The stove in the garage: how to do it yourself

Winter in Russia is more than winter. It is not a secret for anyone that it is uncomfortable to be outdoors with heating at this time of the year, but what if there is such a need? For example, you need to visit the garage and spend some time there. And the love of a strong half of humanity to gathering with friends in the company of their iron horse is known to all.

Of course, gatherings with even a small “minus” outside rarely bring joy, if the garage is not heated around the clock. There is a way out if you can install a homemade stove in the garage.

Features: pros and cons

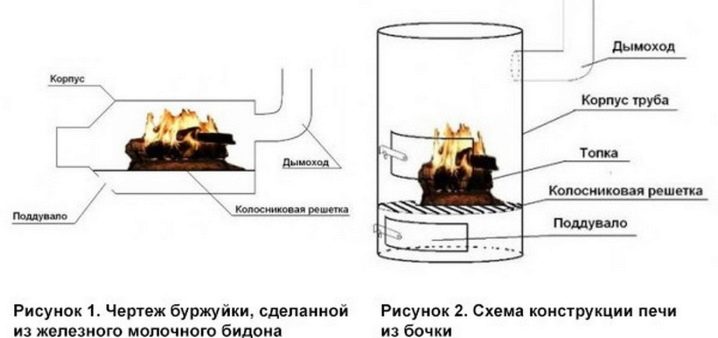

The advantages of a homemade stove made of barrels, usually include:

- fast heating at a cost of the minimum quantity of fuel;

- simplicity and availability;

- the ability to do it yourself from a variety of materials, even improvised;

- unpretentiousness in the choice of fuel (firewood, mining, diesel fuel, coal, peat, etc.);

- sometimes, for better heating and heat exchange, a kind of “labyrinth” of metal sheets is installed on the furnace.

It is quite true that the statement that there are probably more disadvantages to a stove made from a barrel than advantages:

- large heat losses and, as a result, significant fuel consumption during long-term use;

- if the stove is made of an ordinary barrel, then you need to be prepared for the fact that it will last for a relatively short time due to the small thickness of the walls - they will quickly burn out;

- poor temperature adjustment capability;

- if the stove is made in the horizontal version, it will take a fairly large space in the limited space of the box;

- the vertical orientation of the furnace will give a gain in the use of space, but the walls will burn through faster than that of a horizontal pot stove;

- due to the burning of the walls, the furnace can be fire hazardous and will require more attention when heating;

- Such a stove needs a high chimney with a height of over 4 m, which will have to be cleaned regularly.

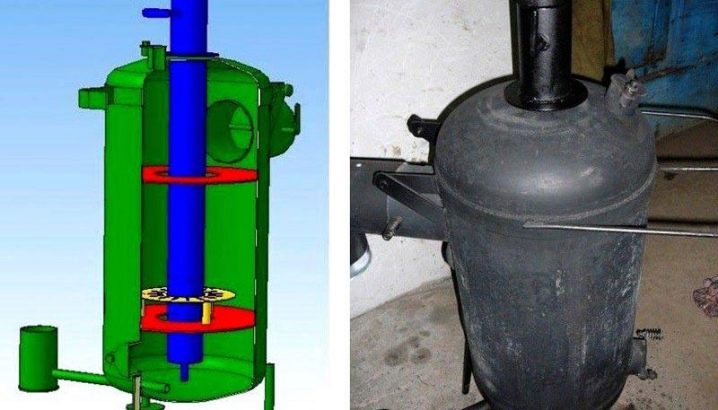

You can get rid of most of these drawbacks by making the body of the stove from the gas cylinder. It has thick heat-absorbing steel walls that are well welded.

Preparation of the old cylinder for welding is very important because of the likely presence of explosive gas residues inside, even if the neck is removed.

There are several preparation options: you can simply fill the balloon with water and leave it for a long time or add alkaline substances to the water to neutralize the gas. However, this method is considered the most reliable:

- the cylinder in a vertical position must be securely prikopat for cutting a hole with a grinder;

- completely fill it with water, wait a few hours;

- outline the cutting line;

- to cut with a grinder until a through hole appears - water starts to flow out;

- complete the cut and drain the water - the risk of fire is guaranteed to be eliminated.

