We warm the metal garage

Metal garage freezes through in the winter. As a result, the car is difficult to start, and repairs due to the low temperature in the room are completely impossible. There are different ways to insulate a metal garage, but not all known materials are suitable for this. When choosing insulation it is important to take into account what load the installation will give on the design of the garage, as well as how many centimeters the internal area will decrease.

Types of insulation

The process of warming the garage depends on the selected insulation material. Somewhere installation implies additional costs for the crate and finish, in some cases, insulation is simply applied to the walls. Since the garage is iron, it heats up in the sun and collects condensate well.Therefore, materials should choose the most moisture resistant.

For example, mineral wool in this case is not suitable. It will start to rot, and it will be necessary to change the insulation soon.

For iron garage the following materials are perfect as a heater:

- extruded polystyrene foam plates, foam plastic or penoizol;

- polyurethane foam;

- heat-insulating paint (for example, “Astratek”).

Styrofoam durable, resistant to moisture, it is cheap to insulate, but it has a high flammability. Penoplex is its variety. It is twice as expensive, but the plates are thinner if the thickness of the walls is important, and also does not require additional waterproofing. Penoplex plates can even warm the floor, making a concrete screed directly on it.

Penoizol essentially the same penoplex, only in the balloon. It is twice as expensive and requires special equipment. It is applied on the walls in the form of foam, as well as foam. Polyurethane foam (PPU) is more expensive, but there are no seams. Environmentally safe, not flammable.

The disadvantages include the need for equipment for foam spraying and vulnerability to sunlight.

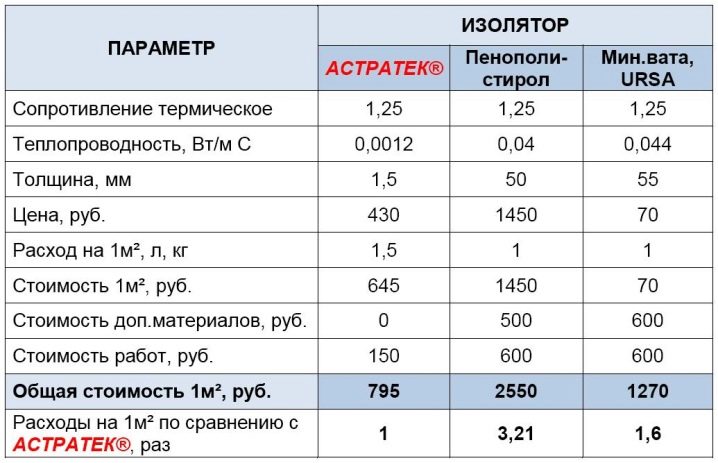

Heat insulation paint do not require additional finishing of the wall, since they are at the same time a finishing coating. They are cold-resistant, not afraid of moisture, quickly applied.A 1 mm paint layer can replace 5 cm of mineral wool. To create the necessary insulation enough to apply two layers. Such material is very expensive, but it does not take the internal useful space.

It is necessary to warm not only the walls and ceiling, but also the floor. It is through him that 20% of the heat goes.

The insulation of iron garages is made exclusively from the inside.

Penoplex and foam

Before warming the surface must be prepared. Remove peeling paint, clean rust. Walls and ceilings are recommended to paint to protect against corrosion. The color and choice of paint is not important, it will still not be visible under the skin. Therefore, you can save and buy something inexpensive. If the garage is made of galvanized profile, then nothing needs to be done.

If there are frosty winters in the region, then the thickness of the foam should be at least 10 cm, the foam complex should be 6–7 cm. A thinner layer does not provide the required insulation. The material is glued to the walls and ceiling with building glue, for example, liquid nails. You can glue on the mounting foam. Within an hour it will expand, so the plates should be periodically pressed against the walls.All slots are sealed with foam. To increase the insulating properties on the plates, you can glue the foil.

If the foam has two layers, then one of them can be replaced with a double-sided foil-insulated izolon.

Next, you need to make a crate. As a frame, you can use the existing metal frame garage. The crate is made of wood in steps of 25-30 cm. You can use a galvanized profile, but then it will be more expensive. Insulation in any case should not bulge for the crate. You can use clapboard, plywood, waterproof gypsum board, OSB panels or plastic siding as a finish. Gates and doors are insulated in the same way as walls.

