Which polycarbonate is better to choose for the greenhouse?

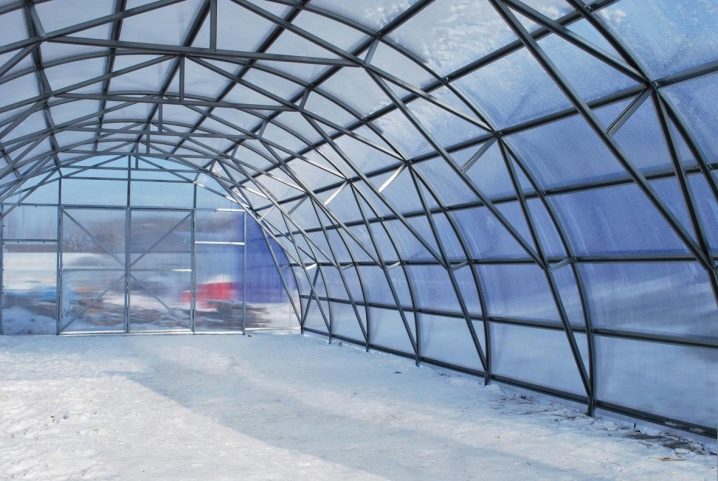

Modern greenhouses and greenhouses can significantly increase the vegetation period of any plant. Similar structures can be found throughout our country - from Sochi to Sakhalin. An important constituent element for such a huge popularity of greenhouses is ease of installation and quality material from which they are made. As a result, these two vectors affect the cost of the object and its service life. If you do everything according to the rules, the greenhouse of polycarbonate can last at least seven years. In recent years, this material is in unprecedented demand.

Features and types

A greenhouse is an object that can reliably protect any crop from cold, rainy and too changeable weather.Crops that are under reliable protection in ideal conditions can be cultivated all year round, taking several harvests in one season. Before you start to operate the structure covered with polycarbonate, it is necessary to carefully calculate and plan everything. The occurrence of miscalculations and errors will lead to material losses, increase the cost of construction, because it will require additional costs to eliminate blemishes.

The first step is recommended to do the following: to find in open access to the Internet design drawings of the most popular greenhouses. The most popular material is polycarbonate, which almost perfectly meets all requirements. He is different brands. There was a whole epoch when in favor there was such a material as glass and PVC film, almost 98% of greenhouses across the country were made of these materials, which have their disadvantages:

- glass is expensive, it is fragile;

- glass is difficult to mount;

- film is not very durable material that will last only one season, it deteriorates very quickly.

The latest generation of cellular polycarbonate in terms of transparency coefficients are not inferior to glass.The weight of the material is three times less, it is cheaper, it is easy to install. The material is excellent in resisting temperature changes, not afraid of moisture.

Polycarbonate has the following structure:

- The outer layer is a solid sheet, it has a special UV film coating. It effectively protects against the destructive effects of ultraviolet radiation.

- Middle layer - the layer structure consists of nano cells that resemble honeycombs. As a heat insulator is better to think of something difficult. The air itself is an excellent heat insulator. The cellular structure gives polycarbonate sheets a significant strength, which makes it possible to use the coating for many years.

- The lower monolithic layer gives additional rigidity to the sheet, provides additional protective functions.

The weight of the greenhouse from polycarbonate is small, so it does not require a solid foundation, such as a band. This fact also significantly reduces the cost of construction of the facility. The warranty period of the "work" of the greenhouse can reach ten years and even more. Polycarbonate has excellent thermal insulation properties, which makes it possible to grow even tropical plants (kiwi, oranges, lemons), even in the Far North.The strength of the sheets allows you to withstand a snow cover with a thickness of a couple of tens of centimeters, which is quite enough for such structures. The polymer is not afraid of high temperatures, inflammation occurs only after heating to 580 degrees, and plastic also has the ability to self-extinguish.

Characteristics and parameters

Dimensions of greenhouses are noticeably different, usually on a plot of 6-8 acres, you can find objects 3.1 x 4.1 meters. Sometimes the length of the greenhouse reaches six and a half meters or more. Maintenance of such an economy requires considerable effort. You can choose the size of the optimal, which ideally corresponds to the specified parameters. Plastic carbonate is a material that is nearly two hundred times stronger than glass. The material is elastic, easily bent along the cell partitions.

