Wood-burning garage stoves: types and features of manufacturing

Often, there is no central heating in the garages and garage cooperatives. On the one hand, this state of affairs seems to be an acceptable option, because housing and communal services rates are steadily increasing. However, the garages need to be heated for repairs.

Each owner independently comes up with a way out of the situation. Furnaces for heating are most often made with their own hands - it is cheap and effective. Such units in a short time can heat the garage room to an acceptable temperature.

Special features

If during the winter a lot of work is being done to repair the car, then it’s almost impossible to be in a cold garage for a long time.Traditionally, it has happened that garages are often heated by a stove, a “stove”, which is simple to use.

It is done as follows: holes are cut in a steel barrel, pipes and corresponding fittings are welded to them. It is important in such structures that the body does not need to be done, it is already ready, it remains only to implement minor modifications.

Heating with a stove, a “stove”, can be quite acceptable: it is rapidly heating up and giving off heat. The main scope of the installation of the stove is really done with a small welding machine.

Sometimes in the garages they put brick ovens, but they take up a lot of space and do not heat the room so quickly. Therefore, the most often used wood "stoves". The name is quite arbitrary, because in such structures you can put almost any combustible material.

Advantages and disadvantages

The advantages of a burger in the garage:

- fast heating

- universality of material for burning.

Two of these decisive factors allow burzhuykam hold the "palm" in popularity among motorists. Among the shortcomings, we can recall the fact that the material in such aggregates quickly burns through, and the stove itself cools down in a short time.

To date, a new generation of “burzhuek” has appeared, in which heat does not evaporate so quickly: if you use a 50-liter cylinder for propane, then such a device can function effectively for a long time. This allows you to securely heat the room.

Stand alone stove to work out. Questions arise here, because heavy metals are present in working off, and in no case should these substances enter the human body. Such stoves should be provided with a strong pitch, they should be made as tight as possible.

"Burzhuyki" also became popular during times of various adversities: during the Civil War in Russia, during the Great Patriotic War. Similar facts suggest that “stoves” are of practical importance.

Key requirements

The best material for the manufacture of such stoves is gas cylinders, they have thick metal walls on which welding can be carried out. Wall thickness should not be thinner than 3 mm (5 mm is best). This is a key security requirement.

By the design of the "stove" can be horizontal and vertical.Long firewood is best used for a horizontal stove - in this regard, the horizontal “stove” is more functional.

Types of stoves

Any brick kiln on the wood really to provide a water circuit. It is possible to place the combustion chamber in the tank itself, it can also be put together before going out to the chimney of a water heat exchanger.

Heat exchangers can be:

- in serpentine shape;

- made up of pipes;

- built-in tanks;

- convection - attached to the wall of the furnace;

- mounted near the chimney.

Butakova stove with a boiler and a water circuit

Benefits:

- pipes are located on the furnace body;

- active heat exchange occurs;

- water circuit does not depend on the combustion process.

Convection is typical of almost all wood-burning stoves. This option is the most rational, it requires a natural circulation of water.

Convection heating system was invented in Canada. Models are mobile convection ovens that heat up in a short time, providing the room with a stream of warm air.Sometimes they have a fan, which contributes to an even faster heating of the room.

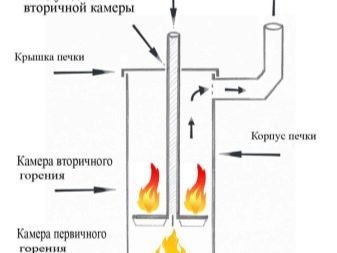

The garage stove is a hollow metal cylinder with a pipe in it that is directed vertically. Air goes from below and rises, heating up, inside the case. Thus, in the garage there is a constant circulation of cold and warm air masses.

How to do it yourself?

It is easy to construct a long-burning stove, should be able to use:

- compact welding machine;

- turbine;

- electric drill.

To get started, it is recommended to make a detailed drawing of the product.

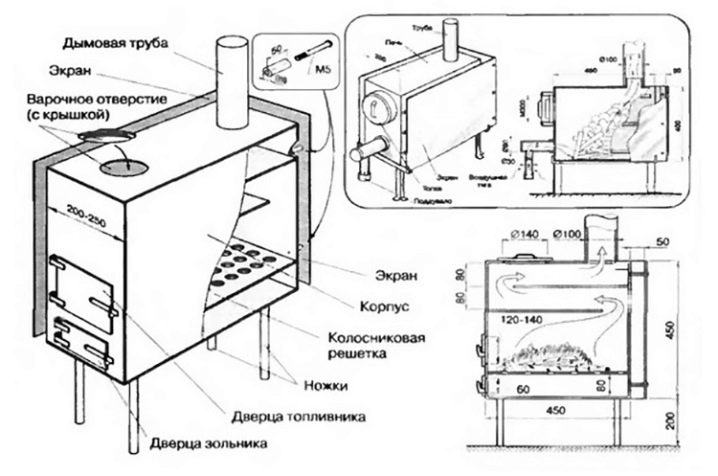

The works begin with the fact that two small doors are cut out: one for firewood, the other to remove the ashes. Fragments of iron, which are cut, will serve as "doors" - it is not recommended to throw them away. A place is planned where the fittings of 10 mm will be welded, the installation step is about 2.5 cm.

The bottom is welded to the bottom (if it is absent), a hole is made in the lid for the chimney. Further the metal strip (about 60 mm) fastens. The cross section of the pipe is most reasonable to make standard: then it will be possible to place the chimney.Hinges and a lock are attached to the door. If done correctly, the gaps will be minimal. (they can not even handle sealant).

