The details of making greenhouses from window frames

Each of us sometimes wants to feel the taste of personally grown vegetables and fruits, but to fully enjoy the taste palette of crops from your garden, you need to make a lot of effort. Many vegetables and fruits, in particular this applies to such fastidious and delicate vegetable crops as tomatoes and peppers, need special greenhouses that will save them from rain, fog, and other adverse phenomena of the external environment. One of the ways to build a high-quality and durable greenhouse is to use old double-glazed windows, and today we will look at all the details of making such a design.

Special features

Surely many of us after the repair of apartments, private houses or structures left a lot of old wooden or plastic windows.Most people simply store these valuable materials in their warehouses or basements, not even knowing that this is a great option for building a warm and moisture-proof greenhouse.

What are the advantages of such buildings is very simple to understand.

- Saving both your money and time: you do not spend money on purchases of seasonal films and carcasses, where the latter in the finished version are very expensive in any season. Such a construction is erected in just a couple of hours (if there is a good foundation, of course), the double-glazed windows are perfectly fastened to each other and stand steadily on almost any kind of soil (while the greenhouse from double-glazed windows is unlimited by any standards in construction, you can build with your own hands any size and height).

- Use for vegetable crops. As you know, glass is great for illuminated areas, as it has great transparency. For crops such as tomatoes, bright sun is one of the main factors for fast and healthy ripening. It should be said about the ease of airing such greenhouses - the correct placement of glass and windows will allow you to open and close them at your discretion in order to save crops from moisture, fog or, conversely, from the heat.

- Strength.Regardless of which material the glass package consists of (whether wood or plastic), a greenhouse made of window frames has unique abilities of resistance to wind and moisture.

- Durability. If you are used to the placement of seasonal films in greenhouses, then you probably faced the problem of loss of film strength. Whether it is reinforced or just plastic film, over time, its structure collapses - holes and yellowing appear in places of attachment or embankment. As a result, the film greenhouse will last no more than 2-3 years on one film, while the greenhouse from window frames, due to the high strength of glass and wood / plastic in the frame, can safely stand in your garden for up to 7 or even 10 years.

The choice of materials: the pros and cons

Each of the materials is distinguished by its individual physical properties, which makes them more or less suitable for certain weather conditions. The most commonly used frame is wood and plastic.

Wood

In contrast to the metal frame, the tree has a lower cost, has sufficient insulation from heat / cold / excess moisture.Wooden frames are very simply fastened to each other, so you can build a greenhouse of any size and shape from them. Such structures have one major drawback: the need for constant care. First of all, it concerns old wooden window frames, because everyone knows that even the highest quality wood is quickly destroyed from moisture, losing its structure, thereby creating many cracks. In this case, you should take care of your greenhouse: constantly inspect for damage, tint or change the destroyed places. If you want to give the construction a longer life, you can pre-treat all the wooden parts of the greenhouse with a special moisture-resistant spray or antiseptics (and this will have to be done regularly).

Plastic

Plastic windows often have double or even triple glazing, which means even better protection and insulation from the external environment. Plastic has great strength and resistance to the negative effects of the external environment - such material is not afraid of either moisture or excessive cold / heat and usually serves much longer than wood, not to mention the fact that no treatment is needed.

From the advantages described above, logical and cons come out:

- plastic structures are much heavier than wood;

- plastic is more difficult to replace or repair - with a broken glass pane in only one place you will have to change the glass part completely.

A common disadvantage for this and other materials in balcony frames will always remain the low strength of the glass itself in the structure. It has excellent passive resistance to an aggressive external environment, but with respect to human mechanical damage it is often helpless. Therefore, one should not walk in such greenhouses with long hoes / rakes or other hard objects that, if not used carefully, can safely leave a large hole in the frame. Judging by the reviews, the biggest problem in the operation of all types of frames in glass greenhouses is the insufficient strength of the glass.

But do not forget that it is possible to use wooden window or plastic frames only as a frame for the whole structure without glass. In this case, the most commonly used film or polycarbonate (another type of plastic is stronger and more durable than film or glass,however, it is more expensive).

