Choosing accessories for PVC panels

PVC panels are a familiar and quite modern material for interior decoration. Their flexible transformation in a different way is largely due to a wide range of components. But that is why consumers are obliged to understand the specifics of these parts for finishing panels.

What is required?

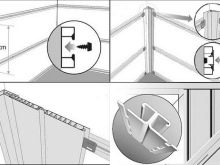

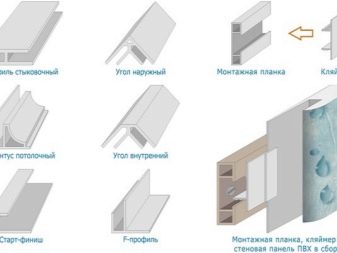

Starting work with the formation of the ceiling of PVC panels, first of all it is necessary to use the starting type of strap. So called molding in the shape of the letter P, which locks the panel from the butt. Similar strips are used when the panels are placed on the walls. But there they are already needed for another task - a more elegant design of door and window openings.

At the ends of the profile is necessarily put in the form of the letter F, it is needed to beautifully file the corners and joints between PVC and other materials.This profile is also used in the design of the grooves under the doors and windows. Docking is done with the help of molding like the letter H. It is used when you need to connect the short edges of the panels due to the fact that one of them is not long enough to cover the ceiling space.

External and internal corner, respectively, are needed to mask the junction points at different angles. With the help of a universal decorative corner, you can cover the outer intersections of cloths, converging at an angle of 90 degrees.

A universal corner can also be called such a molding, which is designed specifically for bending with an arbitrary angle. It can be used both inside and outside. The ceiling plinth is called a galtel that facilitates smoothing of transitions between the ceiling and the walls. Galtel need more and then to cover the joints.

Ceiling skirtings can intersect:

- on ledges;

- near the beams;

- near the columns.

In all three cases, the outer corners of a special type are very valuable (they are called so - for ceiling plinths). Do not confuse such products with similar structures directly to the panels.

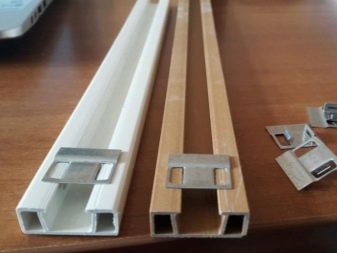

Internal corners for baseboards help to seal the intersection point at the farthest places from the entrance. Sometimes the baseboards do not have enough length, and then a special connecting element helps to solve the decoration task. An important part of the furniture for plastic ceilings are the slats (guides), it is from them that the crate is formed.

How to choose?

The selection of components in the first place focuses on the colors and thickness of the canvas. The durability of fastening elements is very relevant, because they can fall off at any time. Both wooden beams and steel or aluminum profiles can be used for the battens. Their attachment to the rough base is achieved by galvanized nails or screws.

The calculation of the number of fasteners takes into account:

- departure from the edge of the parts of the lathing about 50 mm;

- the location of the transverse elements approximately every 300 mm;

- all the nuances of the geometry of the created structure.

For wall panels

The crate is formed of wooden slats, the size of which is 20x20 mm. When you plan to work in wet rooms instead of treating wooden products with solutions To protect against the fungus, you can apply steel profiles with an external zinc layer.

When selecting fasteners take into account that the distance between the dowel-nails, retaining on the walls of the rail, should be 50-60 cm.

The angles that help close the outer joints of the panels, running at a right angle, can have a size from 100x100 to 500x500 mm. Their choice is determined individually.

additional information

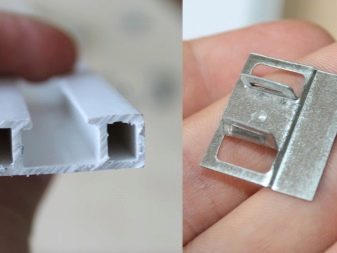

In most kleimer sets, other components of the hardware for PVC panels are made of steel.

In this case, there are designs from:

- magnesium alloys;

- aluminum alloys;

- titanium alloys.

Polymeric structures are used primarily for decorative purposes, since they are too fragile for most works. If it is not possible to select the optimal size elements, choose the closest to them and cut off the excess parts with a construction knife. All additional parts for the installation of plastic panels must comply with GOST 19111-2001. It is required to require a certificate of conformity and carefully study it.

They select an option according to which PVC panels will be fastened taking into account a number of considerations:

- how big is the radius of curvature of the surfaces being trimmed;

- whether the humidity in the room is significant;

- Is there any communication under the communication panels?

- are there temperature bridges.

