How to make a garage from a professional sheet with your own hands?

To date, the car is not considered a luxury item, therefore it is available in almost every family. In order to protect the vehicle from the negative effects of the environment and extend the life, it must be stored in a special building. You can, of course, put the car on a paid parking lot, but this will entail significant financial costs. The right decision in this situation will be the construction of a private garage made of corrugated flooring.

Such structures are very popular, as they have many advantages and fit perfectly into the general appearance of the land plot; moreover, it is quite possible to make similar structures with your own hands.

Features: pros and cons

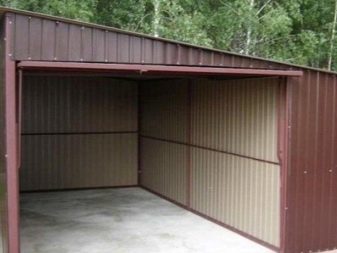

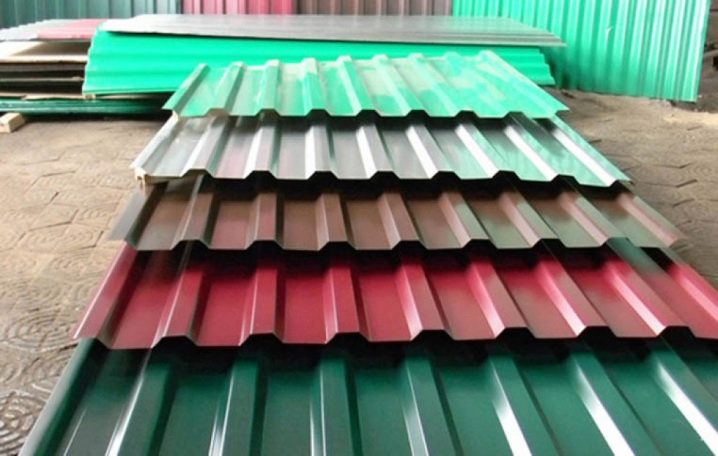

Garage of corrugated flooring is a structure, which is installed from the profiled sheets of steel. This material can have different wave heights and thicknesses; therefore, depending on the type of load on the structure, it is possible to choose professional flooring of the C18 or C21 brand.In this case, the greater the wave height of the sheets, the safer the construction will be. Since the weight of the proflista is small, the installation of such a garage is most often performed on a strip or pipe foundation. To speed up the installation of the structure, it is recommended to purchase ready-made kits.The assembly of which will take no more than 3 days, they, as a rule, consist of a frame, roof, walls, gates and a cornice.

In addition, the garage of the metal can be made on an individual project, for this are preparing the drawings of the building and purchased the necessary material. The main advantage of self-construction is the saving of money and time.

As for the positive qualities of corrugated board, then these include:

- frost resistance;

- a light weight;

- durability and reliability in use;

- incombustibility of the material;

- ease of transportation;

- low cost;

- esthetic look;

- high resistance to rotting;

- does not need additional processing.

Despite the presence of advantages, professional sheets have their disadvantages:

- The possibility of deformation. When rusting metal and strong impact, the protective layer of the material is damaged.

- Ease of hacking. If robbers want to get inside such a garage, then it will not be difficult for them to do so. Therefore, the construction is recommended to install only in the yard.

- Low thermal conductivity. In summer, the metal gets very hot, and in winter it cools.

- The design needs additional support.

Location selection

Before you start building a garage, you must not only purchase profiled sheets, but also choose the place where the future building will be located. The garage is not recommended to be built next to other household objects, as this may prevent the exit and entry of the car. Often the garage is built in such a way that the line of its gate is located on the fence line. Due to this, access to the structure will be simple, and it will additionally fulfill the role of part of the fence.

In addition, the garage can be installed end-to-end to one of the buildings located on the land plot. In this case, do not have to build one of the walls. But it is worth noting that you can not attach the design to the house, as the inside of the premises will penetrate not only the unpleasant smell of gasoline, motor oils, but the sound of the engine.

An important point when choosing a place for the garage is considered and checking the level of groundwater and soil.This should be done so that in future operation, the structure “does not move out” under the influence of the displacement of the soil.