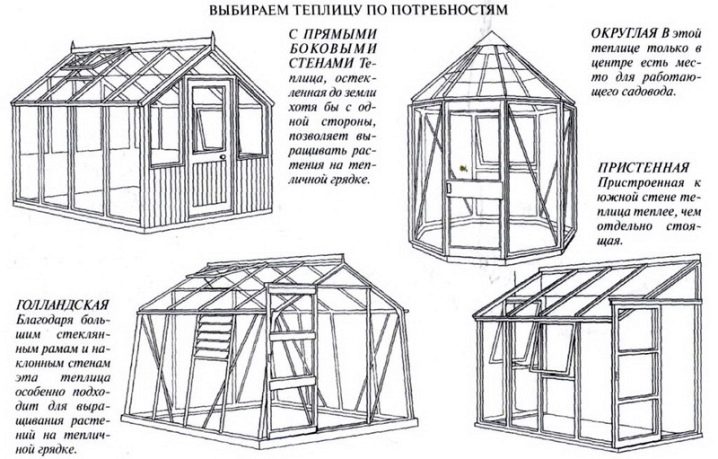

Types of designs

There are quite a few types of greenhouse designs of window frames.

This is explained by the fact that the owner is limited to only two factors when choosing the size and type of design:

- free space for the installation of the greenhouse;

- limitations associated with the number of materials at the disposal of the master.

Based on these parameters, further drawings and forms of the greenhouse are formed; therefore, there is no separate and generally recognized list of typical values for such greenhouses. However, some examples are somehow common in our gardens.

The most common option is a greenhouse without a foundation from a wooden double-glazed window or from a wooden frame with a stretched transparent greenhouse film. This construction is a small greenhouse or greenhouse with household parameters of height up to 2 meters, width not more than 2.5 meters and length up to 6 meters. The most "budget" version of this design looks like a regular glazed box made of wooden frame without a roof.

Greenhouses with wooden or plastic frames are slightly less common, but on a foundation basis. They provide greater reliability and stability of the entire structure.If you have a wooden frame, the foundation can take on some of the negative impacts of the soil, which also increases the lifetime of the entire building.

Another quite common type of greenhouse from window frames can be considered a greenhouse on a concrete strip or wooden foundation with a triangular roof and a roof with a film instead of a double-glazed window (for a smaller load on the supporting elements). This type is much more difficult to meet, since you will spend much more time on its installation and maintenance than on the others. However, the result is expected - well-designed greenhouses of such a plan (regardless of what you will use: PVC / wood / film or glass construction) will serve you for about 10 years or more.

Do not forget about the greenhouses with a metal profile in the frame and window frames at the base. This is one of the most sustainable and durable greenhouse options.

However, there are major drawbacks:

- corrosion of the metal in the frame;

- large weight of the whole structure;

- the cost of high-quality metal is very few people happy.

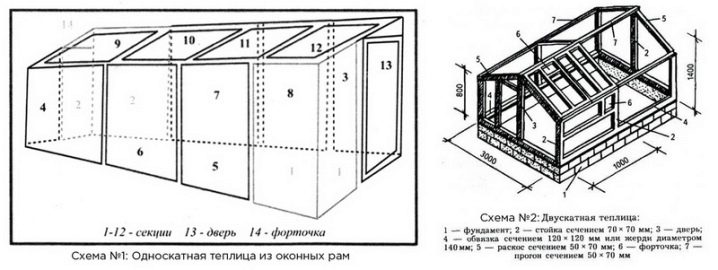

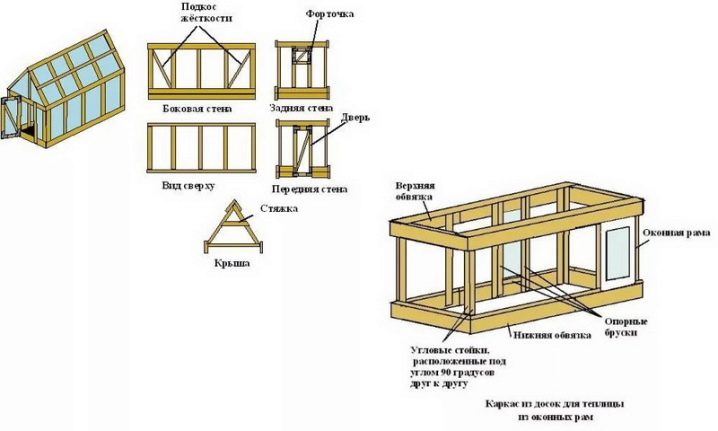

Dimensions and drawings

As already mentioned, there is no clear size of the greenhouse from the window frames, it all depends on the desire of the developer and the volume of crops that I would like to care for.In this article, only proposed generic typical sizes of such greenhouses. The image below shows the optimal dimensions for a greenhouse with a roof and a laid foundation. Immediately it should be said that the installation of any economic structure requires the development of an individual drawing, which would reflect not only the basic values of the building, but also the stages of work on the foundation, frame and the whole structure as a whole. The drawing will help to properly allocate resources and materials and, with proper assessment and marking of the future structure, will ensure the entire greenhouse with integrity and durability.

