How to insulate the garage?

The garage is a home for a car in which the optimum temperature must be maintained throughout the year. It is necessary that the car is always in good condition and that the owner of the garage building was comfortable working in this room. It is for the observance of these conditions that such a procedure is carried out as warming the garage. Many car owners decide to insulate their garage on their own.

But before starting the implementation of this process, it is necessary to become familiar with all the nuances of the procedure, types of materials for insulation and a detailed algorithm of actions.

Special features

Insulation is the finishing of the walls of various parts of a garage building or a gate using a layer of material that retains heat inside the building during the winter and prevents excessive heating of the garage in the summer. This technology allows you to maintain a stable temperature range, which will positively affect the operation of the car or other devices,which you store in this room.

It is necessary to warm the garage room, because if this is not done, condensation may form on the surface of the car - an excess of moisture that is released as a result of the contact of the heated surface of the car with cold air. If this phenomenon occurs regularly, the risk of corrosion on the car body increases, which can significantly reduce its service life.

In the summer, an unheated garage heats up strongly, which also contributes to the disruption of the functions of the car, because the car should not be stored at too high a temperature. Even an indicator of +20 degrees is unfavorable.

To efficiently and cheaply insulate a garage building with your own hands, you need to take into account a number of features of your building. These include:

- The material from which made the garage. Each raw material has different resistance to heating, cooling, has different heat capacity and characteristics. Therefore, some buildings require a more dense layer of insulation, and in the case of others it is enough to do with small layers. In addition, garages of some materials, for example, brick buildings, as a rule, have a standard small thickness of walls.Gates are often made of corrugated board, which is even less resistant to temperature effects.

- Features specific area of the garage, the temperature in which you want to stabilize. In different zones, not only the thermometer indicators, but also the humidity of the air may differ.

- Be sure to separate the concept of warming and ventilation. One process should not violate another. In this case, pay attention to the layout of the building, especially if the garage has a non-standard size.

- Garage space can be insulated with your own hands only from the inside or outside. But the ideal is a double-sided version of the insulation.

- An important factor is the heating of the room. For heated garages insulation is carried out by a special technology. It may also require a different type of material.

- The area of the garage structure also determines the heat loss factor. The larger the size of the garage, the more carefully it must be insulated.

Material selection: varieties

To independently equip the garage room insulation systems, you can use a huge amount of different materials.Each of them has unique features that should be considered in the process of insulation.

Minwat

Mineral wool is a special material that allows the room to "breathe" in the presence of a heat-insulating layer in it. It is presented in the form of mats of various thickness, which consist of special fibers that retain heat. The texture of the coating depends on the place of warming, since soft materials are used for the internal decoration and more rigid for the external one. This insulation has a number of positive qualities:

- universality of use (the material is used for insulation of various surfaces, including walls, floors, gates, various partitions);

- low thermal conductivity;

- democratic price.

Among the minuses of insulation can be noted the impossibility of its operation in conditions of high humidity. Under the influence of water, the structure and thermal insulation properties of mats deteriorate. To prevent mineral wool from losing its qualities, it needs to be protected with a special vapor barrier that will prevent moisture. The basalt variety of material is considered the most versatile and high quality.She has the best thermal conductivity. Also such mats are capable of absorbing sounds.

A variety of mineral wool is a material such as glass wool, which has differences in texture and stiffness. Compared with mineral wool, glass wool is much tougher, its fibers have a caustic texture, therefore, when working with similar mats, you should wear gloves. This insulation is quite cheap, because it absolutely does not tolerate moisture.

If water gets into the glass wool during the insulation process, it will already be unsuitable for further operation. To prevent such an incident, the mats should be carefully insulated with foiled material.

Styrofoam

Insulation foam is in great demand for thermal insulation of garage rooms. This material has many positive characteristics:

- Plates of foam is very easy to install. They are perfectly amenable to cutting with a hacksaw or even an ordinary construction knife (if the thickness of the material is small).

- Polyfoam does not give in to rotting processes.

- The material is resistant to moisture.

To the number of negative qualities include the flammability of the material. Therefore, you need to choose such types of foam that can fade independently. It is usually necessary to extinguish the source of the flame, and the foam products will die out after 4 seconds. Also, a similar insulation does not allow air. Polyfoam is not suitable for warming such surfaces, on which the sun's rays often fall, because under the influence of ultraviolet material is prone to crushing and acquiring a yellow tint.