From such material it is possible to assemble complex structures:

- arbors;

- arches;

- dome roofs.

For the construction of greenhouses used sheets of material with a thickness of 4 and 6 mm. The second type of sheet is used more often, it has a greater density. Practice has shown: the thinner the sheet, the more it requires supporting structures so that deformation does not occur during operation.That is, to create a roof may require more significant costs, and savings on the thickness of the material can go sideways.

Honeycomb shape

The cell size of polycarbonate is about sixteen millimeters. If the sheets are too thick (such are necessary for building extensions), then there may be not one or two layers. The strength of the sheet depends on the shape of the honeycomb. Orthogonal cells are present in arched objects, such sheets can withstand heavy loads. Such material can be deformed, then again restore the initial configuration. Sheets with X-shaped and diagonal ribs are used to create single-slope and dual-slope roofs in greenhouses. It should also be borne in mind: the smaller the cell, the directly proportional less thermal conductivity of such a material.

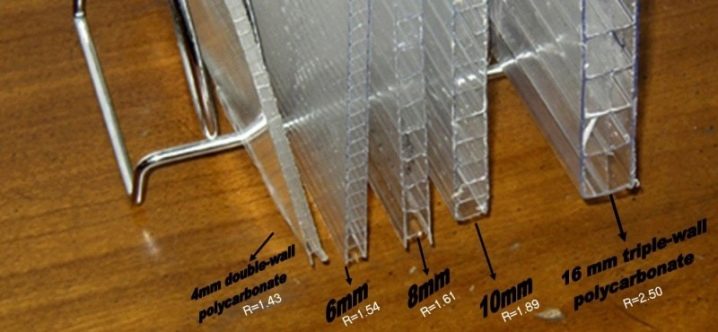

Thickness

When building a greenhouse, it is recommended to take into account the thickness of the sheet, which affects its weight. Some unscrupulous manufacturers go for all sorts of tricks, they make stiffeners in jumpers too thin. You can understand this when the weight of the material becomes known.

Optimum weight of polycarbonate sheet:

- 4 mm thick - 0.81 kg / m2;

- 8 mm - 1.51 kg / m2;

- 10 mm - 1.71 kg / m2;

- 16 mm - 2.701 kg / m2.

Such parameters ideally correspond to the tasks, they can be used in the calculations, their correctness will provide the necessary strength of the roof. If the bulkhead between the cells does not conform to generally accepted standards, then in this case the label should be marked Light. This material is cheaper, but it must be borne in mind that its strength leaves much to be desired. It is more reasonable to buy material with “normal” bridges between the honeycombs, which will increase the coefficient of structural strength.

Sheet size

Polycarbonate has standard parameters, which makes it possible to easily compile and calculate any project. The length of the transparent material is only six meters long and two meters wide. In drawing up the cost estimate, such “reference points” are taken. The sheet is easily cut, that is, if necessary, it can be cut into two pieces of 3 x 2 meters. The format parameters are considered to be 1.5 x 2.1 meters. Cutting the material in width is a laborious job, so usually this operation is not used.

Greenhouses can have a sloping roof shape or a dual slope. The slope of the roof varies depending on the design, most often you can find a roof with a slope of 17 ° to 33 ° or even 47 °. The steeper the roof, the less snow will accumulate on it, which, in turn, prolongs the service life. Shed roofs are usually present on objects that are extensions to the main household.

Also similar structures can be found when they are adjacent to the fence or garage. The fasteners between the sheets most often are the corners of 35 x 35 mm. It is also possible to use corners 40 x 40 mm. Between the beams, the distance does not exceed one meter. The thinner the sheet, the smaller the distance between the supporting rafters. This fact is useful to take into account when calculating the cost of the roof.