Of course, we should not forget about the external environmental factors, which are:

- soil type;

- average monthly rainfall;

- ground water level;

- soil heaving;

- lighting the area with the sun;

- plot location in relation to air flow.

All these factors somehow affect not only the harvest, but also the integrity of the greenhouse structure. Mandatory parameters that should be depicted even in the simplest drawing are the length, height and width of the greenhouse, the dimensions of the reinforcing elements, the size of windows and doors, the depth of laying the foundation and the angle of the roof (if any).In any case, no one keeps you in the strict framework of individual drawings, you can change them, adjusting to your capabilities and capabilities of the site. Just do not forget about the reasonable ratio of all parts, so that in the end you do not get "abracadabra" with a lot of useless windows and with narrow aisles.

If we talk about typical sizes for greenhouses, the height of the whole structure should be at least 1.5-2 meters. If we are talking about an additional roof, then here you should be guided with the height as it is convenient for you, since some crops, for example, peas, some tomatoes and green beans require a lot of free space. Not to mention the fact that low greenhouses up to one and a half meters are far from always convenient to operate, both because of the high growth of the owner himself and because of the inability to use agrotechnical tools in the greenhouse.

The widths of the entire greenhouse are also very vague, it all depends on the type of crops and on the internal layout of the greenhouse. However, the most common variant of the greenhouse as in the image above - up to 2.5-3 meters. In this embodiment, the widest aisles for the owner and enough space on both sides of the aisles for planting greenhouse crops.The length of the greenhouse is always an individual value for each owner, because everything depends on the materials that are available to the master. It is believed that the best option for the greenhouse will be the parameters from 8 to 10 meters. But you can often notice the greenhouses in the style of "mini" - up to 5-6 meters in length.

Erection: step by step instructions

The first step in the installation of a full-fledged greenhouse of window frames is the installation of a strong and sustainable foundation. It not only strengthens the entire structure, but also allows the frame of a heavy greenhouse not to settle under its own weight (which is very "kindly" will contribute to both heavy rains and groundwater levels). The first stage is the preparation of the site for laying the foundation (the most common type of foundation in this case is the tape one).

At this stage, the following actions are carried out:

- the future plot of the building is leveled, weeds are pulled out, irregularities are smoothed out, garbage is removed, and the soil is fertilized if desired;

- marking of the site is carried out in accordance with the drawing for further convenience of placing the foundation and frame;

- in each corner of the future greenhouse, holes should be dug at least half a meter deep (the ideal depth should exceed the level of soil freezing,what is done for the further installation of piles or foundations);

- the bottom of the pits is filled with rubble or sand and compacted;

- further, formwork should be made for fixing the piles and filling the trenches with cement mixture;

- on the supporting structures or piles are laid United bars and attached to the base anchor fastening.

There are several types of materials suitable for the installation of the foundation.

- The first and most budgetary option is wood (or wooden bars at the base). The whole problem with this material is the poor moisture resistance of the wood. Over time, such structures quickly collapse and lose stability.

- The second option is the foundation of its foundation with the help of bricks. Brick elements are very durable, durable and can withstand with proper laying a significant load even from a metal frame. The problem of such material only in its high cost - to find a sufficient amount of cheap and high-quality brick for the foundation is not so simple.

- The third and best option is to install the tape foundation using concrete bars (sometimes even with the use of reinforced concrete structures).They are also wear-resistant, like brick ones, and with high-quality waterproofing they are slightly susceptible to moisture and are just as durable. The biggest disadvantage in this case is that for a couple of hours such a foundation cannot be laid.

Installing a homemade greenhouse on the foundation has its minus - after planting a certain crop on the same piece of land, over time it can lose useful properties and nutrients. This can be dealt with only by regularly fertilizing the soil with natural or synthetic elements.

The second stage is the preparation of materials for construction. This is the simplest step, including the actual estimate of the amount of materials needed for construction, and their processing for convenient installation. First of all, it concerns wooden window frames, from which the paint is cleaned, roughness is removed, handles and hinges - at the stage of connection with other elements all this will only interfere. At the same stage, if desired, everything is treated with antiseptics and sprays. Initially, outline which windows will be used for ventilation, and either dismantle the rest or seal them.