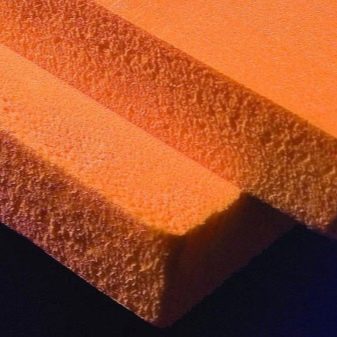

Penoplex

In place of the traditional foam come modified materials. These include such insulation as penoplex. It is made on the basis of extruded polystyrene foam and is used for insulation of garage buildings. Positive material properties are:

- high thermal conductivity;

- uniform small cells give strength to the penoplex;

- material is very easy to install;

- using foam plaster it is possible to warm the garage outside, because the material has low moisture conductivity;

- raw materials do not emit toxic substances in the combustion process.

The disadvantage of penoplex is its volatility to fires.

Polyurethane foam

Polyurethane foam is a material for insulation, which has a very plastic structure and includes air bubbles. It is often used for garage buildings, because it has a number of special characteristics:

- material is difficult to burn;

- resistant to aggressive chemical solutions;

- such material is able to serve for a long time as a heat-insulating layer;

- does not emit any harmful substances and gases, which makes it safe for human health and environmentally friendly;

- similar material is not afraid of moisture;

- It is important that the polyurethane foam does not form a fungus and mold;

- A special property is the resistance of the material to the effects of small rodents, because sometimes mice appear in garages, but polyurethane is usually not exposed to their teeth;

- service life of polyurethane foam reaches 50 years.

Among the negative characteristics of polyurethane foam can be identified:

- Instability to UV light. To protect the material from the harmful effects of sunlight,it will be necessary to cover its surface with special protective paint.

- The price of such material is usually high. But given the life and area of your garage, it is reasonable to choose this raw material as a heater.

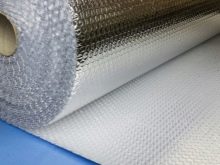

Reflective insulation

The combination in insulation foam polyurethane foam and polished foil forms a new type of material for thermal insulation - reflective thermal insulation. The thickness of this insulation does not exceed 5 mm, so it is sold in rolls. Its main advantages include:

- the ability to carry out internal insulation of the garage without significant loss of space;

- material meets high standards of hygiene;

- reflective insulation is difficult to ignite;

- The material has a low weight, which is very convenient during transportation and installation of their own hands.

The disadvantage of this type of insulation is not complete, but only partial elimination of heat loss, since polyurethane foam with foil is not able to cope with all types of heat loss.

"Warm" plaster

This material is a special combination of fillers, which include expanded polystyrene, sawdust, exfoliated vermiculite. Such material has the following advantages:

- there is no need to level before installation of the warming layer;

- plaster is combined with the bases from practically any materials thanks to the high level of adhesion;

- using the plastic structure of the material, it can be easily applied even to hard-to-reach areas of the garage;

- for such raw materials are not afraid of the effects of mold, fungus, as well as small rodents;

- the material is able to absorb heat and evenly distribute it;

- products of this type are environmentally friendly;

- such plaster is not subject to burning.

Among the minuses of warm plaster can be identified:

- it is necessary to apply a thick layer of such material on the walls, which contributes to the loss of space;

- because of its thickness and structure, warm plaster tends to absorb moisture;

- also a thick layer will dry longer on the surface;

- The material is rather expensive because it appeared on the construction market not very long ago and is an innovation of insulation compared to other methods.

Heat insulation paint

Many people appreciate not only the quality of insulation, but also the attractive appearance of the material.Such users will suit a special paint, which is based on acrylic polymers, organic pigments and synthetic rubber. This coating is similar to ordinary paint, but it has insulating properties. It has a pasty consistency, the standard color of the composition is white, but you can add any color to it. The main advantages of such a coating are:

- the ability to apply the material on the basis of a thin layer that does not exceed 0, 4 cm;

- the material is useful for insulating such hard-to-reach areas where it is not possible to strengthen the rolled insulation;

- paint can be applied using a spray gun, this method allows you to evenly cover the surface;

- although the service life depends on the thickness of the layer to which the material is applied, the heat-insulating paint will perform its functions for a long period of time - up to 40 years;

- The composition is presented in different variations. It helps to choose a type of paint for a certain temperature, in general, the temperature range ranges from -70 to +260 degrees;

- such material is resistant to UV rays;

- The composition applied to the surface is resistant to mechanical loads.

Among the minuses of the material can be identified only its fire hazard. A special kind of materials for warming the garage is izolon. It is made on the basis of polyethylene foam and is a structure with small closed cells. This structure is made in the form of canvases of various thickness. One of the sides of some models is foil. The advantages of isolon include its resistance to moisture and sunlight.

Interior finish

Inside, a heat-insulating layer provides various surfaces of the garage construction: horizontal and vertical, smooth and embossed, dimensional and small, static and mobile.

But when finishing each of them, it is important to take into account a number of special nuances that are not characteristic of other types of surfaces. This will help to quickly and efficiently insulate the garage.

