How to choose the optimal size of the greenhouse?

Cultivation of crops in Russia has always been accompanied by a certain degree of risk. The culprit is a cool climate in most regions of the country. Greenhouses make it possible to grow organic crops throughout the year.

In a constructive respect, it is not difficult to make it, but it is important to find an acceptable option that would meet all expectations.

What affects the size?

In order to build a similar object, it is necessary to draw a drawing taking into account the size of the area where it will be located.

The start of work starts with the collection of information and familiarity with the standard drawings. It is very important what material the object will be made of. In recent years, greenhouses and hotbeds have been sheathed with polycarbonate, insulated with PVC plates, which has its own rational grain.

The size of the greenhouse can be very different, but most often there are structures with parameters of 3x6 meters.These are compact greenhouses that are suitable for private households. Also popular are greenhouses with a length of 8 meters.

Most popular formats:

- 3x4;

- 4x6;

- 6x3.

The long-term mini-greenhouse "Snail", which is indispensable for growing seedlings, is in great demand. This design can be easily moved around the site, which is extremely popular when the seedlings are grown in different beds. The length of this design is only 2.1 meters, width - 1.1 meters. The maximum height reaches 86 cm. In addition to seedlings, it is good to grow small plants in it. The hotbed is mounted for half an hour.

Bearing structures are pipes that can be easily assembled. The main coating is polycarbonate sheets.

For the foundation of the mini-greenhouse "Snail" is often used conventional logs or bricks.

The advantages of this kind of design:

- ease of assembly;

- mobility;

- small price;

- unpretentious in operation.

With proper operation of this greenhouse can be used in the winter. Also popular are greenhouses, which are called "Lemon". Their size is 6x3 meters, they are very similar in construction to the "Snail".

The greenhouse "breadbasket" is quite often found in home gardens.It is ideal for growing seedlings, as its sash can be opened if the temperature of the environment allows.

The greenhouse arched has a gable roof. It is she who is most often found in Russia, so it can be called classic. Often, such structures are format 50 to 10 meters.

Also quite often there are greenhouses of Mittleider, in which the air-exchange system is well thought out. Single-pitch greenhouses are installed on personal plots, especially in those places where they are adjacent to the house or fence. The constructions of such structures are simple and effective.

If such an object is attached next to the house, then the costs for warming and carrying out thermal communications are noticeably reduced. In addition, the homeownership itself can be a reliable protection from northern winds.

Tent greenhouses are a kind of the same “breadbasket”, only of large size. The construction of a hemisphere is a rather laborious task, but in this case such a structure has an increased margin of safety, which allows it to withstand a considerable load of both snow and wind.

The issue of lighting is also solved in a positive way, because the coefficient of illumination in the domed greenhouse is the most significant. The aesthetically attractive appearance is also important - such greenhouses can be an original decoration of any land tenure, often reaching 100 square meters. meters

Purpose

All greenhouses have a transparent roof, which allows them to grow plants all year round. They can also be frame and without frame.

The first type is more durable and durable, so it can be found quite often.

Also greenhouses can be:

- vegetable;

- seedlings;

- floral.

Film greenhouses are often used for growing seedlings, which are then planted in open ground. In the latter, you can guarantee the strengthening of seedlings (it is also called hardening).

Hardening happens:

- air;

- temperature;

- light.

Greenhouses are differentiated by the material from which they are made. For a long time used greenhouses made of glass, which was successfully replaced by polycarbonate.

Forms

The shape of the greenhouse depends largely on the type of plants that they grow.

They can be:

- cylindrical (for example, greenhouse "pepperbox");

- semicircular;

- elongated rectangular with a gable (or shed) roof.

The classic type of greenhouse (except for the dome type) has such a dislocation: various agricultural crops grow along the edges, and a walkway is in the center. This form has developed as a result of long-term operation of such facilities.

The width of the structure is composed of the following parameters:

- track width;

- the length of the beds;

- Wall thickness.

As a rule, greenhouses with a width of 6 meters are quite rarely found on home gardens. The height of the structure is no more than two meters, except for the base, which allows you to increase the height of the structure.

Other types of greenhouses may be of very different heights, there are no restrictions here. Greenhouses "breadbaskets" or "snails" are not distinguished by large dimensions, but they provide an opportunity to work with the material directly from the street, without entering the room. The height of such structures are no more than a person's height. Even the paths for passage in the breadbaskets are not provided, which is an additional saving of space. As can be seen, the technical characteristics and design of greenhouses completely depend on what plants grow in them.Industrial greenhouses can be gigantic in size, they grow vegetables and fruits, which are sent to stores every day.

Technical arrangement

Work on the creation of a greenhouse involves the following steps:

- determines the area where the structure will be present;

- the shape of the structure is determined;

- decide what the foundation will be.

During construction, the following criteria are used:

- distribution and intensity of natural light;

- is there any shading from the nearest building (depends on the time of day).

