PVC sandwich panels: features of choice and work with material

The basis of many modern materials includes PVC. For example, this is the main raw material used in the manufacture of sandwich panels, which are used for decoration. Like any other products, the panels have positive and negative qualities. Let us consider in more detail the features of the selection and installation of sandwich panels.

What it is?

Sandwich is a frequently used concept in the repair industry, in ordinary conversational communication. Literally, this means - "multi-layered sandwich." However, in public catering this word is used much less frequently than in construction activities.

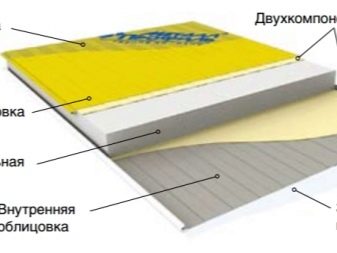

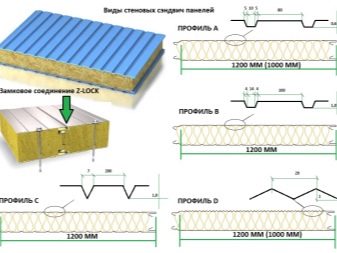

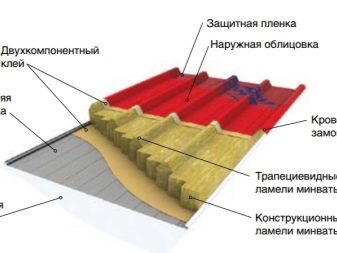

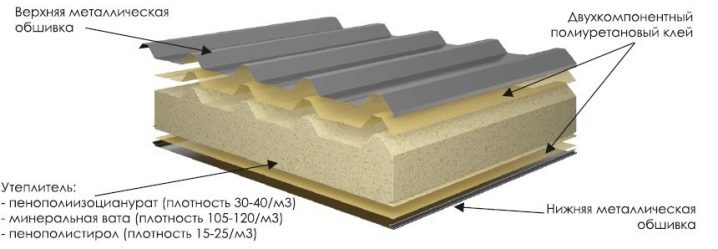

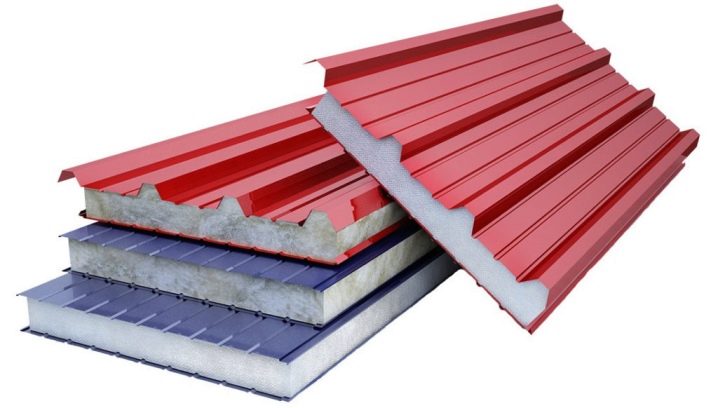

A well-known phrase used in the construction industry is a sandwich panel. This is a multi-part part. The outer parts of the subject are sheet elements of a rigid base. As such, there is PVC, metal, magnesite.The inner filling of the “sandwich” is a heater, which is minavata, fiberglass, polyurethane foam, polystyrene foam.

Sandwich panels with an external metal sheath or of magnesite are used for narrow construction areas. This is usually the construction of industrial and commercial buildings. But also the parts serve as partitions for utility and utility rooms.

Panels with PVC outer sheath are more widely used in the construction industry. In addition to the repair and construction of buildings, these parts are used in shipbuilding, space and other areas. Such a variety has arisen due to the qualities of polyvinyl chloride, which other materials do not have.

For example, PVC is considered resistant to alkaline action. Polyvinyl chloride does not react to the action of mineral oils. And also this material is not subject to deformation due to low temperatures.

For PVC in the plates are taken hard laminated parts or foamed plastic. More often on sale there is hard PVC, the surface of which is glossy or matte. Sheet thickness is 0.8-2.5 mm. Laminated plastic is obtained by pressing.The fabric or paper is taken as the basis for enterprises, then it is impregnated with polymeric compositions. The shape and color of PVC gets already under pressure. Modern sandwich panels can have a different look.

Sandwich panels made of foamed PVC are often perceived not as a finishing material, but as sound insulators. So how exactly these characteristics will rise using exactly this type of materials. Foamed PVC includes small air bubbles, which affect this quality.

Fillers play the role of a layer of insulation. These substances are also gas. Polyurethane foam is a rare component of sandwich panels used in aircraft construction. Standard products include a polymer that increases in volume when exposed to steam. Enlarged bubbles fill the block shape and connect.