Walls

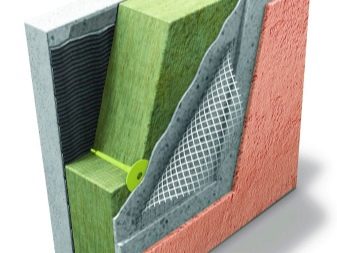

If you decide to protect the garage building from freezing, warming the walls from the inside, then The process of such finishing is as follows:

- Clean the surface of the walls from dirt and grease stains.

- Using drywall, make a partition.It forms the frame for the insulating material. To create partitions use special guides UD, which are attached with dowels to the floor and ceiling. Then every 30 cm in the wall are installed CD profiles.

- In addition to sheets of drywall, asbestos fiber can also be used, a great advantage of which is resistance to fire.

But if you choose asbestos fiber, install frame profiles with more frequent steps, since the fiber is a rather fragile material.

- When the frame is made, you need to add a layer of insulation to the gaps between the partitions. It is most convenient to lay such material as glass wool, which is attached to the surface with the help of special hooks.

- After a layer of glass wool to create a vapor barrier layer. To do this, take a special membrane and is applied close to the insulation.

- From the outside you need to plaster the garage "box" with warm plaster. It will protect the walls from freezing and excessive moisture. Instead of plaster, you can take the paint heat insulator.

- It is necessary to arrange ventilation in the garage, which will be designed for intensive air exchange.

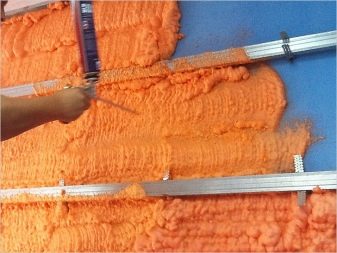

If the surface of the walls is made of iron, then the most optimal is their insulation with polyurethane foam. Also suitable paint insulation with a liquid texture. With the help of special foam generators, liquid foam is produced. It changes its state of aggregation when it is applied to the wall, becoming a hard crust.

You can also warm the iron garage with foam. This material is attached to the walls with glue. The process is carried out in several stages:

- the iron surface is cleaned and degreased;

- sheets of foam cut to the required size;

- insulation is attached to the surface of the walls with glue;

- slots are sealed with foam;

- If desired, a similar insulation layer can be painted.

Floor

To insulate the floor in a garage-type room, it is necessary to make a screed using materials such as sand, crushed stone, expanded clay for additional thermal insulation. To insulate this surface, it is necessary to follow a certain algorithm of actions:

- Arrangement of pillows made of rubble and sand. The crushed stone layer is 10 centimeters thick. Then a layer of sand is applied, its thickness can vary from 5 to 10 cm. Layers need to be poured over with water and tamped using a vibrating plate.

- Waterproofing on the floor is created using roofing felt or polyethylene, which is evenly laid on the base. It is important that the ends of the polyethylene sheet go on the walls to a height of 10 to 15 cm.

- A ten-centimeter layer of expanded clay is poured onto the film and rammed.

- Overlapped put a vapor barrier polyethylene layer.

- On a stand made of wood or brick reinforced mesh. The size of the cells should be 10x10 cm.

- Next, the lighthouses are installed and fixed using a cement-sand mortar.

- At the final stage, the cement-sand mortar mixes, which includes 1 part of water and cement and 4 parts of sand.

- The composition with shovels is superimposed on the floor and subsequently leveled using the rule and processed with a vibrating plate.

- To keep moisture in the screed, it is covered with a film. The surface will be ready for operation after 28 days.

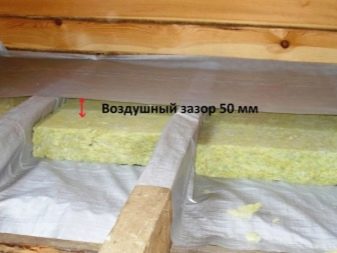

Roof

The main number of garages is equipped with a single-pitch roof, which must be insulated, because it is she who is most affected by various precipitations. But when we warm this floor, it is important to consider the material from which it is made. To the wooden structure with nails and dowels, foam is usually attached.

If the coating is made of concrete, then it is necessary to attach a special frame, made with screws and corners. The foam is fixed to the frame, adhesive tape is used, and the insulating plates are pressed tightly against the ceiling.

If the insulation contains fibers in its base, then a waterproofing layer should be put on the roof side, and a vapor barrier on the ceiling side. To prolong the life of the insulation, the surface is treated with special antiseptic paints.