Principle of operation

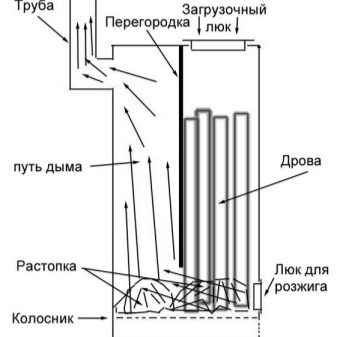

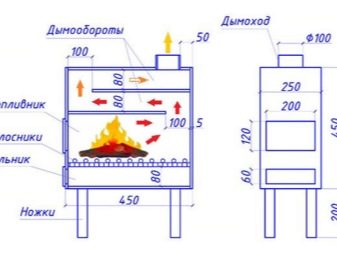

Let us consider in more detail the work of a homemade stove:

- air is blown into the furnace firebox through the blower;

- during combustion, heat is generated, which heats the bricks and walls of the furnace;

- smoke, soot and combustion products are drawn through the chimney;

- combustion control with obtaining the required heat transfer is performed by increasing / decreasing the open gap of the blower door;

- the stove is heated using various types of both liquid and solid fuels (firewood, mining, diesel, coal, peat).

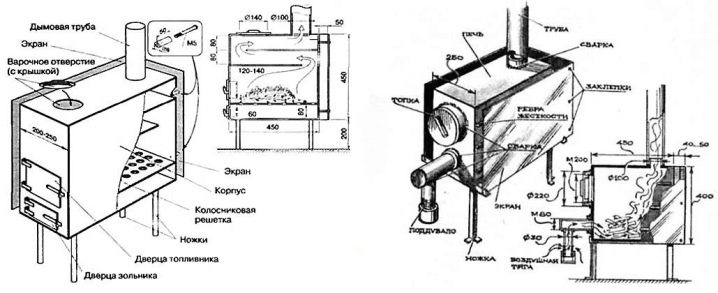

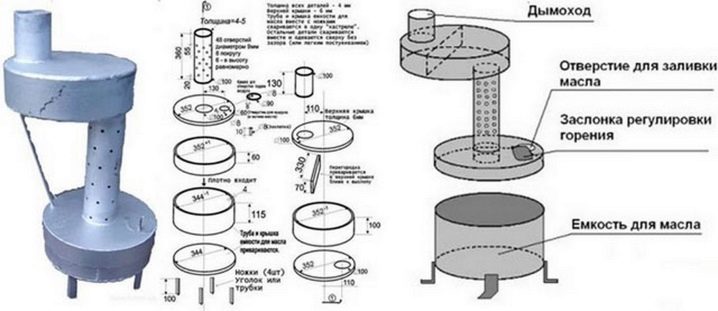

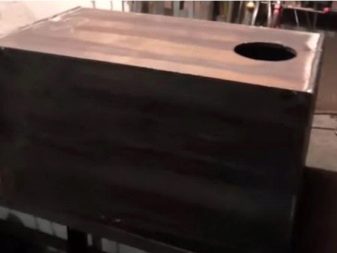

Potbelly stove on working

The stove, fuel for which is not wood, and waste oil, has its own characteristics. It can be a small stove for a conventional garage, or a device designed for heating large areas. In any case, all models work according to the same principle and have similar designs and operating principles.

- The potbelly stove has 2 parts. The lower part is filled with waste oil, where it is kindled and brought to a boil.

- Vapors are drawn through a perforated tube for access of oxygen, where their initial afterburning occurs.

- All fumes are oxidized and burned in the upper part, connected to the chimney.

- The temperature in the lower tank is relatively low, the upper chamber is heated to the maximum, heating the room. Its walls can even glow from the heat. Accordingly, this affects the choice of material for the manufacture of chambers.

Drawing diagram of the stove for working with conventional sizes and proportions.

Consider the merits of a burzhuek to work out.

- Unpretentiousness and "independence". Constantly putting firewood or doing something is not necessary, the main requirement is correct adjustment of the filler clearance (10-15 mm).

- Effective heat dissipation.

- The absence of soot from the chimney, the stove does not smoke.

- Relative fire safety, since the mining of the fuel is not easily flammable, and only oil vapors burn.