The quality of the plastic panels will be related to the equipment used. Aggregates can be complex or semi-professional. It is clear that high-quality products are obtained on professional automated systems. Although in the presence of professional craftsmen, it is permissible to start production of PVC panels on conventional devices.

The use of profiles is very common at the household level, for example, for baths, balconies, creating office partitions. In any case, the selected products must be of high quality. You can check the products in their respective organizations.

More panels can be viewed, touch, this method is called organoleptic. But in order to independently determine the quality, you need to take into account the features of the sandwich panels.

Special features

Features of plastic sandwich panels allow them to be attributed to the universal types. This type of finish can be used in conjunction with various basics. The types of plastic panels differ technically. This should be considered when choosing products.

Among the options used for slopes, products are used:

- two-layer - they include a layer of foam and a protective layer of plastic;

- three-layer - they include another additional insulation inside the closed space on both sides.

For finishing slopes, the first view is considered the best choice. If the plastic comes into contact with the surface to be trimmed, this requires reliable sealing and the use of additional insulation layers,which will fit to the surface.

Summarize the advantages and disadvantages of sandwich panels can be several characteristics.

Let's start with the pros:

- The layer of foam inside the product is an excellent heat insulator. The base blocks cold streams emanating from verticals. The result is a special microclimate. With proper treatment of slopes sandwich panels on them should not form condensate.

- Sandwich panels have an energy saving effect. The thermal conductivity of the material is about 0.041 W / m2K.

- The material is highly resistant to atmospheric conditions. Water absorption is 0.51% relative to the surface.

- Strength characteristics according to GOST - 0.27 MPa, with bending - 0.96 MPa.

- Microbial colonies do not develop inside sandwiches.

- Sandwich panel is often used as a sound insulator.

- The material has a high resistance to burning, especially if there is a component in the panel - a fire retardant. Laying the material is quite simple, and processing is easy.

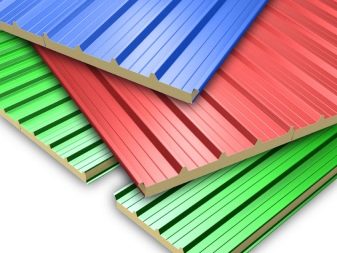

- Sandwiches have a wide variety of colors and textures. The fact that a sandwich is necessarily white is a prejudice. Manufacturers offer a wide variety of colors.

- Sandwich panels are often made to individual orders. The material is selected in accordance with the size of the finished windows. On sale you can find ready-made options.

The negative sides of sandwich panels are as follows:

- the material requires special care, as when cutting is easily damaged;

- sandwich panel finishing requires additional surface treatment;

- the material is voluminous, therefore it requires some space for installation, therefore sandwich panels are not suitable for decoration, if there is little space in the trimmed space.

Kinds

Sandwich slopes There are two types:

- insulated;

- decorative.

Good slopes in any case improve the performance of windows. Choosing a design option, you should take into account that modern fittings have good fittings, and seals keep heat pretty well. A thick glass unit with a thickness of 40-46 mm is distinguished by heat transfer 0.5-0.85. The coefficient of this resistance is sufficient and as a protection against noise.

Good slopes can be used as reinforcement of adjacent nodes, and they can also strengthen these nodes. For example, plaster slopes for plastic windows are not suitable products. Plastic and plaster differ in temperature expansion coefficient. Good adhesion between these two plaster does not achieve any sealants.

If you compare plastic slopes with plaster, then the first ones are more durable. In addition, plaster slopes do not have a closing contour around the perimeter. It is not very beautiful, besides not hygienic. It is more difficult to wash plaster slopes from dirt, and after some time of operation they become yellow at all.

Decorative plastic slopes are beautiful, but do not affect the improvement of the characteristics of windows. However, in some moments they look like a better choice than the warmed ones. For example, decorative slopes for windows are more acceptable for a loggia or as a balcony.

Still such products are used as partitions that divide the space, for example, in the office. But at the same time, the divided zones will not be insulated and soundproofed.

Insulated plastic sandwiches are installed in all other cases with a plastic window. Sandwich panels will add completeness to the appearance of the window from inside the apartment.In addition, such panels will undoubtedly improve the quality characteristics of a plastic window.

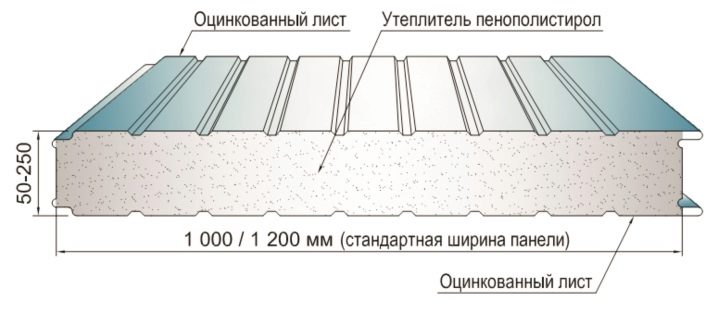

Dimensions

Standard dimensions of sandwich panels allow their use in any construction industry. The length of the decorative plate can be up to 16 meters, and the width of the structure varies from 1 to 1.25 meters. Plate thickness - 0.5-0.24 meters.