Ceiling

Also, the roof is insulated with expanded polystyrene on the side of the ceiling. The process of insulation itself is as follows:

- the surface of the ceiling must be thoroughly cleaned and degreased;

- the ceiling is primed;

- slabs must be glued to the ceiling and leveled by the rule;

- it is necessary to carry out additional fastening with dowels;

- for additional connection between the plates, it is necessary to fasten the stirrup;

- then a plastering layer is applied;

- based on personal wishes, you can make it an additional coloring.

Another suitable material for insulating the ceiling is penofol.It is quite simple to create thermal insulation with penofol because of the light weight of the material and its small thickness.

Door gates

Garage doors are often a sliding metal structure, which is embedded in a small door. Through the gate passes the greatest amount of heat, so they should insulate without fail. To do this, you can use ordinary plastic or fabric with high density. The process is as follows:

- The film of dense polyethylene is cut into strips, the length of which does not reach the floor of the garage by 1 cm. The width of the segments should be from 20 to 30 cm.

- To fasten the strips, you must install a rail of wood.

- Polyethylene strips are mounted with an overlap of 1.5-2 cm. This ensures the absence of cracks through which cold air penetrates.

The most suitable material for insulation of garage doors is foam plastic. They fill the pre-crate installed in advance. Adhesive tape and rubber seals eliminate gaps that can pass through drafts.

In places where the insulation will come into contact with the surface of the base, corrosion is often formed, so it is necessary to apply a special anti-corrosion composition to the surface of the webs beforehand.The final step is to mount the waterproofing frame made of plasterboard, which is pre-grounded.

Exterior design

Many people prefer to insulate garage structures exclusively from the outside. Such users believe that internal insulation significantly hides the space of the room. Also, the hallmark of interior decoration is the release of caustic substances and gases from some heaters.

If you decide to insulate the garage outside, you can additionally design the building with an interesting finish, which not only decorates the appearance of the building, but also helps to withstand environmental factors affecting the condition of the insulation layer.

The most popular design of the garage design with the help of heat-insulating paint of the desired shade. She covered the gate. But if the garage is large and in addition to the gate there are also open areas of the wall that can be trimmed with other materials. The most popular, practical and interesting option is siding.

Basement

Many garages have a basement, which often serves as a cellar.This area of the room should be properly warmed, because it has a special microclimate. One of the popular materials for basement insulation is polystyrene. At the preparatory stage of work it is necessary to thoroughly clean the basement from dust and dirt.

The surface of the walls in the cellar must be leveled with a putty and a ground solution, which will also protect against the possible occurrence of fungus. Using a spray bottle, it is important to moisten the surface of the insulation and the base. Between the wall and insulation, you must create a special ventilation layer.

Next, you need to make a special frame for the plates. Polystyrene itself can be attached in different ways:

- Using an adhesive solution. It is stirred in a special container and applied to the walls in a dotted manner - by the formation of stains at a distance of 0.2 m. With the help of a trowel, another layer of glue is applied. The sheet must be attached to the surface of the wall to tap with a palm.

- Fungal method involves the use of dowels. It is also necessary to use dish-shaped plastic screws. Through holes are made in polystyrene and wall with a drill.It is necessary to leave indents in the corners with length from 100 to 150 mm. The length of the screws should be chosen with the addition to the thickness of the plates of polystyrene another 40-50 mm. The gap between the plates must be sealed after 5 days with the use of foam.

At the last stage, the room is finished, for which plaster or acrylic compositions are used.

Tips and tricks

Do not completely cover all openings for ventilation. This can significantly complicate the further operation of the garage and even harm your health. Due to the absence of even minimal ventilation, harmful gaseous substances will accumulate in the garage building.

- By warming the floor, you can create a slope so that the water flows better.

- When you create a curtain of plastic bands, you should not make them too narrow, because they will cling to the car.

- Consider how harmful insulation is. Some materials are toxic, so they are recommended to be used outside and not indoors.

- To insulate the concrete roof outside, it is best to use extruded polystyrene.

- When insulating the door and garage door, do not forget to cut the material with regard to the holes for the lock.

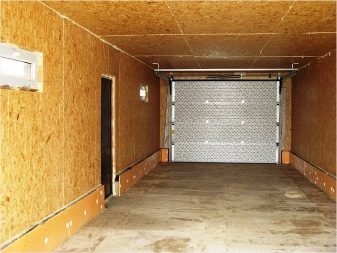

- Instead of drywall, you can use the OSB panels of small thickness.

- If in the process of foam insulation you need to take breaks for a day, then it is better to use a construction gun, with which you can resume working with the train after some time.

- To create additional insulation along the contour of the doorway, you can use roller shutters.

- When insulating with mineral wool, remember that the minimum thickness of the insulating layer should be 100 millimeters.

Taking into account all the recommendations and advice, you can easily insulate the garage building yourself and create in it a convenient microclimate both for the car and for your own stay.

For information on how to warm the garage, see the following video.