Schemes and drawings

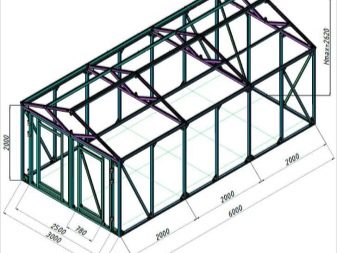

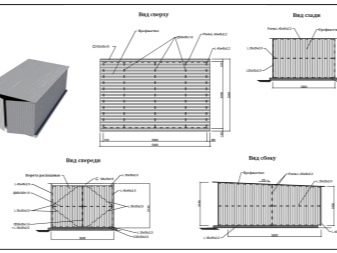

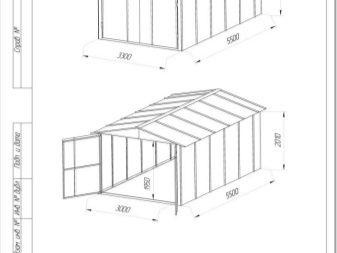

Any construction begins with the creation of a plan, is not an exception to this and the installation of the garage of professional sheets. Before starting the installation work, you need to make an accurate calculation of the dimensions and draw a diagram by which you can easily determine the right amount of material. The size of the garage depends on the size of the vehicle and on what is planned to be additionally stored in the building. If the structure is intended only for a car, then it is enough to equip a place for it to park and place several racks. As a rule, the easiest project with a garage size of 4x6 meters is suitable for this.

To make the building not only convenient, but also harmoniously fit into the landscape design of the site, when designing it, it is important to think about every square meter. Therefore, first draw the layout of the entire structure, and then perform the internal layout. When the width and length of the garage will be known, you can easily calculate the consumption of building material.When creating a drawing, you should pay attention to the fact that the supporting pipes are solid and long.

This is especially true of the frame of the structure, in the diagrams one should indicate the sketch of the frame and register what elements it will consist of.

In addition, in terms of the garage is to provide a way to connect pipes. In that case, if the metal structure is built for continuous operation, and it will not be moved to another place, then it is desirable to use welding for fastening. As for the collapsible garage, then it will need special fasteners in the form of nuts, bolts and corners. The garage layout should also include gate drawings.

After the design is completed, you can make a plan for the execution of works, start construction.

Installing a garage from profiled sheets is an easy process, but in order to make it quick and to please you with a good result, you should purchase quality material and prepare the appropriate tools. For installation work at hand you need to have:

- building roulette or ruler;

- drill and drill bits for metal work;

- Bulgarian;

- spanners;

- color marker for marking.

In addition, you should also worry about security measures by purchasing personal protective equipment such as gloves, glasses and a mask. They will help to avoid injury to the skin and eyes while working with metal.

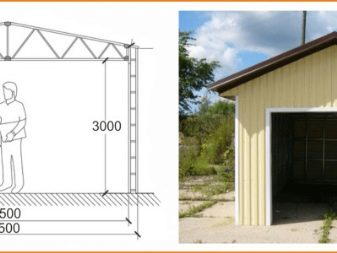

As for the material, the installation of the garage will need pipes made of galvanized metal and profile. Since the construction market sells profiles with square and rectangular sections, it is best to give preference to the first. They are easy to assemble and quickly assembled. The frame of the garage should be iron, therefore, to provide him with good strength, It is recommended to make the main racks of pipes with a diameter of at least 100 mm. Under the frame structure can be laid material with a cross section of 60 mm.

Mounting technology

Installation of the garage is not particularly difficult, so it can be done by hand. To start this, you must first choose a suitable place to place the structure and pour the foundation, it will simultaneously serve as a solid foundation and floor for the structure. Then a frame is erected, the finished parts of which can be welded or assembled for fastenings. The next step in the installation of the frame is considered to be profiled sheeting, it usually takes several days.

After the framework, sheathed by professional sheets, will be ready, there will be only to establish a gate. Their frame is made of a metal corner by welding, and then sheathed with profiled sheeting. For novice masters such construction may seem difficult, but in fact it is not. The main thing when performing all the work is to adhere to one rule: “we build correctly”. Therefore, it is important to do everything slowly, just to comply with the dimensions indicated in the drawings of the garage, since the slightest mistake can cause various problems in operation.

Foundation

The construction of a garage of metal sheets consists of many stages, the first of which is the laying of the foundation. To do this, dig a hole and fill it with river sand, which will serve as a “cushion”. Then, along the entire perimeter of the future structure, metal columns are installed and they are poured with concrete. As a support fasteners can be used as a pipe with a circular and rectangular cross section.

In addition, from concrete it is possible to make not only the foundation, but also the floor of the garage. To fill it, first the top layer of soil is well cleared of debris and the desired level is determined. Concrete floor will be durable if it is further reinforced. The coating is often erected from wood using floorboards or bars.