Disadvantages:

- noisy;

- characteristic odor (it is sometimes disposed of by installing a water circuit or an air heat exchanger with a blower fan, which directs part of the air from the chimney to another room for heating);

- the combustion chamber (perforation connecting pipe) and the chimney must be cleaned often enough;

- The coked layer of burnt oil in the lower chamber is also quite problematic to remove.

When using a stove with a fuel-mining stove, you must adhere to mandatory rules.

- It is not allowed to use oil mining with gasoline or with other flammable impurities.

- Mandatory filtering of mining from solid particles.

- Do not allow water to enter the mining.

- Strong drafts are not allowed.

- Compliance with all fire regulations when installing the stove in the room.

- Mandatory availability of reliable ventilation.

- It is strictly forbidden to leave the oven unattended, sleep while the oven is working.

- Do not use water to extinguish!

- Horizontal chimney exhaust areas are prohibited. The permissible angle of inclination of the chimney is 45 °.

- The chimney should have a length of 4 to 7 m.

- Pour the test into the furnace is recommended to a height of less? volume of the lower chamber.

- It is necessary to have a powder fire extinguisher and / or sand in the immediate vicinity of such a furnace.

Making your own hands

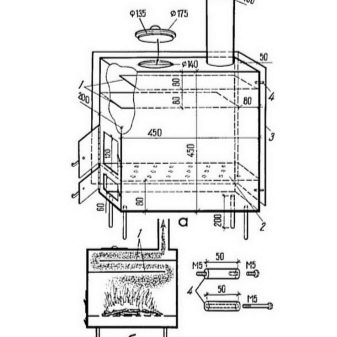

Drawings and sizes

The stove will give the maximum efficiency, subject to compliance with the calculations made.

Consider the design of the chimney.

- The vertical part (up to 2 m) is covered with non-combustible insulation.

- The pipe is tilted or parallel to the floor (2.5-4.5 m), the distance from the ceiling in the absence of heat-resistant protection on it is 1.5 m, from the floor 2.2 m;

- The diameter of the chimney must be calculated with great accuracyso that its speed of operation was less than the rate of combustion of the fuel, and he would not throw all the heated air with the combustion products out immediately, but let it heat the walls, which is the main feature of this type of stove. Estimated patency of the pipe should be 2.7 times the volume of the furnace. That is, with a 40 l furnace, the chimney should have a diameter of 106 mm.

- If there are grates in the stove, the height of the firebox is calculated from the top of the grate.

- Complete combustion of the fuel can be achieved by creating a high temperature, which can be achieved by using a metal or brick three-sided screen around the stove. Install it with a gap of about 70 mm from it. The reflection of heat also has a fire function.

- Litter or fireproof surface under the oven is strictly required because:

- heat radiation from the furnace comes in all directions, including downwards;

- the floor may become very hot, and this will cause a fire.

Sheet metal is used as a litter, its area is 350-400 mm larger (700 mm is better) than the vertical projection of the stove onto the floor. Sheets made from other non-combustible materials with a thickness greater than 1 cm can be used.

Chimneys are installed in different rooms in different ways.

- Part of the pipe lead through the wall of the garage, this is the most common type.

- The chimney is completely left inside the garage box and exits through the roof. Thus, the garage is heated better, but the installation process is much more labor-intensive.

Required materials and tools

For self-manufacturing stoves in the garage will require the following materials and tools:

- sheet metal for the manufacture of ash pan and hob, if the stove is located horizontally;

- metal for chimney pipe (preferably with two bends);

- materials for fixing grates and supports;

- oven doors;

- cast iron wheels;

- welding machine;

- grinding machine;

- welding wire / electrodes;

- hammer;

- measuring tape / tape;

- chisel;

- pliers;

- drill;

- metal cleaning brush;

- chalk pencil.

Consider a step by step manufacturing process.

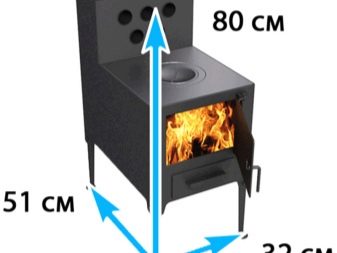

- As already mentioned, the furnace can be made in a horizontal and vertical version.