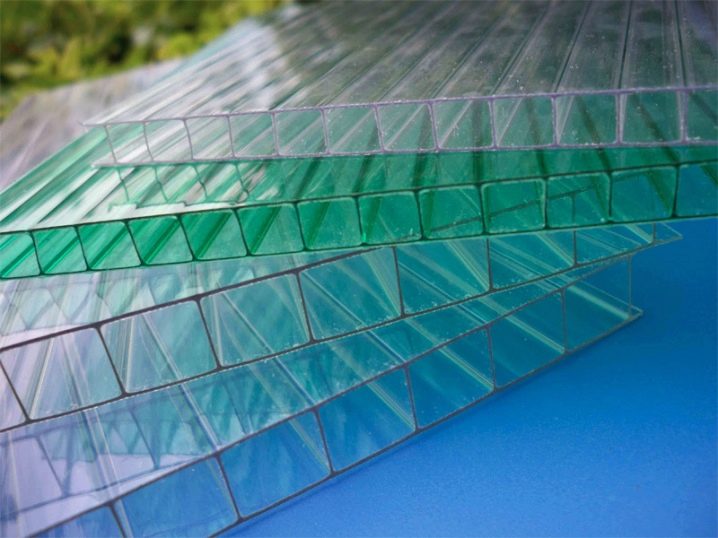

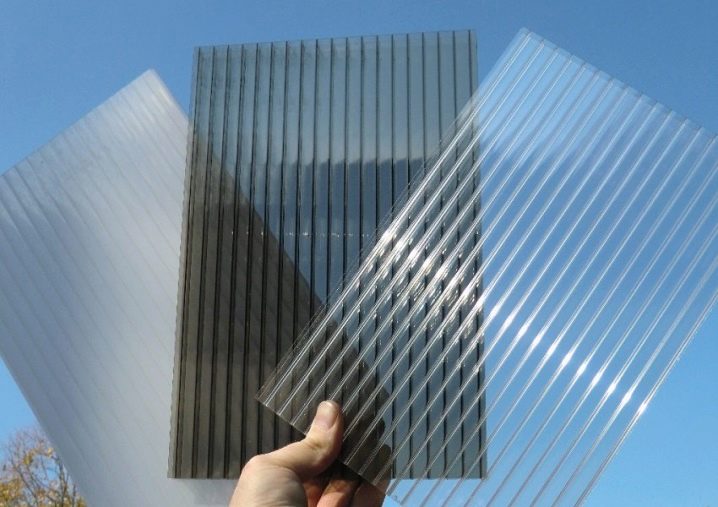

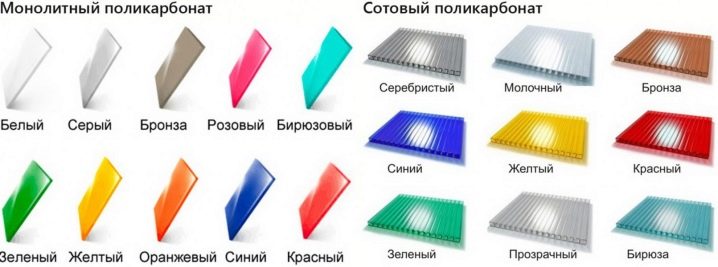

Colour

Thermoplastic sheet can be a variety of colors. Polycarbonate is lighter than glass fourteen times, the transparency of sheets of different colors reaches 50%, for transparent plates this ratio increases to 85%. Sheets can be not only colored, but also with a special texture or tinted. Sometimes this material is necessary and meets the immediate needs, but in the greenhouses most often there are classic transparent sheets of polycarbonate.

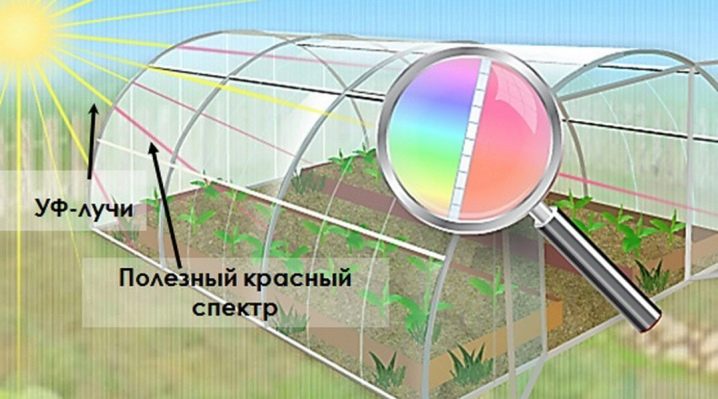

The need for UV protection

Special additives that protect from UV light are added to the raw materials at the production stage. This method is effective because ultraviolet penetrates into the depth of polycarbonate plates. The service life of this material is relatively small, no more than ten years. There is a special film that effectively reflects UV radiation, in this case the life of the material increases by 50-60%. There is another way to protect when two layers of film are present. In this case, the material is completely protected from harmful radiation, its service life must be at least a quarter of a century or even more.