Ideally, natural light is present in the greenhouse at least eight hours a day. Needless to say, the structure should be on a flat stretch. If there is a slope, then the creation of the plane will require additional material costs. The elongated walls are usually located in the direction of the north and south, the ends of the structures are, as a rule, to the east and west. It is important that the greenhouse is not blown by the north wind; otherwise, significantly more funds will be spent on its heating during the cold season. It is also not recommended to make greenhouses on peat bogs, where the temperature is traditionally noticeably lower, which will inevitably affect the growth of plants.

Most often frameworks of greenhouses are made of metal or wood. The tree is cheaper, but it is subject to rotting. There are modern primers that allow you to extend the life of the material several times. At the same time, they are able to effectively protect against the effects of fungus and other pests.

The atmosphere of the greenhouse is saturated with moisture, so the treatment with primer of wooden knots and elements is a very hot topic. Metal also requires protection against corrosion, it must be painted over with a special primer.

In recent years, PVC profiles have been increasingly used. In terms of strength, such knots are in no way inferior to traditional wood or metal. However, one should pay attention to the structures so that they do not bend or deform under the influence of snow. Structures made of PVC materials may not be inferior in strength of steel, but they are quite difficult to assemble. Only a master with great experience can do such work.

If the greenhouse has a greater length, then most often a strip foundation is made. In areas where groundwater is located close to the surface, foundations are often made on piles. For strength and durability, they are not inferior to the strip foundation.The warranty period of the pile is at least 50 years.

If the greenhouse has a length of more than 6 meters, then, as a rule, it makes two doors with a size of 1.6-2 meters and a width of 0.76-0.95 meters. Be sure to in the greenhouse there are vents and windows (located on the south side). Depending on the size of the structure, they are made of certain parameters, harmoniously distributed over the entire length. From what will be the ventilation system, depends largely on the growth dynamics of the plants themselves.

Standard technology implies that the highest point on the ridge of the greenhouse has a certain ratio to the side walls. The height of the ridge is about 2.3 cm, and the side wall is 1.65 meters. Thus, a coefficient of 1.4 is obtained. The standard size of greenhouses that manufacturers make is a multiple of 60 cm.

It is important to understand from the very beginning how much it is planned to place on the rack of pallets with seedlings. Only then it will be possible to finally determine the length of the structure.

An ordinary pallet has dimensions of 28.1 x 53.1 cm, which means that the rack parameter is correlated with these figures. It should also be borne in mind that the smaller the rack, the brighter it will be in the room. This fact is sometimes extremely important.Often make greenhouses of double frames, whose width is 85 cm.

Exact parameters are:

- length - 6.04 meters;

- the thickness of the ends - 10 cm;

- glass ceiling - 7.54 cm.

If everything is folded, it turns out that the length of the greenhouse is about six meters. The bars between the glasses have a thickness of 152 by 52 mm, the glasses are connected to each other closely. This design is very practical, it is only important that the metal fasteners do not connect with the glass, so you should make gaskets of damper rubber.

Manufacturing materials

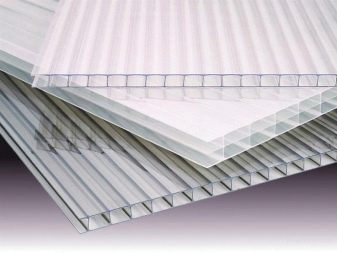

More recently, greenhouses made of glass and PVC film. Both of these materials have their drawbacks. Glass has great fragility, and polyethylene does not withstand long service life. Cellular polycarbonate is increasingly used as the main material for the construction of greenhouses.

The top layer of polycarbonate has a UV film that is able to effectively protect the material from any damage. The middle layer consists of many honeycombs that make the sheets more rigid and at the same time light. The bottom layer makes the sheets more durable and structured. The standard length of this material is 6 meters, and the width is 2.12 meters.

A greenhouse can last at least six years, while the load on the walls is minimal, and the sheets are light in weight. At the same time, the cellular structure allows the material to have excellent thermal conductivity, and the air is one of the best heat insulators.

Tips for choosing

The optimal size of the greenhouse is determined not only by the size of the land plot for home ownership, but also by the crops that it is planned to select and grow. Standard greenhouses are simple: a foundation is mounted on which a transparent case is installed, capable of transmitting sunlight. The most important thing is to make the right choice of material from which the greenhouse will be created.

The most convenient way to use aluminum bearing angles (format 2x2 cm). This material is not susceptible to corrosion and can withstand high loads.

Bearing arcs withstand the main load of the structure, the distance between them should be no more than 74 cm. The correct arcs are solid structures, they have the greatest coefficient of strength.

The arched shape of the greenhouse for the whole family in a private household is the right choice, since it has a smaller load on it in winter time, there is more space inside. Also inside there is an opportunity to put additional racks.

In winter, the surface must withstand loads of at least 100 kilograms per square meter.

How to make a greenhouse with your own hands, see the next video.