options have a very interesting "brick" texture.

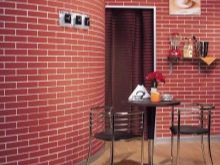

PVC panels have excellent performance properties, sufficient strength and long service life. Unlike a real brick, such panels delight an abundance of shades.If you wish, you can choose a material in natural colors, but contrasting colors look no less beautiful in the interior.

It should be noted that most manufacturers of PVC panels are carefully working on the relief, so that it is as close as possible to the existing types of brick.

Today on sale you can find a variety of options for imitation brickwork. These are products of natural light and dark tones, the image of aged materials, fashionable white, black "bricks" and much more. A variety of colors allows you to choose an option that fits perfectly into any interior.

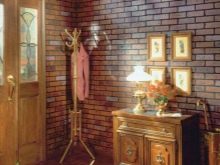

Polyvinyl chloride - a modern unique material., resistant to wet and aggressive environment, so these panels can be used even when facing the bathroom, hallway and kitchen. Also sometimes they are used as a material for facade decoration. There are single and double layer (based on polystyrene foam) products.

Brick panels are sometimes used to hide wall defects. In this case, the installation is carried out on frame technology, when the crate is installed or the wall is plywood before the brick is laid directly.This allows a little hardening of the casing, since polyvinyl chloride is a fairly soft material, easily deformable.

Usually the panels are mounted on glue. At the same time, the presence of small irregularities on the wall is not an obstacle for high-quality laying of the material. When facing, slight deviations are allowed, and curvature, on the contrary, can give the skin naturalness.

Thus, the scope of the panels includes:

- facing the internal walls of residential and public buildings;

- interior decoration;

- finishing of terraces, loggias, balconies;

- facade finish (in some cases).

Although these materials are included in the affordable price range, some of them are of high cost.

There are several factors affecting price formation.

- Brand manufacturer. The price of products of famous brands is overestimated due to the popularity of the company.

- Specifications. Thicker and thicker products are a bit more expensive.

- Design. The cost may be affected by the color, the complexity of the pattern, the quality of the paint used.

Advantages and disadvantages

PVC panels are a unique finishing material that can be used for wall cladding as well as for decorating podiums, columns, and walls.For several years, they are included in the lists of sales leaders, and all because they have an impressive list of advantages.

There are seven reasons why you should pay attention to decorative PVC panels.

- Durability. Manufacturers managed to achieve a long product life. Modern options are able to maintain their performance up to 15 years.

- Decorative features. In addition to impeccable imitation of the texture of natural material, the panels are able to hide well the irregularities and defects of the walls, as well as elements of communication systems.

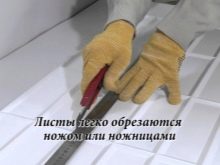

- Ease of installation. Panels are easily cut with a regular stationery knife, which allows you to customize products to the desired size. In addition, they are distinguished by their low weight, therefore they are suitable for cladding weak constructions.

- Practicality. Products are unpretentious in care, resistant to most external negative factors (such as humidity, mold, pollution, dust, fungus).

- Design. Realistic texture and a wide color palette allow you to use the panel in the interiors of residential buildings, apartments, offices, cafes and hotels. They are in perfect harmony with other finishing materials and notneed finishing coloring.

- PVC panels do not visually weigh down and do not reduce the space.

- Maintainability. If necessary, it is possible to easily replace an unsuitable cladding element without dismantling the entire web.

Like any other material, PVC panels have several drawbacks. Facing made panels, has sufficient strength. However, when carelessly handling the material is easy to scratch or break. In addition, some types of panels do not tolerate low temperatures. That is why they are not recommended for use as facade cladding, although it is allowed to place products in unheated buildings.

Among the drawbacks, it is also possible to note the low resistance to fire: PVC bricks do not ignite, but under the influence of high temperature they quickly deform. Therefore, they are not used for decorating fireplaces and stoves.

The nuances of editing

PVC plates are easy to install, but wanting to create the perfect decorative wall, do not forget about the key rules of the process.

Before you start laying the panels, you should carry out the preparatory work:

- walls are cleaned from traces of the previous finish;

- remove all contamination;

- repair cracks and repair damaged areas;

- if the surface is highly deformed, it must be leveled.

There are two ways to mount these products:

- gluing;

- fixing on the crate.

In the first case, use high-quality adhesive compositions designed to work with PVC. When choosing an adhesive, its purpose, composition and thickness of plates should be taken into account.

Glue is usually used when laying on a flat surface. The crate is installed in cases where the walls are too deformed, and it is not possible to level them. There is a second reason - the presence of crates makes the lining more durable and protects it from the appearance of dents and sagging.

Experienced experts recommend using liquid nails as an adhesive. For example, neoprene nails form excellent adhesion to the base. In this case, gluing occurs instantly.

How to glue?

As already mentioned, you should first prepare the wall, clean it from unnecessary parts, old whitewash or lining, get rid of dust and grease.

The first stage of work - primernecessary to protect the surface from mold and moisture.It also contributes to better grip. Full drying of the primer occurs within 6-12 hours.

It is worth noting that the process of pasting panels only at first glance seems easy. In fact, this requires special skill and accuracy.

You will need:

- construction gun;

- sponge;

- mineral solvent to remove excess glue (water can be used);

- sealant.

It is better to work with liquid nails with the help of a construction pistol. To do this, cut off the tip from the package and screw the cap, after cutting it. Insert it into the socket of the building gun.

Apply liquid nails on the wall should be zigzag or in the form of a grid. If the panels are small, then point application will be sufficient. Then the product should be pressed to the wall, for greater effect, you can gently "walk" on top of the roller (without pressing). If the panel has moved out, then its location can be corrected within 2-3 minutes. Full drying of the glue occurs after a day, and he will have time to “grab” in 15 minutes.

After facing the entire wall, it is recommended that the seams between the panels and the ceiling be coated with a sealant.If the panels were installed by gluing to the installation glue, then the final step is the joint jointing with special compounds that can be bought at any hardware store.

Installation of PVC products should start from the corner to the center. If the panels need to fit a certain size, this can be done with a regular knife or jigsaw.

During laying, the adhesive solution is applied not to the material itself, but to the wall. Verify the correctness of the vertical and horizontal fixation by using the construction level.

Care rules

Decorative PVC wall panels look very beautiful, but the service life of such lining is largely dependent on the accuracy of operation.

Due to the nature of the material, care must be taken in carefully and carefully.

- It is recommended to remove dust and dirt with a soft cloth moistened with soapy water.

- Do not use powdered, aggressive alkaline or acidic cleaning products. They can damage the top decorative layer of the panels and leave scratches on them.

To learn how to install PVC sheet panels, see the following video.