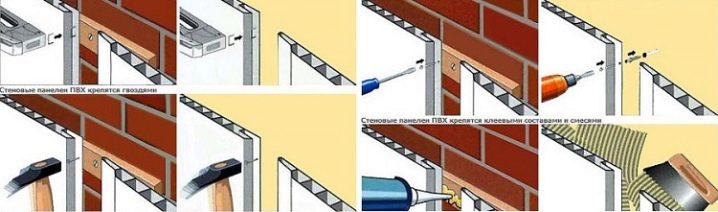

It is cheaper and easiest to fix plastic with silicone-based adhesives or “liquid nails”. But we must not forget that only compositions resistant to high temperatures will do. Advantages of fastening on silicone consist in fast drying, excellent mechanical resistance and the possibility of mounting panels in a short period. In this case, the weaknesses of such a solution will be unsuitable for use on at least minimally uneven surfaces and the impossibility of changing deformed panels. because in most cases, however, fasten parts made of PVC with nails or dowels, making a choice between them according to the material of the walls and ceilings.

Since the crate is often made on the basis of wooden parts, they need to be fixed with special dowels, which are equipped with polymer sleeves. It is recommended to use liquid nails to enhance the contact.

But we must be prepared for the fact that it is necessary to cut the timber and impregnate it with an antiseptic.Such manipulations clearly do not accelerate the construction.

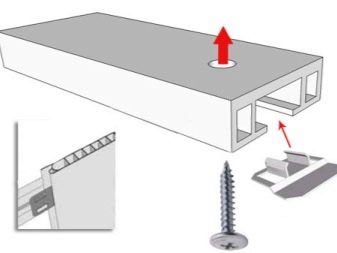

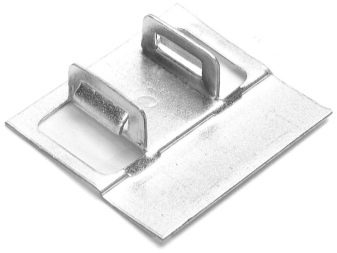

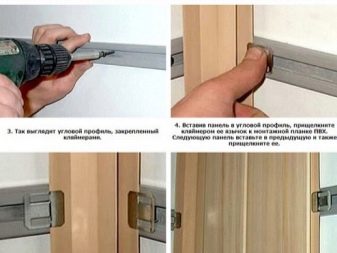

Talk about the installation of PVC panels leads to pay close attention to klyimery. The length of such structures may vary, but usually reaches 5 cm, larger products are quite difficult to find. The mounting plates must be made of steel with a zinc layer.

Attention should be paid to the appearance and quality of the retaining tongue, holes for dowels and nails. However, high-quality klyimery allow you to abandon the use of additional mounting blocks. They are much more sparing for the points of joints and panel locks, provide a tight fit to the surfaces and improve the quality of the assembly.

It should be remembered that even the most durable brackets leave a slight curvature that allows the walls to sag, keeping the panels whole - this is another advantage. In order for it to please the owners of the house, it is necessary to control whether the grooves with the spikes on the Klymer well fit. When the lathing is mounted on a minimally uneven surface, its stability is ensured by wooden linings.

You will have to make such linings yourself, because it is impossible to predict the need for them and the exact dimensions in advance.The height of the staples should be no more than 0.2 cm, using such parts is sufficient for 2 m in length (but if the perimeter is large, you can add more).

Selection of accessories is not the right time to save. Where it is more important to take care of the manufacturability of used components. The seemingly more expensive designs ultimately justify their price in practice.

Start profile must be:

- UV resistant;

- resisting yellowing for at least 10 years;

- elastic and non-brittle;

- containing a minimum amount of chalk and other harmful substances;

- easy to fit (due to its configuration) even with partially uneven surfaces.

Proceeding from this, plastic moldings are a big question, and metal elements are of primary importance in practice. Among them, preference is given to those parts that have a special anti-corrosion treatment. It is customary to allocate 4 format profiles, according to which the values of moldings are selected. Most often, the plastic construction in length reaches 3 m. Only 0.3 cm thick profiles have a length of 250 cm.

The calculation of the required volume of components must be completed before the installation. It should be remembered that all the moldings, including the corners, are implemented individually. Whatever profile is installed, it is recommended to maintain a gap of 0.5 m between separate parts.. This will cover all surface defects.

Selecting adhesive mixtures, you need to take into account that they are always calculated for specific values of temperature, air saturation with water and other parameters.

On the ceilings, all PVC sheets are rolled into profiles on three sides. The long edge focuses on the original molding. The final panel should be clamped in profiles on both sides.

All these points should be taken into account when determining the need for components. For each modification of the panels, a set is selected; ideally, this should be done simultaneously with the purchase of facing material.

Also note the following important points:

- in places without openings for windows and corners, you can do by purchasing the sheathing profiles;

- most outlets offer white moldings;

- color designs are sought in special stores or even ordered;

- Of all the plastic elements, those with the highest strength are preferred.

- you should always remember about the width of the grooves for the panels;

- all parts with sharp burrs and deviations from the normal form are unacceptable.

In the next video you will find instructions for the installation of PVC panels for the ceiling and walls.