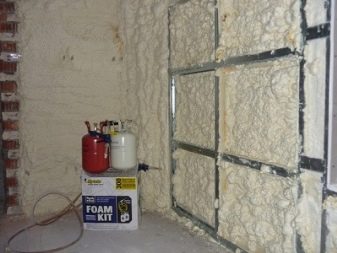

Polyurethane foam

The surface of the garage walls should also be prepared, special attention to oil stains - they should not be. The air temperature in the garage should not be below 10 degrees Celsius. Both walls and ceiling are insulated. PU foam is sprayed with the help of special equipment under pressure, something like the process of dyeing. The components are mixed and at the exit they give the same reaction, due to which foam is formed. The material hardens very quickly.The difference between polyurethane foam and penoplex is that It gives extra rigidity to the structure; no glue is required. The thickness of the foam formed should be 3-4 cm. For comparison, this replaces 5 cm mineral wool.

Another advantage of polyurethane foam is that it does not require crate. It is possible to coat it with paint or plaster. The high cost of polyurethane foam is compensated by savings on glue, lathing and facing material, not to mention the thickness of the walls and the load of the structure.

It is impossible to leave PPU without facing, as the sun's rays affect it destructively.

Paints "Astratek"

Paint "Astarek" is a mastic that can be applied with a brush or by spraying. After drying, an elastic coating is formed. The paint at the same time acts as a heater, is used for waterproofing, has anti-corrosion properties.

A great option for garages of shells. For example, it is quite difficult to insulate the corrugated material with plates; an additional frame is required. All this will take even more useful living area of the building. The process of applying thermal insulation paint is the same as usual.Surface required to prepare. To put with a layer in 1 mm, the second layer only after full drying previous. Two layers for insulation is enough. Paint can be applied to walls, ceilings and gates. It does not exert any additional load on the structure of the building.

Material consumption per 1 square. m is 0.5 liters of paint. Due to its cost, the total consumption for garage insulation will be substantial. But you can warm the inside with their own hands, without resorting to outside help. All work is carried out quickly, does not decrease the total amount of space. Saving other building materials, for example, the absence of glue, crates and cladding. The paint itself is a topcoat.

She is not afraid of moisture, the walls can be washed, and fasten shelves. Paint "Astratek" you can insulate the garage not only from the inside, but also from the outside, which other types of insulation cannot boast.

Basement insulation

In some garages has a basement, cellar or observation pit. It will be correct to warm them too. Because of the limited area, it is inconvenient to use mineral wool or foam. Therefore, it is worthwhile to draw a photo on such materials that require the construction of additional structures. For example, walls can be insulated with polyurethane foam and Astratek paint.These materials do not require additional waterproofing, which is very important in such rooms. But PPU will need to be painted.

Another option is a warm plaster. These are expanded vermiculite or expanded polystyrene granules. This insulation is also a finishing coating, but the walls must be pre-plastered. It is possible to pour expanded clay with a fraction of 5 to 20 mm on the floor. A larger version will shrink. The thickness of the coating should be about 10 cm.

You can also fill the floor with rubble (10 cm), on top of the sand (soft layer) and pour bitumen on top.

Floor insulation

If the floor is earthen, then it can also be warmed. To do this, remove the top layer of soil by 15 cm. Next, pour a layer of sand or expanded clay. This is necessary for drainage, so that moisture does not accumulate under the insulation, at the same time will allow to level the surface.

Next, stacked plates of foam. Sufficient thickness is 5 cm. This material does not require additional waterproofing. A 3–4 cm thick sand is poured onto the insulation. It is necessary to mount a framework of reinforcement in two layers of 1 cm over the structure. It is necessary for screeding.Pour cement mortar and allow to dry.

Instead of a tie, you can put a grooved board. To do this, wooden logs are laid on the drainage with a step of 30–40 cm, between them there is foam polystyrene or foam. All gaps need to be sealed with foam. From above to lags attach the boards. As a topcoat you can put linoleum. Any insulation of the garage is better to start from the floor.

Otherwise, doing all the work without damaging the wall finish will be problematic and inconvenient.

Insulation outside

Metal garages are most often insulated from the inside, but if space allows, then all the work can be done outside. This will save internal space, especially if the garage is small.

Around the garage is erected a frame for the batten. As a heater using foam or penoplex. The seams are sealed with foam. Siding is used as a cladding. If the roof has a truss system with one or two slopes, then:

- with a wide step, warm the mineral wool between the rafters and cover it with waterproofing from above;

- at a frequent step - to lay a heater under rafters;

- in the presence of an attic, the floor covered with expanded clay.

If the roof is flat, then outside you can cover with insulating paint or insulate the ceiling from the inside.

The method of insulation is chosen based on the area and location of the garage, as well as the financial capabilities of the owner.

When calculating the estimate, all costs should be increased by 10%, so that there is a stock of materials for an emergency.

On how to insulate the garage, see below.