Build a wooden garage with your own hands

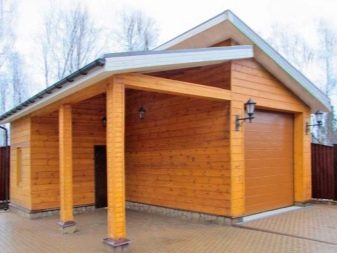

Many owners of suburban housing prefer to build wooden garages on their land, as these structures not only allow you to store a car, reliably protecting it from the negative environmental effects, but also act as an ideal addition to the architectural design of the house.

In addition, in such a building you can conveniently place large-sized objects, various tools and comfortably equip a place for repairing a motor vehicle. It is worth noting that the process of installing a wooden structure is simple, and it can be done with your own hands.

Features and benefits

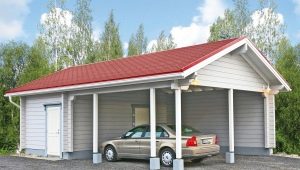

Garage made of wood is a multifunctional design, the frame of which is sheathed with a bar or planks. Thanks to modern design in this garage you can freely place 2 cars, while using the minimum land area.

Unlike brickwork, the construction of a profiled bar is inexpensive, and the finishing work can be performed using both new and recycled material.

Assembly of all parts of the garage is carried out quickly, does not require special training and the use of sophisticated equipment.

Installation of a wooden garage is also chosen in the case when the plot already has wooden buildings, made in the same style. Therefore, in order to create a general image in landscape design and not to destroy harmony, the owners of a country home have to build a garage of wood with their own hands. In order for such a construction to serve as a reliable place to store a car, it is desirable to place it in a fenced or protected area, this will help avoid hacking and theft.

The main advantages of a wooden garage include a fairly large number of properties.

- Durability and durability.

- Stylish look. This structure fits perfectly into the design of the site.

- Reliable protection of transport against changes in temperature and moisture.

- Fire resistance Modern buildings are treated with chemical composition, so they are “not afraid” of fire and tree insects.

- Efficiency.To install the structure, you can choose wood of any kind, and you do not need to hire builders, which, in turn, significantly saves the family budget.

- Easy installation. Construction work is carried out quickly, and the installation of the garage is “clean”, after its completion there is no garbage, which can take a lot of time to clean.

- The possibility of various interior finishes. Since car owners spend a lot of time in the garage, its interior should be cozy. To give the room a homely warmth, the walls inside the building can be decorated in an original way. Thus, you will get an additional room in which you will have a good rest after work.

- Huge selection of projects. Recently, many buildings of various sizes, shapes and styles have been created. Garages of 6x4 m are very popular, thanks to their compact size, you can not only save on material, but also make rational use of the land plot.

- Environmental friendliness. Wood is a natural raw material that fills the room with a pleasant smell and does not emit harmful substances.

The choice of design

Before you start building a wooden garage, you need to decide on its appearance, which will determine the visual perception of the building and its combination with other objects on the site.

To date, there are the following types of designs:

- frame;

- team;

- log house

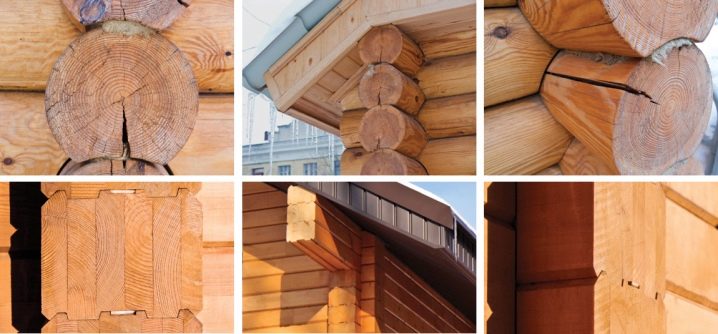

The most beautiful and expensive construction is considered a felling. This garage has a high aesthetics, its wooden trim can be easily combined with other materials. In addition, the building has good strength indicators, as it is installed monolithically, and the bars fit snugly together. As well as the design is resistant to mechanical damage, its walls are difficult to break through or drill, which is important when protecting the garage from burglars. Installation of a log house does not require much time and, as a rule, it is carried out from 3 to 7 days.

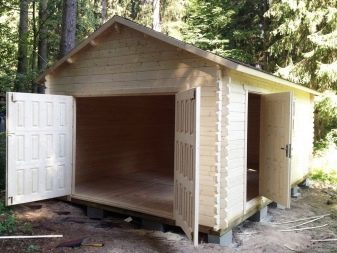

A good option for the garage is the prefabricated construction of timber. Its installation is carried out by a special technology. First, a parallelepiped is made around the perimeter of the future building, then it is attached to it on both sides of the board. Externally, such a garage can be sheathed with siding, and inside to finish with any material.

As for the frame structure, it is considered the most advanced type in construction. Unlike a prefab garage, when installing a parallelepiped, the location of windows, doors and gates is immediately taken into account. The assembly of parts is carried out in such a way that the plane of the frame looks like a chessboard. In addition, all internal floors are carried out on the cellular principle, which significantly increases the strength of the building and makes it warm.

Foundation

Usually in the construction of wooden objects used strip foundation, is no exception to this and the installation of the garage. Such a foundation extends the life of the building. If the finishing of the structure will include other materials than wood, then it is best to choose a monolithic foundation. It can be either poured with concrete or laid using ready-made slabs.

The only drawback of such a base is poor thermal conductivity, but since the garage is a non-residential space, it will not be a big problem.