Decorative panels in demand in the market have the following values:

- length - 1.2-1.4 m;

- width - 1.025 (1.0) m;

- thickness - 0.05; 0.06; 0.08; 0.10; 0.12; 0.15; 0.20; 0.25; 0.32 m

Sandwich panels used for slopes have more modest dimensions.

Standard dimensions: 300-150 cm, and thickness 1-1.5 mm. Plastic sandwiches can be cut for any kind of window verticals. The standard panel is white, but the colors can be very diverse. The weight of the panels varies depending on the size.

Color solutions

It is known that the color design of the interior has an effect on a person, in particular, on his mood. More colors visually increase or decrease the space. White sandwich panel gives rigor, but it's boring. Modern designers offer to approach the business with fantasy.For example, in modern interiors a separate specific design of each window in the room is allowed. What will look great in the nursery, is not suitable for the living room. Therefore, it is important to carefully consider the finishing of window slopes and partitions, if any.

Owners of private houses especially often come to an extraordinary embodiment of the design of window openings. Openings sometimes do not just attract attention, but are a bright accent.

Sandwich panels allow you to translate any design decisions, as in the range there are more than 100 options for the palette of colors. Even various exotic flowers are available for order. The choice of sandwiches is complicated by the fact that the characteristics of light absorption and reflection of the products are different. Designers are advised to pay attention to the basic shades, which manufacturers have enough, for example, NZSP offers buyers 18 basic panel colors.

There are some nuances:

- if the panel is classic, it will be made quickly;

- if you need a panel of the original color, its cost will be higher;

- for a sandwich panel of the original color, it is more difficult to choose the shaped elements, most likely, the difference will be noticeable;

- The colors of the sandwiches, which are presented in the table at the manufacturer, may vary with what you get in fact.

If sandwiches are chosen for design, you should consider the effect of tones on people's mood:

- cold shades (blue, blue, green) soothe, visually increase the room;

- warm shades (orange, red, yellow) excite, visually enlarge the rooms located on the north side.

If sandwich panels are selected for the office, corporate color is often considered. This contributes to the recognition of the company's premises if there are several companies in the same building and it is not possible to hang a sign.

Different materials are used as coating materials.that are suitable for outdoor or indoor use. When choosing one or another option, manufacturers' recommendations should be taken into account.

Manufacturers Overview

Production of sandwich panels are engaged in many, both domestic and foreign companies. In the domestic market there are products of many enterprises.

"TSP-panel" - The company's production is known for high-quality, high-quality products.Available sandwich panels are ready for installation. Products have all the necessary certificates of conformity.

"Lissant" - the company's production activities are widespread in all Russian regions. Therefore, the panels of this company come across in stores everywhere. Products comply with both Russian and foreign certification.

"Teplant" - an enterprise from Siberia, which unites several manufacturing companies. This production has an environmental control system and ISO 14001 certification.

"Vesta Park" - an enterprise from central Russia that produces a huge range of products. Products have both domestic and foreign quality certificates.

"Technostil" - a company with some of the most modern production lines. The company's equipment is European, purchased from Italian and English manufacturers.

"Stroypanel" - Major sandwich makers. It differs from the others by an automatic stand production line.

Stimet - a manufacturer that independently sells its products on the market. Sandwiches of this company - one of the most affordable.

As you can see, the materials are produced by different companies, but nevertheless they have general guidelines for operation. Installation of different products is identical.

Recommendations for use

Sandwich panels can be finished in any conditions, however installation during rain is not recommended. Mineral wool insulation can get wet, and this will reduce the quality characteristics of products.

Installation can be difficult during strong winds. The panels at the time of the hurricane is better to put somewhere inside the buildings. This is due to personal safety.

In the process of using sandwich panels, periodic inspection of the appearance of products is needed. Shaped parts, fasteners must be sealed. If this is not the case, the interior of the panels can be additionally planted on the glue. Dirty exterior surfaces should be cleaned with a soft brush. If the top coating of the panels is lamination, the use of abrasive cleaners is unacceptable.

Possible damage can be cut off and replaced with new ones, or it can be repaired with a suitable repair paint, if the type of polymer coating of the panel is known.Variants of paintwork can be alkyd enamel or latex acrylate paint.

On the production of sandwich panels, see the following video.