Walls

Professional sheets are considered to be a versatile building material, so they are well suited for wall cladding in a garage. For these purposes, recommended profiled category "C", it is attached to the crate with screws. At the same time it is recommended to expose sheets in height, thus, the design will get an attractive appearance. The panel of material must be mounted strictly according to the level, and all fastening elements should be “planted” on rubber gaskets.

For more reliable fastening of sheets, the places of their joints can be closed with special rivets.

Roof

Roofing, erected for the garage, is done both with insulation, and without it. Depending on this, it can be installed in one or two ramps. In that case, if the construction is closely located to the walls of other economic objects, then it is desirable to choose one ramp with placement in the same plane with the ramp of the adjacent building. In addition, a shed roof is very popular in construction, as it is easier to build.

Professional sheets for the roof are selected in length, and they do not have to form many joints during installation, which in the future can serve as a problem and give a leak. If the sheet was purchased earlier, and its length is not enough, it is possible to stack the sheets overlap, and the resulting seams to cover with bitumen or a special sealant. It is necessary to level a professional flooring before its fastening, considering lines of eaves.

Warming

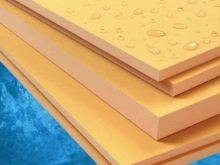

During the construction of a garage of profiled sheet, it is important to provide for its temperature inside. The best indicator for it in winter is the temperature from + 1C to + 5C. It is worth noting that even with large frosts, it is not recommended to warm up the garage room, as this can harm the work of the car’s units. Therefore, to ensure the structure of a constant temperature, it must be warmed. To date, there are many types of insulation, among which are:

- liquid polyurethane foam;

- insulation based on mineral fibers;

- polystyrene plates.

Each of the above heat insulators is characterized by its advantages and disadvantages.So, the garage insulated with polystyrene foam plates will provide excellent conditions for storing the car, but after laying the insulation it will be necessary to even out the surface of the walls and ceiling. In addition, polystyrene is very hot under the influence of sunlight and can release harmful substances. The result will be a warm, but safe for health garage.

Well-proven as a reliable insulation plate of basalt fiber.

They are placed in a small layer of 5 cm and they can even replace brickwork with a thickness of 80 cm. This material is environmentally friendly and fireproof and meets all standards of operation. The insulation is laid in the intervals between the profiles pre-installed in the wall.

The most convenient to use is liquid polyurethane foam, it is applied to the surface by spraying. The heat insulator does not form cracks and seams. This material, in addition to insulation, also serves as an excellent waterproofing and sound insulation, well protects the metal structure and serves up to 50 years.

As for the insulation of the roof of the garage, for it mainly used rolled materials of bitumen.In this case, the insulation of the roof is best done outside. For this, the slab covers are thoroughly cleaned and sealed with all mortar joints. Then, several layers of thermal insulation are laid in staggered manner on the prepared base and reinforced with a cement screed with a thickness of no more than 50 mm.

Useful recommendations

In order for a metal-shaped garage to serve reliably for many years, it is important not only to draw up its project correctly, to choose quality material, but also to comply with the construction technology. For car owners who decide to build a garage themselves, the following tips from experts can help:

- It is important to accurately calculate the dimensions of the whole structure and especially to pay attention to the height of the building. In that case, if it is lower than the neighboring buildings, the roof may eventually subside. In addition, the roof frame is desirable to do with a slight bias on the rear wall. Reinforce the roof is recommended wooden planks.

- After pouring the foundation, you should wait a few days and only then proceed to install the garage.

- When choosing professional sheets, you need to pay attention to their brand, and buy material with the designation "C". Such sheets are characterized by increased waviness and strength.

- All fastenings should be carried out using special rivets and screws.

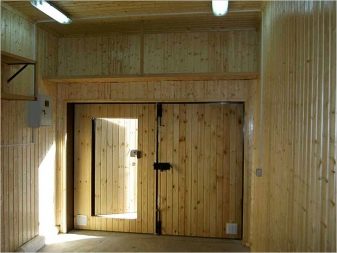

- For the interior of the garage you can use various finishing materials. Beautifully looks in the design of the garage as a tree, and a panel with an imitation of stone. Covering these materials will be cheap and the room inside will get a cozy look.

- The color of professional sheets for the garage is chosen individually, taking into account the style of other buildings that are located next to him.

To learn how to make a garage out of a professional sheet with your own hands, see the following video.