Before you start pouring the base, you must first draw the drawings and carefully prepare the place. For this, the construction site is cleared of debris, then a 40 cm recess is made in the soil. It is important to make the surface even and smooth. The width of the recess should have a small margin: 150x150 cm on all sides. A pillow of river sand and gravel not more than 160 mm thick must be laid under the foundation. First, you should ram the sand, and then evenly distribute a layer of rubble.

After the pillow is ready, you need to install a formwork along the contour of the future structure. It is best to make it from vertical bars, leaving a gap of 20 cm on each side. In addition, attention should be paid to the height of the formwork, it should not be too high above the soil level, the optimal indicator for its height is 200 cm. the reinforcement grid will serve as the frame and foundation of the foundation, it is prepared in advance, and cells of 100x100 mm are formed. Under the bars of the reinforcement it is necessary to lay a brick and pour the concrete in such a way that it covers only half of it.

Subsequent stages of construction can be performed after the foundation has completely dried. It usually takes a few days.

Frame and roof

Most often, for the installation of wooden garages choose a single type of roof, as it does not represent a huge load on the frame and does not require additional reinforcement. If the premises are planned to be used for two cars, then it is desirable to use special profiles covered with anti-corrosion mixtures under its basis. As for the garage frame, before you build it, you need not only to choose the technology and place of assembly, but also to take into account the proximity to communications, climatic conditions and groundwater level. It is also important to determine the area of entry and type of gate.

As a rule, wooden garage erected from glued or rounded timber. For work, it is recommended to purchase slats and boards with a moisture content of not more than 18%. At the same time for the bottom strapping used timber size 100 × 50 mm, for longitudinal elements 50 × 50 mm, and for floors and rafters 100 × 100 mm. Mounting the frame requires a temporary fixation of the racks, this allows for an increase in the rigidity of the mount. Therefore, the rack connected with metal corners and screws.

Erection

Installation of frame construction begins with the bottom trim, which is performed around the perimeter of the garage, using bars. The surface of the tree must be coated with mastic and antiseptics.In addition, ruberoid is laid under the bottom trim. At the corners of the frame place the corner posts and fasten them to the strapping using metal mowings.

Thus, the design becomes durable and withstands stress after plating.

After the corner posts are exposed, the top strapping is performed. At the same time it is necessary to ensure that the supports have a clearly upright position, for this it is recommended to use a level. Then reinforce the frame with additional ribs. Boards with a cross section of 50 × 100 mm are placed between the lower and upper strapping and fixed. The ribs can be mounted both on steel corners, and with the help of complete or incomplete cutting of bars. The distance between the ribs is calculated depending on the width of the finishing plates that will serve as the walls of the garage.

Sheathing

Facing the structure can be done only in the case when the issue of thermal insulation. If, however, in the garage is not planned the arrangement of the workshop, then its walls can not be insulated. In this situation, it is enough to fill the voids and seams with foam and nail the boards, leaving the areas under the windows and gates.

As for the inner lining of the building, it is necessary to first put sheets of steam and heat insulation, then carry out decorative finishing of boards or any building material. Beautifully looked inside the garage walls, sheathed clapboard or plasterboard.

Roofing device

Usually, the roof of a wooden garage is made angular in shape, as this provides good drainage of precipitations. In addition, you can apply other design options, the choice of which depends on the length and width of the building. Therefore, even at the assembly stage of the frame, you should carefully consider the type of future roofing and draw a drawing of its model. Small garages cover the triangular roof and slightly raise the bottom of the puff. If the structure is large, then for the roof it is best to use bolts or vertical stops.

The fabricated form is mounted on the top trim, taking a step every two meters. Fixation is usually carried out with the help of special corners, roof beams are mounted from inside the garage to the rafters. A layer of waterproofing is applied on top of the blanks and a crate is made on which the coating itself will be laid in the future.A similar procedure is performed for a single-pitch roof, but its roof systems may be different.

It is worth noting that single-pitch roofing is much worse in operation, since it creates uneven loads on the frame, therefore, it is undesirable to install it.

Gate: options

An important issue in the construction of the garage is the choice of gates. The type of their design is determined by the drafting and fits into the drawings. To date, several options are widely used gate.

- Swing. This is the most popular type of construction, which is characterized by its simplicity and convenience. Such gates consist of two canvases, their construction is cheap and does not require special knowledge of installation, therefore, garage doors are easy to do with your own hands and sheathe with wood or profiled sheets.

- Swivel. This type of gate is provided with a hinged mechanism, thanks to which the canvas rises when opened. The design does not take a lot of place, is practical and convenient in operation.

- Sectional. In these gates, the canvas is made of several sections.During their opening, construction details are refracted and lifted vertically to the ceiling due to the operation of the system of profiles and spring mechanisms. They well save garage space and provide the room with excellent tightness.

- Rolling. Externally resemble rolling shutters. Door plates can easily be folded into a box under the ceiling, therefore, they are considered the most modern and practical type of construction.

All of the above gate options are well suited for wooden garages., but each of them has its advantages and disadvantages. So, swing structures are inexpensive and quickly assembled, but they are largely inferior to sliding gates.

If you choose products with lifting mechanisms, you will have to spend additional money on their equipment and installation, since the assembly is complicated.

When self-manufacturing gate is important to take into account certain requirements.

- The design should be not only light, but also provide convenient entry / exit of motor transport. Therefore, you should correctly calculate the size in accordance with the dimensions of the machine. As a rule, the distance from the goal post to the side of the car should not be less than 30 cm.As for the height, its optimal size is 2 meters.

- In order to increase the protection of the gate, it is recommended to trim them with steel sheets 5 mm thick. In addition, they can be further strengthened with the help of external pads and patch constipation.

- For the exterior of the structure, any construction material will be suitable, starting from boards and ending with profiled panels.

How to build a garage yourself, see the next video.