The third stage - the formation of the floor inside the greenhouse. If desired, laying the floor or convenient paths (which will also give the entire structure additional stability) should be dug not less than 10-15 centimeters deep. The base is compacted, freed from stones and covered with gravel or rubble up to 10 cm thick. Further, for waterproofing, tamped gravel may be covered with roofing boards or plastic plates. A little later, everything is filled with sand and again compacted or poured cement mixture. If bricks are used instead of cement mortar, possible gaps between them should be filled with the same building sand.

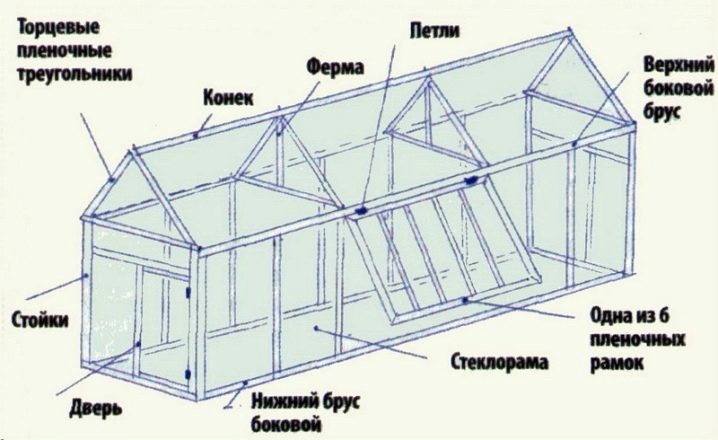

The fourth stage is to build a durable and reliable frame (consider the example of a wooden frame). A timber is laid out and strengthened on a concrete foundation, which is sheathed with boards for greater stability, while the latter should protrude over a bar for at least 10 centimeters. Corners are beams, fastened to the lower bar with screws with steel corners. The cross-section of the racks of the bar should be 50/50 mm. Top strapping is done in the same way with mounting on poles.Note, if the greenhouse is long (more than 4-5 meters long), you should think about additional supports, in addition to the corner ones.

Next, the frame is filled with window frames and here also has its own sequence of actions.

The installation of frames always starts with a corner, this allows you to more accurately estimate the approximate distance to the support or the next frame. Fixing windows to the frame is carried out by installing metal plates or corners with self-tapping screws. The installation of subsequent frames is the same way, while ensuring that the interframe gaps are minimal. At the end of the work, you still have to inspect the entire structure for cracks and fill the last with foam.

At the same stage it is worth thinking about the need to install the roof and the roof of the greenhouse. It is advisable to install the latter only with sufficient strength and stability of the entire greenhouse. On top of the roof can be covered with a special film with light stabilization for additional protection of vegetable crops.

The fifth and final stage is the inspection of the structure for the integrity of the entire installation. Carefully inspect the greenhouse, check the ventilation system, make sure that the structure is stable and durable - there are no cracks, holes or holes in it.At this stage, the owner is fully entitled to fantasize - to provide his greenhouse with beautiful paths, platforms for agricultural tools, insulating elements or lamps, air vents and windows for ventilation.

Beautiful examples of finished buildings

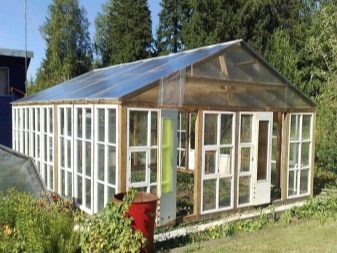

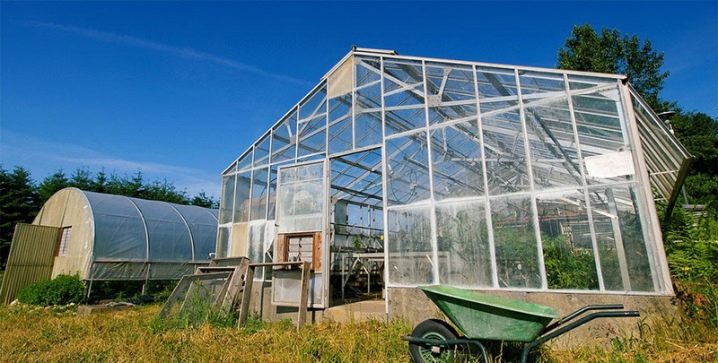

We present to your attention successful greenhouse projects from window frames. Standard greenhouse without a solid foundation and roof. A more modernized version with a foundation basis and a fairly solid roof. The optimal variant of the greenhouse with a solid foundation base and a reliable roof.

How to build a greenhouse of window frames, see the following video.