Starting profile for PVC panels: beginning of facade work

Installation of PVC panels is not possible without connecting elements of various shapes. These plastic parts are most often called profiles, moldings or components. There are several variations of these elements, each of which is designed for a specific purpose. Without the use of moldings design will not look whole, neat and complete. And, of course, without starting a profile, the installation of PVC panels will not start at all.

Special features

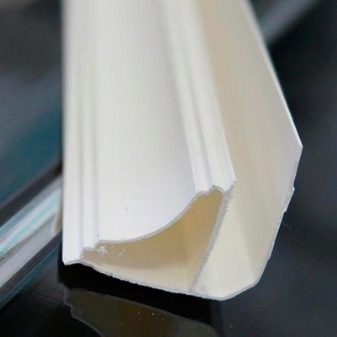

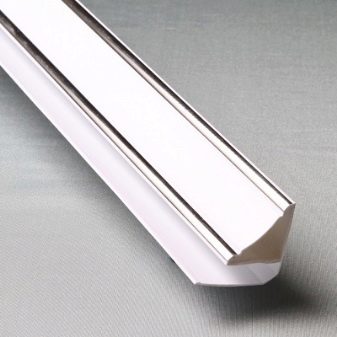

The plastic starting profile for PVC panels looks in the shape of the letter P, one side of which is usually slightly shorter than the other. As a rule, installation of the whole structure begins with its installation, which is why it is also called initial.He "sets" the direction of the entire plastic finishing structure. This molding is used to close the ends of the panels, and, moreover, in cases where the PVC sheet is adjacent to the openings of windows or doors. Its application allows to save time and materials for finishing and installation work.

Such elements have a number of distinct advantages. They, as a rule, demonstrate resistance to ultraviolet rays and are able to avoid acquiring yellowness for up to 10 years. The material is elastic, but not brittle, so when cutting it is possible to prevent the appearance of cracks. The composition is good because it contains the minimum amount of chalk and substances harmful to the human body.

The moldings are easy to assemble, and, thanks to a convenient form, they calmly fit even with non-aligned walls.

Species

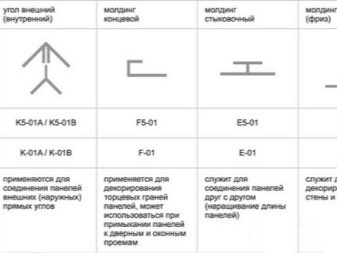

In addition to starting, there are other types of moldings. F-shaped is used when it is necessary to beautifully “close” the docking of the ends. For example, it may be the corners in which two PVC sheets, windows or doors, other slopes, or the combination of two different materials, for example, plastic panels and wallpaper, are joined.In other words, it is used when moving to another plane. Judging by the name, one can guess that this docking profile resembles the letter F.

The following mounting molding - connecting - is chosen in those situations when two panels need to be connected to each other. For example, when it turns out that the height of the panel is much smaller than the walls, and you have to “grow it”. Such a profile resembles the letter H and is therefore also called H-shaped.

The outer corner, as the name suggests, hides the places where the panels form the outer right corners. The outer corner is the outer corner. The inner corner, in turn, masks the joining of sheets in the inner corners, necessarily straight.

The general-purpose universal corner has approximately the same characteristics as a decorative corner. It is available on the market in several sizes: its sides can be from 10 to 50 millimeters. It is used to hide those places where the panels are joined at a right angle. This molding can serve both external and internal corners, due to its design, it bends in the right direction.

Galtel, also known as ceiling plinth, is used at the joints of the ceiling and the upper edges of PVC panels.It masks this transition and gives completeness to the overall picture. This molding can be colored and thus perfectly fit into any interior. In addition to fillets, at the top you can find profiles called external corners. They are used when peculiar ledges are created at the top, for example, columns or beams. Finally, the internal corners on the ceiling are mounted where the walls form an inner corner.

The ceiling plinth, if necessary, is supplemented with a connecting element. This detail fixes two plinths among themselves, when one is simply not enough. It is worth noting that the length of the standard plinth is 3 meters, but in large rooms this may not be enough. Guide rails for the batten, in the opinion of some experts, are also considered a type of profile. The purpose of this element is the simplified installation of PVC panels. If the crate, like the sheets themselves, is made of plastic, then their connection is carried out using special clips.

Finishing molding, as you can guess from the name, is used to secure the last panel. He "completes" the entire structure.

Material selection

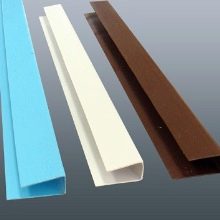

Currently on the market are profiles made of plastic and metal. Plastic moldings are cheap, but not of high quality. They will simply be unreasonable to use for serious tasks, so most often they are chosen as a decorative addition.