The cost of such sheets is rather big, but in some cases such material pays off many times over. If the greenhouse is built for more than one decade, then it makes sense to seriously think about purchasing sheets with an expensive protective coating. It should also take into account the fact that ultraviolet radiation is useful for the plant, without it photosynthesis is impossible. That is, to spend large sums so that ultraviolet does not penetrate the room by 100% is also not the best idea if we are talking about a greenhouse. It is also important to know that ultraviolet light will not pass through a film with a thickness of 25 to 75 microns.

In recent years, technologies have emerged that can drastically reduce the UV coefficient. Special additives have been developed, they are added to the material during its manufacture. These compounds create a co-extrusion layer (also called a “stabilizer”), it can effectively counteract the excess of ultraviolet radiation. Such a layer can only be detected with an electron microscope. The coextrusion layer significantly increases the cost of production, not every company can afford to take such a step.

Full world coextrusion layers are made only by global industry leaders, such material is expensive, and all the output data can be read on the packaging. Unscrupulous manufacturers often produce polycarbonate, which has only an optical protective layer. In this case, the sheets do not protect properly from UV radiation. There are also optical layers, they can be seen if the polycarbonate sheet is illuminated with an ultraviolet lamp. Russian manufacturers for the most part are limited to the manufacture of only optical layers, this allows you to sell products at low prices.

Recommendations for selection and feedback

Reviews of modern polycarbonate material in most cases are always positive. Many questions arise about UV protection. If you enter into the material the desired concentration of the stabilizer, the price increases dramatically, such material is extremely rare. When sellers claim that UV protection is present in the mass of polycarbonate, then we can say with certainty that it is completely absent there.

Choosing polycarbonate, it is impossible to check what kind of protective layer is in the material, which is why you need high-quality branded goods from a reputable manufacturer. It is better to choose a polycarbonate material, which made the world famous company - it means to protect themselves from counterfeit. Also during the construction of the greenhouse and installation of polycarbonate sheets, many different questions arise.

At installation it is necessary to pay attention to marking. Plates with a special polycarbonate layer from ultraviolet radiation are designated by the word "Top". Installation and installation of a greenhouse starts with the definition of the area where it will be.Depending on the depth at which the groundwater will lie, the question of what the foundation will be for the object follows. Most often they make the foundation on screw piles. It is cheap and very effective. The similar basis can be mounted even in winter time.

By the nature of the loads and the long duration that the pile foundation can withstand, it is in no way inferior to the strip one, and at a price it costs, as a rule, three to four times cheaper. The pile foundation does not require several months for shrinkage, which cannot be said of the belt foundation. On average, it takes about 4-6 months of a temporary pause for the desired shrinkage to occur.

If the greenhouse is located on wet soil or in a valley, then it is imperative to make a gravel bedding (10-20 mm) so that the water after melting snow or rain does not penetrate into the room. It is necessary to calculate in advance the number of door and window openings, since the more light in the greenhouse, the better for plantings. Daylight in the greenhouse should be at least five hours each day, then the plants will feel quite comfortable.

Properly positioning all the ventilation units should be on the south side of the greenhouse. The long walls are facing south, the ends facing west and east.The best shape for an object is rectangular, with the “point of reference” being the parameter of a sheet of polycarbonate sheet. The height of the object is usually no more than two and a half meters. Experienced farmers also use the base as a “tool” to adjust the height of the greenhouse to the desired parameters. The width of the beds is usually 1 meter each, and the width of the walkway is about 0.5 meters.

About what polycarbonate is better to choose for greenhouses, see the next video.