Garage of SIP panels: pros and cons

There are quite a few options for the construction of garages, and above all the variety manifests itself in the materials used by builders. Brick and metal buildings, structures made of various types of concrete have been known for a long time. Some developers even experiment with wood and other exotic materials in this case. But one of them - CIP panel - remains little known. The article will discuss what their parameters are, whether the use of such units is justified in the construction of a garage, and if so, why.

Special features

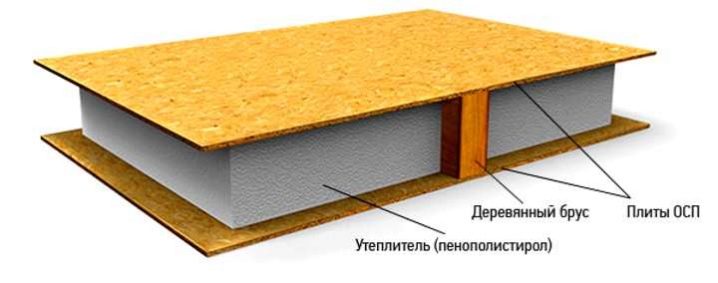

CIP panels are constructively insulated, on top of which are placed the so-called oriented chipboard. This material:

- plastic;

- mechanically strong;

- lets out or inward little heat.

An additional insulator is polystyrene foam in most modifications. As the long-term practice has shown, CIP panel is able to compete with chipboard on an equal footing.The general conclusion of experts on it is just that material which will allow creating the necessary structure without wasting time, money and physical strength.

The undoubted advantages of building from CIP panels are also ease of care for them, the availability of the material and the ability to get it at any time, in any quantity. You can complete the work by building a full-fledged garage in 4-5 days, even without hiring a special technique.

Since the CIP panel is one of the varieties of wood plus plastic of a special kind, it is easily cut with a saw on wood or a power saw with an electric drive. External fragility is deceptive, in fact, the design being created is very durable. The geometric accuracy of the blocks, which is obviously unattainable for bricks, boards or other materials, allows us to accurately calculate the need for products.

Make a perfectly smooth and smooth walls will not be difficult. CIP panel is not prone to fire, which will greatly please any responsible owner.

Many are interested in the question of why these structures are inexpensive, due to which such a low price is achieved.This question is justified, after all, relatively affordable goods of low quality have become familiar, unfortunately. But here the situation is different: the CIP panel has only recently appeared on the market, it is not yet in great demand, and therefore the price level is not too high.

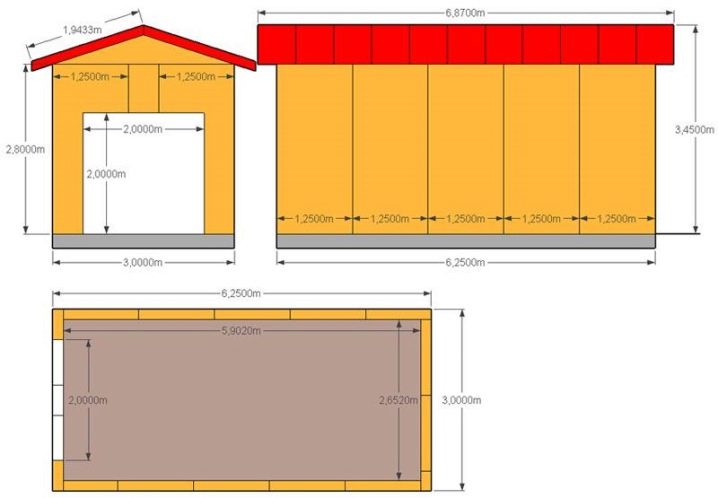

As in the case of any other garage, you need to make a well-thought-out project, taking into account in it the exact construction site, the dimensions of the structure, the type of foundation and the electrical wiring device.

Base

Garage-based panels are often placed on tiled foundations (slabs must be 12 or 17 cm thick). Among all slabs, deemed best are those that have recessed stiffeners. The tape basis means overlappings on the basis of plates of concrete goods; Such a solution is unacceptable for flowing, excessively mobile soils. Pillar base is a pillar, serving for laying beams, over which put the overlap.

What is needed for work?

The approximate demand for CIP panels during the construction of a garage can be determined very simply: one unit must be laid per 1 square meter. m surface. More accurate calculations will help to conduct online calculators, and even more reliable consultation with professionals. In addition to the panels, you will need:

- perforators and screwdrivers (for making holes and securing individual elements);

- building level;

- silicone sealant to block gaps and excess holes;

- facing material (internal and external);

- marker (it’s convenient to make notes while working);

- roulette;

- corners.

The work process does not begin with the preparation of a set of panels, but with the selection of the place where the work will be conducted. The type of foundation is determined by how the garage will be operated - for a single passenger car, the simplest strip base is enough. The construction site is pre-cleared, digging a trench, filled with a mixture of sand and crushed stone (in a 1: 1 ratio). After this comes the turn of the introduction of piles and concreting them - and when the filled solution hardens, it will be possible to work on the frame.