Generally, if we talk about how to connect the panel of PFH and profilethen it turns out that the panel is partially “placed” in the profile itself and fixed in the same place. Therefore, to ensure the reliability of fastening, preference should be given to metal molding, which can be steel or aluminum.

As a rule, metal elements in addition are treated with a special compound that can prevent rust.

If we talk about batten rails, then they can also be made of wood, however, this material is quite capricious. Despite the savings in price, this design will not be able to please the owners for a long time - the tree may begin to rot, be exposed to fungi or be covered with mold. Therefore, the choice is still made in favor of other materials.

Dimensions

The dimensions of moldings for PVC panels depend primarily on the plastic sheets themselves, or rather, their thickness. Usually there are four subspecies of profiles, the thickness of which corresponds to 3 mm, 5 mm, 8 mm and 10 mm. The usual profile length corresponds to 3 meters, and for a profile with a thickness of 3 millimeters, 2.5 meters.

Installation

Even before the installation of auxiliary components to calculate their required number. Both corners and other moldings are usually sold individually. They are selected in accordance with the color of PVC, as well as taking into account their thickness. Planks to be mounted on nails coated with zinc, or conventional screws. When mounting is carried out, it is necessary to retreat from the edge of the part by at least 5 millimeters. If the element is external, then it is glued to the plates with a composition based on polymers. It is also worth mentioning that, if necessary, profiles are easily cut and reduced to the required size. So that they are aligned and placed parallel to each other, a regular thread is used.

Before installing the starting profile, it is important to clean the surfaces from contamination and, if necessary, level andx, the quality of the alignment can be estimated by using the level. In general, if you are to design a window opening, the walls should be thoroughly cleaned from fasteners and other protruding parts.

It is also recommended to check the window openings and frames for irregularities and deficiencies.

Starting profile to be fixed on the crate screws. In general, regardless of the type of profile, they must be installed so that a distance of 50 centimeters is maintained between them - in this way it will be possible to mask all surface irregularities. Then this panel is installed in the profile, which is mounted on the rail. When the coating reaches the corner, it is time to use the corner profile, external or internal. Toward the end, window and door slopes are closed with an F-profile, and the joints with the ceiling are closed with plinths. If necessary, involve and connecting molding. Installation occurs by staples, screws, nails or adhesive solutions. In the second case, however, it is worth remembering that the use of chemicals is possible only with specific indicators of temperature, humidity and other factors.

If the installation of PVC sheets occurs on the ceiling, then each sheet is to be rolled into profiles on three sides, and so that the long side is in the initial molding. To correct errors, use a screwdriver. Again, speaking of the ceiling, the last panel is mounted so that the two sides appear in profiles.

In general, it is possible to allocate a certain sequence of fastening moldings. First, elements are installed along the perimeter of the wall or ceiling, that is, the surface to be decorated. Opposite elements are mounted in such a way as to be kept in the same plane. Otherwise, the curvature of the structure may occur, which will affect the docking of the panels themselves and, as a result, their appearance. The first profiles are mounted either on the bracket or on the screws.

Corners both external and internal are fixed according to the same principle.

Finally, intermediate profiles are attached to connect the parts for which they are intended. Ends any process installation of baseboards for floor and ceiling and corners. They perfectly hide the docking and give the walls a complete look.

Be sure to keep in mind that plastic panels are able to transform under the influence of temperature differences. Therefore, when connecting the profile and the plastic sheet, a small gap is left. But you should also not start work at temperatures below +10 degrees - some parts may break. Before fixing the moldings, it is also important to choose a further direction for laying PVC panels.

Pro tips

In order not to be mistaken with the choice of profiles, it is better to contact the store, where sellers will offer a ready-made kit suitable for the corresponding model of the PVC panel. Otherwise, you can buy moldings that will not dock with the coating, or else not to buy something important.

When buying, it is necessary to take into account where this molding will be used, and already depending on this to buy one or another type. For example, if it is necessary to arrange a part of the surface where there will be neither window openings nor corners, then only the profiles that form the crate are needed.

If you have to arrange the ceiling, then we must not forget about the ceiling plinths.

Almost all companies produce white moldings that fit any interior. However, if there is a need for color models, then you need to either look in specialized stores, or order individually.

Choosing plastic moldings, it would be good to find those that have increased strength characteristics. Speaking about the technical parameters, it is important to pay attention to the width of the groove intended for the panel.

To learn how to install PVC panels, see the video.