Traditionally, it turned out that garage stoves are leaky. If the gaps are too large, cut a strip 1 cm wide and weld it along the seam. Then the chimney is mounted, after which it makes sense to start work.

Horizontal stoves are made in a similar way. In a horizontal oven, a ash box is placed at the bottom. You can make it from a sheet of steel using the corners. You can lay a brick stove, but it will take up too much space.

But metal stoves are good because they heat up in a matter of minutes and effectively give off heat.

Anyone who has ever dealt with the "stove" is well aware: the stove body is often red-hot. This is not very comfortable, and sometimes - unsafe. To make the airflow and heating more efficient, special designs were invented.

In the upper part of the fixed pipe for mounting the chimney (to do this, it is recommended to weld a small piece of pipe of the desired cross section). After the installation took place, the metal inside is removed.

It is important not to forget about the legs (so that there is a gap between the floor and the balloon): they are easiest to make from scraps of pipes or corners. Metal squares are welded to the legs for greater stability.

Then install the door. The ash pit is made of a piece of metal, to which the hinges and the lock are welded. The existence of small cracks is a blessing, oxygen is supplied through them, which will contribute to a better burden.

It is more reasonable to make the doors a little more than the opening - then a higher tightness will be observed.

The question can be solved with the help of a small engineering trick: two barrels of different sections are taken, and one is inserted into the other. The resulting gap is filled with fine gravel, which is mixed with seeded sand. Thus, the inner barrel is a firebox, and the outer barrel is an improvised body.

The advantage of this design is that it is more massive and heats up longer, but it will also give off heat longer.

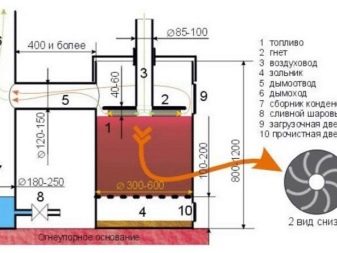

From the same gas cylinders, you can make a furnace a longer burning. The design is called "Bubafonya", it appeared a few years ago.Not only wooden fragments are put into the furnace, but also sawdust, paper and other combustible materials.

Often also connect water heating and have pipes on the walls of the garage. This design will be more complicated and expensive, but if in the winter time daily repairs are carried out in the garage, it is highly desirable.

The principle of functioning of such a system is that combustible materials are put on the burning ones. As a result, the combustion process is not so impetuous, and the heat transfer occurs more rationally, stretching significantly in time.

The design is efficient enough to warm the standard room of medium parameters: the furnace is of an ordinary round shape, the body is cylindrical, the bottom has no cover. The whole point lies in the device of the movable unit. In common parlance it is often referred to as "cargo."

This part ensures the supply of oxygen to the combustion zone. The shape resembles a circle; a pipe is attached to it. On this circle corners are attached. Thus, improvised air ducts are created, through which the air necessary to sustain combustion is injected. The smoke pipe is mounted at the top of the enclosure.The horizontal part does not exceed 35 cm.

It is recommended to make the pipe taller: from 2.5 meters high. Thus, there will be a normal thrust required for full burning.

Having prepared combustible materials, a “charge” is made and set on fire. A cap is attached to the pipe, and oxygen is supplied through the pipe, which ensures the combustion process.

Bubafonya works in a similar scenario. The size of the cargo is inferior to the size of the hull. Through a special gap, the combustion products enter the chamber. In this zone, the contents of the furnace is ignited, there is a burning process. It is not recommended to make the furnace airtight - the gaps present will provide greater traction.

The contents of the furnace, burning down, will fall lower and lower, and the advantage is that:

- the process is not so fast;

- burns everything without residue;

- the oven gives off heat evenly.

To make such a unit, you need the appropriate materials. Usually for this purpose cylinders of 50 liters are used, in which propane is stored. The required pipe (cross-section up to 60 cm, and its height can reach two and a half meters).

You will also need:

- a hollow tube with a section of 80-95 mm, a length of about 2 meters;

- a hollow tube with a section of 122-155 mm, a length of just over 4 centimeters;

- metal sheet with a thickness of 3 mm (from it is necessary to cut a circle for the load or duct);

- metal cut (width - 3 cm, thickness - 3 mm).

The cylinder is thoroughly cleaned from the inside, the cap is cut off. Cut points are equal and processed. The faucet is removed - a pipe will come out through the opening. The design is good because it does not require 100% tightness.

A metal band is welded around the circumference, the edge of which should protrude slightly, which will ensure the fastening of the cover on the body. Then handles are mounted, which can be made from reinforcement "8". Then all the components are assembled on the same principle as the other types of "burzhuek."

Useful recommendations

The use of an electric heater allows you to choose the optimal power, but it will cost tangible material resources. Working with an electric stove requires heightened precautions: this is the law.

Gas boiler - one of the most effective solutions for heating the garage. Unfortunately, not everyone has access to gas mains. Without the participation of specialists, such equipment is forbidden to be installed independently.

Stoves in which solid fuel can be burned are the best option for placing a garage. Furnaces in which you can burn used engine oil are easy to design yourself.

The furnace is recommended to do:

- not heavier than 30 kg;

- volume up to 15 liters;

- with parameters: 0,8x0,6x0,4 m.

Such units are optimal designs for heating the garage.

How to make a stove on wood from a pipe, see the following video.