- The dimensions of the stove are selected based on the dimensions of the garage box, taking into account all fire safety measures.

- The walls must be welded from sheet metal with a thickness of more than 4 mm.

- The grate is welded to the inside of the firebox or placed on fasteners welded to the walls of the firebox from the inside (removable version). It can be purchased in retail chains or make your own hands from steel sheet by drilling holes no more than 20 mm in diameter, or from thick wire.

- Welded bottom.

- Cut a convenient hole for the supply of fuel and 5-7 cm below - for the ash pan.

- The doors can be made from sheet steel on their own, or you can purchase a ready-made cast iron block

- The stove is installed in the selected location of the garage.

- At this stage, attach the chimney. The longer its area inside the room, the warmer in the garage, as it also heats the air around it.

- At the last stage of the work it is necessary to put the stove on the legs. They are made of pieces of the profile, connecting by welding or screwing screws to the body. You can also use a metal box without a front wall (used as a woodshed), even the materials for the base can be bricks or forged elements.

Where to place?

Compliance with fire safety rules for garage use and the operation of the stove is vital.Here we are talking about the safety of the car, and the preservation of the life of the person. The location of the stove - one of the important tasks. Most often choose the corner of the garage box, formed by two walls, which is located opposite the gate. Direct contact between the stove and the car is strictly prohibited.

The distance must exceed one and a half meters. Similar conditions must be observed for distance from flammable substances and objects.

The surface of the walls near the stove should be covered with refractory material.. They can be additionally lined with bricks. If the garage is wooden, then the distance from the stove surface to the nearest wall should exceed 1 m.

Recommendations for use

If a stove is used for heating or cooking, it is very important to follow the rules for its operation. Their implementation, in addition to fire safety, will help to increase its service life.

- Before the first kindling of the stove, it is necessary to check and make sure that all joints and assemblies are tight, immediately correct all deficiencies in order to avoid penetration of combustion products and carbon monoxide into the garage room.

- For well-defined reasons, the chimney must be displayed outside. Its part, located inside the garage space, must be sealed.

- The chimney is strictly prohibited to bring into the ventilation system. Even if the furnace is installed in the basement, it should have a separate chimney.

- Passages of the wall or the overlap of the chimney pipe must be insulated with non-flammable refractory materials.

- A sandbox and a fire extinguisher are required to be in the garage, in accordance with fire safety regulations.

- The stove-stove is also used as a stove and for boiling water. To do this, install a hob with burners on it (usually it is made of a cast-iron stove) or a tank for heating water.

- The oven-stove heats up quickly, but also quickly cools. This deficiency can be partially compensated by a brick screen, which accumulates heat and returns it to the room as it cools after the stove is extinguished.

Direct contact of the screen and the stove is prohibited. The gap between them is left no less than 10 cm.

- Typically, a brick screen has considerable weight, so most likely it will need its own foundation. Consider the stages of its manufacture.

- Dig a hole about 50 cm deep.

- The bottom of the pit is covered with a layer of sand (the average consumption of sand 3-4 buckets), tamped.

- The next layer is 10-15 cm of rubble, which is also tamped.

- Lay the layers flattened, then pour a layer of cement mortar.

- Expect full hardening of the cement layer. The longer the hardening time, the better (usually the time interval is more than a day or longer, this will give the foundation extra strength).

- Then stack several layers of roofing material.

- The screen itself is laid out in half a brick, the initial two rows are carried out in continuous masonry on roofing felt. In the 3-4 row, you need to do the ventilation gaps, then again continue to lay the brick in a continuous layer.

Proper cleaning of the stove is basically a matter of removing the dirt inside the chimney, which is relatively rare. Mostly use a brush. It can be done with your own hands from a cylinder-shaped brush, tied to a rope.

It is best to use brushes with plastic bristles or iron wire. The diameter of the brush is chosen so that with the passage of the chimney there is no significant resistance.

Cleaning is used to increase the flow of smoke through the pipe, to improve heat transfer. The sequence of the cleaning process:

- plug the hole with a rag;

- make 2-3 careful movements with a brush in order not to disturb the tightness of the chimney (make stops if the brush moves freely);

- repeat point 2 as many times as necessary;

- remove coals, ash and soot from the ash pan.

How to install the stove in the garage, see the next video.