The peculiarity of CIP panels is that they can be laid both vertically and horizontally; to connect to the foundation is convenient to use the corners.

Attaching the blocks is ensured by bolts that are driven through pre-drilled holes. It is advisable to fasten the panels on both sides at the same time, this will help prevent the occurrence of the slightest bias or uneven relief.In most cases, the panels are installed from the corners, each joint is made denser by adding sealant.

When all this is done, do:

- roof;

- attic or uninhabited attic;

- electricity wiring;

- laying of heating mains;

- the creation of ventilation systems;

- arrangement of the gate;

- interior and exterior trim.

It should be noted that there is an easier way to install CIP panels when building a garage. It does not require the use of a frame, therefore it is applicable only in areas where earthquakes, strong winds and storms, as well as significant snowfall are excluded. The base panel is placed where the strapping beams intersect, is leveled and driven with a neat hammer blow on the timber.

In this case, the use of adhesive and sealant is indispensable.

The groove serves to introduce the connecting beam. And then according to this exact scheme, they work until all the details are interconnected. The panels on the corner are attached with self-tapping screws, for greater reliability they are lubricated with specially selected glue.

The advantage of a garage of CIP blocks is also the fact that it can be put on the roof with one or with two ramps.

Light material obtained by the method of pressing, is mounted in such a way that the load from the rafters and floors falls on the internal columns. This solution allows you to minimally fill the internal volume of the building, freeing from pressure to a large extent the external walls and supports of the supports. If a garage similar to all other characteristics is built of brick, then an additional internal wall is required.

In addition, the cost of brick, aerated concrete and foam concrete structures is 80% higher, even if you leave facing and insulation material behind the brackets.

How to care, and about the shortcomings

This is not difficult, but it is necessary to strictly observe the key requirements so as not to run into unnecessary problems. So, from the very beginning it is very important to choose a material with a high degree of moisture resistance. Not every panel meets this requirement, because many manufacturers are trying to mislead consumers. If a brick or aerated concrete block can be taken calmly - they are always safe - then this cannot be said about this material.

Sales can be found products that are not classified as E1, they emit an excessive amount of formaldehyde and may pose a health hazard. Next to the walls of CIP is unacceptable:

- put fireplaces and stoves;

- place electric heaters;

- accumulate substances that are prone to fire (fuel).

This imposes certain restrictions on the layout of the internal space and the storage of various items. And when in winter there is a significant snow drift, you will have to take care of cleaning the structure. If it gets wet, the consequences will be much sadder than in the case of a brick, metal or concrete garage. Literate exterior finish minimizes the negative effects of snow and ice, but it increases the cost and complicates the work.

CIP panel does not allow steam, which increases the role of proper installation of ventilation. And even if it is equipped to all standards, it is necessary to refuse to work with food products, from the placement of baths, baths and saunas.

Importantly, the panel is not a supporting structure, and when exposed to any load quickly collapses. Therefore, its installation should take place in such a way that even its own load goes as far as possible onto the beam elements and the beam. If this requirement is met, you can safely build even two-story garages, no limits on the volume of buildings and their height is not.

Like other constructions made from standard blocks, the key difficulty is the insufficient strength of the plate joints. So that the thermal expansion of the heating material does not damage the ends of the external RSD, a special gap is necessarily left.

The design of the garage on the basis of CIP panels should have a very good level of waterproofing, because it is extremely important to ensure the stability of the material.

Manufacturers and sellers invariably say that the plate is insensitive to liquid moisture and water vapor, because the technology uses resins and paraffin, blocking getting wet. But the experience of actual operation shows that the prolonged action of water or a wet atmosphere, badly affects the state of the RSD. Because the slightest gap, not to mention the joints, should be covered with a layer of aerosol containing silicone.

The outer walls are covered with a layer of waterproofing (film) and provide a ventilation gap. For the facial finish is recommended to use siding or decorative panels.

The sandwich panel, where the insulation is mineral wool, is even more sensitive than usual to moisture. It is advisable not to take it, but a block filled with expanded polystyrene. Since the panel joints can form cold bridges, it is necessary to seal each seam well and then overlap it with fittings. It is important to take into account that the coating applied in production is very susceptible to mechanical impact - only staining or another protective layer will help reduce the danger.

And yet, the advantages of CIP panels outweigh their disadvantages. To perform the work as it should be able to any builder, even a beginner. It is enough to be able to work with a hammer and a screwdriver; walls are erected in turns, and in order for the garage to become more rigid mechanically, it is required to use steel strapping. Profiles for ceiling structures should be wider than for wall structures; the connection should be made only with self-tapping screws with a zinc outer layer.

The walls must be installed, constantly verifying their geometry with plumb lines and precise building levels. It is impossible to cut the CIP panel, therefore it is necessary to immediately calculate their consumption as accurately as possible.

To learn how to build a garage with your own hands from CIP panels, see the following video.